SF6 gas micro-water treatment device

A treatment device and gas technology, applied in the field of SF6 gas micro-water treatment device, can solve the problems that can only be carried out alone, the effect of insulation and arc extinguishing is reduced, and the circulation treatment cannot be carried out, so as to avoid risks and hidden dangers and protect the circuit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

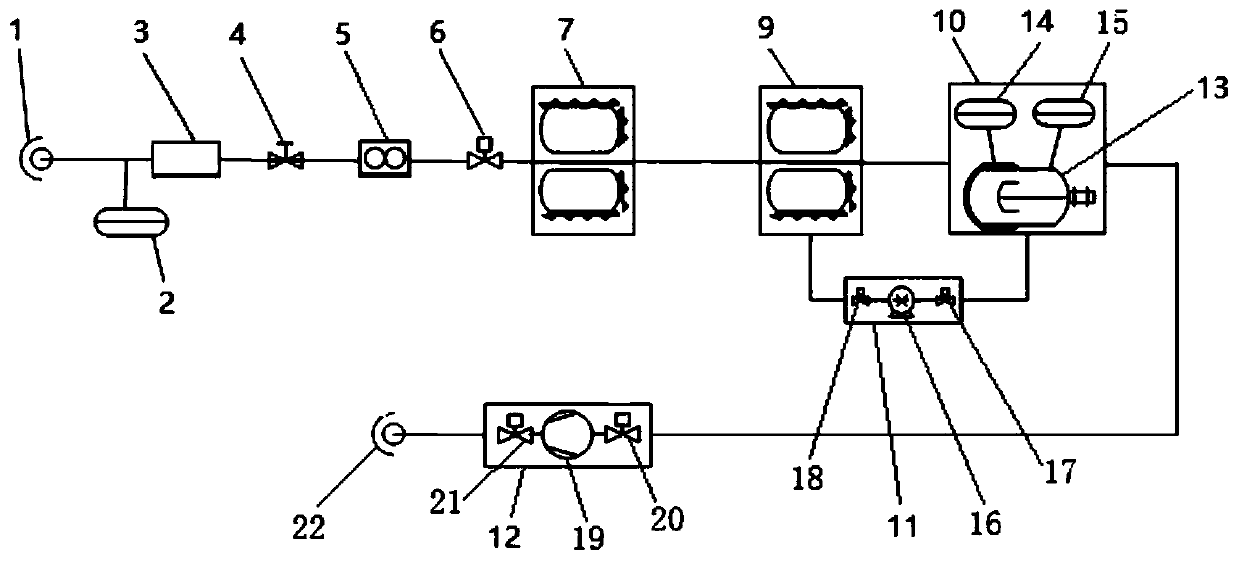

Embodiment 1

[0027] Such as figure 1 shown, a SF 6 The gas micro-water treatment device includes the first joint 1, the first moisture measuring instrument 2, the first pressure gauge 3, the manual valve 4, the gas flow meter 5, the filtering mechanism, the drying mechanism, the gas compression unit 12 and the The second joint 22 is equipped with a double joint series structure to realize the circulation treatment of micro water and decomposed matter in the equipment, and adsorb SF through the filter mechanism 6 The decomposed products produced by the gas, and the drying mechanism filters the water, which can not only ensure the SF in the equipment 6 The gas is always in a stable range, which better protects the circuit in the equipment, and can be connected to the equipment for a long time to realize real-time processing, and the moisture and decomposition products can be processed at any time, avoiding the hidden risks caused by the processing lag of the existing technology.

[0028] T...

Embodiment 2

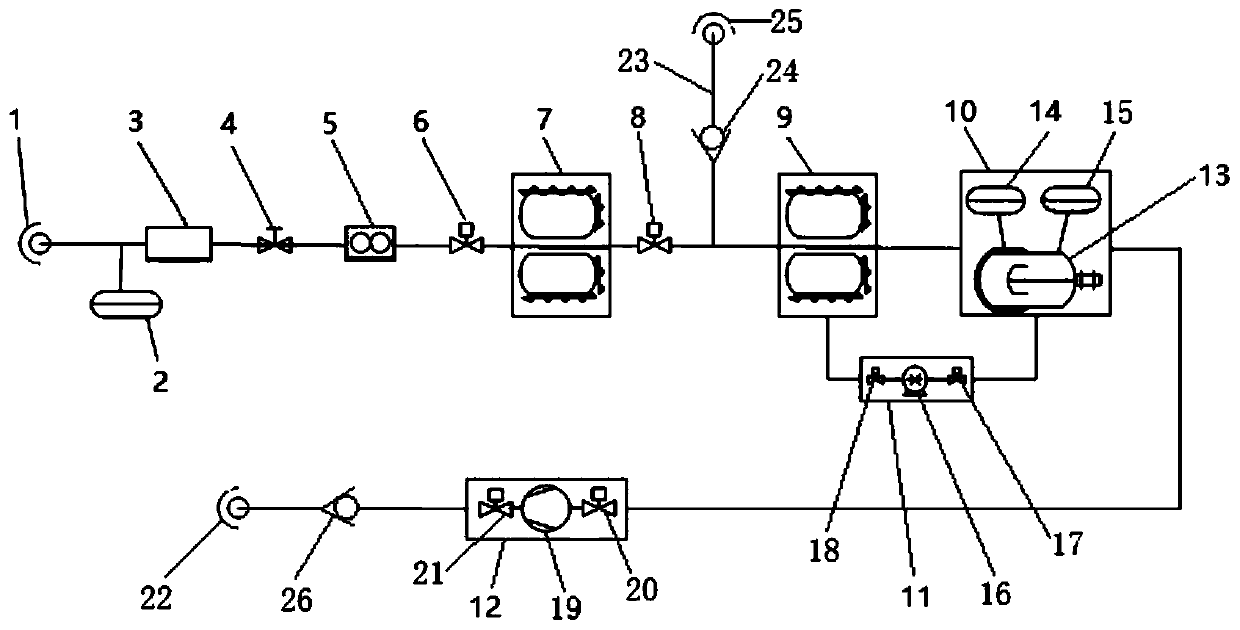

[0036] Such as figure 2 As shown, on the structural basis of Embodiment 1, the following improvements are made:

[0037] The drying mechanism also includes a second solenoid valve 8, the second solenoid valve 8 is arranged between the filter mechanism and the heat-tracing adsorption regeneration unit 9, which is convenient for supplementing SF 6 Control the on-off of the gas circuit when the gas is in the air.

[0038] A one-way input gas path 23 is also connected between the second solenoid valve 8 and the heat-tracing adsorption regeneration unit 9 through a three-way, and a first one-way valve 24 is arranged on the one-way input gas path 23 to realize gas source direction One-way input gas in the processing device, the end of the one-way input gas path 23 is provided with a third joint 25, when the first pressure gauge 3 monitors the SF 6 When the air pressure is low, close the second solenoid valve 8, SF 6 The gas source fills the drying mechanism with SF through the o...

Embodiment 3

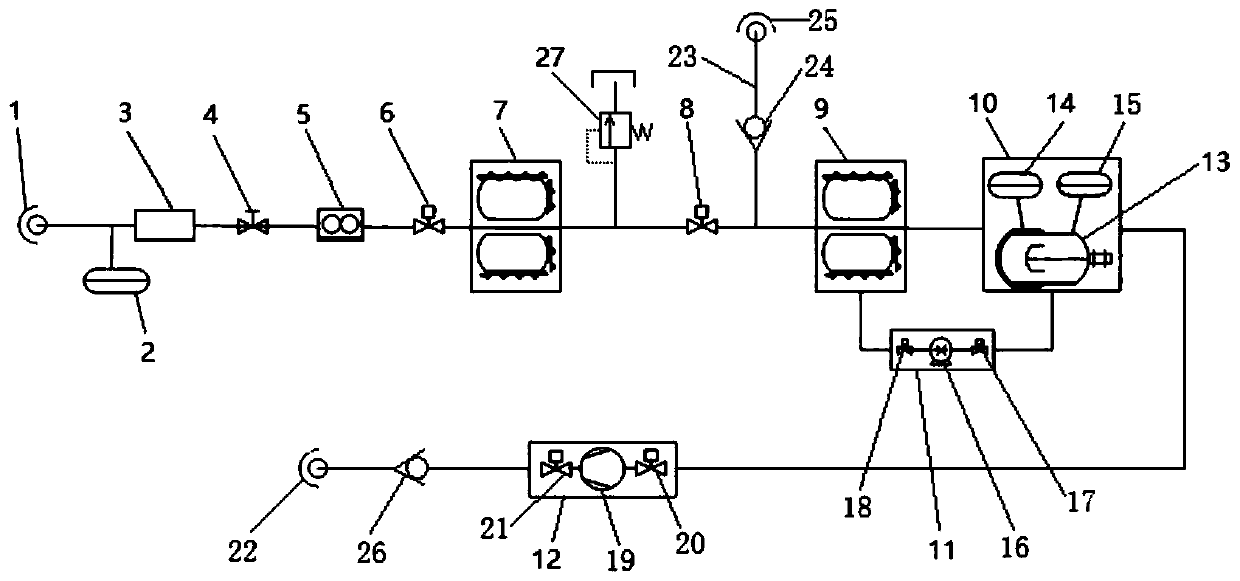

[0042] Such as image 3 As shown, on the structural basis of Embodiment 2, the following improvements are made:

[0043] Also includes an overflow valve 27, the overflow valve 27 is connected between the filter mechanism and the second solenoid valve 8 through a three-way, when the SF 6 The gas source is filled with too much gas, resulting in SF in the equipment 6 When the air pressure is too high, the excess gas can be removed through the overflow valve 27 to realize the dynamic balance of the air pressure and further ensure the SF in the equipment. 6 The air pressure is always in the optimum range, while the discharged SF 6 The gas is filtered to avoid pollution to the environment.

[0044] A kind of SF provided by the invention 6 The gas micro-water treatment device realizes circulating treatment of micro-water and decomposed products in the equipment by setting a double-joint series structure, and adsorbs SF through the filter mechanism 6 The decomposed products produ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com