A method for compounding leather on the surface of automobile door interior parts using a binder containing modified diatomite

An automotive door and surface compounding technology, applied in special leather manufacturing, adhesives, vehicle parts, etc., can solve the problems of complex production process, large equipment investment, and large use of cutting craftsmen, etc., to achieve high efficiency, high bonding strength, compound effect smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

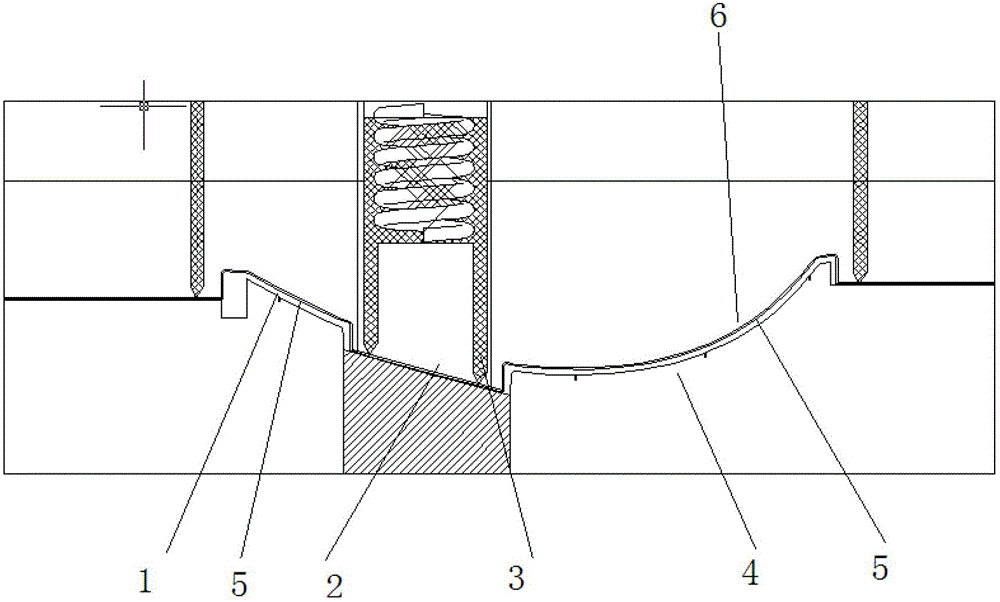

[0025] Referring to accompanying drawing, mold of the present invention comprises upper die 6, lower die 4, has on the lower die 4 the boss 1 that places and fixes for interior trim 3, is glued with leather on the trim 5, on the lower die 4, convex The periphery of table 1 is surrounded by an annular concave cavity 2 for accommodating upper die cutter 3; Upper mold 6 cutter moves to realize cutting function. The above-mentioned upper die cutter 3 structure also can not be established, adopts manual trimming. The mold of the present invention has left and right two bosses, and can carry out the composite leather of two different structure interior parts 5 simultaneously.

[0026] A method for using a modified diatomite-containing binder surface composite leather for an automotive door trim, comprising the following steps:

[0027] (1) Soak the diatomite in a 12% hydrochloric acid solution for 6 hours, then wash it with deionized water until neutral, and dry it;

[0028] Calc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| shear viscosity | aaaaa | aaaaa |

| softening point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com