Patents

Literature

68results about How to "No burnt smell" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

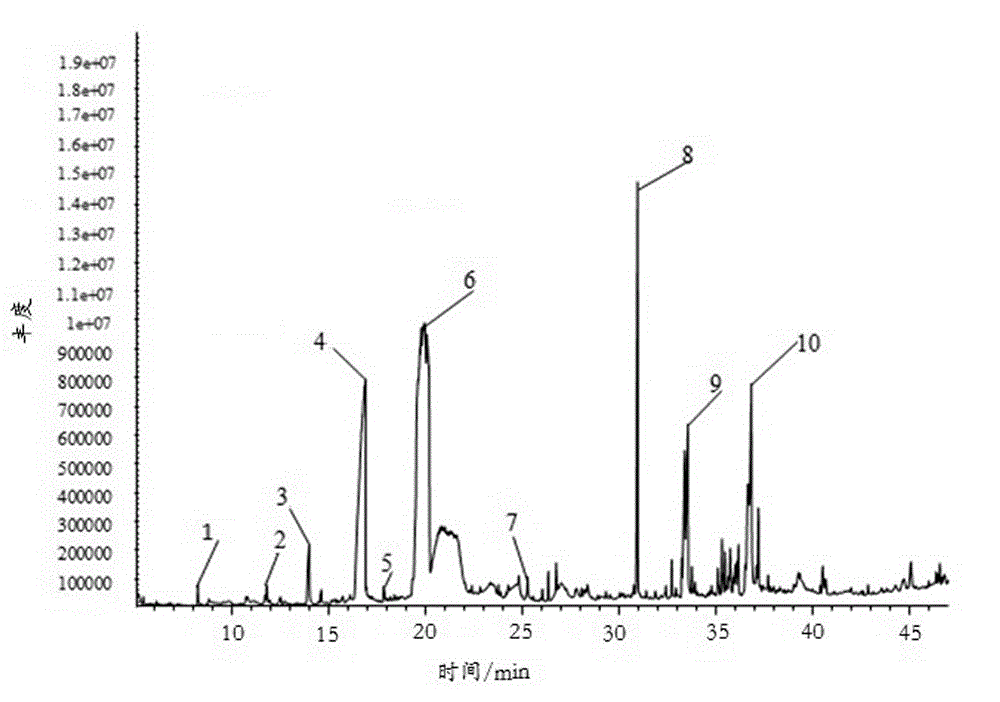

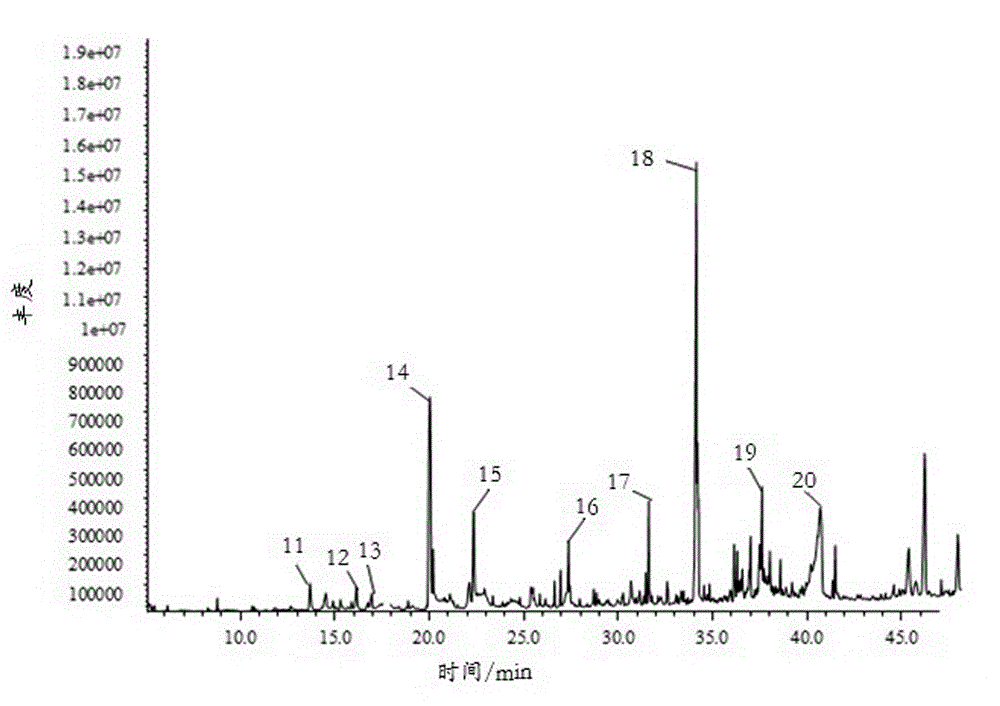

Preparation method of burnt malt with high caramel aroma and beer

ActiveCN108102825AFully stimulate vitalityIncrease concentrationMalt preparationMaillard reactionHordeum vulgare

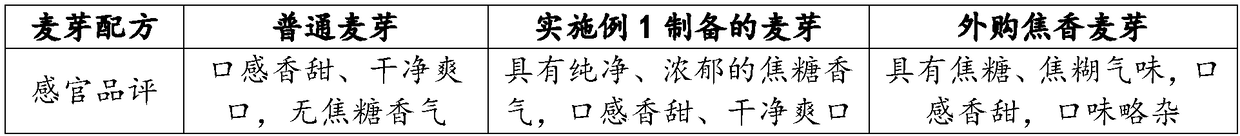

Belonging to the malt manufacturing field, the invention provides a preparation method of burnt malt with high caramel aroma and beer. The malt preparation method includes the steps of: barley selection, raw material pretreatment, wheat dipping, germination, green malt saccharification, baking and root removal. Specifically, during barley selection, barley with moderate protein content is adoptedas the raw material; the wheat dipping process provides barley grains sufficient internal moisture content to fully stimulate the vitality of the endogenous enzyme system of malt, thus providing sufficient conditions for subsequent acquisition of a Maillard reaction substrate; the saccharification process is carried out in four stages, so that green malt can effectively degrade cellulose, proteinand starch under an appropriate water condition, and the concentration of the Maillard reaction substrate is increased; and then baking is carried out at an appropriate generation temperature of DMHFso as to enrich DMHF product substantially. The obtained malt has significant caramel aroma, the aroma is pure and strong, sensory evaluation indicates that the malt is free of scorched flavor, burntflavor and other foreign and miscellaneous smell, and can be used for production of beer with high caramel aroma.

Owner:TSINGTAO BREWERY

Yogurt with low glycemic index

InactiveCN102613289ALess rise in blood sugarGood blood sugar controlMilk preparationLow glucoseSucrose

Owner:INNER MONGOLIA MENGNIU DAIRY IND (GRP) CO LTD

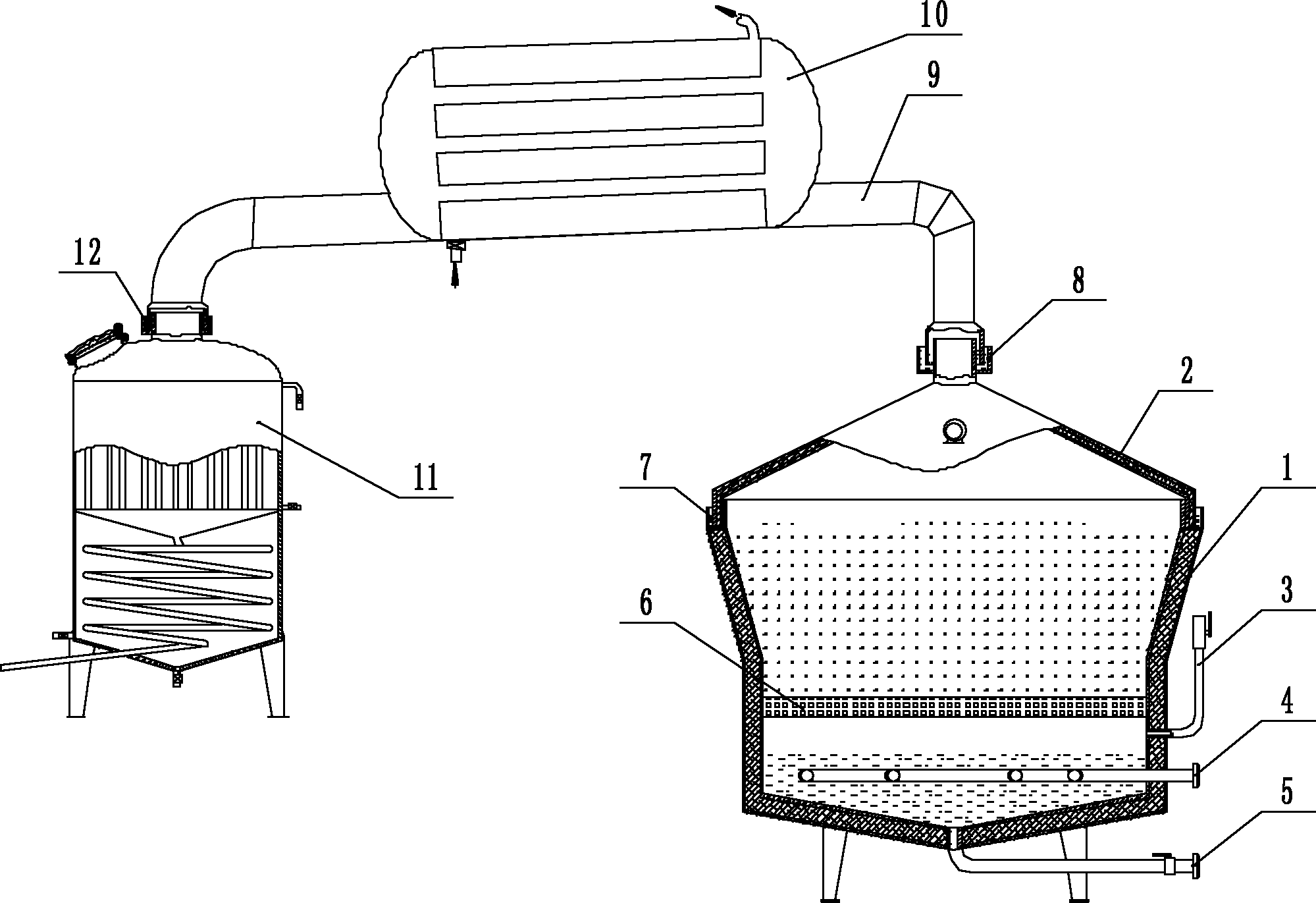

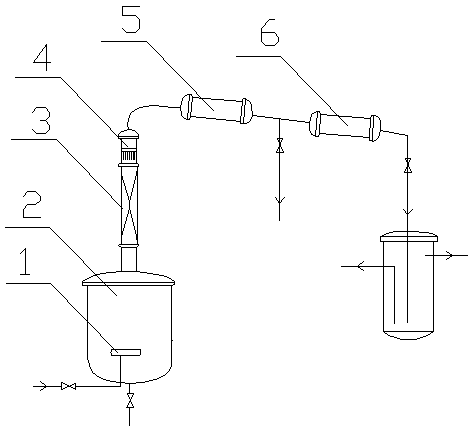

Energy-saving distilling apparatus for wine

InactiveCN102660446ANo burnt smellImprove qualityAlcoholic beverage preparationInsulation layerCooling tower

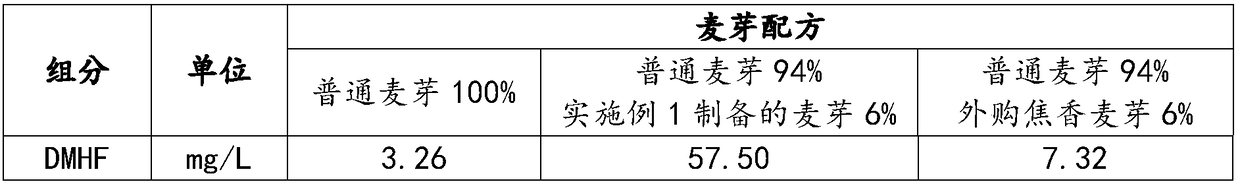

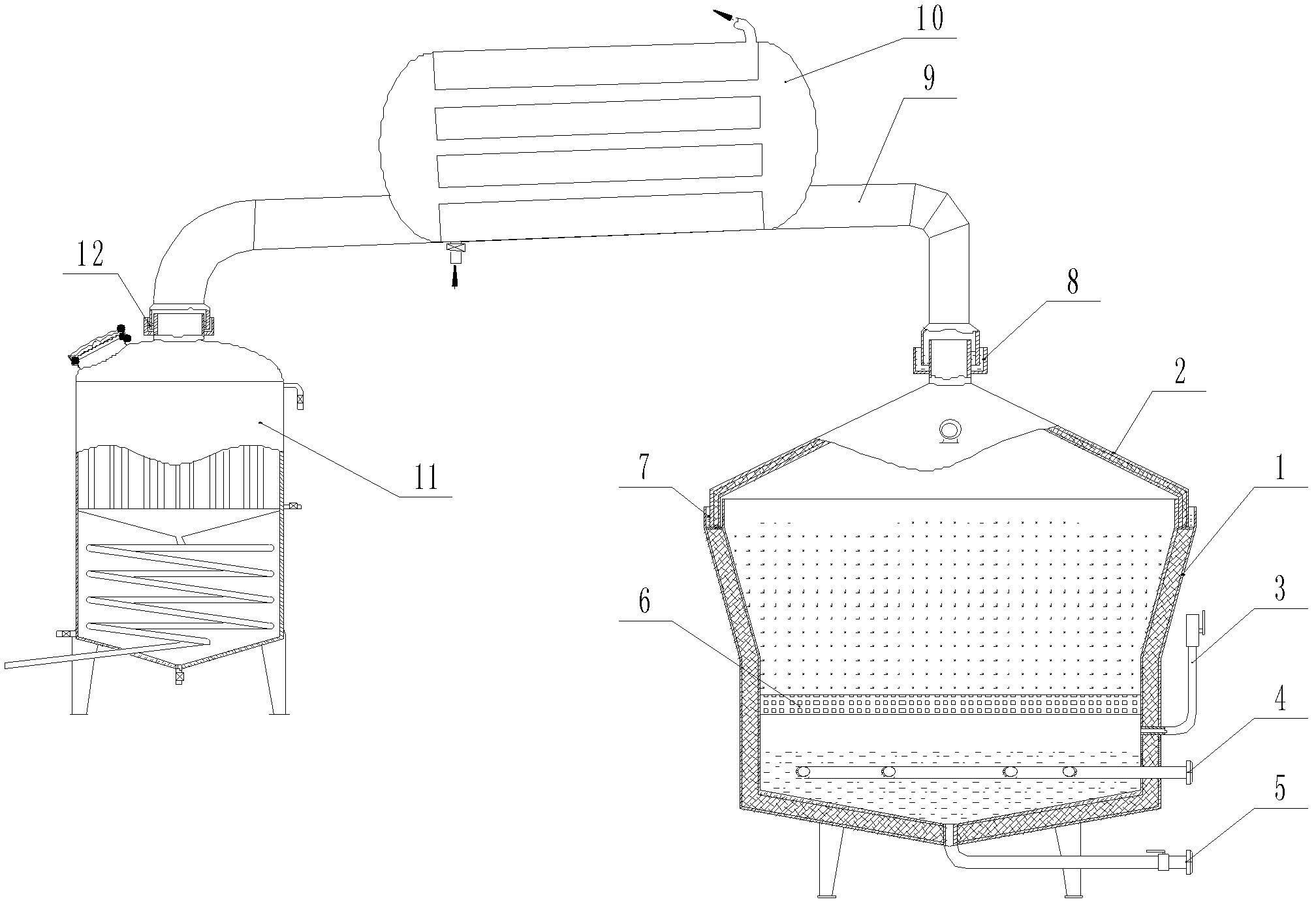

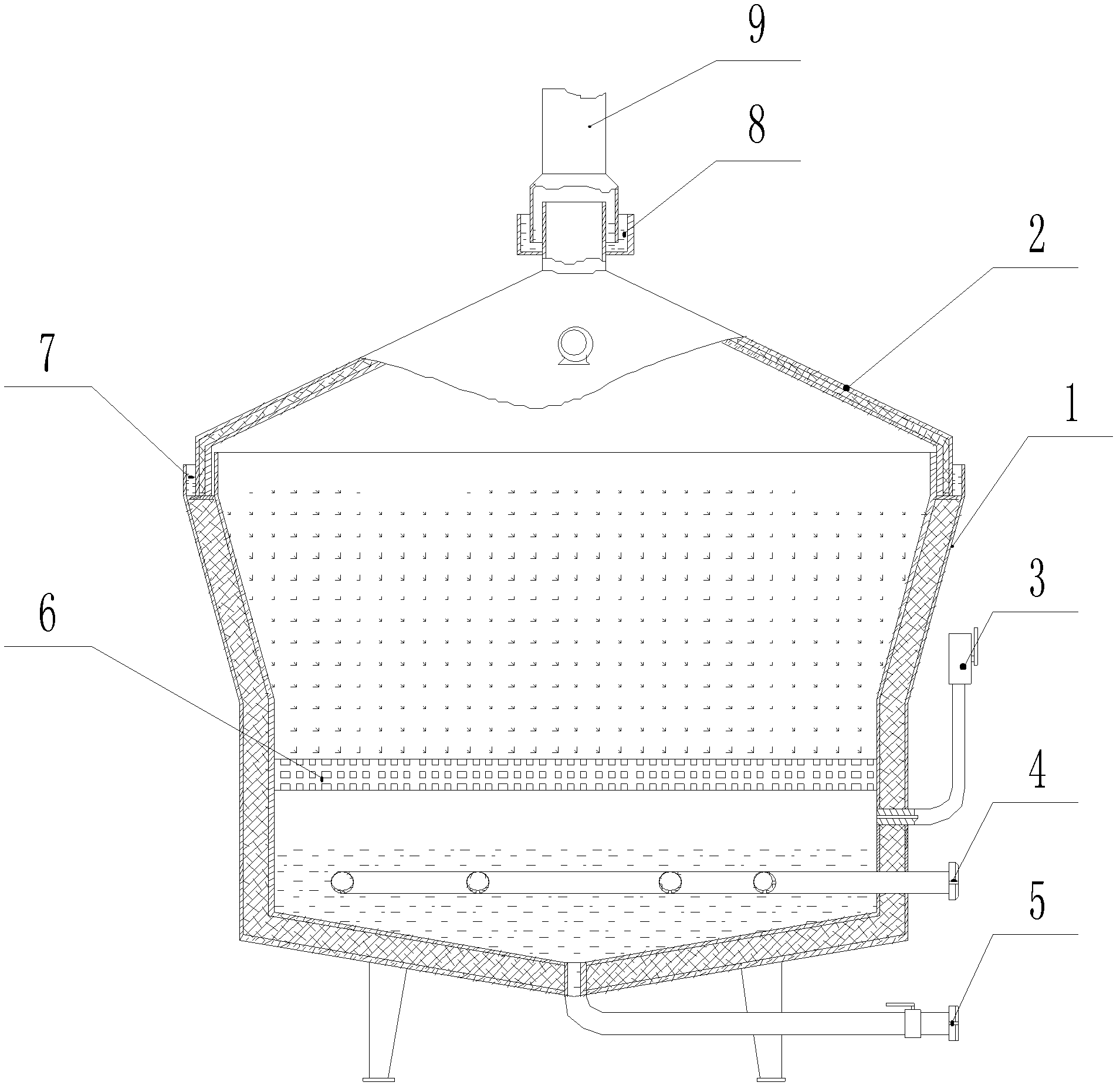

The invention discloses an energy-saving distilling apparatus for wine. The energy-saving distilling apparatus comprises a distillation retort, a communicating pipeline and a cooling tower. The energy-saving distilling apparatus has the advantages that firstly, indirect heating is performed, heating temperature is easily controlled, the produced wine cannot generate burnt smell, and the quality of the wine is improved; secondly, a water seal is arranged on a joint of the distilling apparatus to avoid leakage; and thirdly, evaporated wine steam is cooled twice, cooling water is recovered into a boiler and reused, a heat insulation layer is arranged on a cover of the distillation retort, and the energy-saving effect is fine.

Owner:湘潭林海机械制造有限公司

Fragrant camellia oil and preparation method thereof

InactiveCN107325882AKeep active ingredientsRetain nutritional valueFatty-oils/fats refiningFatty-oils/fats productionFlavorAdditional values

The invention provides a preparation method of fragrant camellia oil, and belongs to the technical field of edible oil processing. The preparation method comprises the following steps: preprocessing, mechanical squeezing, filtering, deacidification, washing, destaining, deodorizing and degreasing. The camellia oil prepared with the method is free from chemical reagents, a relative low-temperature pure physical method is adopted to effectively keep the effective active ingredients of the camellia oil, and additional value is improved; the natural flavor and the nutrition value of the camellia oil are kept. Meanwhile, through later-stage special technologies of washing, destaining, deodorizing and degreasing, impurities are removed, the quality of the camellia oil is improved, peculiar smells are removed, taste is improved, and the camellia oil with faint scent and relatively high nutrition value is provided.

Owner:田林县康益土特产有限公司

Tobacco extract and electronic cigarette liquid

ActiveCN104939305ASweet and deliciousRoasted aroma style Tobacco aroma is goodTobacco treatmentBiotechnologyAqueous ethanol

The invention discloses tobacco extract and electronic cigarette liquid. A preparation method of the tobacco extract comprises the following steps that (1), tobacco powder or / and tobacco shreds serve as raw materials, the raw materials are extracted with ethanol water with the volume fraction more than 75%, an extracting solution is concentrated to obtain ethanol extract, ethanol is used for dissolving the ethanol extract, then the ethanol extract is frozen, dissolved out, precipitated and filtered, and filter liquor is concentrated to obtain extract I; (2), the raw materials extracted with the ethanol are extracted with water, water extract is obtained, the water extract is leached with a solvent A, water phases are collected and then are used for leaching a solvent B, and organic phases are collected and concentrated to obtain extract II, wherein the solvent A is one or more of petroleum ether, normal hexane and cyclohexane, and the solvent B is ethyl acetate or dichloromethane; (3), the extract I and the extract II are mixed to obtain the tobacco extract. The tobacco extract keeps the tobacco aroma, the amount of aroma is full, no black residue exists after atomization, and no scorched flavor exists.

Owner:CHINA TOBACCO HUNAN INDAL CORP

Hakka green tea processing technology

InactiveCN105532934AReduce dosageImprove production and processing efficiencyPre-extraction tea treatmentGreen teaUltimate tensile strength

The present invention discloses Hakka green tea processing technology. The processing technology includes a picking process, a withering process, a de-enzyming process, a rolling process, a drying process and a finished tea product making process. In the processing technology, the finished tea product making process is mainly machinery production based and supplemented by artificial production, and greatly reduces labor force demands with a labor intensity reduced by 70% compared with the traditional manual production. The production efficiency per unit time is significantly increased, and the efficiency of tea leaf production and processing is improved. In particular, the machinery used in each process is essentially not overlapped and duplicated, does not produce burned taste or raw smell, and is stable in processing performance.

Owner:CHONGQING HENGHE AGRI TECH CO LTD

Manufacturing method of preserved peach and apricot

The present invention discloses a preserved peach and apricot manufacturing method, belongs to a preserved fruit manufacturing method and aims at providing a preserved fruit manufacturing method which has short sugar permeating time, even sugar permeating and less loss of nutrients, does not produce browning fruits, and can maintain intact fruit shapes. The manufacturing method includes the steps of washing, color maintaining, sugar permeating and oven-drying; and the manufacturing method is as follows: the peaches or apricots are immersed in the cleaning solution, soaked and cleaned, fished out, denucleated, and cut into pieces; the fruit pieces are immersed in the color-protecting solution and pre-cooked, then immersed in water to cool; the color-protected fruits are immersed in a first sugar permeating solution, a second sugar permeating solution, and a third sugar permeating solution respectively to conduct the treatments of vacuum hot sugar permeating , vacuum cold sugar permeating and ordinary pressure cold sugar permeating successively; the fruit pieces with sugar permeating treatments are rinsed with fresh water, and then oven-dried to obtain the preserved fruits. The manufacturing method can not only improve the processing efficiency and product quality, but also retain the flavour of traditional preserved fruits; the produced preserved fruits have plump and smooth shapes, fresh and transparent color and luster, and uniform distribution of sugar, are sour, sweet and delicious, and have moderate softness and hardness, strong original fruit tastes and rich nutrition.

Owner:GUIZHOU PANFU FRUIT & VEGETABLE CO LTD

Preparation method of pucker-free non-cleaning dried jujubes

ActiveCN103843875AImprove qualitySolve the darkening of jujube skinFruits/vegetable preservation by dehydrationCold airPhysical chemistry

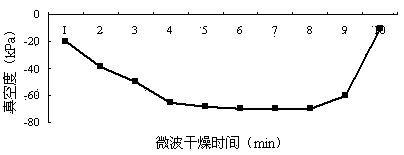

The invention discloses a preparation method of pucker-free non-cleaning dried jujubes, belongs to the technical field of food drying processing, and relates to a method of carrying out microwave vacuum puffing drying on red dates, aiming at solving the technical problems that jujube skin pucker, surface color darkening, nutritional ingredient loss, and the like appearing in a drying process of the red dates. According to the adopted technical scheme, the preparation method of the pucker-free non-cleaning dried jujubes comprises the following steps: pickling jujubes, grading the jujubes, rejecting defective fruits and impurities in materials; cleaning jujubes; drying water on the surfaces of the red dates by an air knife after cleaning the red dates; pre-drying for 3 hours-6 hours by cold air, regulating moisture of the red dates, and keeping the moisture of the red dates uniform, so that moisture content of the red dates reaches 35%-38%; carrying out microwave vacuum puffing drying on the red dates; spreading materials which are pre-dried by the cold air in a tray of a microwave vacuum unit, exhausting and then reducing pressure, wherein the conditions for carrying out the microwave vacuum puffing drying are as follows: vacuum degree is 65kPa-75kPa, microwave power is 6W / g-10W / g, drying time is 5 minutes-10 minutes, and final moisture content is controlled at 20%-25%.

Owner:交城天娇红农业科技有限公司

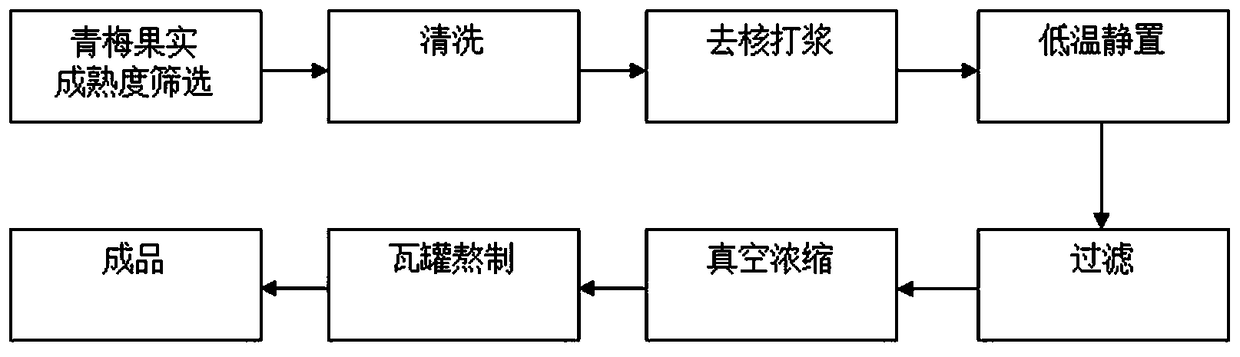

Preparation method of green plum essence

InactiveCN108936658AEffectively retain organic acidsRetained organic acidNatural extract food ingredientsFood ingredient as mouthfeel improving agentSugarFood flavor

The invention relates to a preparation method of a green plum essence. The preparation method comprises the following steps of (1) screening green plum fruits as a raw material according to maturity;(2) performing washing; (3) performing kernel removing and pulping; (4) performing low-temperature standing; (5) performing filtering; (6) performing vacuum concentration; and (7) performing decoctingwith a crock. According to the preparation method disclosed by the invention, the maturity of the raw material is strictly controlled, so that the situation that the quality of the green plum fruitsis unified and stable is guaranteed; besides, the problems that conventional high-temperature decocting is long in time consumption, and the effective components of the green plums are damaged are solved; and through determining the sugar acidity of the raw material, a preparation method of combining vacuum concentration with decocting with the crock is utilized, so that the time consumption is low, the energy can be saved, and the prepared green plum essence is thorough in reservation of effective components, good in quality and good in flavor.

Owner:GUANGXI SUBTROPICAL CROPS RES INST GUANGXI SUBTROPICAL AGRI PROD PROCESSING RES INST +1

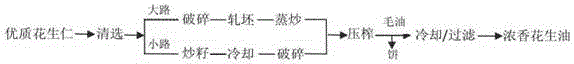

Press prepared peanut oil pretreatment method

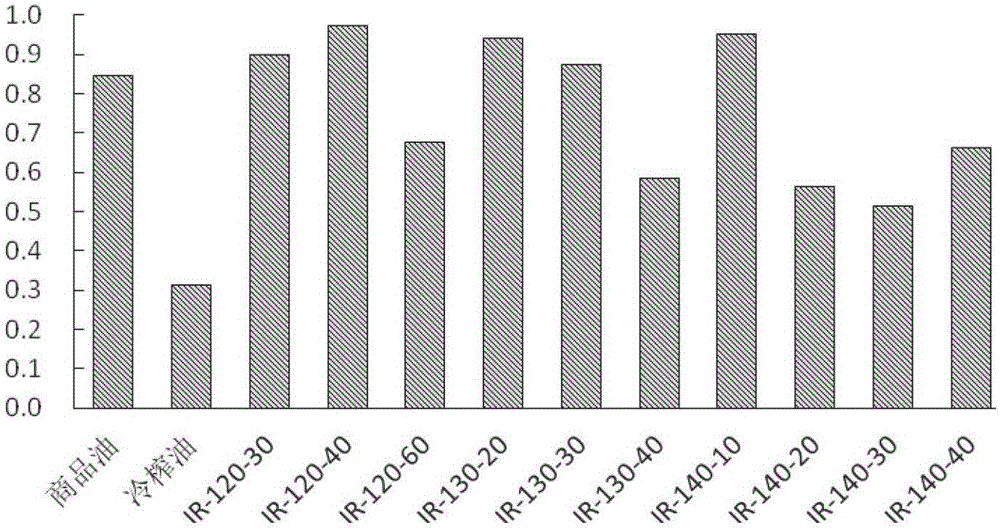

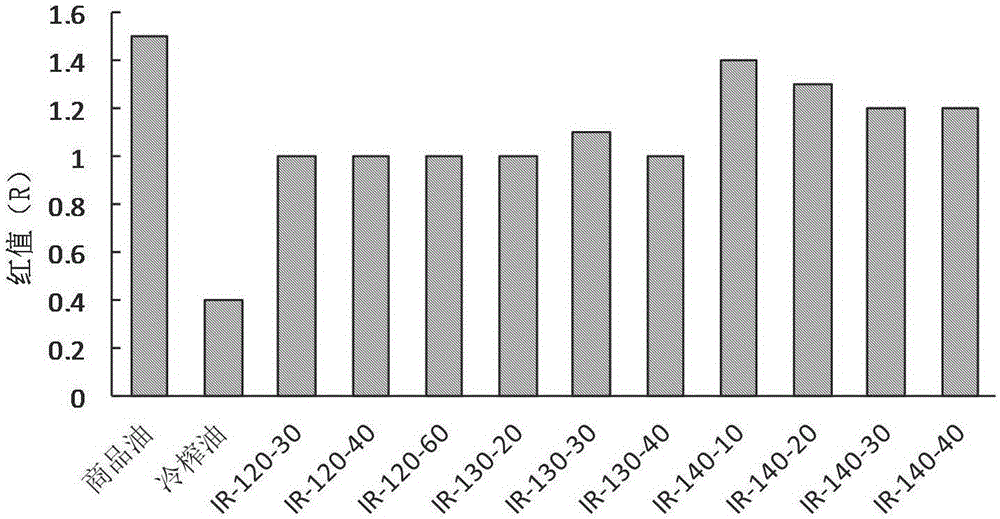

InactiveCN106433945ASimple processLow investment costFatty-oils/fats productionEdible oils/fatsMiddle infraredBiotechnology

The invention discloses a press prepared peanut oil pretreatment method, belonging to the technical field of food processing. The invention adopts the pretreatment method of short and middle infrared heating, overcomes the adverse effects of high temperature stir-frying seeds in pretreatment, the obtained peanut oil, has the unique rich aroma and taste of smooth aromatic peanut oil, is light in color, has no burnt smell, the obtained peanut meal has less denaturalization after the peanuts are pressed into oil, can be recycled, is simple in preparation process, the cost of investment and operation at an early stage is relatively low.

Owner:无锡德合食品科技有限公司 +1

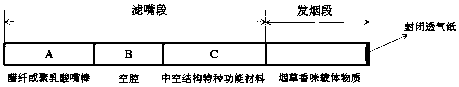

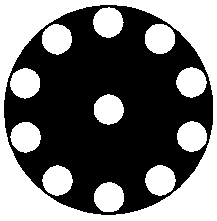

Novel heat-not-burn cigarette and preparation method thereof

The invention discloses a novel heat-not-burn cigarette and a preparation method thereof. The cigarette comprises a filter tip section and a smoke generation section, the filter tip section comprisesa part A, a part B and a part C; wherein the part A is an acetate fiber or polylactic acid filter tip with the length of 7-10mm; the part B is a section of cavity with the length of 10-15 mm, and thecigarette is characterized in that the part C is a functional material body with a hollow structure, the length of the part C is 5-10 mm, the length of the smoke generation section is 15-20 mm, a tobacco aroma carrier substance is arranged in the fuming section, and the exterior of the fuming section is sealed by a layer of breathable paper. The material has the advantage of remarkably reducing the smoke temperature, is environmentally friendly, and is non-toxic and harmless; the product is sufficient in sensory smoking fog amount, high in tobacco aroma quality, fine and soft in sense and freeof scorch flavor.

Owner:CHINA TOBACCO JIANGXI IND CO LTD

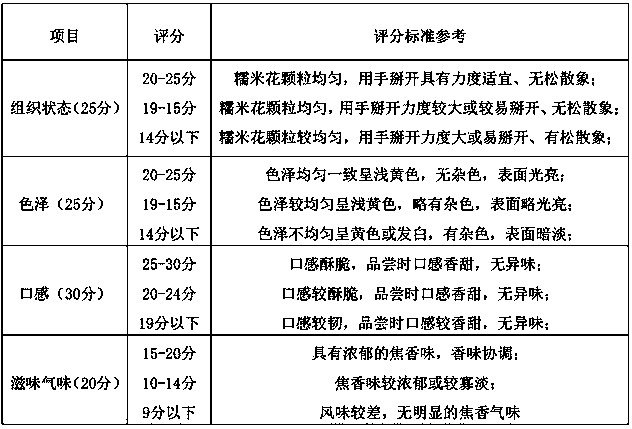

Preparation method of egg rice crackers

The invention relates to a preparation method of egg rice crackers. The preparation method is characterized in that a popcorn machine is used for puffing glutinous rice to the bulk density of 75-80 g / L, the moisture content of puffed glutinous rice grains is less than or equal to 5%, and the puffed glutinous rice is maintained at a certain degree of crispness; whole egg liquid and glucose powder are compounded into slurry to be mixed with the puffed glutinous rice to be formed, the mixture is baked in a baking oven, and the puffed glutinous rice grains can be colored on the basis of effectivebonding of the puffed glutinous rice grains; and finally, moisture is further removed from the rice crackers by secondary oil spray coating and low-temperature hot air drying. The preparation method of the egg rice crackers has a simple process and low cost, and is suitable for large-scale industrial production. The prepared egg rice crackers are the same in color from top to bottom of cake bodies, are light yellow and have a uniform color and no mottle, a bright surface and a full appearance, the texture is crispy, no burnt flavor is generated, and the cake bodies are firm and not brittle.

Owner:BENGBU COLLEGE

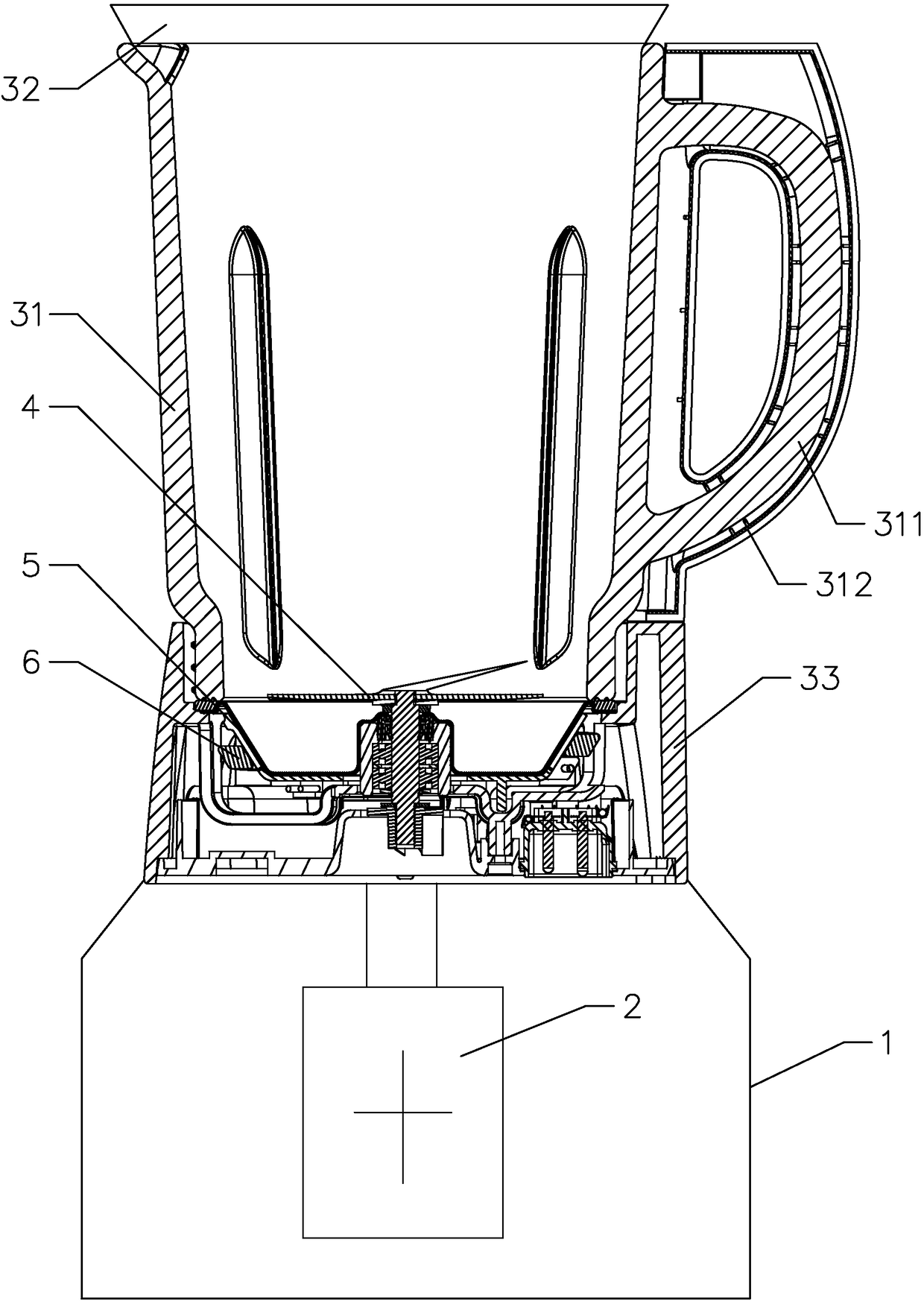

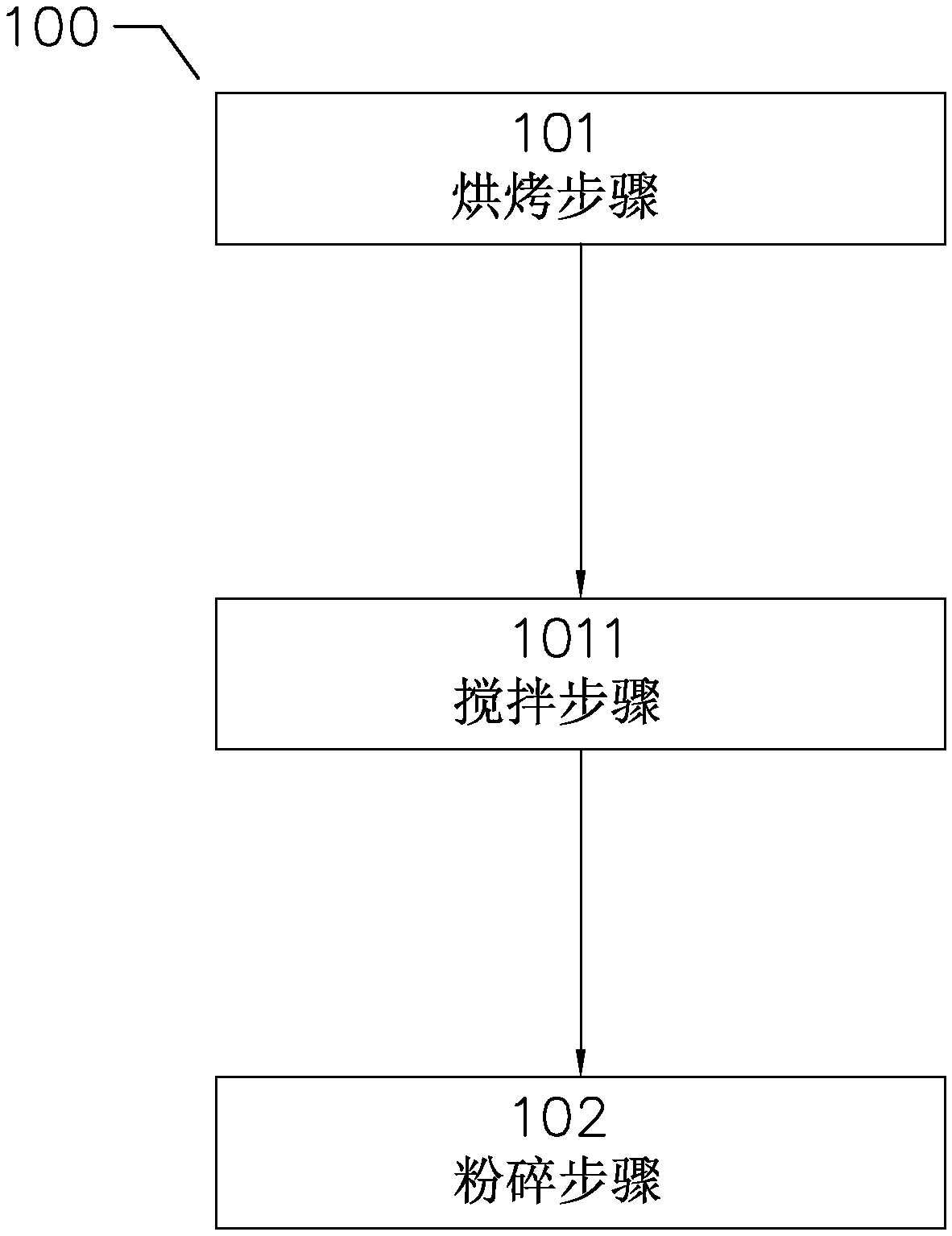

Nut paste processing method of food processer

The invention provides a nut paste processing method of a food processer. The method includes the following steps of braking and crushing, wherein in the braking step, a heating plate is used for heating nuts in a cup body until the nuts are cooked, and in the crushing step, a motor drives a crushing blade to rotate so as to crush the nuts in the cup body. The food processor is used for preparingnut paste, compared with a traditional household making method, the method is more convenient and faster, preparation steps are few, required utensils are few, the preparation process is pleasant, pleasure obtained by users in the preparation process is greatly increased, and the DIY fun of the users is increased. Meanwhile the heating plate is arranged at the lower end of the cup body, the heating plate includes a heating plate body and a heating pipe arranged on the side wall of the heating plate body, in this way, the nuts on the bottom are not burnt, the nuts are heated from the side face,the nuts can thus be heated more uniformly, it is ensured that the nuts are cooked, have no scorched flavor and also can produce strong nut fragrance, and therefore the made nut paste is more delicious and mellow.

Owner:JOYOUNG CO LTD

Making method of peking flowering crab candied fruits

The invention discloses a preparation method of peking flowering crab candied fruits, and belongs to a preparation method of candied fruits. The invention aims to provide the preparation method of candied fruits, which is short in sugar permeating time, uniform in sugar permeation, free from color brown stain, few in nutrition losses, and complete in fruit shapes. The preparation method comprises the following steps: a cleaning step: cleaning pears on which dry sulphitation is performed; a color protecting step: immersing pear pieces into color protecting liquid for precooking, and then cooling the precooked pear pieces; a sugar permeating step: respectively immersing the pear pieces on which the color protection is performed in a first sugar permeating solution, a second sugar permeating solution and a third sugar permeating solution for sequentially performing vacuum heat sugar permeation, vacuum cold sugar permeation, and constant-pressure cold sugar permeation; and a drying step: drip washing the pear pieces on which sugar permeation is performed with clean water, and then drying the washed pear pieces by baking. The preparation method disclosed by the invention can improve the processing efficiency and the product quality, and reserve the style of traditional candied fruits. The candied fruits prepared by the preparation method disclosed by the invention are plump and smooth in shape, are fresh and transparent in color, are uniform in sugar distribution, are moderate in sour and sweet, are delicious to eat, are moderate in soft and hard degrees, are strong in the taste of original fruits, and are rich in nutrition.

Owner:GUIZHOU PANFU FRUIT & VEGETABLE CO LTD

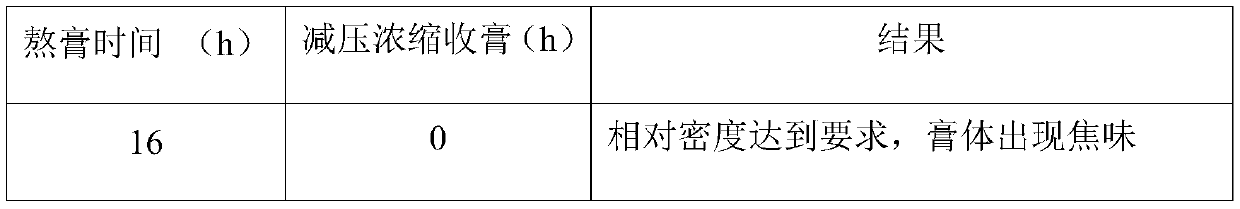

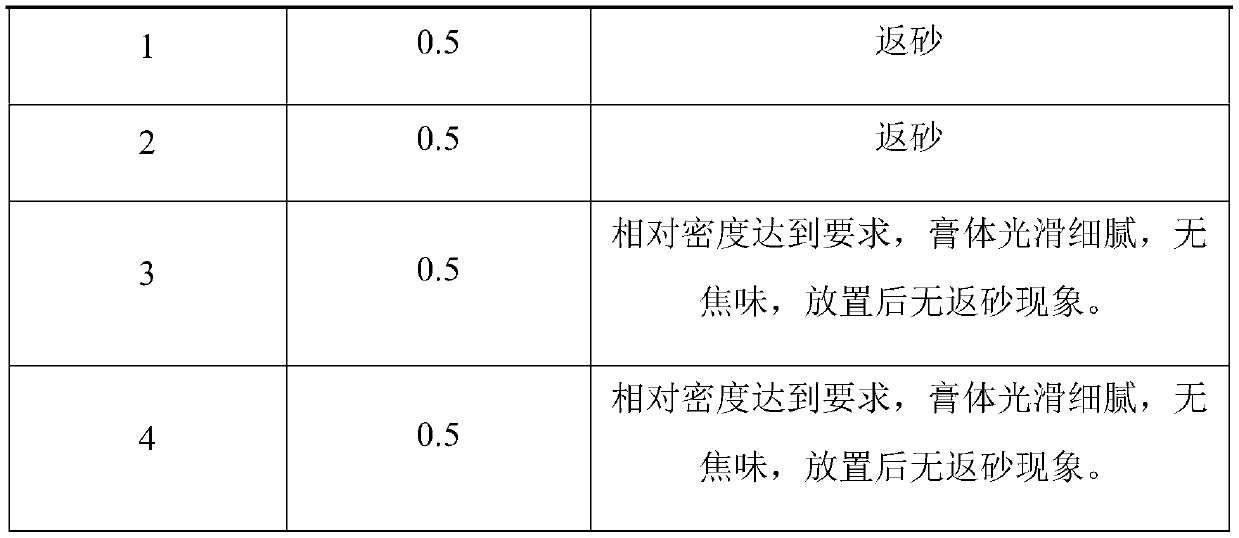

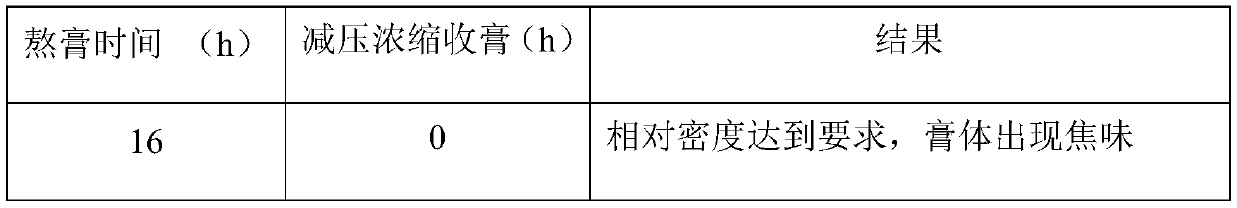

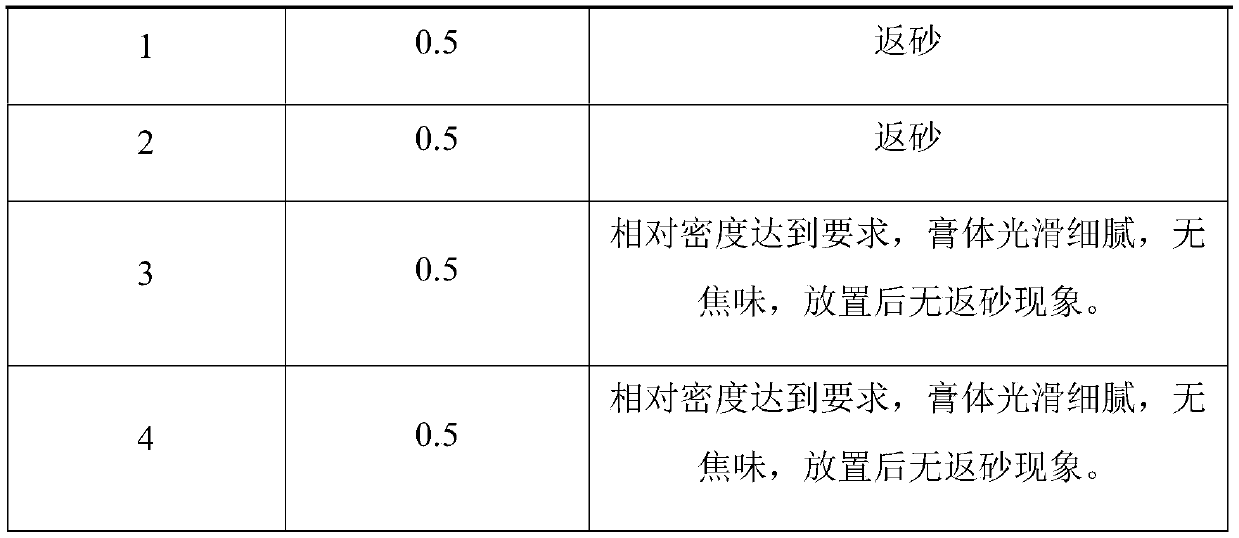

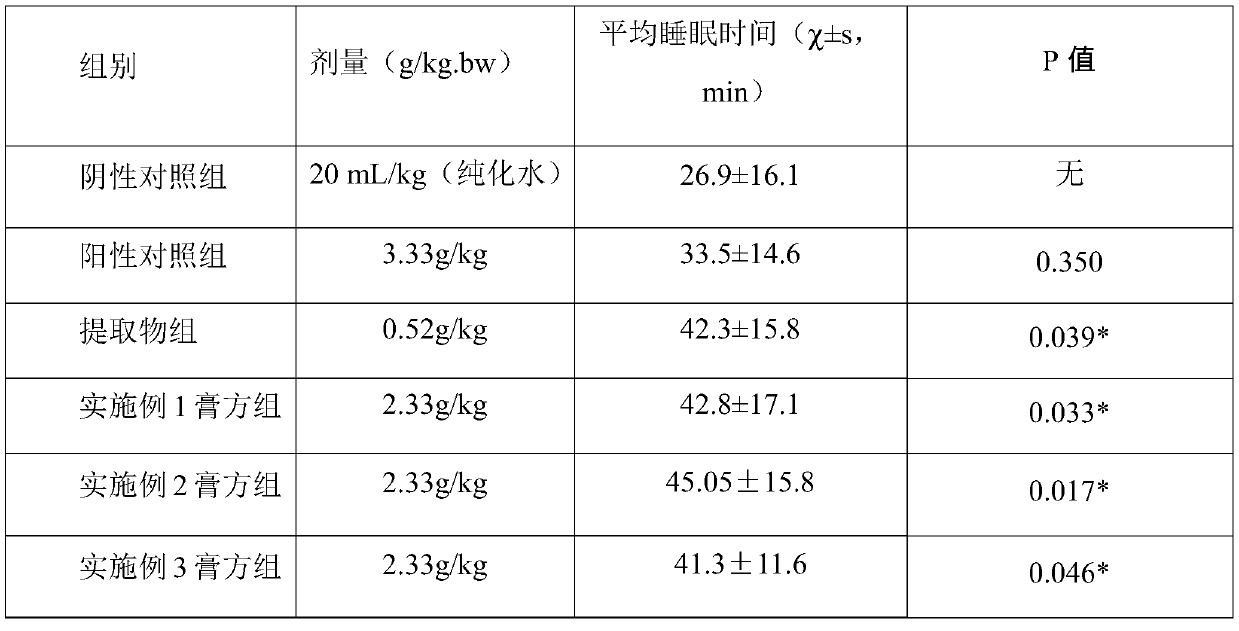

Paste composition and preparation method and application thereof

InactiveCN109999091AGood sleep effectPromote digestionNervous disorderAerosol deliverySugar refiningDigestion

The invention belongs to the field of traditional Chinese medicine compositions or traditional Chinese medicine health care products, and relates to a paste composition and a preparation method and application thereof. Specifically, the preparation method of the paste composition comprises the steps of preparation of a pure paste, sugar refining, paste decocting and reduced-pressure concentrationfor paste collection. According to the preparation method of the paste composition, reduced-pressure concentration is conducted in the paste collection process, and the preparation time for the pastecomposition is greatly shortened; meanwhile, the quality of the paste composition is excellent, the drawing and flagging effect is better, the paste body is smooth and delicate, no burnt smell is caused, and the sand returning phenomenon does not occur after placement. The invention further relates to the paste composition prepared by means of the paste composition preparation method and the application of the paste composition in preparing sleep aiding or digestion aiding foods or medicines.

Owner:东莞东阳光保健品研发有限公司

Preparation method of strigose hydrangea juvenile leaf tea

InactiveCN107467232AReduce bitternessRemove bitter substancesFood ingredient as antioxidantPre-extraction tea treatmentBiotechnologyAnimal science

The invention discloses a preparation method of strigose hydrangea juvenile leaf tea. The method includes the following steps: (1) performing withering; (2) performing deactivation of enzymes; (3) performing treatment before tea molding: performing bitterness-removing treatment on part of tea leaves, performing stewing to obtain tea soup and spraying the tea soup onto the remaining tea leaves; (4) performing tea molding: performing compression molding on the tea leaves through the methods of progressively increasing pressure and progressively increasing pressing time; (5) performing roasting: adopting stepwise roasting by controlling a temperature from high to low; and (6) performing fermentation and sterilization. According to the invention, through spraying the bitterness-removed tea soup before the tea molding, tea leaf sweetness is increased; and after performing roasting, eurotium cristatum is adopted for fermentation to remove bitterness. The strigose hydrangea juvenile leaf tea prepared through the method provided by the invention has high sweetness and has no lingering bitterness.

Owner:广西金秀县圣昌生态种植专业合作社

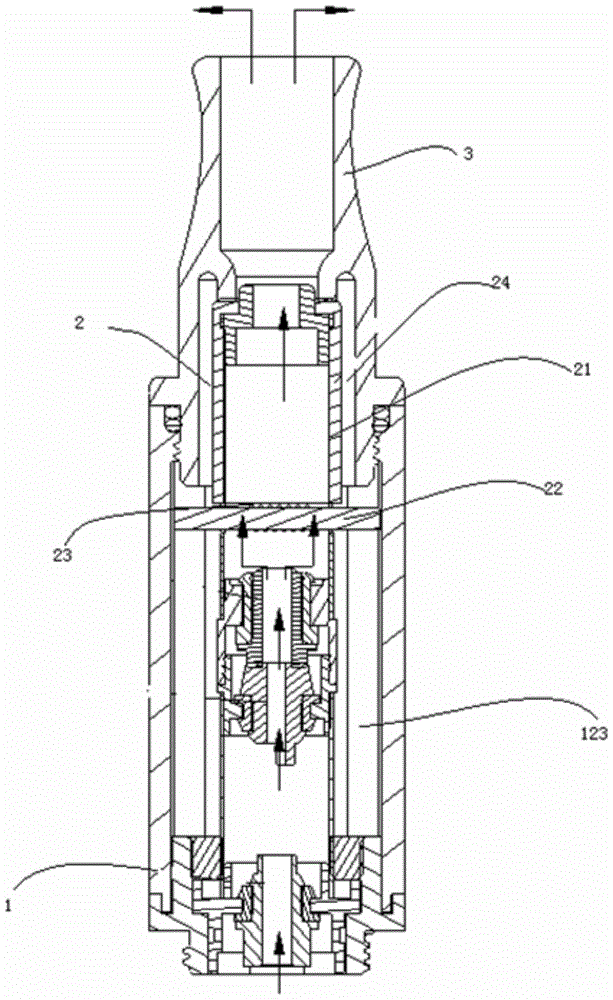

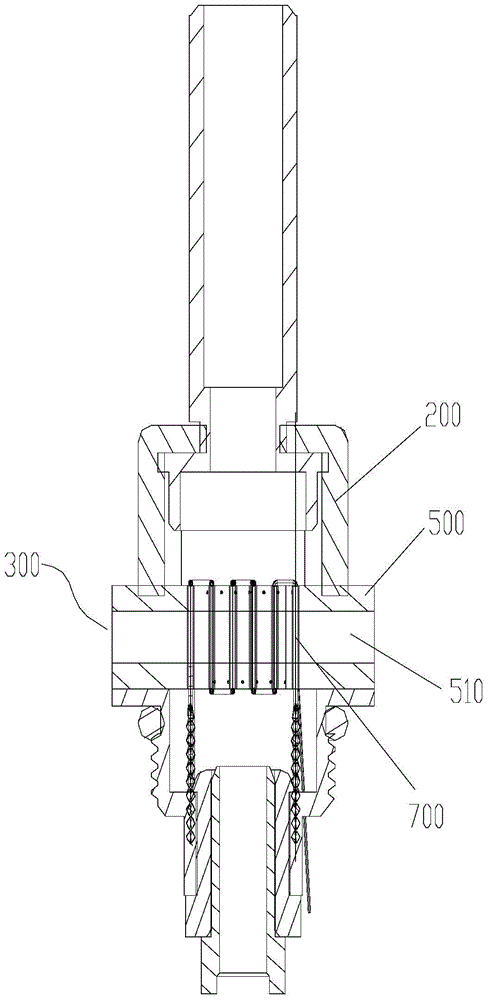

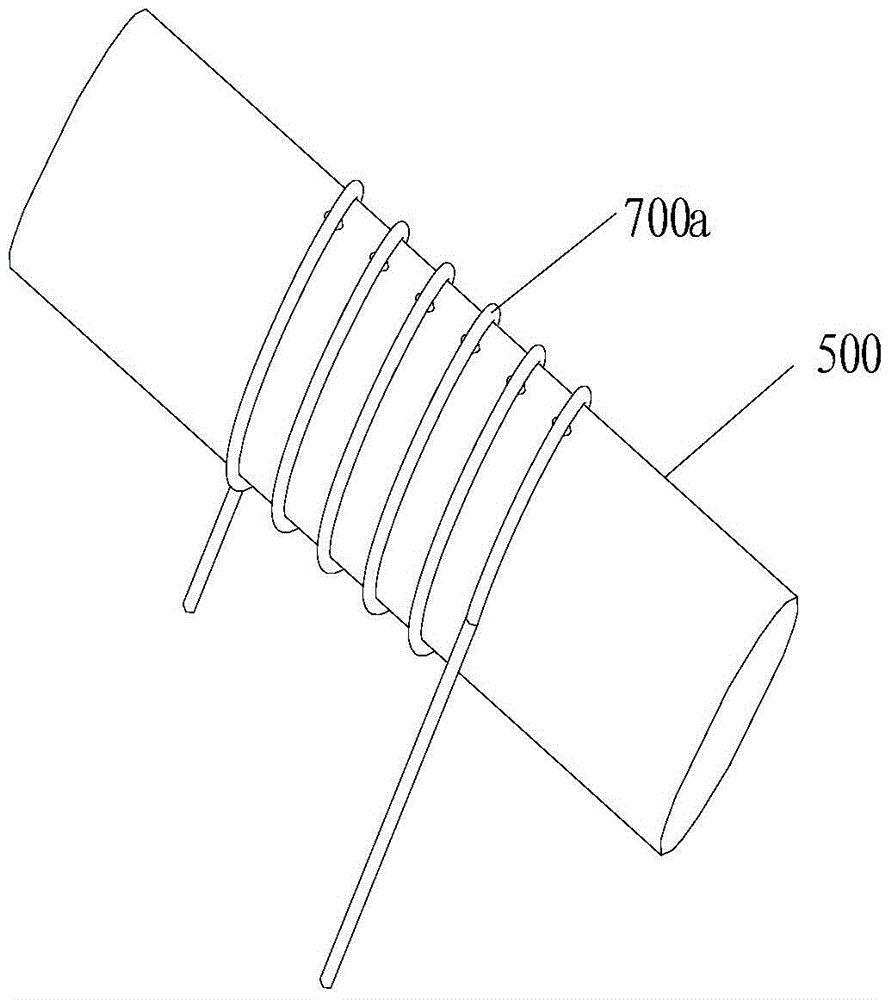

Heating components and atomization structures of electronic cigarettes

The invention discloses a heating component and an atomizing structure of an electronic cigarette, which comprises a liquid-conducting ceramic rod and a heating wire arranged on the liquid-conducting ceramic rod. In the present invention, the liquid-conducting ceramic rod is used to replace the existing fiber rope as the liquid-conducting carrier from the liquid storage chamber to the hollow atomizing rod and the supporting carrier for the heating wire. It has the characteristics of high temperature resistance and no burning smell, thus The generated airflow is more in line with the requirements of electronic cigarettes, and the taste is closer to real cigarettes; moreover, the liquid-conducting ceramic rod is not easy to damage, and the liquid-conducting is uniform and long-lasting, which can effectively ensure the reliability of liquid-conducting of electronic cigarettes; furthermore, the liquid-conducting ceramic rod The hard material characteristics of the rod can realize various layouts of the heating wire on the liquid-conducting ceramic rod, so that the positional relationship between the liquid on the liquid-conducting carrier and the heating wire can be distributed more reasonably, so as to improve the heat utilization rate and make the mist The chemical effect is obviously improved, and raw materials are saved.

Owner:SHENZHEN KANGER TECH CO LTD

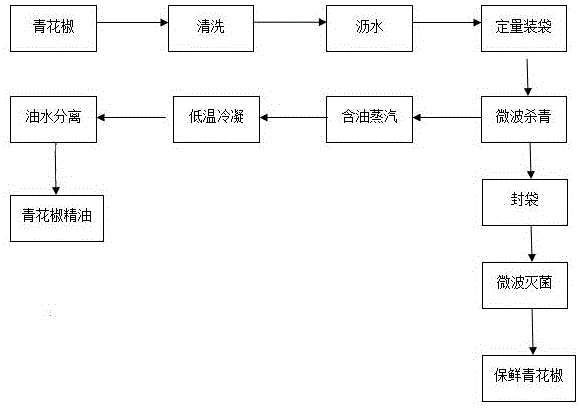

Method for green prickleyash microwave water removing preservation

InactiveCN105145792ARound fruitBright colorFruits/vegetable preservation by heatingEdible oils/fatsHeating timeOil water

The invention discloses a green prickleyash microwave water removing method. The method includes the steps that after being cleaned and drained, green prickleyash is quantitatively bagged through plastic bags and enters a microwave water removing line, microwave heating water removing is conducted, the plastic bags are sealed while the green prickleyash is hot after water removing is completed, microwave sterilization is conducted again, and vacuum-packaged preservative green prickleyash is obtained after cooling is completed. In the microwave water removing process, a large amount of essence-contained steam is generated at high temperature, the steam is led out through an induced draft fan and enters a low-temperature condenser through a pipeline, and condensed and liquefied essence-water mixed liquid is separated through an essence-water separator to obtain green prickleyash essence. Microwave water removing is used, time is short, the effect is good, sterilization can be conducted while water removing is conducted, the green prickleyash variety subjected to water removing through steam originally can be obviously improved, and the fragrance of the obtained green prickleyash essence obtained while microwave water removing is conducted is more similar to the natural fragrance of green prickleyash due to short heating time. The quality of the preservative green prickleyash is improved through the microwave water removing method, the quality of the green prickleyash essence obtained synchronously is more similar to the natural fragrance of the green prickleyash, and the green prickleyash microwave water-removing method has the advantages of being good in water removing effect, low in energy consumption, moderate in operating condition, free of additives and the like.

Owner:NANJING INST FOR THE COMPREHENSIVE UTILIZATION OF WILD PLANTS CHINA COOP

Production method of green plum essence

The invention discloses a production method of green plum essence. The production method includes the steps of: 1) washing and pre-boiling green plums, removing pits and squeezing the green plums to obtain green plum pulp; 2) sterilizing the green plum pulp and filling and sealing the green plum pulp and storing the green plum pulp for 1-2 years at normal temperature; 3) pouring the green plum pulp into a heat-preservative jacketed pot, heating the green plum pulp to boiling, performing boiling reflux for 8-10 h, and stopping heating and maintaining the temperature for 8-10 h; 4) heating the green plum pulp to boiling again, and concentrating the green plum pulp under normal pressure, filtering the green plum pulp to remove pulp fibers, and maintaining the temperature of the filtrate in a heat-preservative material for 8-10 h; and 5) heating the filtrate to boiling, and concentrating the filtrate under normal pressure to obtain the green plum essence. The green plum essence is high in content of mumefural and reaches more than 0.5% in mass percentage content of the mumefural. The green plum essence has a clear and bright color, has good solubility, is free of coking taste and has a pure mouth feel and high nutritional value. The method is simple in operations, is low in production cost and is easy to achieve large-scale industrial production.

Owner:广东科贸职业学院

Fur burning-out improving process

The invention discloses a fur burning-out improving process which is characterized by adopting the following steps: (1) selecting fur; (2) chrome tanning; (3) dyeing; (4) nailing on a board for drying, tumbling and finely cutting; and (5) burning out: printing a pattern onto the surface of hair by a printed screen board by using caustic soda of 400g / L, gelatin of 24g / L and HAC (glacial acetic acid) of 2ml / L then drying for 1 hour in a drying chamber at high temperature; and (6) finishing. According to the method for burning out with caustic soda disclosed by the invention, the pattern obtained by burning out is complete and beautiful without smell of scorching, and the color of the pattern obtained by burning out is the same as that of the ground color, thus being approved by customers.

Owner:HUASI HLDG CO LTD

Preparation method of mumefural

The invention provides a preparation method of mumefural, which comprises the following steps: selecting raw materials; performing pretreatment; preparing green plum slurry; performing biological enzymolysis; performing inactivation; performing primary filtration; performing primary concentration; performing secondary concentration; and performing secondary filtration to obtain the mumefural. Themumefural prepared by the invention has bright color, good solubility and high nutritional values, and has no burnt taste, no carcinogenic substance, pure taste and high nutritional values because a traditional high-temperature boiling process is not adopted.

Owner:NANJING FORESTRY UNIV

Fried walnut with long shelf life

InactiveCN107279927AExtended shelf lifeNo tasteFood ingredient as antioxidantConfectioneryAluminum foilChemistry

The invention discloses fried walnut with a long shelf life. The fried walnut with the long shelf life is prepared through the following steps: S1, an antioxidant is added to oil, walnut kernels are fried, and fried walnut kernels are obtained; S2, the fried walnut kernels are cooled and packaged in deoxidizer-containing aluminum foil bags. Nutrients of the walnut can be guaranteed effectively, and the shelf life of the fried walnut kernels can be prolonged.

Owner:YUNNAN MOER GARDEN BIOLOGICAL SCI & TECH DEV

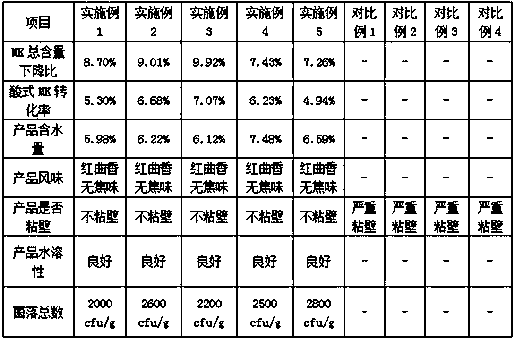

Method of preparing functional monascus powder based on spraying drying method and effectively maintaining total content of MK and stability of acid MK

PendingCN111019843ANo residual hazardsNo hidden dangerFungiMicroorganism based processesBiotechnologySubmerged fermentation

The invention relates to a method. The method comprises the following steps: step A, using tartary buckwheat powder, tartary buckwheat peel powder or a combination of the tartary buckwheat powder andthe tartary buckwheat peel powder as a carbon source design culture medium, and performing liquid submerged fermentation in a 1500-L fermentation tank in combination with monascus purpureus to preparefunctional monascus fermentation liquor taking Monacolin K (hereinafter referred to as MK) as a main target product; step B, performing solid-liquid separation on the fermentation liquor obtained inthe step A by using a pressurized plate-and-frame filter press, and performing falling film evaporation and vacuum concentration on the obtained filtrate; step C, fully stirring and mixing the concentrated solution obtained in the step B with 6-15% by mass of auxiliary materials to prepare homogeneous spray liquid, and performing filtering for later use; and step D, preparing the spray liquid obtained in the step C into a powder product by using centrifugal spray drying equipment. According to the invention, the total content of MK and the stability of acid MK can be effectively maintained under the conditions of high temperature and short time; and a problem of hot melting wall adhesion is avoided. Moreover, the drying time of the monascus product is greatly shortened, and the produced functional monascus powder is free of scorch aroma and bitterness and good in water solubility.

Owner:GUANGDONG TIANYI BIOTECH CO LTD

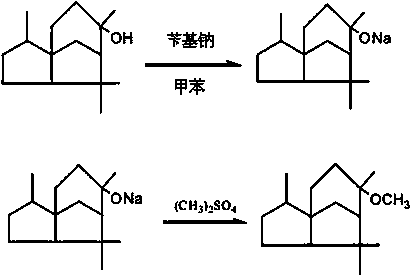

Method for preparing methyl cedryl ether from Chinese fir oil

ActiveCN104045526ASimple post-processingMild reaction conditionsPreparation of metal alcoholatesEther preparation by ester reactionsSodium bicarbonateEngineering

The invention discloses a method for preparing methyl cedryl ether from Chinese fir oil. The method comprises the following steps: by taking Chinese fir oil as a raw material, reacting the separated Chinese fir alcohol with benzyl sodium to obtain Chinese fir alcohol sodium, and reacting for 1-1.5h, wherein the molar ratio of the benzyl sodium to the Chinese fir alcohol is (1.0-1.6):1, the volume ratio of a solvent methylbenzene to the Chinese fir alcohol material in the reaction product is (2-3):1; carrying out methylation on the Chinese fir alcohol sodium and dimethyl sulfate, wherein the molar ratio of the dimethyl sulfate to the dimethyl sulfate is (1-1.2):1; reacting at 60-80 DEG C for 2.4-2.6h, and washing the reaction product by using 10% sodium bicarbonate solution, standing and layering, washing an oil layer to neutral by using 10% sodium chloride solution, and then distilling to obtain the methyl cedryl ether. Compared with a sodium hydride method and a sodium amide method, the method is mild in reaction condition, high in product yield, and pure in fragrance, the methyl cedryl ether prepared from cedar wood oil as a raw material can be replaced with the prepared methyl cedryl ether, and the situation of shortage of cedar wood oil resources can be relieved.

Owner:江西华晨香料化工有限公司

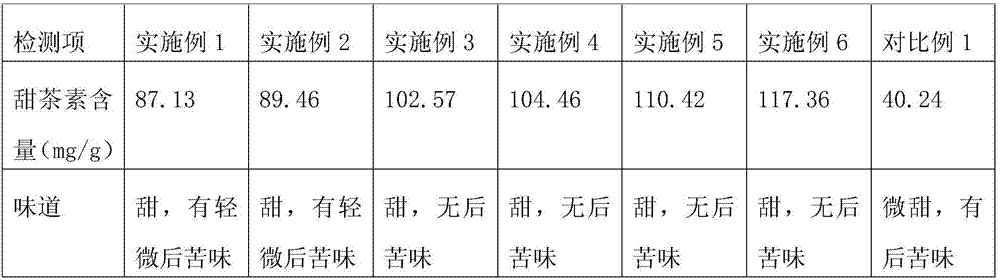

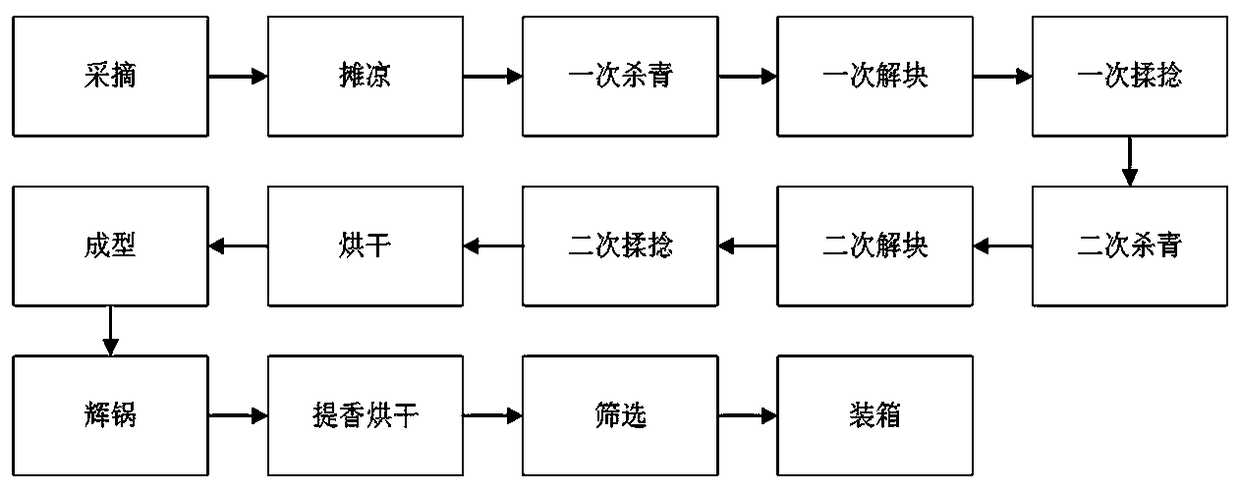

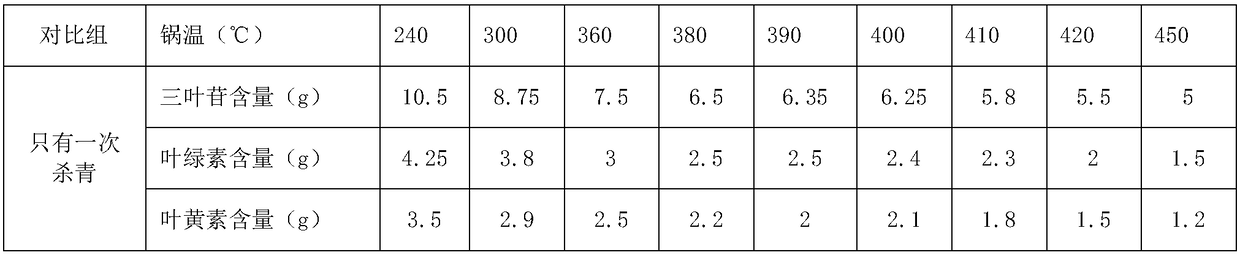

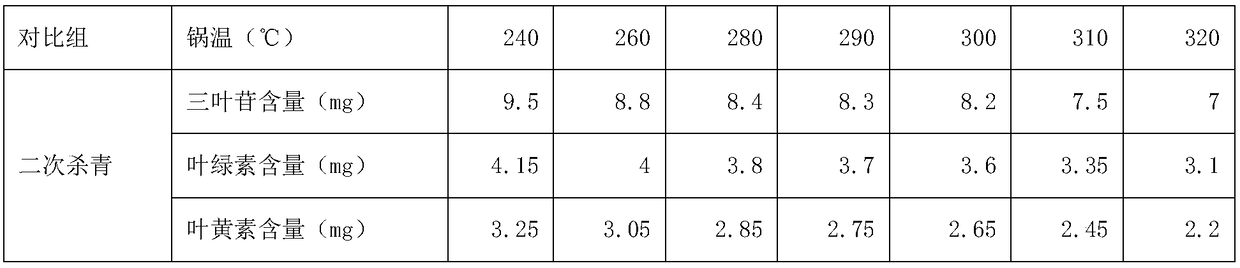

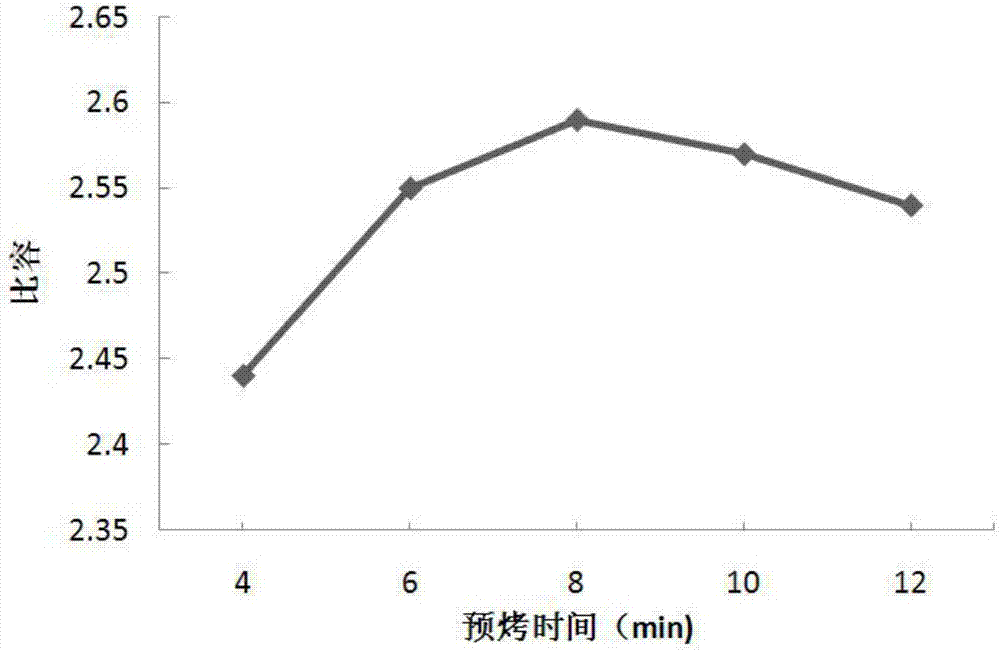

Preparation method of lithocarpus litseifolius sweet tea

The invention discloses a preparation method of lithocarpus litseifolius sweet tea. The preparation method comprises the following steps: S1, harvesting lithocarpus litseifolius tender leaves as a rawmaterial of tea and performing spreading and airing treatment; S2: performing primary fixation treatment on the spread and aired tea leaves, and performing spreading and airing for cooling; S3: performing primary deblocking and dispersing on the thoroughly cooled tea leaves and performing primary rolling treatment; S4: performing secondary fixation, secondary deblocking and secondary rolling treatment on the tea leaves subjected to the primary rolling; and S5: sequentially performing drying, forming, final-panning, fragrance increasing by drying, screening and box packing treatment on the tealeaves subjected to secondary rolling. The preparation method disclosed by the invention realizes the purposes that the lithocarpus litseifolius sweet tea is round, tight, green and smooth in appearance, sweet and lasting in fragrance, yellow green and bright in liquor color, sweet, mellow and refreshing in taste, and yellow green and soft in tea dregs.

Owner:芦山县石刀沟乡村旅游发展有限公司

Making method for pre-baked mashed potato bread

PendingCN107410424ANo burnt smellThe pores are fine and uniformDough treatmentBakery productsFrozen storageFermentation

The invention discloses a making method for pre-baked mashed potato bread. The method comprises the steps that 1, 170 g of high gluten flour, 132 g of mashed potato, 32 g of water, 40 g of sugar, 8 g of milk powder, 0.8 g of bread improver, 20 g of butter, 2 g of salt, 16 g of eggs and 4 g of yeast are accurately weighed; 2, dough kneading, standing, shaping and fermentation are conducted; 3, pre-baking is conducted for 8 min with the bottom fire being 180 DEG C and the surface fire being 230 DEG C, and then cooling is conducted to reach the room temperature under the environment with the humidity being 75%; 4, dough is wrapped by preservative film and moved to the place at -18 DEG C for frozen storage; 5, the dough returns to the room temperature and is brushed with egg liquid and baked to be golden yellow with the bottom fire being 180 DEG C and the surface fire being 230 DEG C. The method has the advantages that the bread is made into a semi finished product for frozen storage, when a person want to eat the bread, he / she only needs to bake the bread, the obtained bread has the burnt flavor and the unique flavor of potatoes, the bread is soft and elastic and has the color of thick and uniform golden brown, the surface is a smooth curved surface and is free of crease and not likely to fall off, the bread core is soft, wet, milky white, glossy, fine and uniform in pore, soft, palatable, non-sticky and pure in taste, and the quality is almost the same as that of bread made from fresh dough.

Owner:HEBEI UNIV OF ENG

Sweet gynostemma pentaphylla tea and processing method thereof

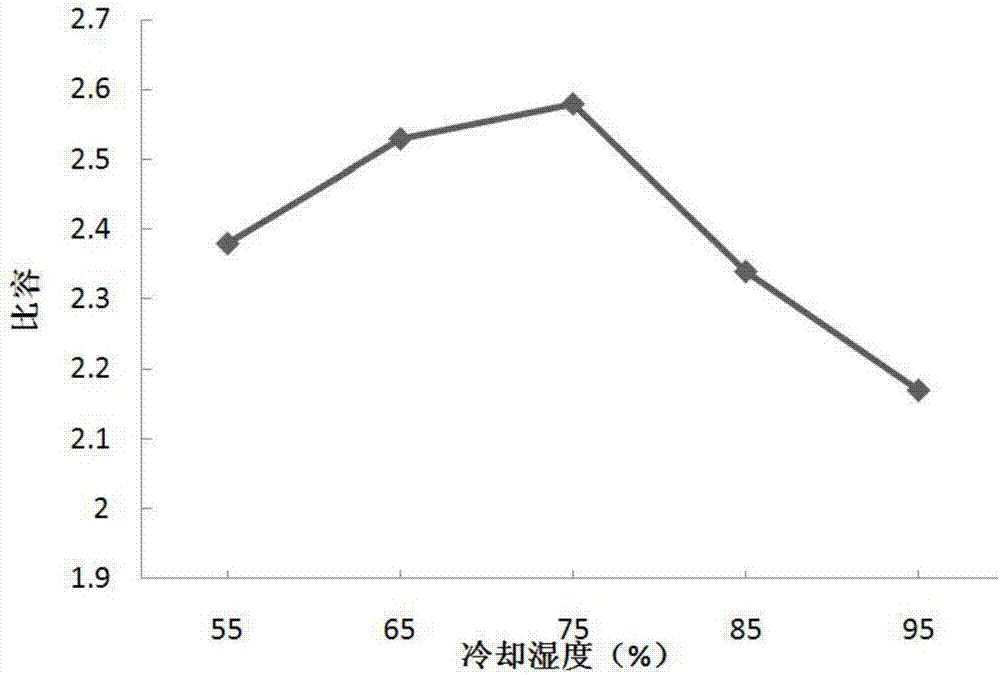

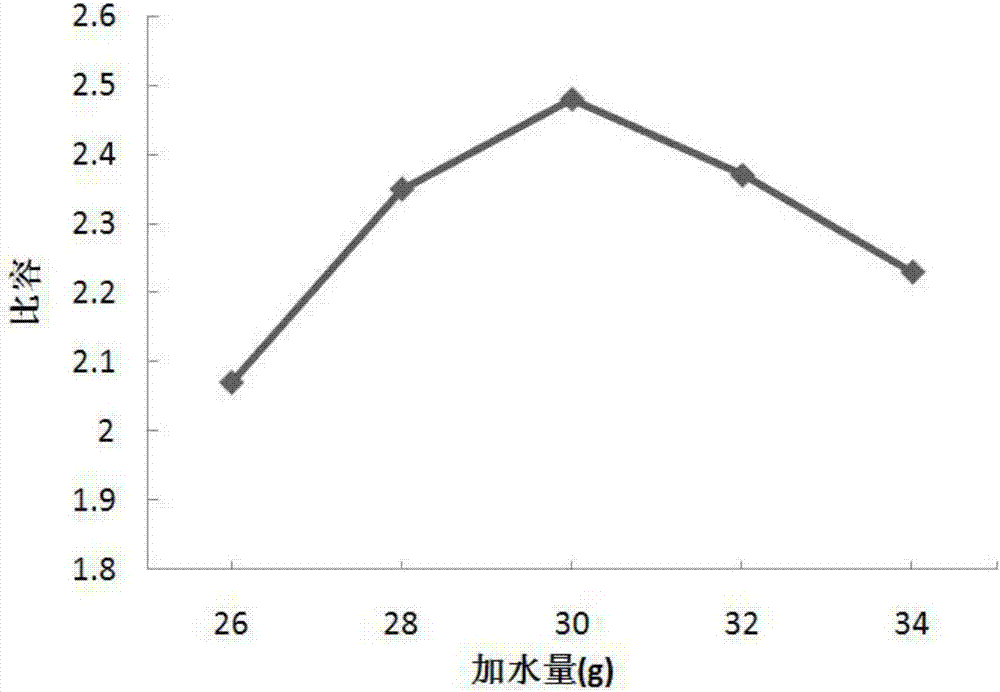

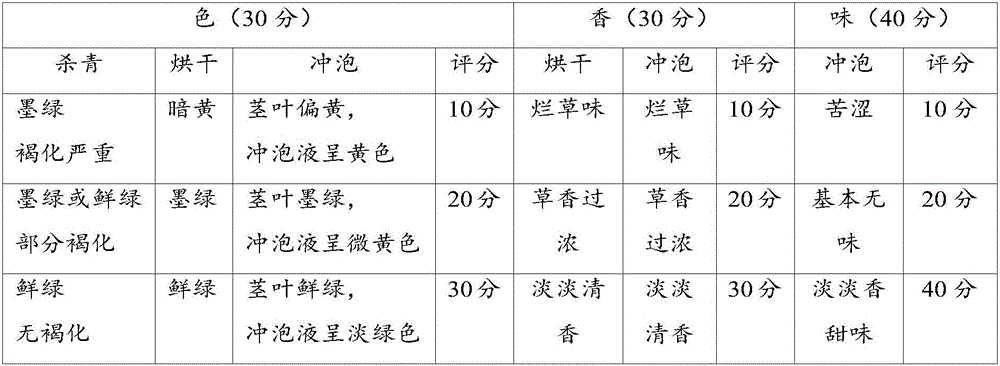

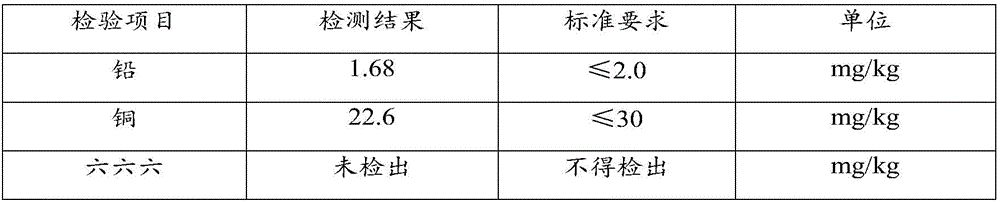

The invention provides sweet gynostemma pentaphylla tea and a processing method thereof, and belongs to the technical field of tea processing. The processing method includes picking up and washing tea leaves, killing out, cooling and dewatering tea leaves until water content of tea leaves ranges from 55% to 65%, drying the tea leaves until the water tent of the tea leaves is smaller than or equal to 7%, and flavoring the tea leaves. By adopting high-temperature killing-out, the tea leaves are uniformly heated, killing-out is short in time, and quality of tea is upgraded. In addition, drying temperature is 60-80 DEG C, effective activity is increased on the premise of not losing saponin, and health care of products is optimized. After flavored, the semi-finished products are cooled, and color and water of the tea leaves can be guaranteed. The sweet gynostemma pentaphylla tea is good in taste and soup. The sweet gynostemma pentaphylla tea is processed by the aforementioned method. The sweet gynostemma pentaphylla tea has green tea soup and leaves, and is fresh and sweet without burning smell, good in taste and soup, and healthy.

Owner:湖北省农业科学院农业经济技术研究所 +1

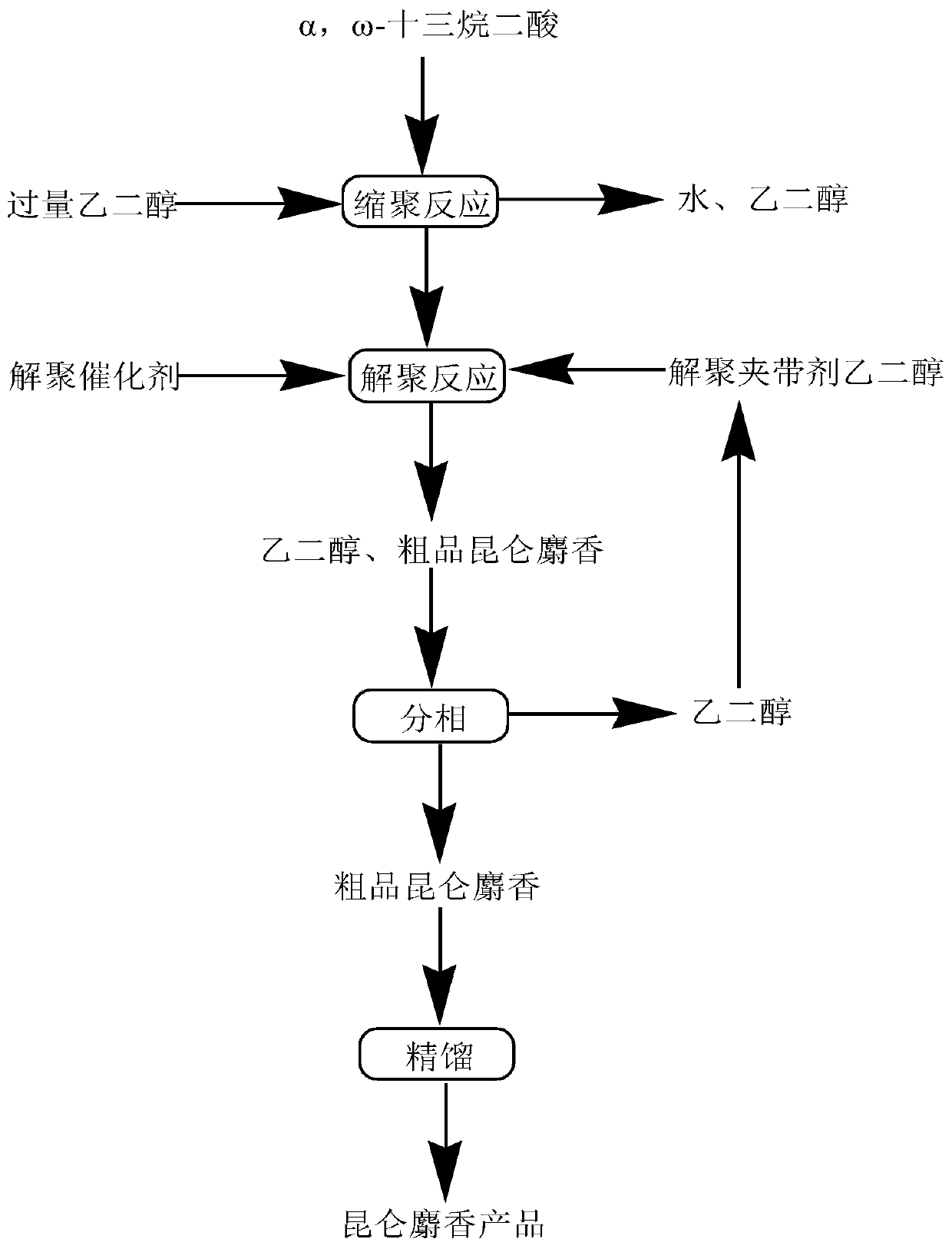

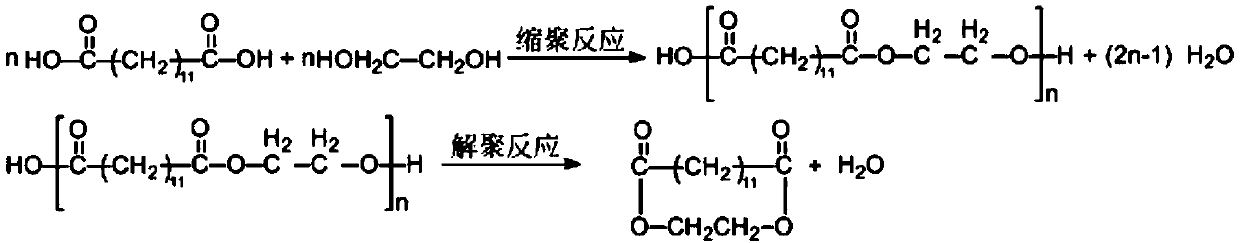

Preparation method of Kunlun musk

PendingCN111499609AReduce production energy consumptionLess side effectsOrganic chemistryDepolymerizationPtru catalyst

The invention discloses a preparation method of Kunlun musk, which includes steps of with alpha,omega-tridecanedioic acid and ethylene glycol as raw materials, preparing the Kunlun musk through low-temperature polycondensation reaction and low-temperature depolymerization reaction. The condensation polymerization reaction only needs 170 DEG C, wherein titanium isopropoxide is used as a depolymerization catalyst with cooperation of an entrainer ethylene glycol, so that the depolymerization reaction temperature only needs 220-240 DEG C, which is greatly reduced than that inthe prior art. Compared with a traditional Kunlun musk preparation method, the method has the advantages that the yield is high, conditions are mild, the purity of the obtained Kunlun musk product is larger than or equal to 99%, the fragrance is purer, bad offensive odor such as burnt smell is avoided, and the quality is better.

Owner:绵阳三香汇生物科技有限公司

Preparation method of chili animal oil

The invention discloses a preparation method of chili animal oil. The preparation method comprises the following steps of (1) drying dry chilies at the temperature of 30-50 DEG C until the water content is smaller than or equal to 10%, performing crushing, and performing screening through a 20-60-mesh sieve so as to obtain chili powder; (2) adding the chili powder and animal oil to a high-pressuretank in the proportion of the chili powder to the animal oil being 1 to (5-7), performing heating so that the pressure achieves 90-110KPa, and maintaining the pressure of 90-110KPa for 10-20min; and(3) lowering the pressure to normal pressure, opening the cover of the high-pressure tank, dispersing water vapor, and performing filtering to obtain filtrate namely the chili animal oil. Under the high-temperature high-pressure condition, the chili animal oil is refined, so that the solubility of capsaicine substances is increased, the boiling time is shortened, and the chili animal oil has goodremoval effect on green raw taste of the chilies. According to the method, the obtained chili animal oil is rich in fragrance, fragrant and mellow, free from burned taste and bright and red in color.

Owner:TIANJIN AGRICULTURE COLLEGE

Traditional Chinese medicine composition, preparation and use thereof

InactiveCN109925356AGood sleep effectPromote digestionNervous disorderDigestive systemTangerine PeelDigestion

The invention belongs to the field of traditional Chinese medicine compositions or traditional Chinese medicine health care products, and relates to a traditional Chinese medicine composition, a preparation and use thereof. Specifically, one aspect of the invention relates to a traditional Chinese medicine composition containing poria cocos, spina date seeds, tangerine peel and ginseng and a preparation thereof. The traditional Chinese medicine composition and the preparation thereof have better sleep-aid effects and better digestion aid effects. Another aspect of the invention relates to useof the traditional Chinese medicine composition and the preparation thereof in the preparation of sleep-aid or digestion-aid foods or medicines.

Owner:东莞东阳光保健品研发有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com