Polyvinyl chloride loop route production method

一种聚氯乙烯、生产方法的技术,应用在高分子材料科学与工程领域,能够解决高耗能、汞污染等问题,达到解决汞污染环保问题的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1: basic loop method PVC production technology

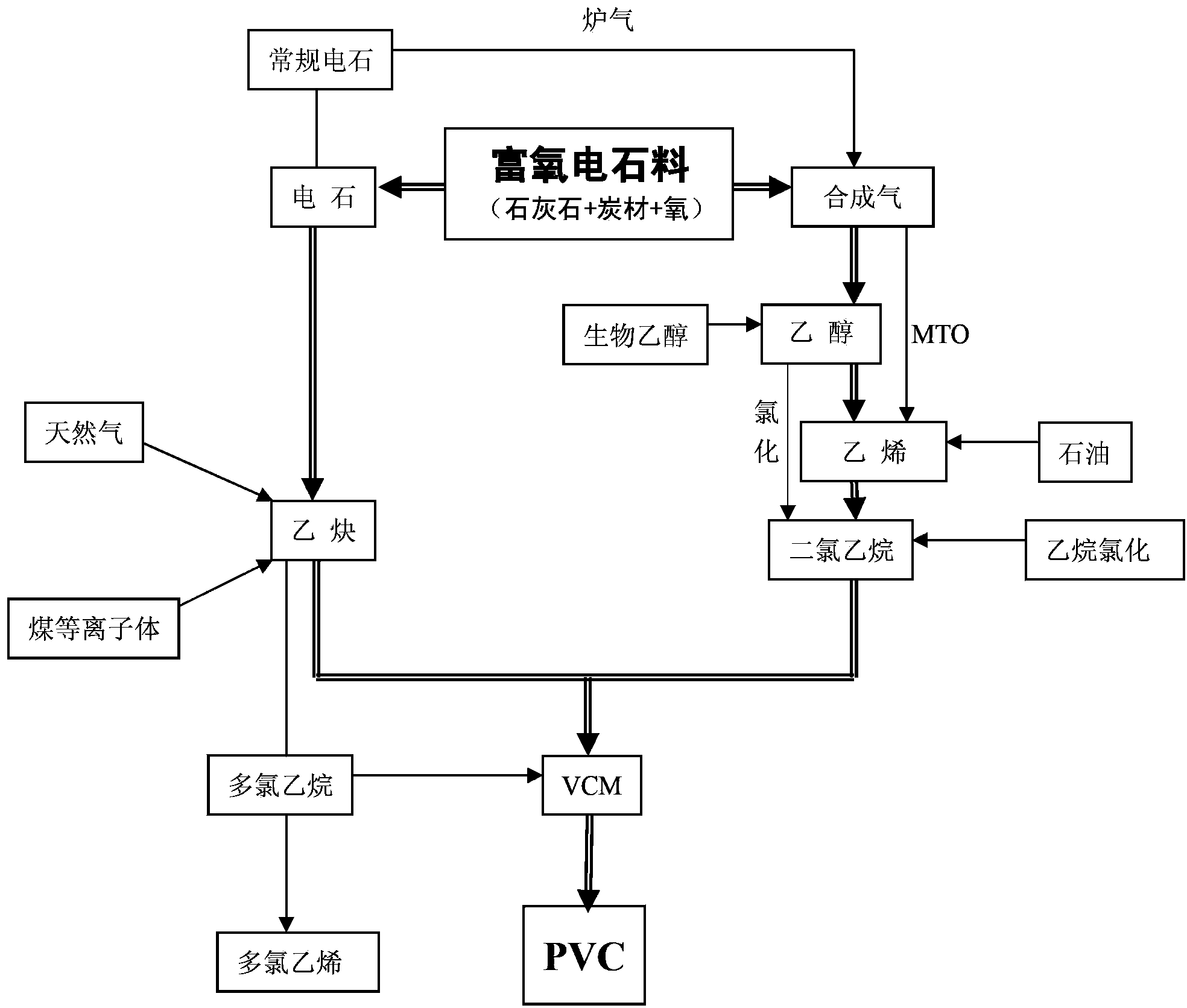

[0036] The polyvinyl chloride basic loop method technological process of the present embodiment is as Figure 4 As shown, the production process and equipment implementation plan are as follows:

[0037] 1) Initial: The oxygen-enriched calcium carbide furnace adopts a shaft furnace, and a raw material pretreatment and mixing device is used to prepare limestone powder and coal powder, and a uniform mixture of limestone powder and coal powder with strict ratio requirements is delivered to the furnace. Stable reaction with oxygen under the optimized process conditions, the upper part exports the synthesis gas CO, and the lower part exports calcium carbide, such as Figure 4 As shown, enter the next process from the left and right sides respectively.

[0038] 2) Left path: export calcium carbide from the shaft furnace reactants, use waste heat to utilize high-efficiency acetylene generator, make calcium carbide r...

Embodiment 2

[0042] Embodiment 2: extended loop method PVC production technology

[0043] The polyvinyl chloride extended circular route of this embodiment is to use the diversity of resource structures in different countries and regions. An open window is set in the middle link of the basic circular route to accept the addition of external intermediate raw materials, such as Figure 5 Shown is a specific feasible solution:

[0044] in the above Figure 4 In the basic circular process flow shown, when the acetylene in the left path can be supplemented by natural gas resources, the right path can be supplemented by bioethanol from natural resources.

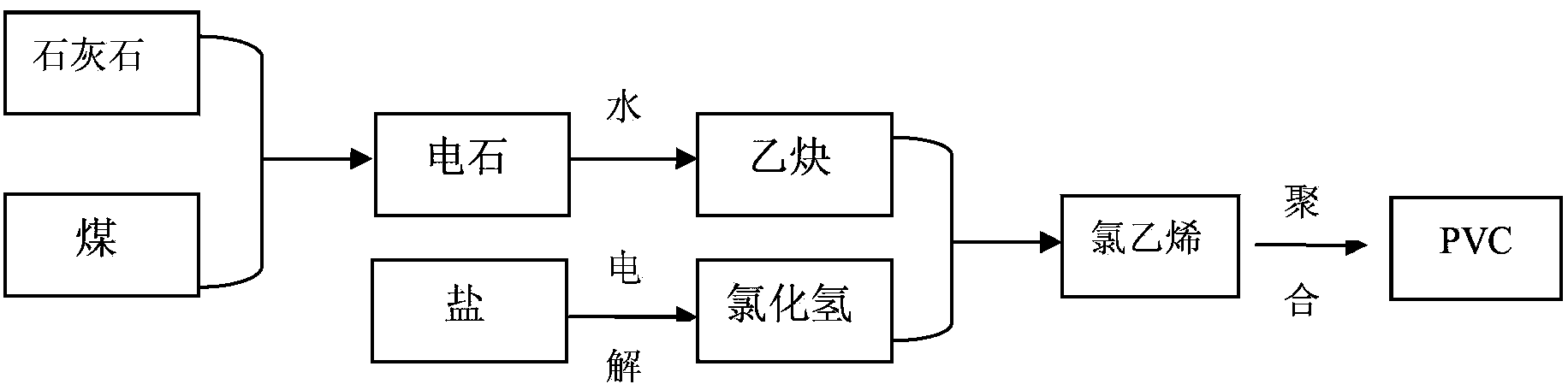

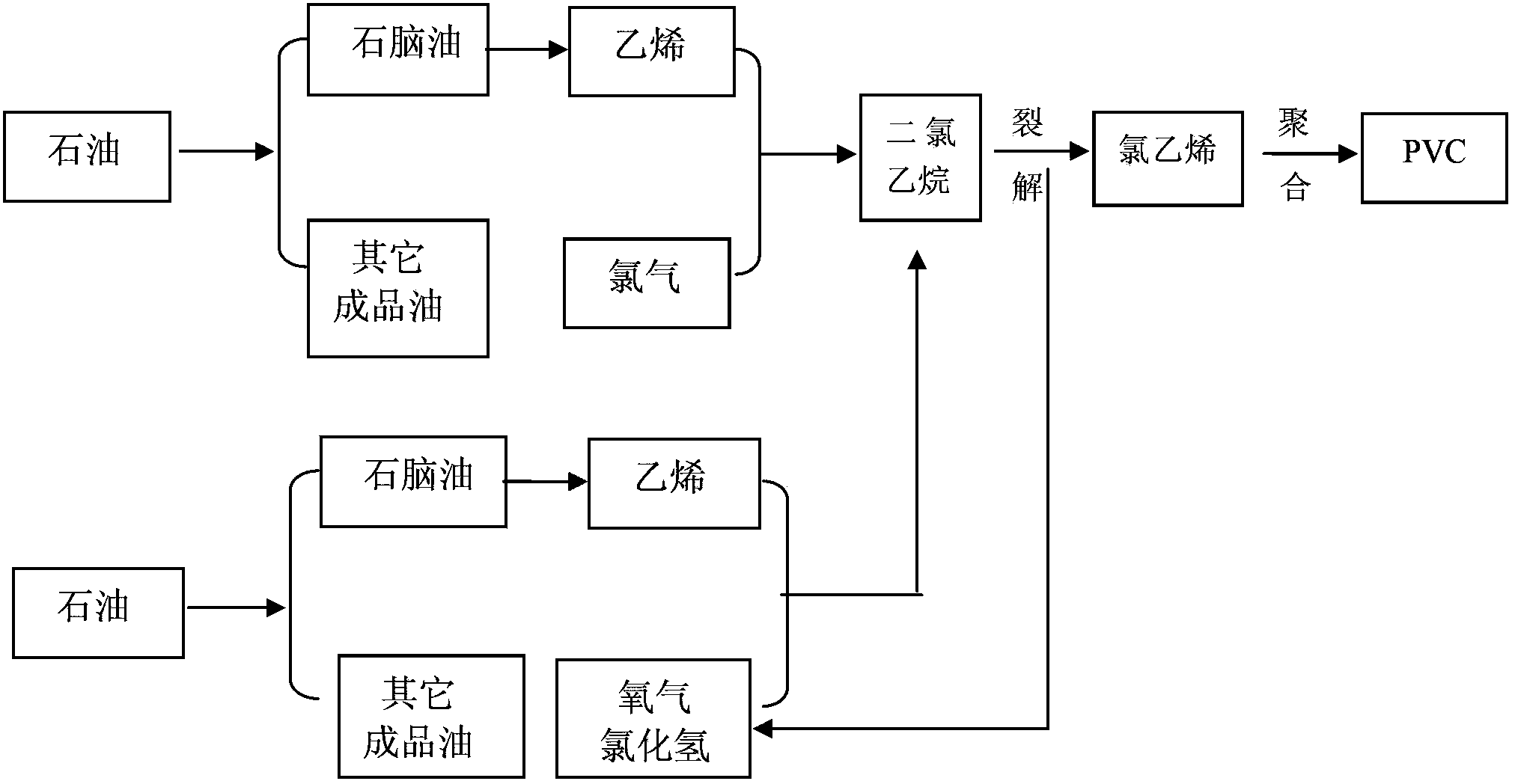

[0045] In addition, as in image 3 In the green PVC production process shown in the loop method, if any part of the closed loop is turned into an open-loop process, it can become a feasible production process. figure 1 with figure 2 The two current processes shown can be regarded as open-loop process routes formed by removing some units i...

Embodiment 3

[0046] Embodiment 3: basic loop method production system

[0047] The polyvinyl chloride basic loop method production system of the polyvinyl chloride loop route production system of the present invention is as Image 6 As shown, the implementation scheme is as follows:

[0048] 1) Start: The oxygen-enriched calcium carbide furnace 13 is a shaft furnace, and the solid material crushing and compounding equipment 11 and the solid material conveying equipment 12 are used to deliver the limestone powder and carbon powder with strict ratio requirements to the oxygen-enriched calcium carbide furnace 13 Homogeneous mixture, the oxygen-enriched calcium carbide furnace 13 is provided with a solid material inlet 15 and an oxygen gas inlet 17, and oxygen is input into the oxygen-enriched calcium carbide furnace 13 by the oxygen-enriched gas blowing device 14 through the gas inlet 17, and the solid material is processed under the optimal process conditions set. Underneath and with the pa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com