Automobile body coating method

A coating method and technology for automobile bodies, which are applied to devices for coating liquids on surfaces, coatings, electrolytic coatings, etc. The effect of energy consumption, reduction of heating energy consumption, and reduction of energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

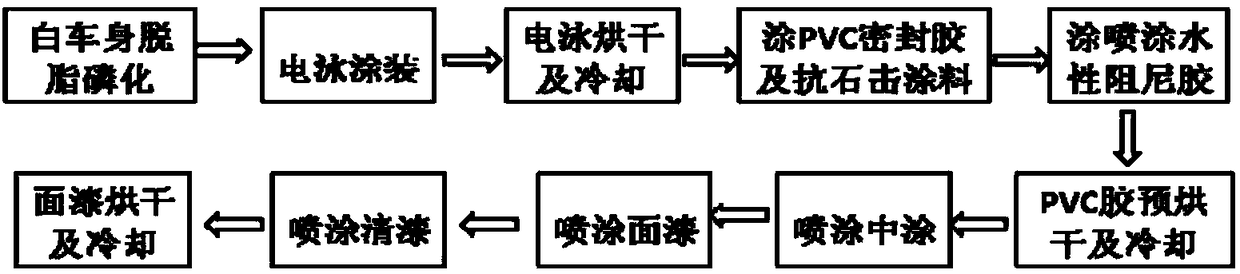

[0045] Such as figure 1 As shown, the automobile body coating method of the present invention, the steps are as follows: body-in-white coating, degreasing and phosphating → electrophoretic coating → electrophoretic drying and cooling → coating PVC sealant and anti-stone impact coating → spraying damping glue → PVC glue pre-baking Drying and cooling→Spray intermediate coating→Spray topcoat→Spray varnish→Topcoat drying and cooling.

[0046] The degreasing and phosphating process includes: flood water rinsing→pre-degreasing→degreasing→water washing 1→water washing 2→surface adjustment→phosphating→water washing 3→water washing 4→pure water washing 1→draining.

[0047] The flood water washing method is: spraying, the treatment time is 100s, the temperature is 40-50°C, and the pH value is 10-12.8.

[0048] The pre-degreasing method is: spraying, the treatment time is 100s, the temperature is 43°C, and the degreasing liquid is prepared by using SF-3000 degreasing agent and deionized...

Embodiment 2

[0068] Such as figure 1 As shown, the automobile body coating method of the present invention, the steps are as follows: body-in-white coating, degreasing and phosphating → electrophoretic coating → electrophoretic drying and cooling → coating PVC sealant and anti-stone impact coating → spraying damping glue → PVC glue pre-baking Drying and cooling→Spray intermediate coating→Spray topcoat→Spray varnish→Topcoat drying and cooling.

[0069] The degreasing and phosphating process includes: flood water rinsing→pre-degreasing→degreasing→water washing 1→water washing 2→surface adjustment→phosphating→water washing 3→water washing 4→pure water washing 1→draining.

[0070] The flood water washing method is: spraying, the treatment time is 100s, the temperature is 40-50°C, and the pH value is 10-12.8.

[0071] The pre-degreasing method is: spraying, the treatment time is 80s, the temperature is 40°C, and the degreasing liquid is prepared by using SF-3000 degreasing agent and deionized ...

Embodiment 3

[0092] Such as figure 1 As shown, the automobile body coating method of the present invention, the steps are as follows: body-in-white coating, degreasing and phosphating → electrophoretic coating → electrophoretic drying and cooling → coating PVC sealant and anti-stone impact coating → spraying damping glue → PVC glue pre-baking Drying and cooling→Spray intermediate coating→Spray topcoat→Spray varnish→Topcoat drying and cooling.

[0093] The degreasing and phosphating process includes: flood water rinsing→pre-degreasing→degreasing→water washing 1→water washing 2→surface adjustment→phosphating→water washing 3→water washing 4→pure water washing 1→draining.

[0094] The flood water washing method is: spraying, the treatment time is 100s, the temperature is 40-50°C, and the pH value is 10-12.8. The pre-degreasing method is: spraying, the treatment time is 120s, the temperature is 50°C, and the degreasing liquid is prepared by using SF-3000 degreasing agent and deionized water, i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com