Hot process regenerative apparatus for tectorial sand using for casting

A technology of thermal regeneration and coated sand, which is applied to casting molding equipment, manufacturing tools, lighting and heating equipment, etc., can solve the problems of high cost, high cost of use, high energy consumption, etc., and achieve convenient gas control and transportation, and environmental protection Energy-saving effect, the effect of reducing the cost of use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

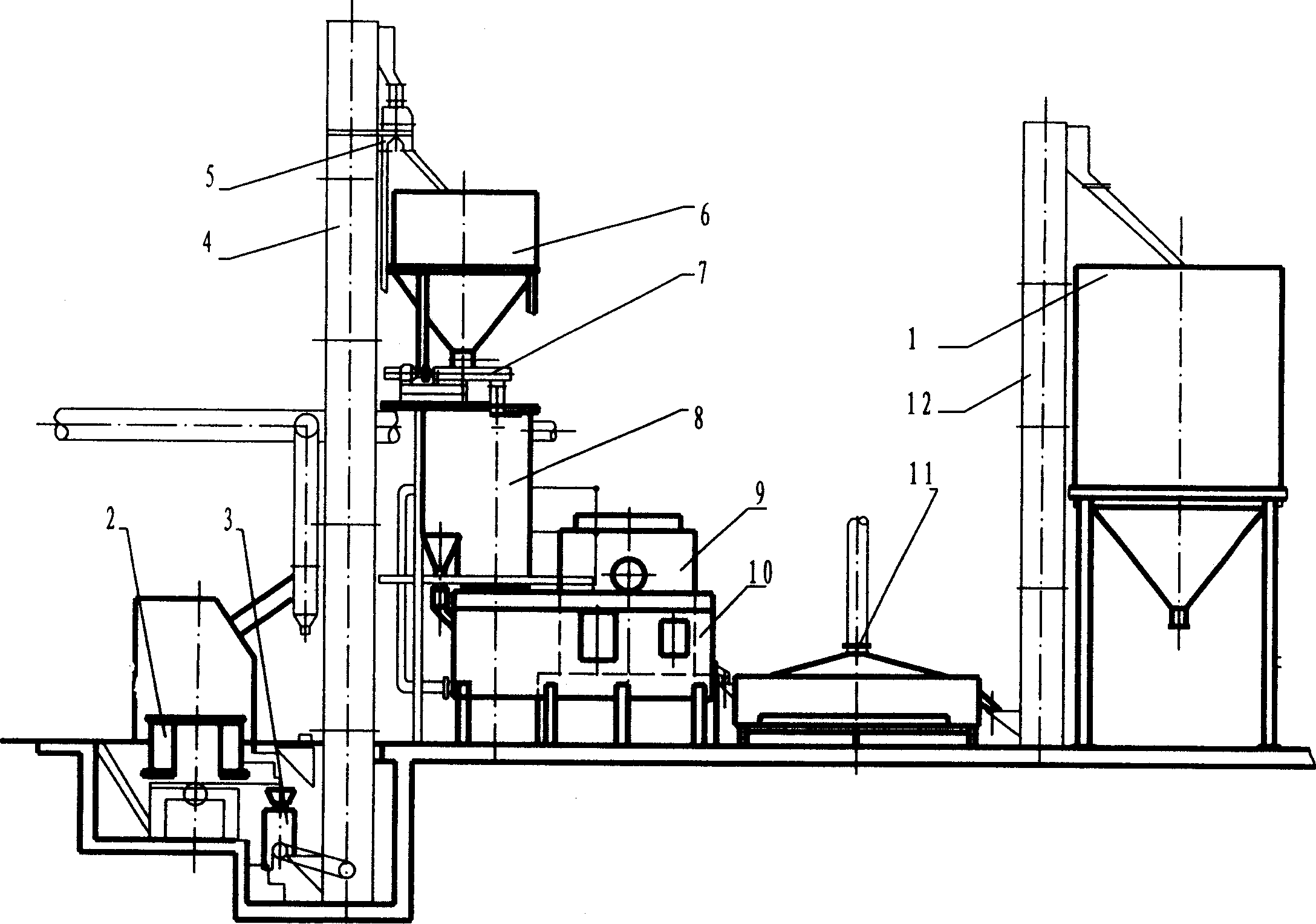

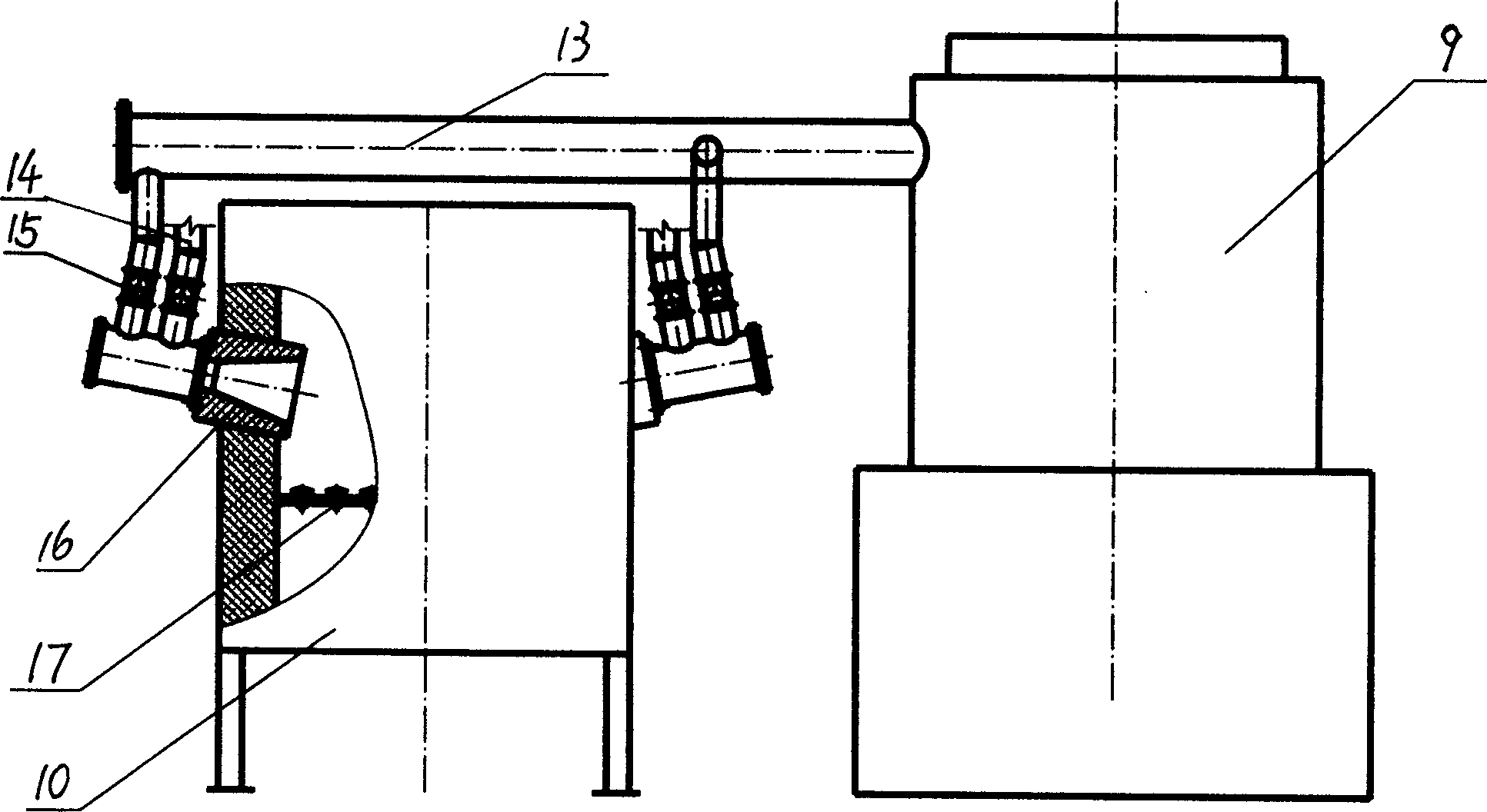

[0016] See figure 1 The device includes vibrating crusher 2, powerful magnetic separator 3, bucket elevator 4, secondary magnetic separator 5, intermediate bucket 6, screw feeder 7, preheater 8, fuel supply mechanism, fluidized roasting furnace 10. Cooling bed 11, bucket elevator 12 and recycled sand bucket 1. Wherein the fuel supply mechanism includes a low-pressure hot gas generator 9 and a secondary air blower. Depend on figure 2 It can be seen that the structure of the connection between the fluidized roaster 10 and the gas generator 9, that is, two gas burners 16 are asymmetrically installed on the furnace wall on the upper part of the fluidized roaster 10 boiling hood 17, and the ends of the gas burners pass through the gas pipe respectively. 13 and blast pipe 14 are connected with gasifier 9 and blower fan, and regulating valve 15 is installed on the gas pipe 13 and blast pipe 14 respectively.

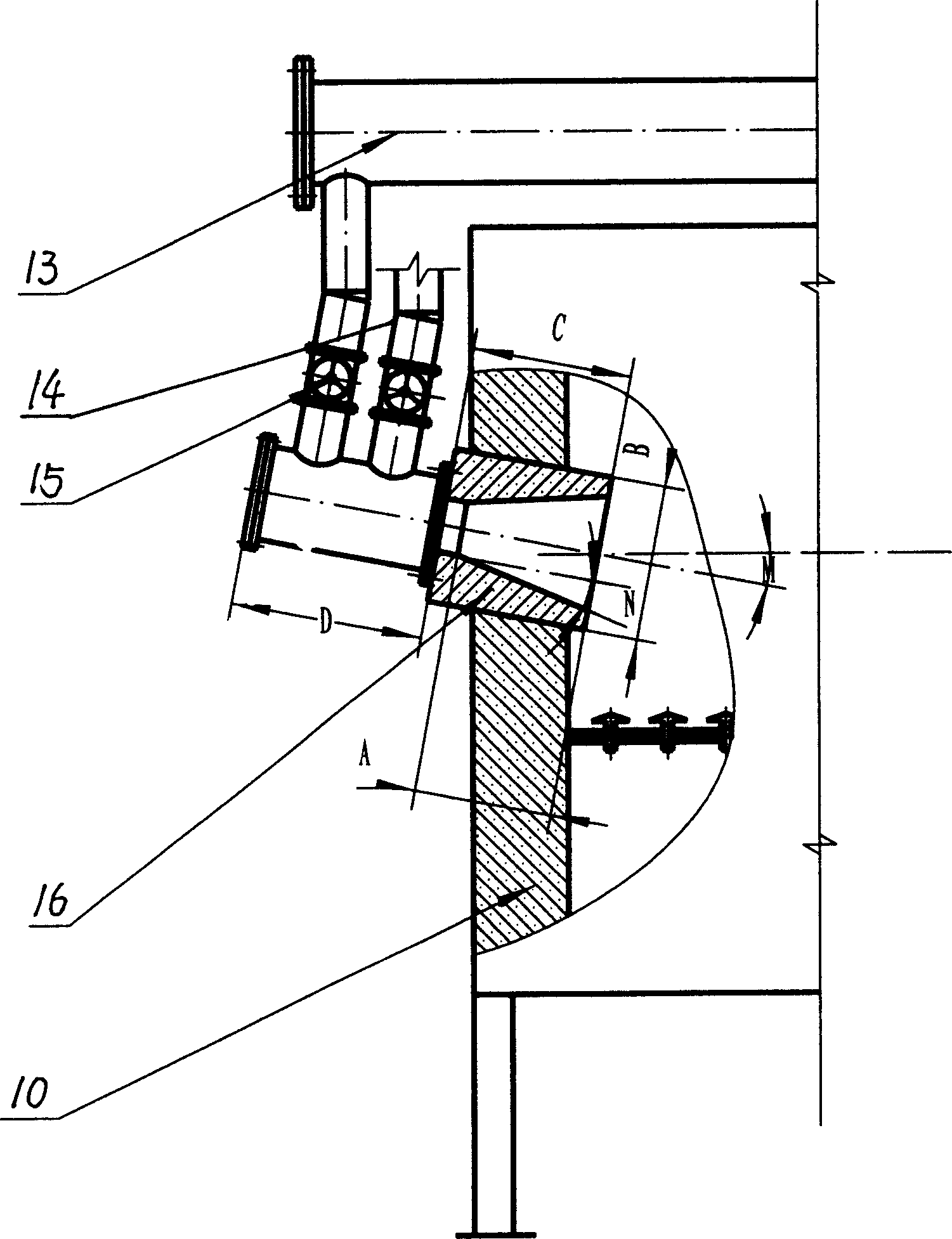

[0017] The gas burner used in this device is a multi-stream type, the a...

Embodiment 2

[0023] Also can be installed 4 gas burners 16 on the furnace wall of fluidized roasting furnace 10 boiling hoods 17 tops. Other structures are the same as

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com