Combustion chamber and wall-mounted gas boiler

A combustion chamber and combustion chamber technology, which is used in heating fuels, household stoves/stoves, gaseous heating fuels, etc., can solve the problems of easy flame-out, unstable combustion, etc., to ensure gas volume, and not easy to flame-out , the effect of stable combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be further described below in conjunction with embodiment, but is not limited to the content on the description.

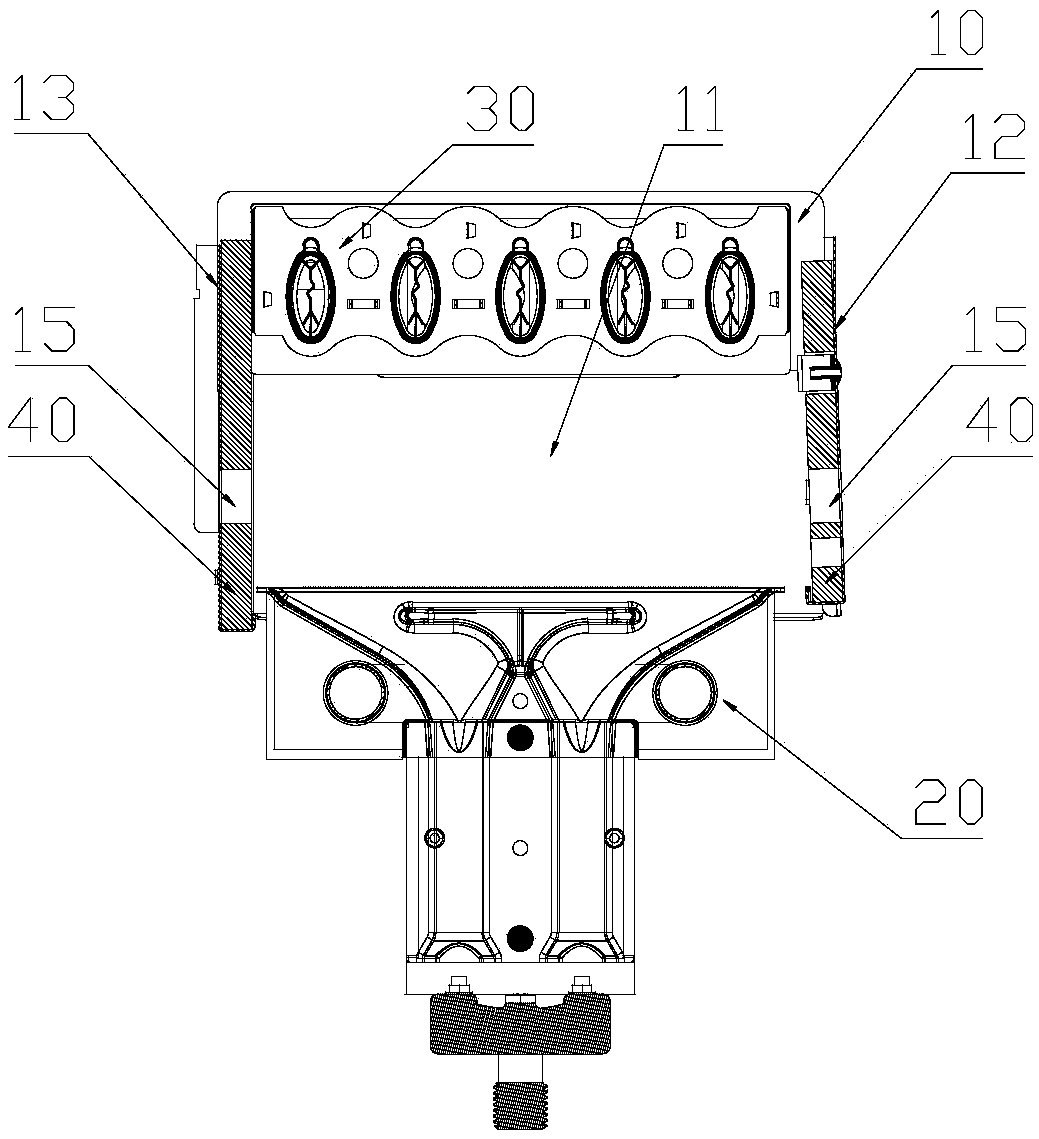

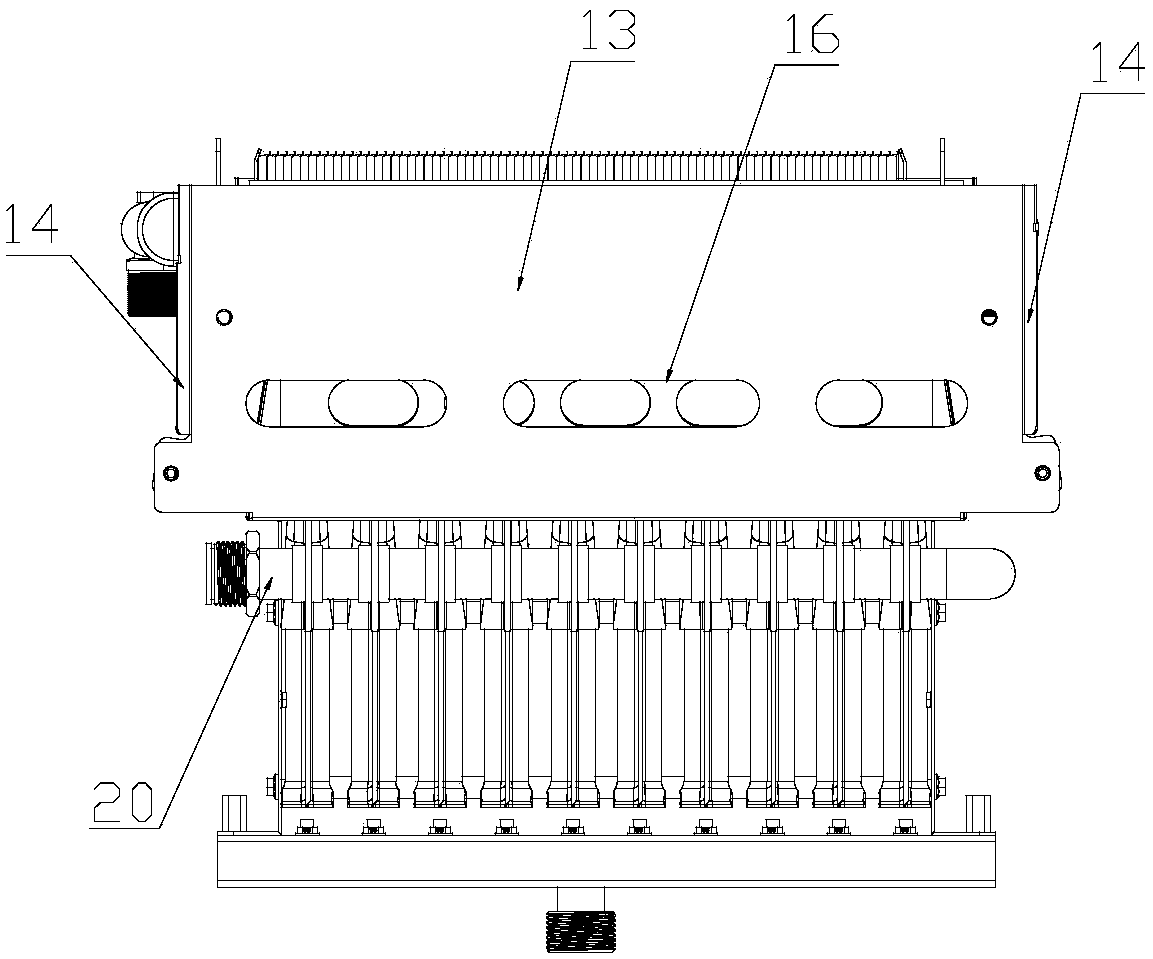

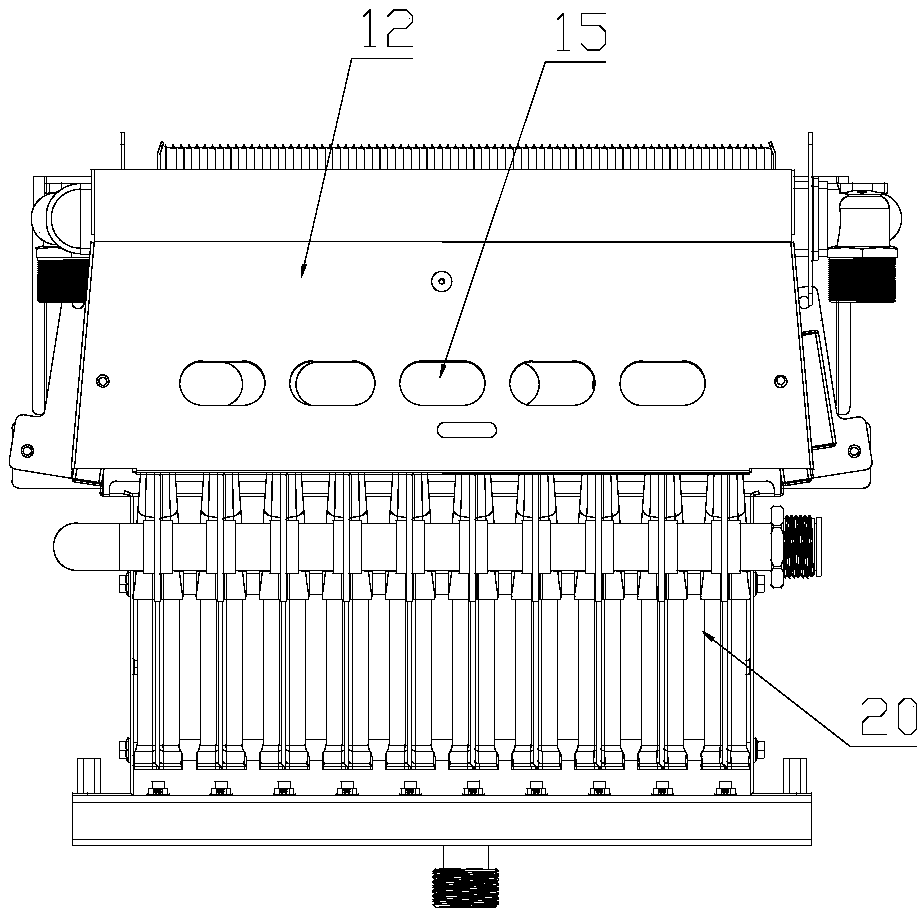

[0020] The invention discloses a combustion chamber, which comprises a combustion chamber body 10. A combustion chamber 11 is arranged inside the combustion chamber body 10. An air hole 15 communicating with the combustion chamber 11 is arranged on the combustion chamber body 10. The air hole 15 is also connected to the outside of the combustion chamber body 10. connected. During use, the air enters the combustion chamber 11 from the air hole 15 provided on the combustion chamber body 10, and the combustion chamber body 10 is provided with the air hole 15 communicating with the combustion chamber 11, the air hole 15 is also communicated with the outside of the combustion chamber body 10, and the combustion chamber No longer sealed, air can still enter the combustion chamber from the air hole 15. Under light load conditions, the co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com