Method for green prickleyash microwave water removing preservation

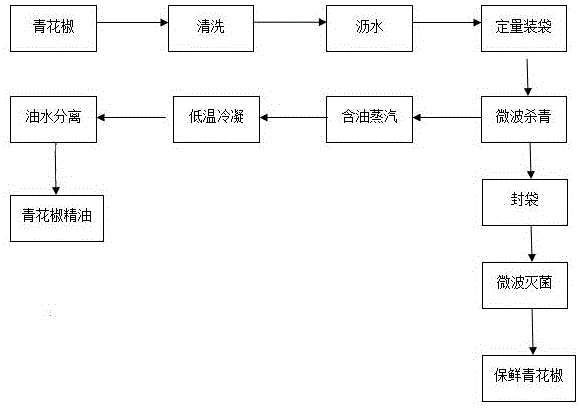

A technology of microwave killing green and green prickly ash, which is used in the preservation of fruits and vegetables, food preservation, and heating and preservation of fruits/vegetables, etc., can solve the problems of essential oil volatilization, non-recycling and waste, and oil sacs being ruptured by heat, and achieve high product quality and round fruit. , the effect of high economic efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Clean the green peppercorns, remove impurities and bad fruits, and pack them into bags according to the ration of 500g. Set the temperature of the microwave production line to 180°C, preheat for 2 minutes, put the green pepper into the microwave killing line, turn on the induced draft fan, adjust the microwave power to 21kw, so that the material temperature reaches 92°C, and keep it for 6 minutes; open the inlet and outlet valves of the low-temperature condenser , keep the inlet temperature of the condensate at 5°C, and the outlet temperature at 30±2°C, guide the hot steam guided by the induced draft fan into the condenser, and the cooled oil-water mixture enters the oil-water separator, let it stand for 60 minutes, and collect the green pepper on the upper layer Essential oil; green peppercorns that have been killed, sealed in bags while they are hot, placed in a microwave sterilization line, heated at 80±2°C for 10 seconds, sprayed and cooled to room temperature after ...

Embodiment 2

[0028] Clean the green peppercorns, remove impurities and bad fruits, and pack them into bags according to the ration of 250g. Set the temperature of the microwave production line to 180°C, preheat for 2 minutes, put the green pepper into the microwave killing line, turn on the induced draft fan, adjust the microwave power to 18kw, so that the material temperature reaches 95°C, and keep it for 5 minutes; open the inlet and outlet valves of the low-temperature condenser , keep the condensate inlet temperature at 3°C, and the outlet temperature at 30±2°C, guide the hot steam guided by the induced draft fan into the condenser, and the cooled oil-water mixture enters the oil-water separator, let it stand for 90 minutes, and collect the green peppercorns on the upper layer Essential oil; green peppercorns that have been killed, sealed in bags while they are hot, placed in a microwave sterilization line, heated at 80±2°C for 8s, sprayed and cooled to room temperature after coming out...

Embodiment 3

[0030] Wash the green peppercorns, remove impurities and bad fruits, and pack them into bags according to the ration of 100g. Set the temperature of the microwave production line to 180°C, preheat for 2 minutes, put the green pepper into the microwave killing line, turn on the induced draft fan, adjust the microwave power to 15kw, so that the material temperature reaches 95°C, and keep it for 5 minutes; open the inlet and outlet valves of the low-temperature condenser , keep the condensate inlet temperature at 3°C, and the outlet temperature at 28±2°C, guide the hot steam guided by the induced draft fan into the condenser, and the cooled oil-water mixture enters the oil-water separator, let it stand for 45 minutes, and collect the green peppercorns on the upper layer Essential oil; green peppercorns that have been killed are sealed in bags while they are hot, placed in a microwave sterilization line, heated at 78±2°C for 10 seconds, sprayed and cooled to room temperature after ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com