Telligent dry separator (TDS)

A dry sorting machine and intelligent technology, applied in sorting and other directions, can solve the problems of low sorting accuracy, low processing capacity, and no energy saving, and achieve the effects of excellent sorting accuracy, energy saving, and improved space utilization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0060] Embodiments of the present invention will be further described below in conjunction with the accompanying drawings.

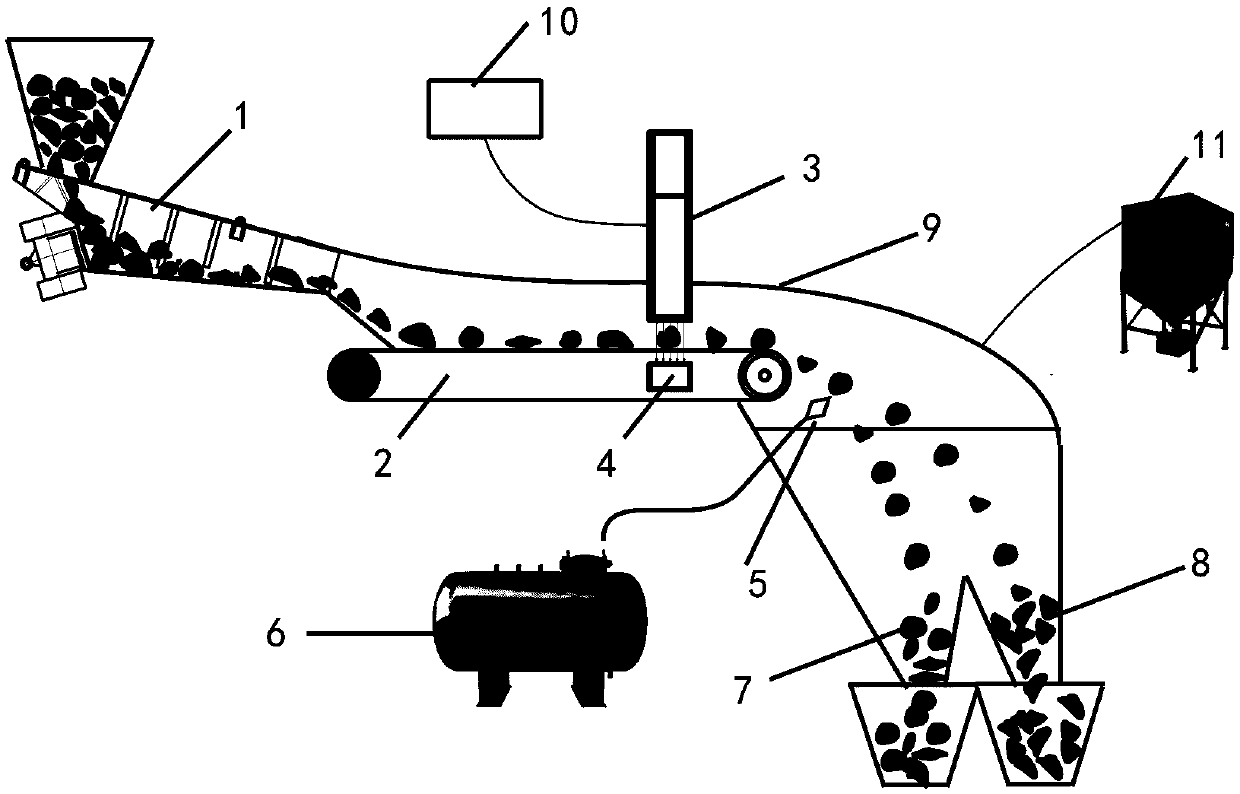

[0061] Such as figure 1 As shown, the TDS intelligent dry separation machine is a dry separation equipment that uses rays to intelligently identify and sort minerals. It identifies clean coal and gangue according to the difference in the amount of radiation absorbed by clean coal and gangue, and uses air nozzles as the actuator. , which is suitable for the sorting of 300-3mm block and granular minerals.

[0062] The raw material is fed to the material distribution device 2 through the feeding device 1, and the material distribution is completed on the material distribution device 2 to realize the single-layer arrangement of the objects, and there is a certain distance between each object and the front, rear, left, and right adjacent objects. Spacing creates conditions for detection execution. The raw material is judged by the X-ray source 3 and the X-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com