Method for producing agricultural fertilizer by using waste liquid of monosodium glutamate

A technology of monosodium glutamate waste liquid and monosodium glutamate tail liquid is applied to fertilizers, organic fertilizers, inorganic fertilizers and other directions made of biological waste, which can solve the problems of difficult market sales, large energy consumption, adverse effects on soil, etc., and achieve outstanding environmental protection and energy saving effects. , The effect of reducing energy consumption and saving energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

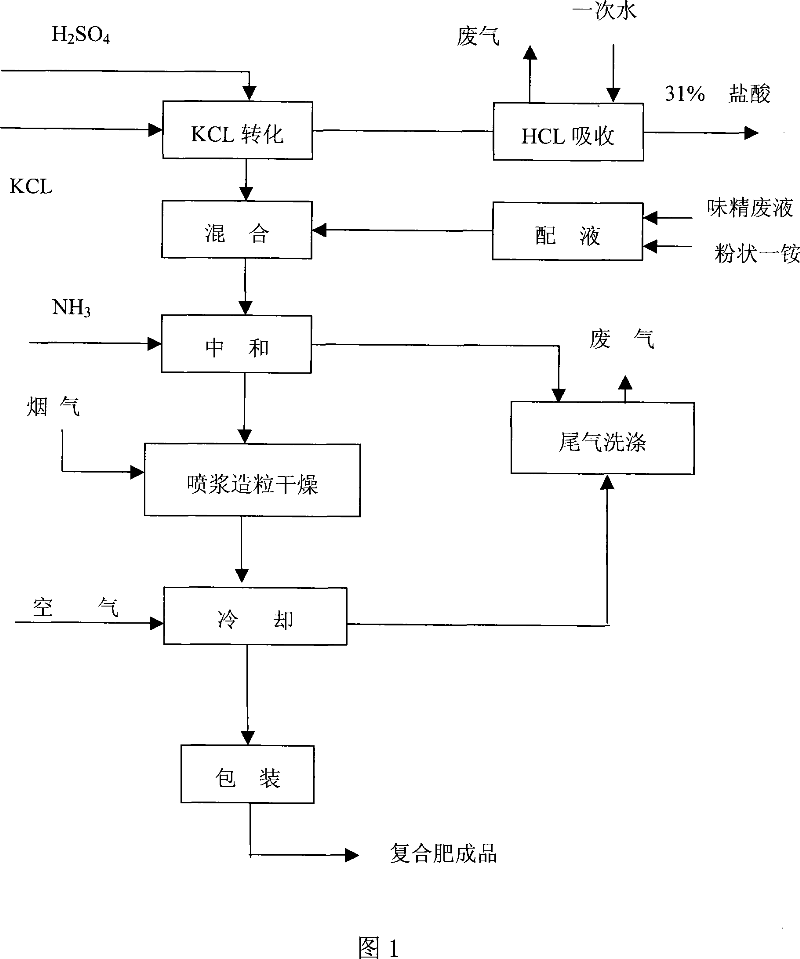

[0058] The technological process of this embodiment is as shown in Figure 1, and its main raw material has:

[0059] Monosodium glutamate waste liquid with a solid content of 8%

[0060] 90% sulfuric acid

[0061] Potassium Chloride with a purity of 95%

[0062] 55% Total Nutrients Powdered Monoammonium Phosphate

[0063] liquid ammonia

[0064] Its production process is as follows:

[0065] 1) Sulfuric acid and potassium chloride are added into two reaction tanks connected in series after metering respectively, the conversion reaction temperature is 130° C., and the conversion reaction time is 2.5 hours, so that potassium chloride completes the metathesis reaction, and the generated potassium bisulfate continuously overflows to Mixed acid tank, the gas from the two reaction tanks enters the graphite heat exchanger at the same time, and then introduces two falling film absorbers in series with a fan, absorbs in countercurrent operation with water, and makes 31% hydrochlori...

Embodiment 2

[0073] The technological process of this embodiment is as shown in Figure 1, and its main raw material has:

[0074] Monosodium glutamate waste liquid with a solid content of 30%

[0075] 93% sulfuric acid

[0076] Potassium Chloride with a purity of 96%

[0077] 55% Total Nutrients Powdered Monoammonium Phosphate

[0078] liquid ammonia

[0079] Its production process is:

[0080] 1) Potassium bisulfate is produced by reacting potassium chloride and concentrated sulfuric acid, the conversion reaction temperature is 150° C., and the conversion reaction time is 3 hours;

[0081] 2) Add powdery monoammonium phosphate to the monoammonium glutamate tail liquid in proportion to form a mixed ammonium liquid, the mixing temperature is 10°C, and add 1% powdery monoammonium phosphate in every ton of monoammonium glutamate tail liquid;

[0082] 3) Mix the above-mentioned mixed ammonium solution with potassium hydrogensulfate to form mixed acid, and add 60% potassium hydrogensulfate...

Embodiment 3

[0088] The technological process of this embodiment is as shown in Figure 1, and its main raw material has:

[0089] Monosodium glutamate waste liquid with a solid content of 40%

[0090] 96% sulfuric acid

[0091] Potassium Chloride with a purity of 97%

[0092] Powdered Monoammonium Phosphate 58% Total Nutrients

[0093] liquid ammonia

[0094] Its production process is:

[0095] 1) Potassium bisulfate is produced by reacting potassium chloride and concentrated sulfuric acid, the conversion reaction temperature is 130° C., and the conversion reaction time is 2.5 hours;

[0096] 2) adding powdered monoammonium phosphate to the MSG tail liquid in proportion to form a mixed ammonium liquid, the mixing temperature is at 30° C., adding 30% powdered monoammonium phosphate in every ton of MSG tail liquid;

[0097] 3) Form mixed acid after above-mentioned mixed ammonium liquid is mixed with potassium bisulfate, add 27% potassium hydrogen sulfate in every ton of mixed ammonium l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com