Preparation method of Kunlun musk

A kunlun musk and vacuuming technology, which is applied in the direction of organic chemistry, can solve the problems that affect the final product quality of kunlun musk, greatly affect the product refining and purification, and affect the effect of depolymerization reaction, so as to achieve good catalytic effect, improve product quality, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

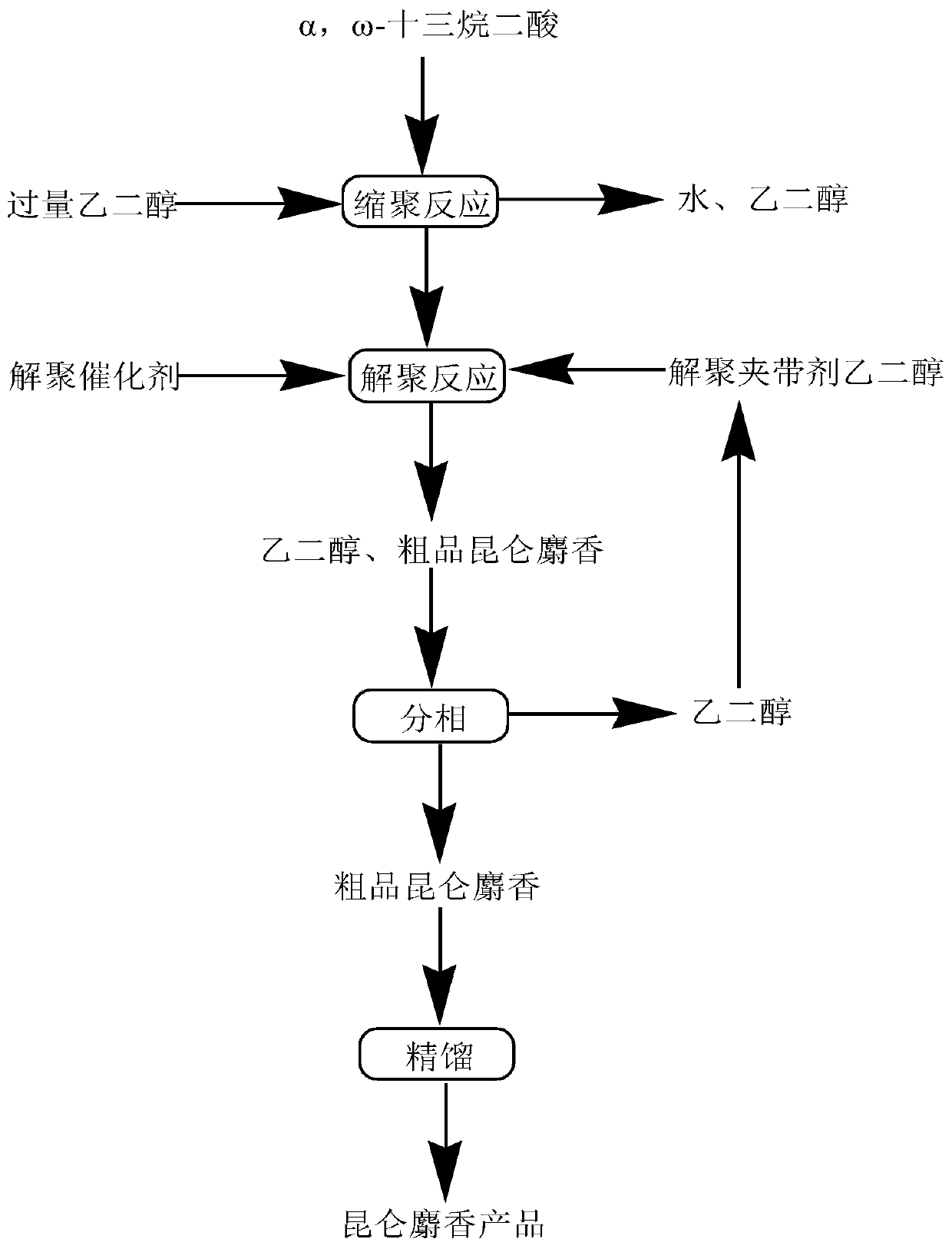

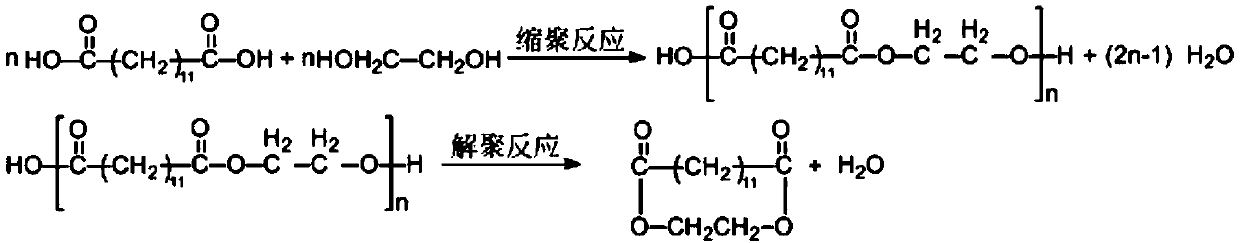

Method used

Image

Examples

Embodiment 1

[0045] 1. Feeding

[0046] First put 360kg of ethylene glycol into the polycondensation reactor; then add 1200kg of tridecanedioic acid from the manhole of the reactor, and then add 450kg of ethylene glycol; vacuumize to 100mmHg, and return to normal pressure with nitrogen.

[0047] 2. Polycondensation reaction

[0048]Turn on the cooling water of the condenser and raise the temperature to 120°C without stirring; continue to heat until there is reflux, and then start stirring again, at this time the temperature of the kettle is about 138°C; it takes 3 hours to raise the temperature of the kettle from 138°C to 170°C , the top temperature is 120°C, about 225kg of water is distilled out, and the water is collected as waste water and enters the collection tank; then the vacuum is evacuated to 200mmHg at a speed of 3mmHg / min, and the temperature of the kettle is kept at 170°C during the process, and the top temperature is about 128°C. About 330kg of water / ethylene glycol is distil...

Embodiment 2

[0060] 1. Feeding

[0061] First put 210kg of ethylene glycol into the polycondensation reactor; then add 1200kg of tridecanedioic acid from the manhole of the reactor, and then add 450kg of ethylene glycol; vacuumize to 100mmHg, and return to normal pressure with nitrogen.

[0062] 2. Polycondensation reaction

[0063] Turn on the cooling water of the condenser and raise the temperature to 120°C without stirring; continue to heat until there is reflux, and then start stirring again, at this time the temperature of the kettle is about 138°C; it takes 3 hours to raise the temperature of the kettle from 138°C to 170°C , the top temperature is 120°C, about 225kg of water is distilled out, and the water is collected as waste water and enters the collection tank; then the vacuum is evacuated to 200mmHg at a speed of 3mmHg / min, and the temperature of the kettle is kept at 170°C during the process, and the top temperature is about 128°C. About 200kg of water / ethylene glycol is disti...

Embodiment 3

[0075] 1. Feeding

[0076] First put 360kg of ethylene glycol into the polycondensation reactor; then add 1200kg of tridecanedioic acid from the manhole of the reactor, and then add 450kg of ethylene glycol; vacuumize to 100mmHg, and return to normal pressure with nitrogen.

[0077] 2. Polycondensation reaction

[0078] Turn on the cooling water of the condenser and raise the temperature to 120°C without stirring; continue to heat until there is reflux, and then start stirring again, at this time the temperature of the kettle is about 138°C; it takes 3 hours to raise the temperature of the kettle from 138°C to 180°C , the top temperature is 125°C, about 230kg of water is distilled out, and the water is collected as waste water and enters the collection tank; then the vacuum is evacuated to 200mmHg at a speed of 3mmHg / min, and the temperature of the kettle is kept at 180°C during the process, and the top temperature is about 130°C. About 330kg of water / ethylene glycol is disti...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

| degree of polymerization | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com