Tobacco extract and electronic cigarette liquid

A technology of tobacco extract and electronic cigarette liquid, applied in the field of electronic cigarettes, can solve the problems of insufficient tobacco aroma, poor taste, easy to appear burnt taste, etc., and achieve the effects of comfortable aftertaste and delicate and soft smoke.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] This example provides a tobacco extract and e-cigarette liquid. The preparation method is as follows: add 500 ml of 85 vol% ethanol to 50 g of Sangzhi B3F, extract at room temperature for 1 day, filter, and concentrate the filtrate to dryness to obtain an ethanol extract. Add 40 ml of hot ethanol to dissolve the ethanol extract, and then place the dissolved solution at 4°C for 2 hours to freeze to precipitate a precipitate, filter, and concentrate to 10 ml to obtain extract I. The shredded tobacco extracted by ethanol is ultrasonicated for 30 minutes at room temperature with 500 ml of water, and the water extract is obtained by filtration. The water extract is first degreased with 300 ml of n-hexane. Extract and collect the water phase (degreasing process, the same below); the water phase was then extracted with 300 ml of dichloromethane, and the dichloromethane phase was concentrated to 10 ml under reduced pressure at 30°C to obtain Extract II. Take 2 ml of extract I a...

Embodiment 2

[0031] This example provides a tobacco extract and e-cigarette liquid. The preparation method is as follows: add 2000 ml of 95 vol% ethanol to 180 g of shredded Zimbabwean tobacco, extract at room temperature for 1 day, filter, add 150 ml of hot ethanol to dissolve the filtrate after concentration , to obtain the ethanol extract, placed at 4 ° C for 2h to freeze and precipitate the precipitate, filtered, concentrated to 30 ml, and the extract I was obtained. The shredded tobacco extracted by ethanol was ultrasonicated for 30 minutes at room temperature with 2000 ml of water, and the water extract was obtained by filtration. The water extract was first degreased with 1000 ml of petroleum ether, and then extracted with 1000 ml of ethyl acetate. Concentrate under reduced pressure to 40 ml at 40°C to obtain extract II.

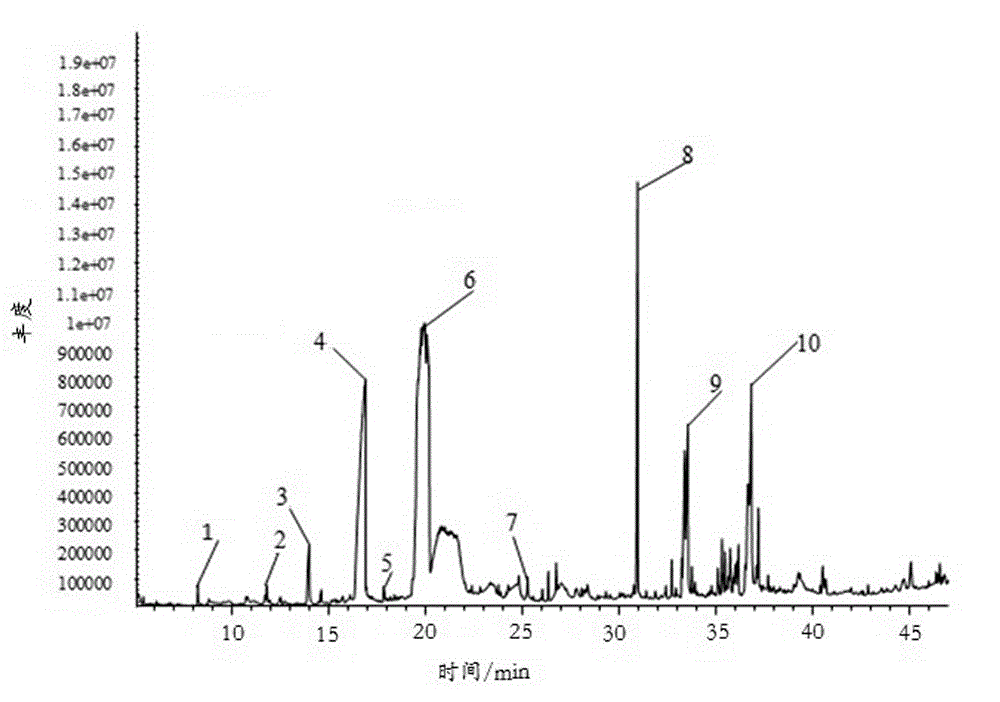

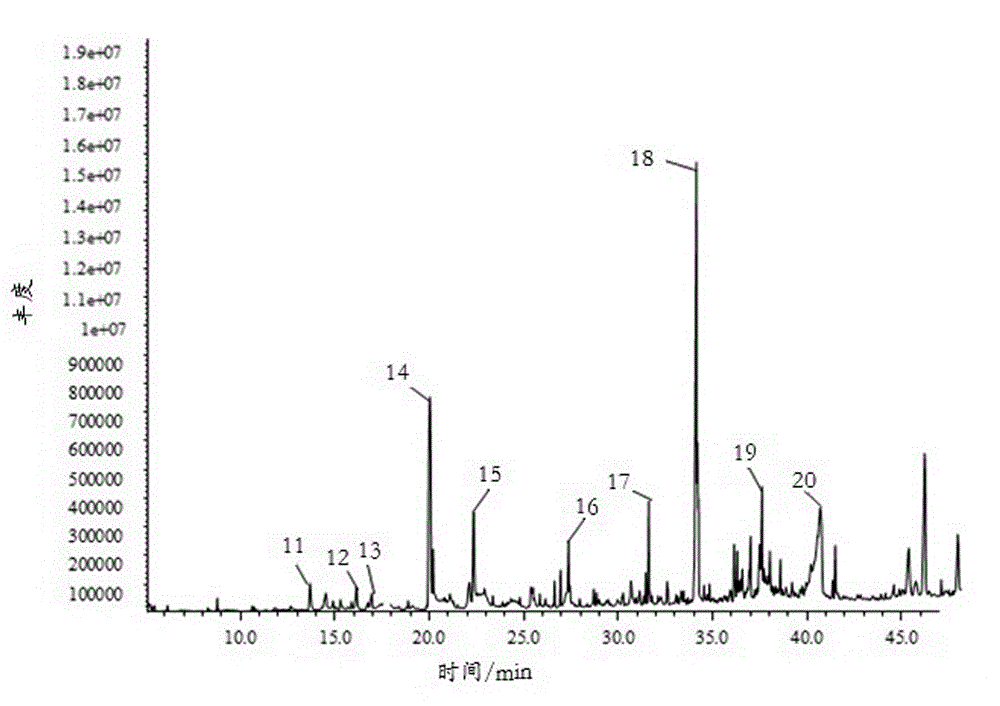

[0032] Chromatographic analysis, such as figure 1 As shown, the substances represented by the peak positions of each label in the figure are as follows: 1 is 5-m...

Embodiment 3

[0035]This example provides a tobacco extract and e-cigarette liquid. The preparation method is as follows: add 800 ml of 75% ethanol to 80 g of Baishaye group formula tobacco powder, extract at room temperature for 1 day, filter, and concentrate the filtrate to dryness to obtain ethanol For the extract, 60 ml of hot ethanol was added to dissolve the ethanol extract, and the dissolved solution was placed at 4° C. for 2 hours to freeze to precipitate a precipitate, filtered, and concentrated to 15 ml to obtain extract I. The shredded tobacco extracted by ethanol was ultrasonicated for 30 minutes at room temperature with 800 ml of water, and the water extract was obtained by filtration. The water extract was first degreased with 500 ml of petroleum ether, and then extracted with 500 ml of dichloromethane. Concentrate under reduced pressure to 20 ml at 40°C to obtain extract II. Take 5 ml of extract I and 8 ml of extract II, mix them, and dilute them 3 times with a base solvent t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com