Patents

Literature

143results about How to "Comfortable aftertaste" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Low-harm type cigarette capable of reducing cigarette harm and manufacture method thereof

ActiveCN101322579AStay in Style and FragranceComfortable aftertasteTobacco preparationTobacco treatmentTarFlavor

The invention discloses a low-hazard cigarette which can reduce the harm of the cigarette and a preparation method thereof, and the technical problem needs to be solved is to reduce the harm of the cigarette to the human health. The low-hazard cigarette of the invention adds additives in the cut tobacco of the cigarette, the additives are egg flower and coral grass extracts, the weight ratio of the egg flower and the coral grass is 8:2, the prepration method comprises that: the egg flower and the coral grass extracts are extracted, extract liquid is prepared and evenly sprayed on the ordinary cut tobacco, and the cigarette is prepared by adopting the conventional cigarette technology. Compared with the prior art, the egg flower and the coral grass extracts are added in the cut tobacco, the effective ingredients in the egg flower and the coral grass are absorbed in the human body along with the volatilization of the mainstream smoke, thereby maintaining the original style and the flavor of the cigarette, being capable of inhibiting the cancer-causing mutation of the cigarette tar to the human body and timely preventing and mitigating the smoking-induced cough, the shortness of breath, the sputum stasis and other various adverse reactions.

Owner:SHENZHEN DABAIHUI TECH

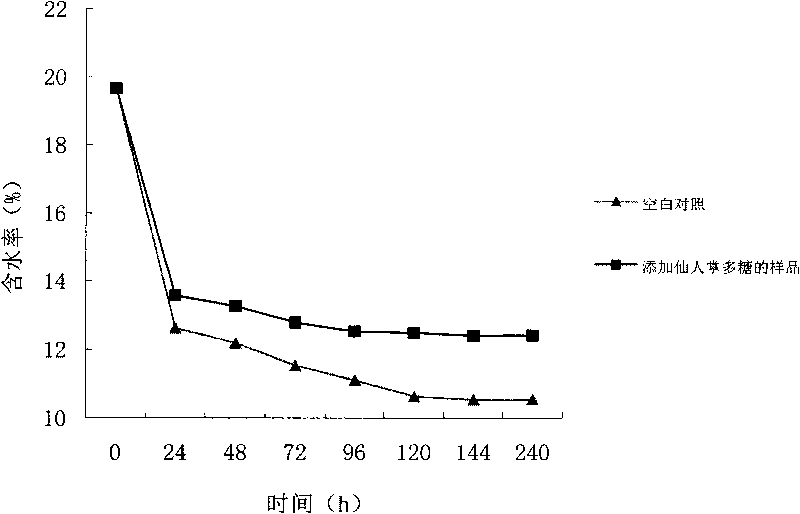

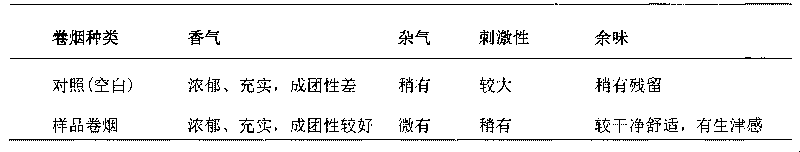

Extraction method of cactus polysaccharide and application thereof in cigarettes

ActiveCN101704900AImproves moisture retentionMoisturizing effect is obviousTobacco treatmentIrritationFiltration

The invention discloses an extraction method of cactus polysaccharide, which is characterized by comprising the following steps: high temperature enzyme inactivation; drying and crushing; extraction, centrifugal separation and filtration; filtrate concentration, adding into alcohol, precipitation, and crude cactus polysaccharide collection; dissolving of the crude cactus polysaccharide and purification; and obtaining of the cactus polysaccharide after collecting, washing and vacuum drying the precipitation. The cactus polysaccharide is applied to tobacco threads along with feed liquid after being dissolved with water, therefore, the smoke has no peculiar smell when a person smokes, the cactus polysaccharide can improve quality of aroma, mellow degree and sweet taste, improve oral comfort, reduce unpleasant smell and irritation, improve the dry sensation to a certain degree and obviously improve the moisturizing performance. The cactus polysaccharide does not change the original properties and the original processing technology of cigarettes, and does not change or influence the smoking quality of the cigarettes, thus having practical production significance and value.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

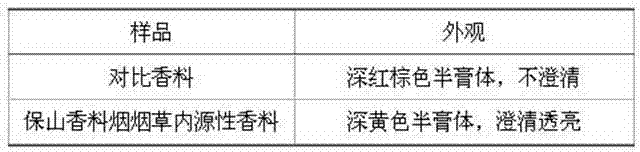

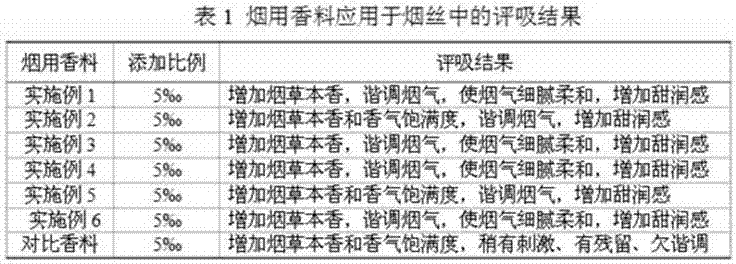

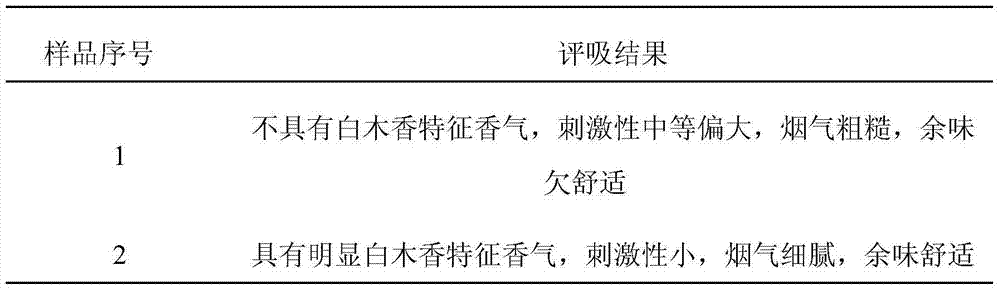

Preparation method and application of tobacco endogenous spice of Boshan aromatic tobacco

ActiveCN102952638ATake advantage ofHigh value of potent aromatizing ingredientsTobacco preparationTobacco treatmentFlavorHigh pressure

The invention discloses a preparation method and application of a tobacco endogenous spice of Boshan aromatic tobacco. According to the preparation method, the crushed Boshan aromatic tobacco is placed in an extra-high pressure extracting tank for extra-high pressure extraction and then is subjected to column separation by using macroporous resin, and finally, the tobacco endogenous spice of the Boshan aromatic tobacco is obtained. The spice is clear in appearance, and thus the spice is more suitable for being added in cigarettes to bring remarkable effect of improving the quality of cigarettes. The preparation method disclosed by the invention is simple and practical, convenient for operation and lower in cost; resin can be repeatedly used; the time is greatly saved; the value of the extracted effective aroma components is high; and tobacco raw materials are utilized more fully.

Owner:CHINA TOBACCO GUANGDONG IND

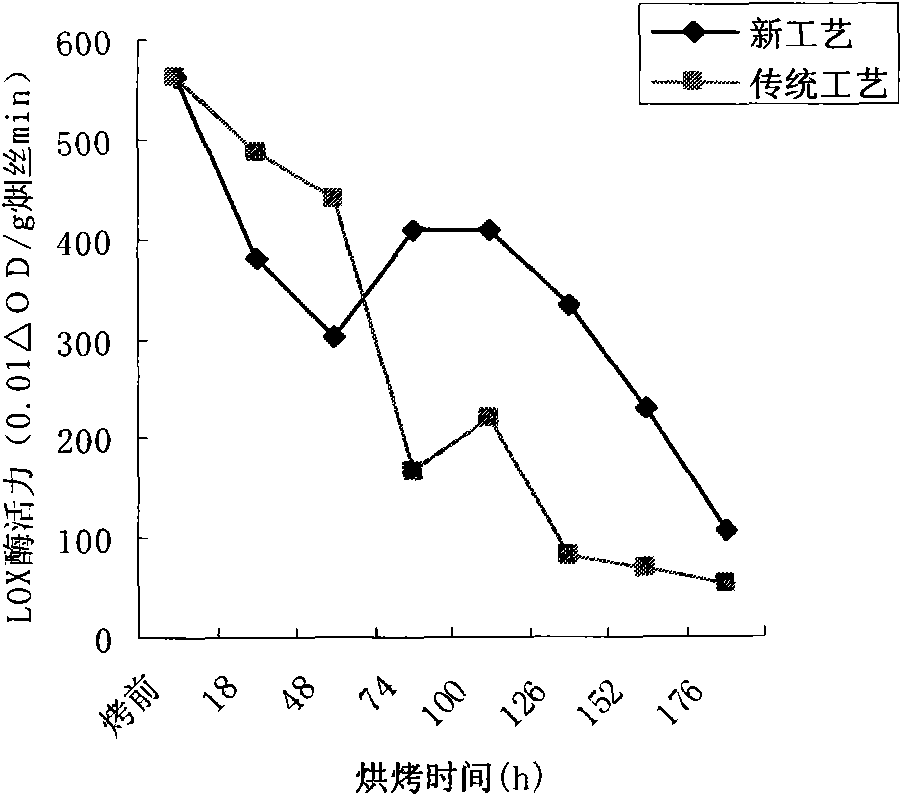

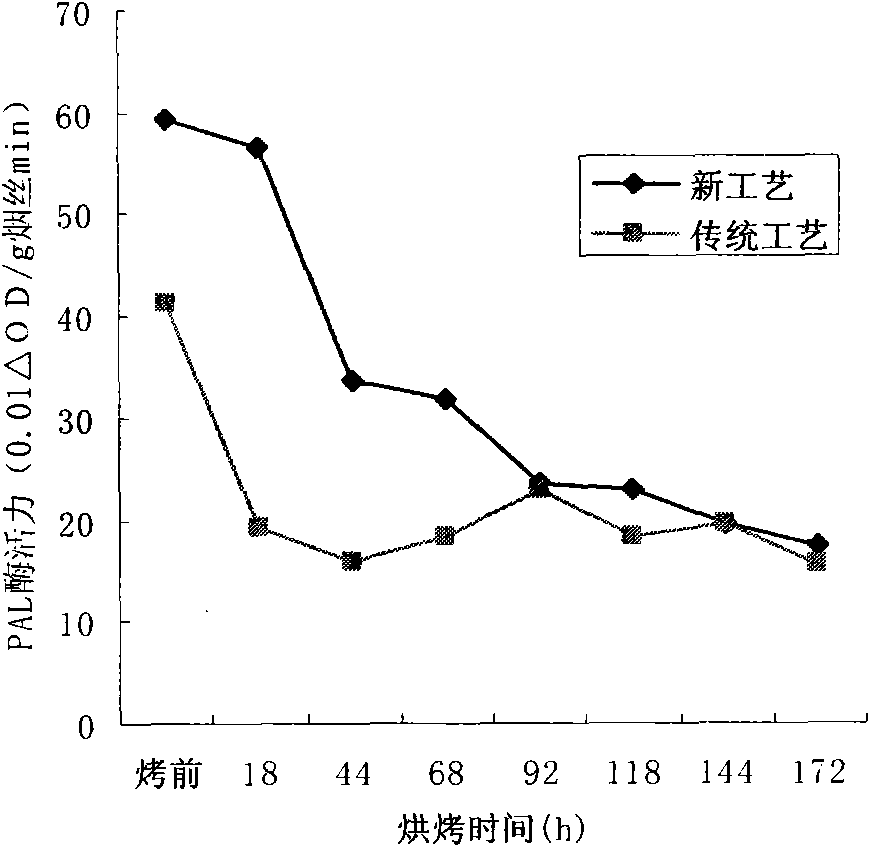

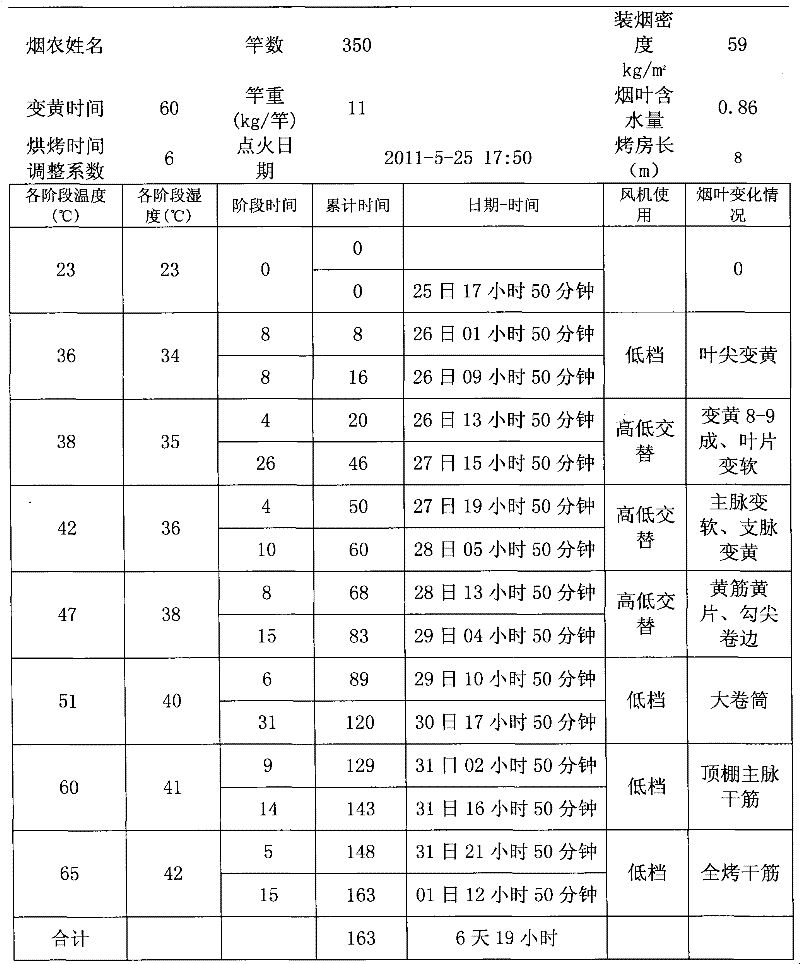

Process for baking Hongda tobacco leaves

The invention relates to a process for baking Hongda tobacco leaves, which belongs to the technical field of tobacco application. The method is an improvement of the traditional baking process and has the main improving points that the total baking time of the tobacco leaves grown at the lower part is shortened to 156 hours from original 168 hours; the total baking time of the tobacco leaves grown at the middle part is shortened to 168 hours from original 180 hours; and the total baking time of the tobacco leaves grown at the upper part is shortened to 170 hours from original 178 hours. The baking temperatures are adjusted by increasing the braking temperature in a yellowing stage to 31-32 DEG C from original 27-29 DEG C, increasing the braking temperature in a withering stage to 40-41 DEG C from original 38-39 DEG C, increasing the braking temperature in a leaf drying stage to 47-49 DEG C from original 43-45 DEG C, and increasing the braking temperature in a leaf ribbing stage to 66-67 DEG C from original 63-65 DEG C. The process for baking Hongda tobacco leaves is favorable for the conversion of chemical substances and the activity of enzymes by improving the baking time and thebaking temperature, the quality of the tobacco leaves is improved obviously, and the Hongda tobacco leaves with the optimum braking quality can be obtained.

Owner:YUNNAN TOBACCO CO LTD KUNMING BRANCH +1

Method for preparing microcapsule clove essential oil and application of clove essential oil in tobacco

InactiveCN104178341AImprove performanceImprove solubilityTobacco smoke filtersEssential-oils/perfumesBiotechnologySucrose

The invention discloses a method for preparing microcapsule clove essential oil and application of the clove essential oil in tobacco and belongs to the technical field of cigarette processing. The method is characterized by comprising the following steps: uniformly mixing three substances, namely chitosan, sucrose and glucose which are used as wall materials at a mass ratio of (1-2):1:(1-2), adding water which accounts for 10-15wt% of three substances, heating at 85-95 DEG C until the mixture is in a molten state, cooling to 30-40 DEG C, adding clove essential oil which accounts for 15-25wt% of wall materials, carrying out high-pressure homogenization to obtain an emulsion and finally performing a spray drying technology, thereby obtaining the microcapsule clove essential oil. 100% of the clove essential oil microcapsule is dissolved in water, diluted with water, added into a cigarette filter and finally rolled into a cigarette, wherein the diluted clove essential oil microcapsule accounts for 1-3wt% of the filter. By virtue of the clove essential oil microcapsule, the influence of offensive odor in the cigarette product can be improved, the aroma quantity, aroma quality and coordination of the cigarette are greatly enriched and the smoking quality of the cigarette is improved.

Owner:NANJING BIAOKE BIO TECH

Preparation method of mint essential oil burst beads for cigarettes

ActiveCN107723091AImprove compactnessImprove the airtightness of the cyst wallTobacco smoke filtersEssential-oils/perfumesWater soluble polymersIon

The invention provides a preparation method of mint essential oil burst beads for cigarettes, belonging to the technical field of cigarette processing. The preparation method of burst beads comprisesthe following steps: performing high-speed homogenization and emulsification on mint essential oil, a calcium ion water solution and a surfactant to form an emulsion, directly and dropwisely adding emulsion drops into a sodium alginate water solution through an orifice by controlling the flow velocity of the emulsion at 1-5mL / minute by using a peristaltic pump, enabling the emulsion drops to stayin the sodium alginate solution for 2-40 minutes to obtain calcium alginate beads, taking out the beads, washing the beads with distilled water, putting the beads into an oxidizer water solution, performing soaking for 1-20 minutes, taking out the beads, washing the beads with distilled water, soaking the beads in a water-soluble polymer solution for 5-30 minutes, taking out the beads, washing thebeads with distilled water, and performing natural air drying, thereby preparing the mint essential oil burst beads for cigarettes, of which the grain size is 1-20mm. The mint essential oil burst beads for cigarettes are applied to cigarette filters to achieve the goal of improving the quality of cigarettes.

Owner:WUHAN YELLOW CRANE TOWER NEW MATERIAL TECH DEV

Preparation method of Yunnan black tea extract and use thereof

ActiveCN101473879AReduce dosageQuality improvementTea extractionChromatographic separationHeating time

The invention relates to a method for preparing extract of yunnan black tea and application thereof. The extract is prepared and obtained by extraction with ultrasonic extraction method and the combination of silica gel chromatographic separation method; the extraction processes comprise fetching of yunnan black tea, ultrasonic extraction, silica gel chromatographic separation, concentration, and obtaining of extract in sequence. When the extract of yunnan black tea is added to the tobacco of cigarettes, the invention can cause the fragrance of cigarettes to be permeable and abundant, the smell of cigarettes to be refined and fine, and the rest smell to be significantly improved in the aspect of comfort. Compared with the traditional extraction method, by using the yunnan black tea which is extracted by the ultrasonic wave of mixed solvent, the dosage ethanol is greatly reduced, the extracting and heating time is shortened, and the extraction efficiency is improved; by combining the silica gel chromatographic separation, the quality and purity of active ingredient is improved. The method relates to uncomplicated equipment, is easy for operation, has no pollution, and provides an improved extraction method which has good effect for the preparation of the extract of yunnan black tea.

Owner:澳华达香精(广州)有限公司

Chinese herbal medicine additive for cigarette

ActiveCN1931039AImprove immunityReduce spicy stimulationTobacco treatmentRespiratory tract diseaseRhizome

The Chinese herbal medicine additive for cigarette consists of moxa leaf, epimedium and mangosteen in the weight ratio of 0.2-30.0 to 0.5-25.0 to 0.5-30.0 as the main medicine materials as well as one of glossy ganoderma, ophiopogon root, astragalus root, acanthopanax bark, mint, sacandra glabra, Chuanxiong rhizome and honeysuckle as the supplementary material. The preparation process includes the first preparing extracted solution and the subsequent decompression concentration to form ointment. The Chinese herbal medicine additive for cigarette has reasonably combined Chinese medicinal materials with treating function and Chinese medicinal materials capable of invigorating kidney and raising human body's immunity, and can reduce the spicy stimulation of cigarette gas, reduce respiratory tract disease, improve taste of cigarette and reduce harm of smoking.

Owner:CHINA TOBACCO GUANGXI IND

Method for utilizing protein and sugar of tobacco leaf to prepare tobacco flavor

InactiveCN104138029AEfficient extractionRich varietyTobacco preparationTobacco treatmentMaillard reactionHydrolysate

The invention discloses a method for utilizing protein and sugar of tobacco leaf to prepare tobacco flavor, which comprises the following steps: (1) drying and crushing the tobacco leaf, then putting into a circulating type ultrasonic extractor, adding an alkaline aqueous solution for performing ultrasonic circulation extraction, and filtering, thereby acquiring a mixed extraction solution containing protein, amino acid and sugar; (2) concentrating the mixed extraction solution, adjusting pH value of the acquired concentrated solution, adding compound protease and performing deep enzymolysis, and then concentrating again, thereby acquiring the mixed enzymatic hydrolysate rich in amino acid, small molecule peptide and sugar; (3) taking the amino acid, the small molecule peptide and the sugar in the mixed enzymatic hydrolysate as raw materials and performing maillard reaction, thereby acquiring the tobacco flavor. According to the invention, the protein and the sugar which are efficiently extracted from the tobacco leaf are utilized to prepare the tobacco flavor, no additional raw materials are added, and the prepared flavor can effectively reduce the irritation of tobacco and approaches the tobacco flavor.

Owner:WUHAN INSTITUTE OF TECHNOLOGY

A kind of Bacillus subtilis preparation for shredded tobacco treatment

InactiveCN102286404AIncrease the amount of aromaIncrease pleasureBacteriaTobacco treatmentIrritationMicrobiology

The invention discloses a microbial preparation for tobacco, a preparation method and application thereof, and belongs to the technical field of tobacco additives. The present invention obtains corresponding microbial preparations after liquid fermentation and culture of production strains. The production strain is Bacillus subtilis.Van3, which has been preserved in the General Microorganism Center of China Committee for the Collection of Microbial Cultures on August 16, 2010, and the preservation number is CGMCC No.4091. The microbial preparation of the present invention can significantly improve the aroma and pleasantness of shredded tobacco, reduce miscellaneous gas and irritation, reduce smoke concentration and strength, and make the aftertaste more comfortable, thereby achieving the purpose of improving the smoking quality of shredded tobacco.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Additive agent for osmanthus fragrance type cigarette, preparation and application thereof

InactiveCN101317690ASimple preparation processLow costTobacco preparationTobacco treatmentNicotiana tabacumPropanediol

The invention relates to an osmanthus flower additive for tobacco and the preparation method and applications thereof. The osmanthus flower additive essentially consists of the osmanthus flowers. The preparation method includes the steps that the osmanthus flowers are extracted by heating and refluxing of petroleum ether or ethanol solution or by soaking at ambient temperature; the extracted fluid is filtered and then decompressed and condensed into osmanthus flower soaking cream which is mixed with honey in certain proportion to obtain the osmanthus flower additive for tobacco. The osmanthus flower additive is dissolved in the solution of ethanol and propanediol with certain concentration to form saturated solution, which is then evenly sprayed on cut tobacco, tobacco stems or tobacco sheets which are then prepared into cigarette. The dosage of the osmanthus flower additive accounts for 0.01 to 5 percent of the weight of the cut tobacco, the tobacco stems or the tobacco sheets. The osmanthus flower additive is characterized by the harmony of the osmanthus flower fragrance and the tobacco fragrance and can soften the cigarette fragrance and reduce the irritation of the cigarette smoke to the respiratory system and the harm of smoking.

Owner:CHINA TOBACCO GUANGXI IND

Method for fermenting Baimao tobacco

The invention provides a method for fermenting a Baimao tobacco (an important raw material for cigar), which comprises the following steps: uniformly spraying aqueous solution of distiller's yeast enzyme prepared by adding a distiller's yeast enzyme into water and stirring onto tobacco leaves; rolling the tobacco leaves into spiral wisps, piling the wisps, tightly covering the piles to ferment at normal temperature, turning the piles for once when the temperature in the piles reaches 45 to 55 DEG C, and piling for 2 to 3 days; after tying the tobacco leaves into big bundles, piling the tobacco leaves, fermenting the tobacco leaves for 6 to 7 days, and turning the piles for once again when the temperature in the piles reaches 45 to 55 DEG C; and after tying the tobacco leaves into bundles according to parts, quality and length, piling the tobacco leaves, fermenting the tobacco leaves for 15 to 20 days, and turning the piles for once every 7 to 10 days, wherein the times for turning the piles is two, and when the moisture in the tobacco leaves reaches 18 to 22 percent, completing the fermentation. The method for fermenting the Baimao tobacco of the invention can increase the fragrance of the tobacco leaves, reduce the acrimony of the tobacco leaves and bring comfortable aftertaste, and has the advantages of readily available raw material, low cost, wide resources, high safety, simple operation and low cost of the obtained Baimao tobacco.

Owner:CHINA TOBACCO ANHUI IND CO LTD

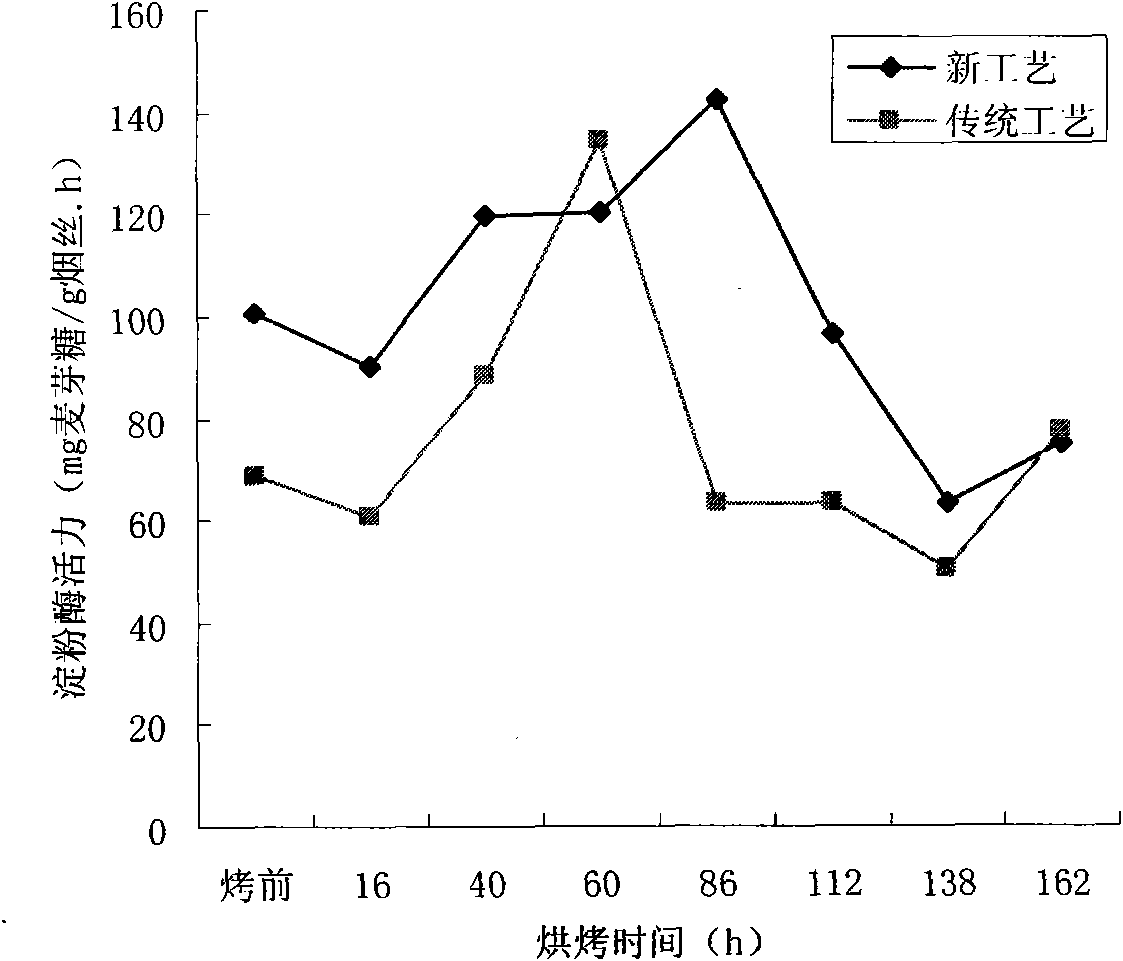

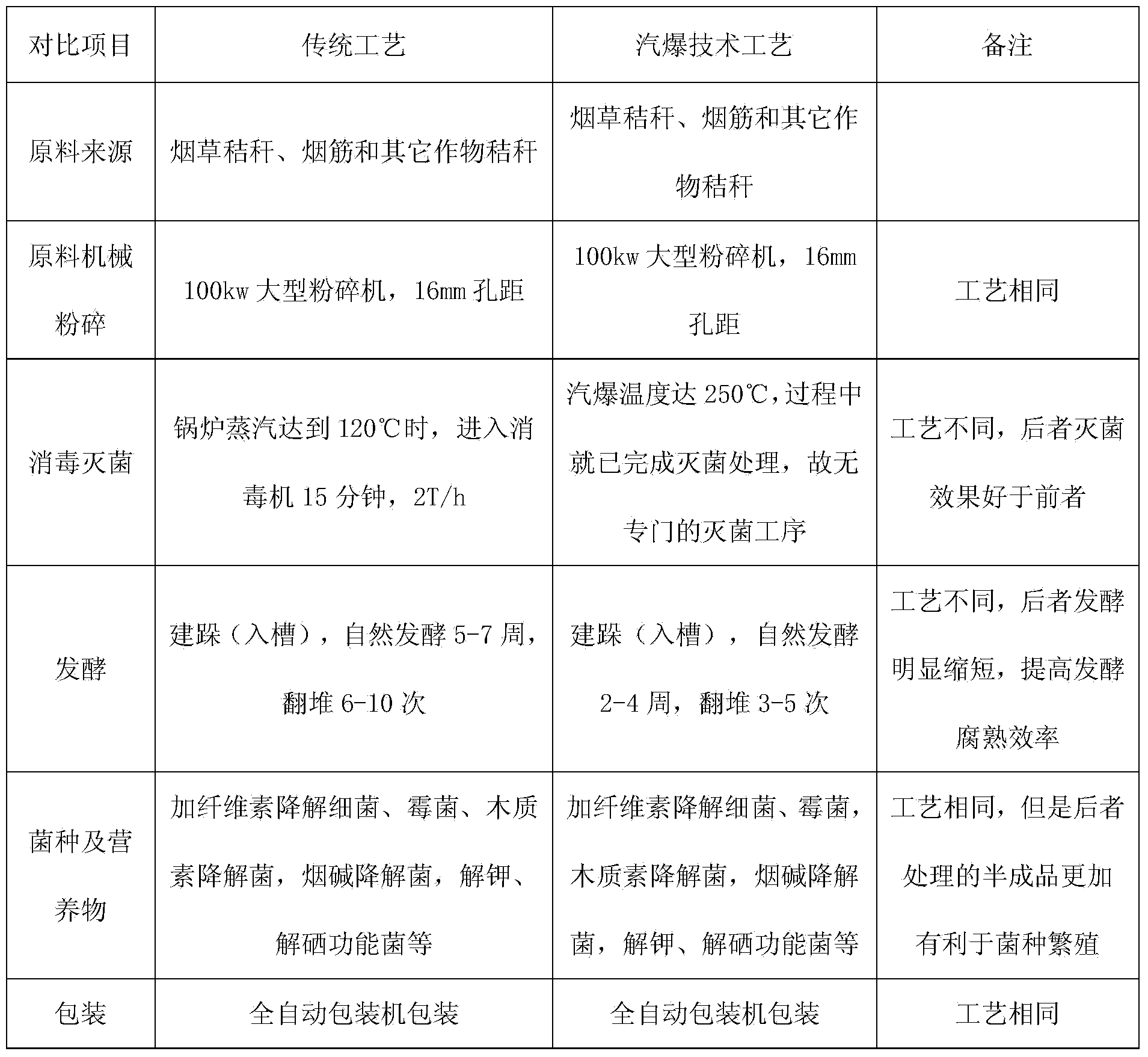

Method for of producing bioorganic tobacco fertilizer by steam explosion technology

InactiveCN104355708AImprove qualityEnsure safetyBio-organic fraction processingOrganic fertiliser preparationEngineeringBacterial strain

The invention provides a method for of producing a bioorganic tobacco fertilizer by a steam explosion technology. The bioorganic tobacco fertilizer is characterized by being produced according to the following steps: a, mechanically grinding raw materials; b, pressurizing and exploding; c, adding a bacterial strain; d, fermenting; e, mixing proportionally. The steam explosion technology has the effect of improving the inherent quality of the bioorganic fertilizer: after steam explosion, straws contain a large amount of saccharides and have the humic acid content as high as more than 30%, so that the bioorganic fertilizer is very suitable for growth and breeding of microbes; by adopting a porous structure, the bioorganic fertilizer is beneficial for solid fermentation; the microbes can grow fast on a fermented material treated through the steam explosion because of pressure change; in the steam explosion technology, high temperature and high pressure can effectively kill pathogenic bacteria and eggs in the straws, so that the safety of the bioorganic fertilizer can be ensured; by the steam explosion technology, a link of sterilizing the raw materials is omitted; compared with the conventional process, the steam explosion technology has the advantages as follows: the fermentation time can be shortened by about 10-15 days and the problem of a large floor area of a fermenting workshop is solved.

Owner:湖北省烟草公司恩施州公司

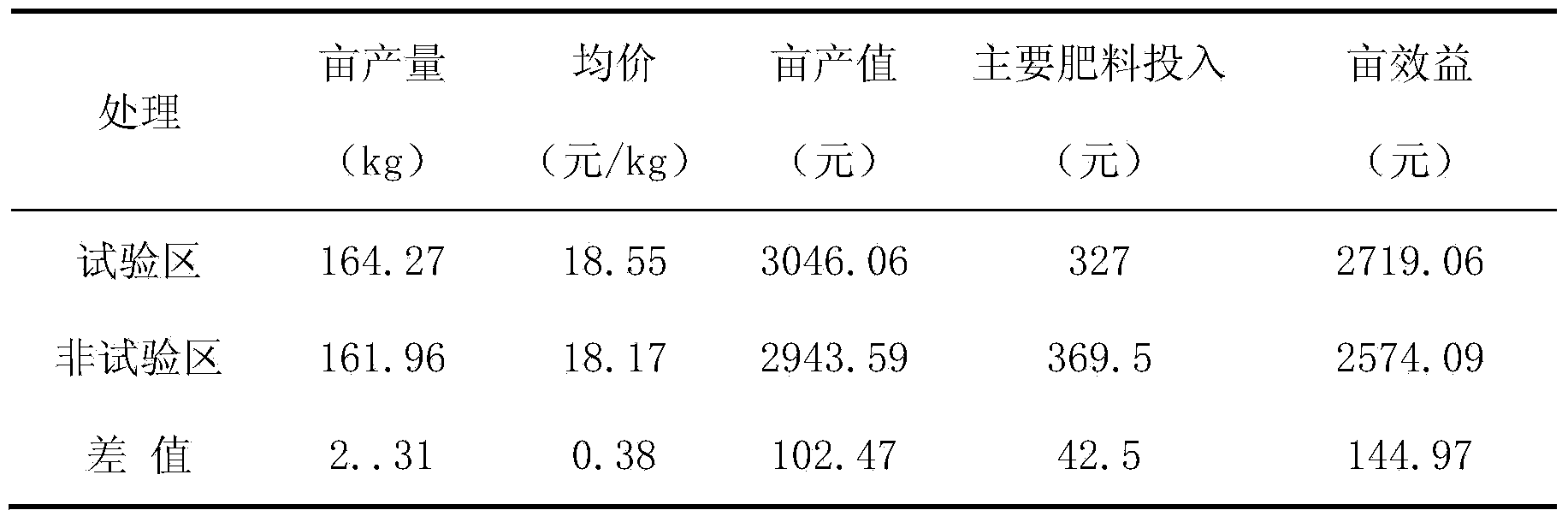

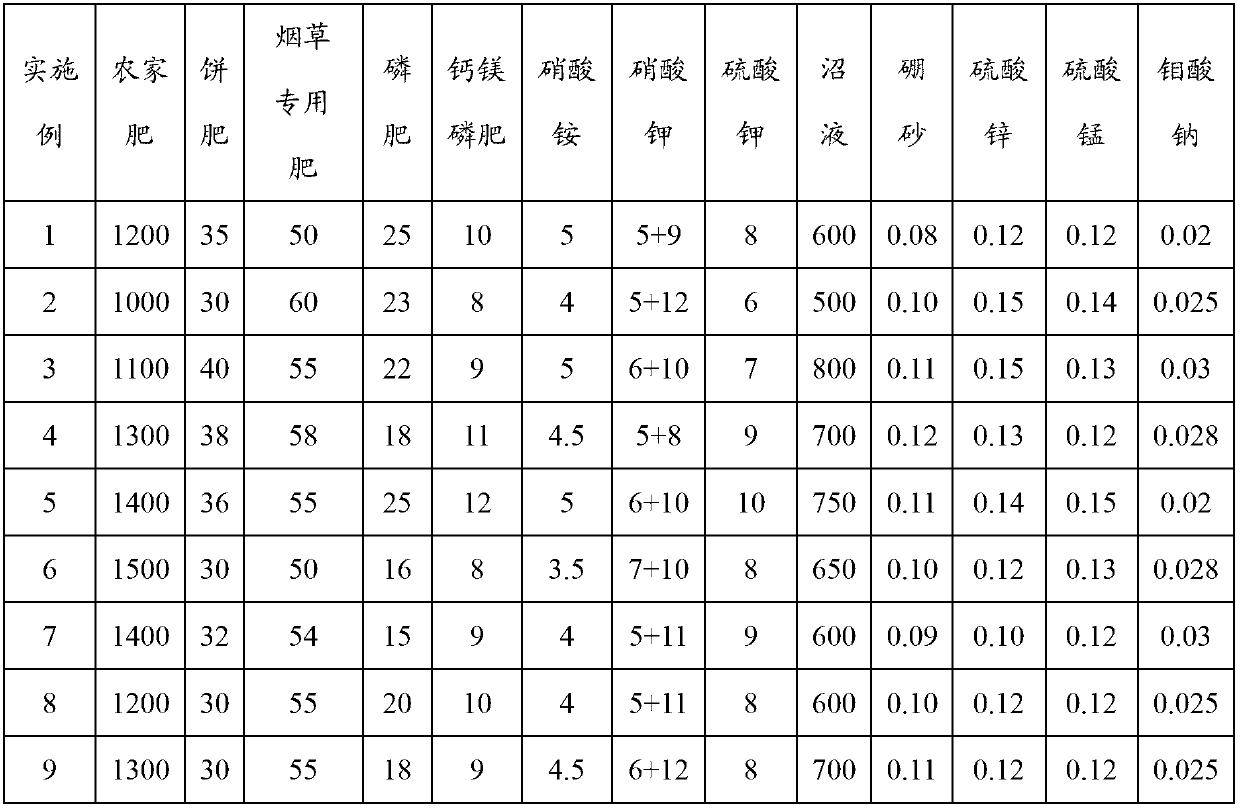

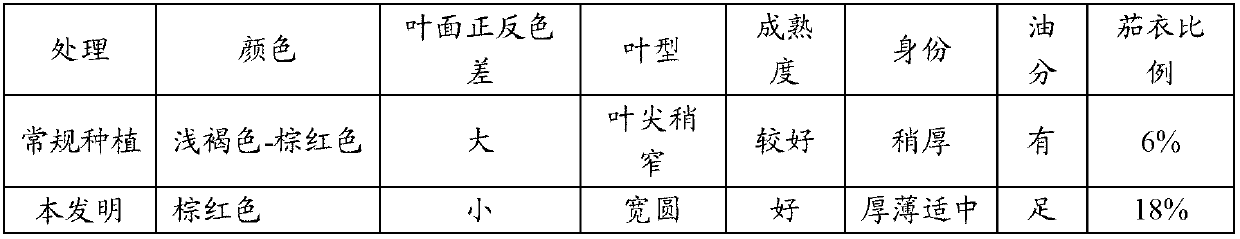

Fertilizing method for planting cigar tobacco

InactiveCN102939818AReasonable ratioReasonable collocationFertilising methodsFertilizer mixturesPotassium nitrateSlurry

The invention provides a fertilizing method for planting cigar tobacco. The fertilizing method comprises the following steps of: firstly, early fertilizing base fertilizer: in 20-30 days before transplanting, trenching on the formed land with the interval of 110cm, the depth of 10-15cm and the width of 8-10cm, uniformly paving the base fertilizer at the bottom of the trench and ridging; secondly, applying seedling protecting fertilizer for transplanting: when small cigar seedlings are transplanted, dissolving ammonium nitrate into water, injecting the mixed solution and pesticide as transplanting water into the root parts of the seedlings, wherein 3-5kg of ammonium nitrate is fertilized in each mu; thirdly, irrigating roots by using seedling restoring fertilizer: in about 7 days after the tobacco seedlings are transplanted, irrigating the roots by using 5-7g / mu of potassium nitrate and an insect infestation resisting pesticide and then covering a layer of fine soil around tobacco roots; fourthly, timely applying seedling eccentric fertilizing; fifthly, digging holes and applying and burying growth flourishing fertilizer and irrigating by matching the growth flourishing fertilizer with biogas slurry; and sixthly, carrying out additional fertilizer and spraying at the mature stage. The fertilizing method disclosed by the invention has the advantages of simplicity in operation, standard specification, strong pertinency and greatly-improved yield and quality of cigar tobacco.

Owner:HUBEI CHINA TOBACCO IND

Preparation method of functional additive capable of improving cut stem quality

The invention provides a preparation method of a functional additive capable of improving the cut stem quality. According to the method, the following ingredients are weighed in percentage by weight: 5 to 15 percent of fresh tobacco leaf compound enzyme, 25 to 30 percent of functional enzyme preparations, 40 to 60 percent of tobacco extracts and 10 to 15 percent of propanediol, the ingredients are uniformly mixed, and the functional additive is obtained. the fresh tobacco leaf compound enzyme is water-soluble solid powdery compound enzyme with the bioactivity obtained by adopting fresh tobacco leaves as raw materials to be subjected to juice extraction and to be treated by a thiamine precipitation method, the functional enzyme preparations are one kind of several kinds of materials from cellulase, pectinase, amylase, glucoamylase, catalase or protease. The method provided by the invention has the advantages that the irritation and the impurity gas of the expansion cut stems can be reduced, the fragrance quantity can be increased, and the fragrance texture is improved.

Owner:YUNNAN REASCEND TOBACCO TECH GRP

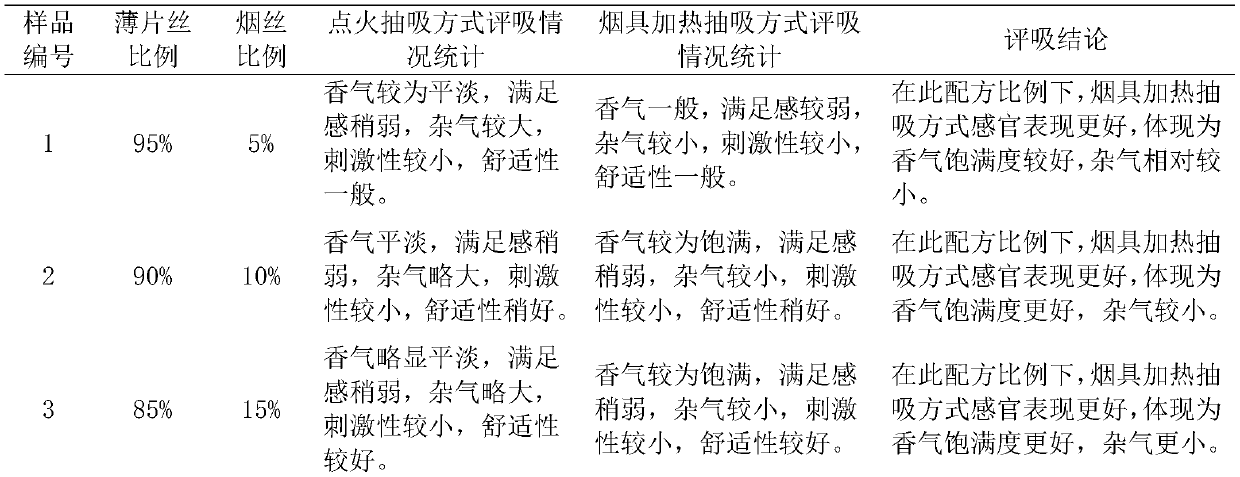

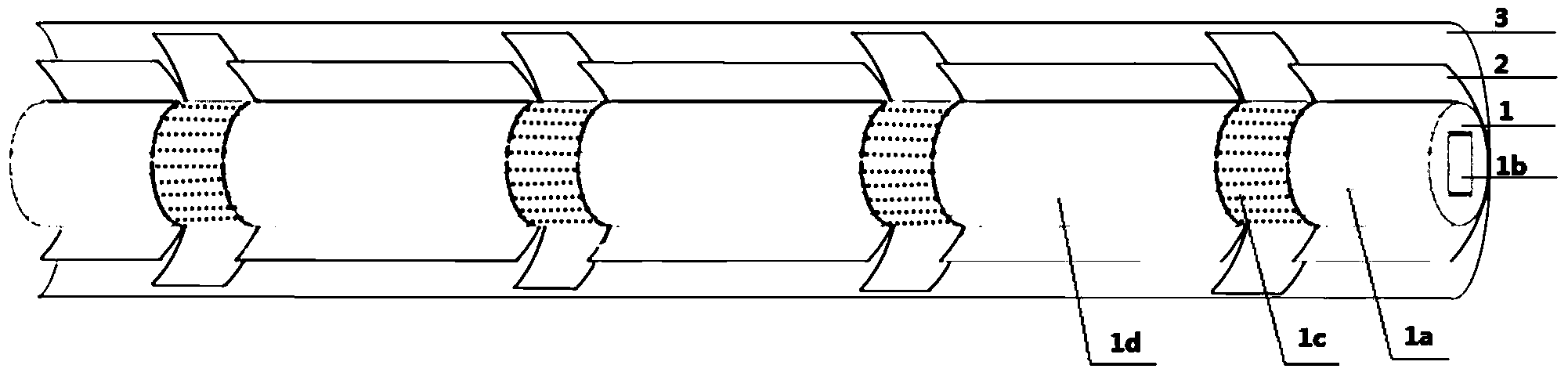

Cigarette core material capable of being ignited and heated at low temperature to suck and preparation method thereof

InactiveCN109938397AImprove applicabilitySmooth releaseTobacco treatmentElectricityInternational market

The invention relates to a cigarette core material capable of being ignited and heated at a low temperature to suck and a preparation method thereof and belongs to the technical field of novel tobaccopreparation. The cigarette core material is prepared from the following components in percent by weight: 50-95% of sliced cut tobacco and 5-50% of cut tobacco. The sliced cut tobacco is prepared fromthe following components in percent by weight: 40-55% of a cut tobacco sheet base, 15-25% of a tobacco refined product, 0-5% of essence and spices and 15-30% of a fuming auxiliary agent. The cigarette core material is prepared by mixing the sliced cut tobacco and the cut tobacco in a reasonable proportion. Compared with an existing heating incombustible tobacco product, the cigarette core material can be heated to suck at the low temperature. When a smoking set is out of electricity, the cigarette core material can be directly ignited to suck. The two ways have high quality sensing experienceand can improve the cigarette core applicability to the maximum extent. The cigarette core material provided by the invention is a symbiotic product of conventional tobacco and novel tobacco, is a novel product divided in a brand new market in the international market, and has far-reaching significance in opening the international tobacco market, occupying the external market shares and enhancingbrand influence of state-owned tobacco and generating income of foreign exchange.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

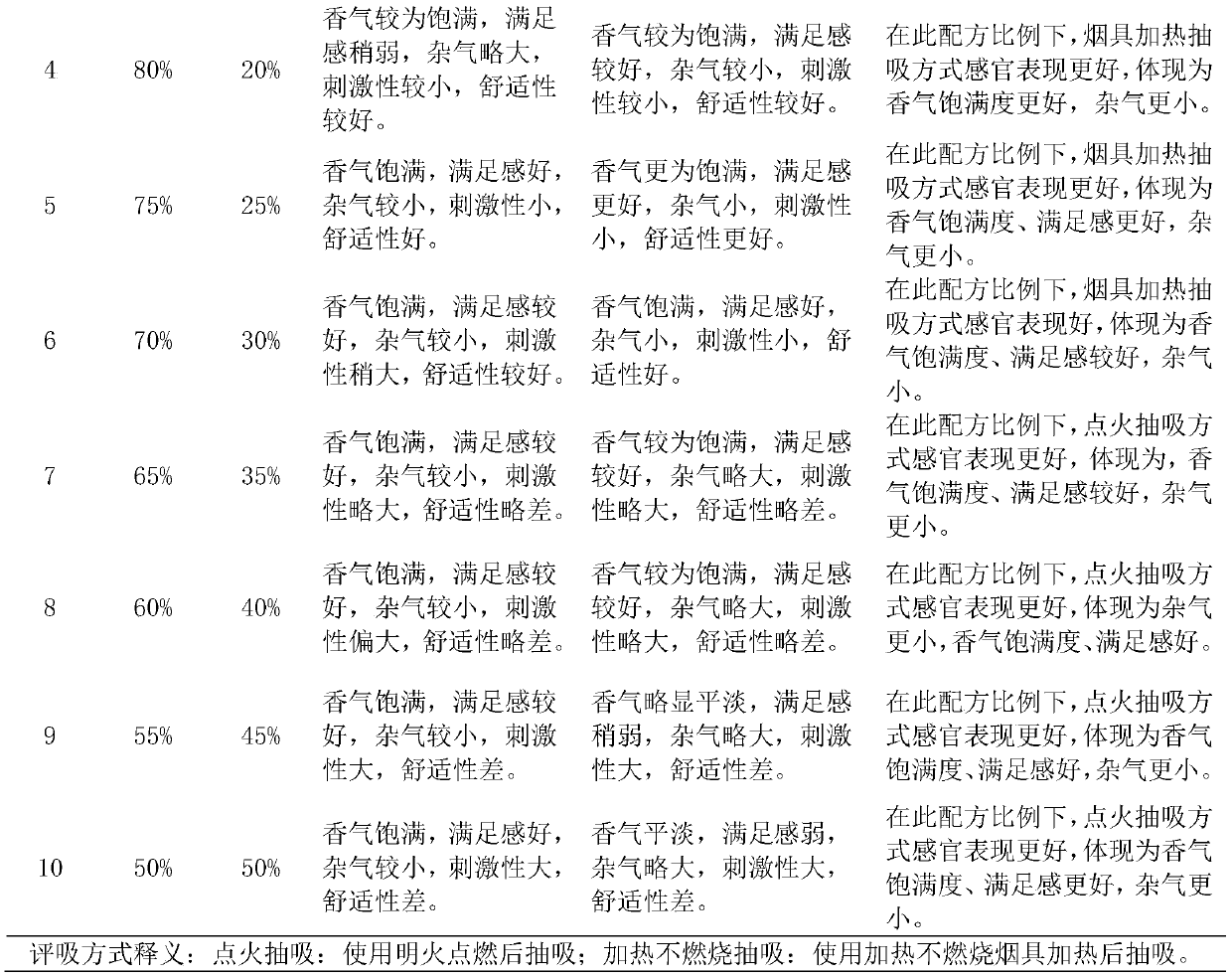

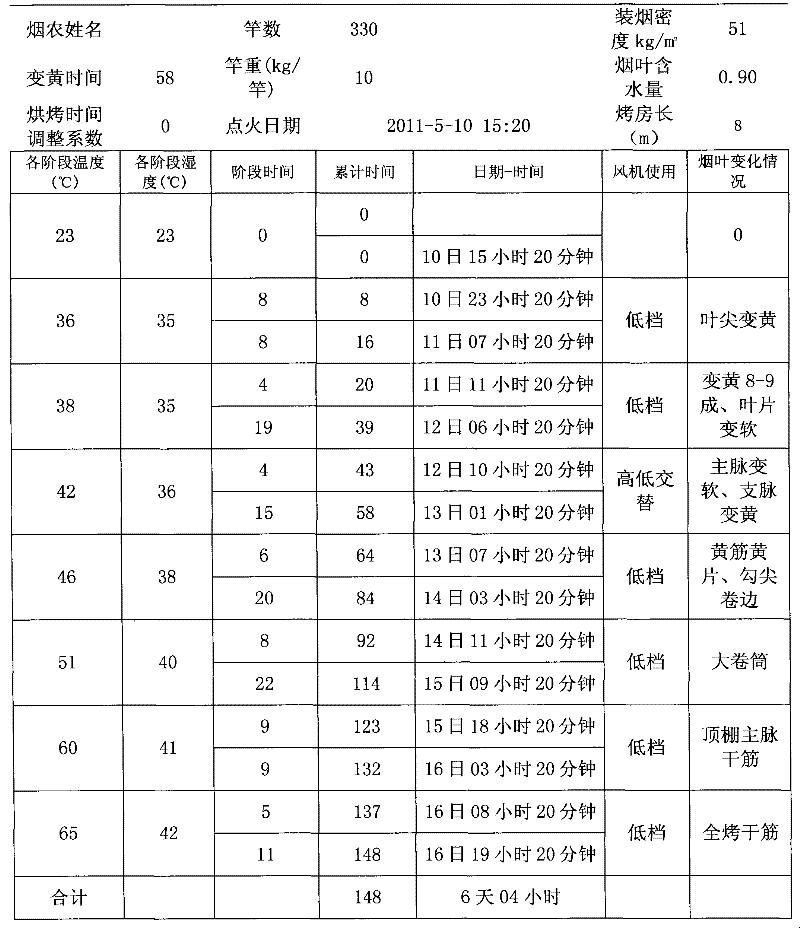

A Method for Accurately Controlling the Curing Time of Tobacco Leaves in Intensive Barns

InactiveCN102283432AAchieving Quantitative ControlPowerful computingTobacco preparationSimultaneous control of multiple variablesEngineeringTobacco processor

The invention discloses a method for accurately controlling the flue-curing time of tobacco leaves in a bulk curing barn. In the method, a tobacco leaf drying function model which relates to factors such as water content of tobacco leaves, loading density and loading amount, temperature and humidity as well as psychrometric difference, fan delivery, flue-curing time and the like is established according to the conventional material drying principle and tobacco leaf drying characteristics; according to different species, the drying model is multiplied by water loss regulation coefficients of tobacco parts and various flue-curing stages respectively, so that water loss rates of the tobacco leaves of different parts, different species and different stages can be calculated; and the flue-curing implementation scheme of the tobacco leaves of the bulk curing barn which is designed by the method for accurately controlling the flue-curing time of the tobacco leaves in the bulk curing barn according to the national technical specification for the flue-curing in bulk curing barns provides the accurate information of the temperature, humidity, time and fan startup of various flue-curing stages of the tobacco leaves for broad tobacco growers, and is the innovation and development of the traditional flue-curing method.

Owner:江西省烟草公司赣州市公司

Frangipani shaped Cigarette with egg extraction for reducing

PendingCN101044918AKeep the styleKeep the scentTobacco treatmentAntinoxious agentsEnvironmental healthTar

A frangipani type cigarette without toxic by-effect to human body is prepared from the tobacco shreds and the component A chosen from the volatile oil, liquid extract and shreds of frangipani, and their mixture through spraying said component A onto or mixing it with said tobacco shreds, and conventionally making cigarettes.

Owner:温纯青 +2

Beer production method

InactiveCN101691532AEffective Dissolution DiffusionEffectively achieve dissolution and diffusionWort preparationBeer fermentationFermentationAqueous extract

The invention discloses a beer production method, belonging to the beer production field. The invention particularly relates to a production method of healthy beer. The production method comprises the steps of wort boiling, primary fermentation and secondary fermentation. The method is characterized by adding hot water extracts of hops, honeysuckle and roses at the stage of wort boiling and adding ethanol extraction liquid of sweet osmanthus and chrysanthemum into secondary fermentation liquid of beer. The obtained beer has good nutritional value and health care effects.

Owner:CHINA NAT RES INST OF FOOD & FERMENTATION IND CO LTD

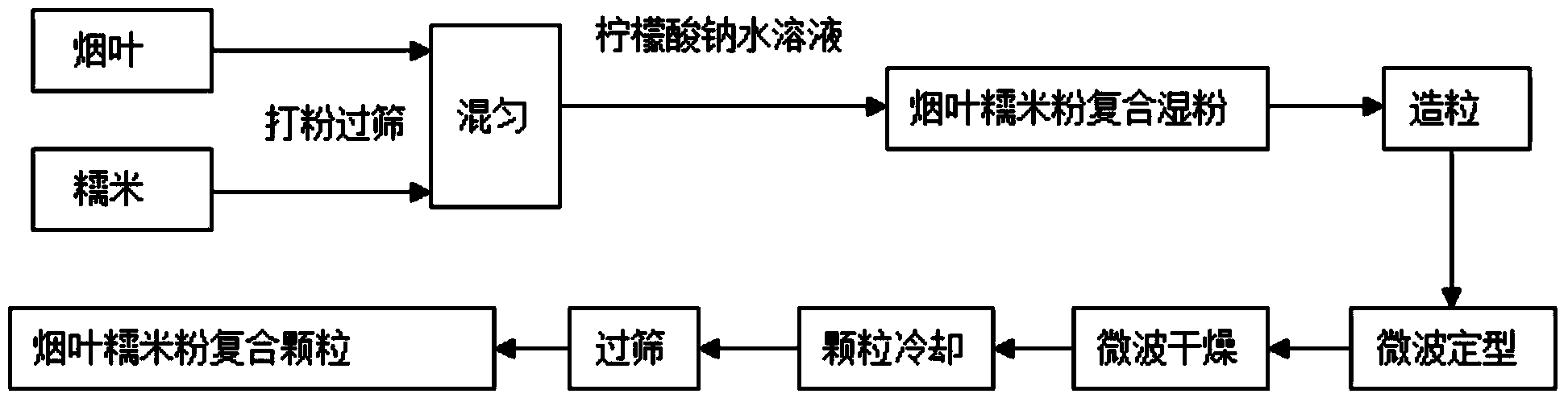

Tobacco leaf and glutinous rice flour composite particle preparation method and aroma enhancement application of tobacco leaf and glutinous rice flour composite particle to filter tip

ActiveCN104026732ALarge specific surface areaGreat tasteTobacco preparationTobacco treatmentAdhesiveFiltration

The invention discloses a tobacco leaf and glutinous rice flour composite particle preparation method and aroma enhancement application of tobacco leaf and glutinous rice flour composite particles to a filter tip. The preparation method includes: mixing powder smashed from tobacco leaves with glutinous rice flour according to a certain proportion, then evenly spraying a certain proportion of sodium citrate water solution into the mixture prior to stirring and compositing to form wet tobacco leaf and glutinous rice flour composite powder, and then performing granulation, microwave shaping, microwave drying, particle cooling and sieving to obtain the high-strength tobacco leaf and glutinous rice flour composite particles. The tobacco leaf and glutinous rice flour composite particles are added into a cigarette filter rod to prepare a binary or ternary composite filter rod which is rolled into a cigarette. Sensory evaluation proves that aroma of the tobacco leaf and glutinous rice flour composite particles can effectively compensate tobacco aroma reduction caused by filtration of the filter rod and perforation dilution, and smoking quality of the cigarette is improved. Meanwhile, raw materials of the particles are from the tobacco leaves and adhesive is from edible glutinous rice, so that new hazardous substances cannot be brought in.

Owner:CHINA TOBACCO GUANGXI IND

Tobacco flavor prepared from liquorice fermentation and application of tobacco flavor

ActiveCN104223352AImprove comfortIncrease aromaTobacco treatmentMicroorganism based processesPhenethyl alcoholFood flavor

The invention discloses a tobacco flavor prepared from liquorice fermentation and application of the tobacco flavor. A dominant microorganism is separated from fresh tobacco leaves of flue-cured tobacco, and the classification name of the dominant microorganism is Lodderomyces elongisporus. CGMCC 6645; the Lodderomyces elongisporus is inoculated into a culture medium, taking liquorice as a raw material, for fermentation cultivation; a fermentation product after culture has a natural fragrance, and contains various aroma components, such as 2,4-resacetophenone, 2,4,5-methylphenol, 3,4-dimethyl benzyl alcohol and phenethyl alcohol. The tobacco flavor is added to tobacco shreds, and thus, the aroma and the moistening effect of a cigarette can be enhanced, and the cigarette quality is improved; the sweetness of smoke is rich, local offensive odor and wood odor are reduced, the throat comfort is enhanced, the remaining taste is comparatively comfortable, and the mouth astringency is strong; the whole production process for the tobacco flavor is simple and practical, and the tobacco flavor has a good application prospect.

Owner:CHINA TOBACCO YUNNAN IND

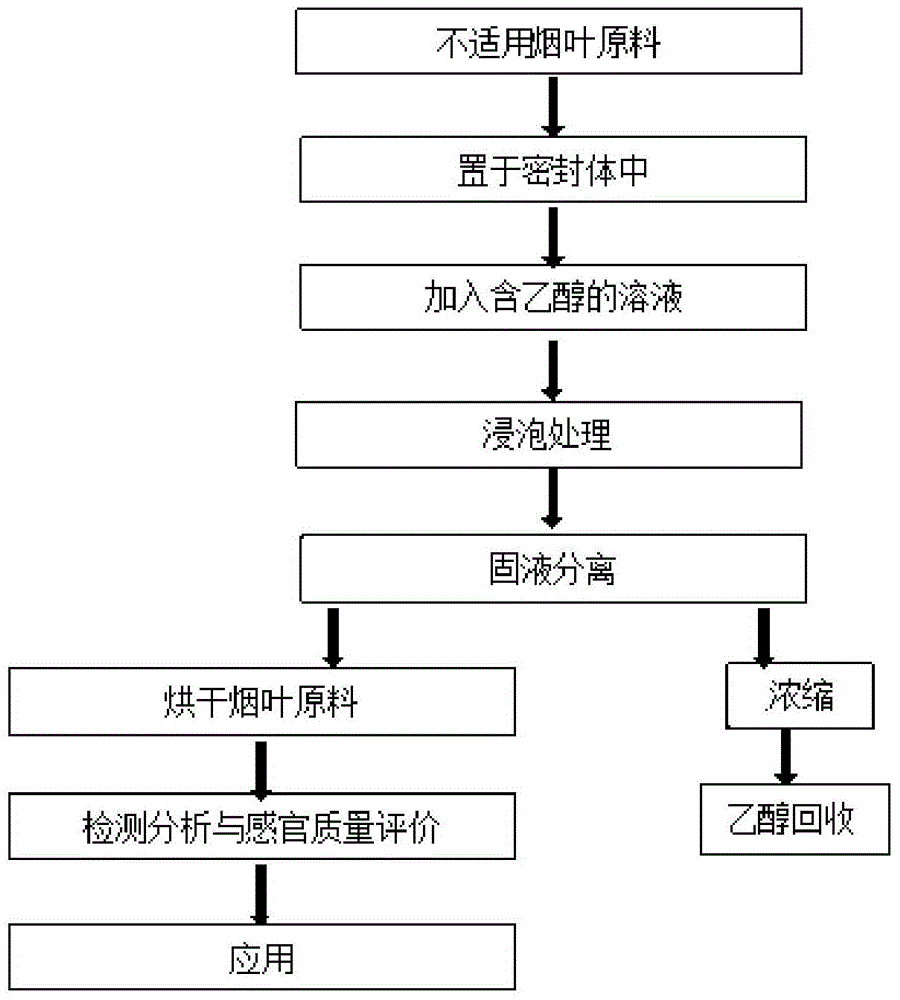

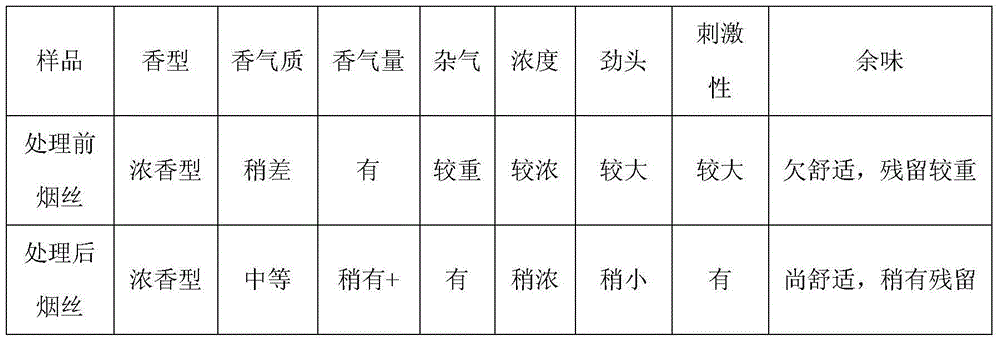

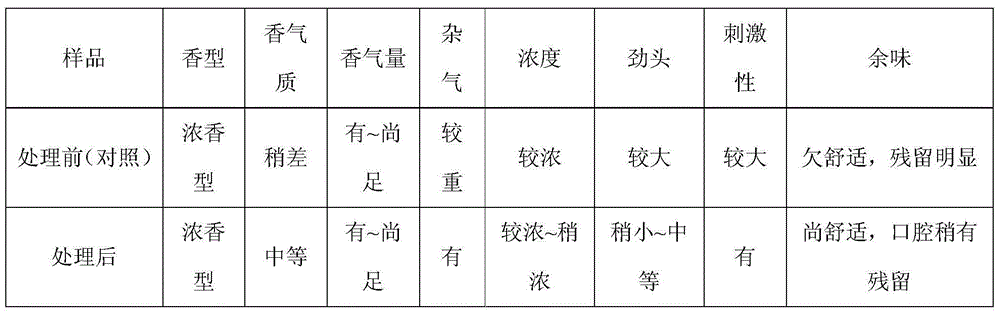

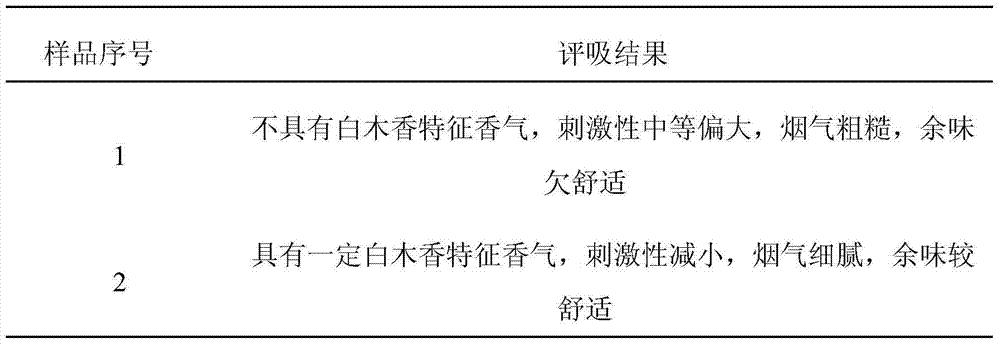

Method for improving inapplicable upper tobacco leaf raw material quality

The invention discloses a method for improving inapplicable upper tobacco leaf raw material quality. According to the method, inapplicable upper tobacco leaf raw materials are placed in an ethanol solution to be soaked, then vacuum decompression processing is conducted, and next solid-liquid separation is conducted; after the inapplicable upper tobacco raw materials obtained after the solid-liquid separation is conducted are dried, the product formula processing process can be conducted. The method is easy to operate and low in cost, the inapplicable upper tobacco raw materials processed through the method still have better forming and processing performance, the inherent sensory quality is obviously improved, the utility value of the inapplicable upper tobacco leaves in cigarettes is increased, and the inventory pressure of the inapplicable upper tobacco leaves is effectively relieved for cigarette companies.

Owner:CHINA TOBACCO HUNAN INDAL CORP

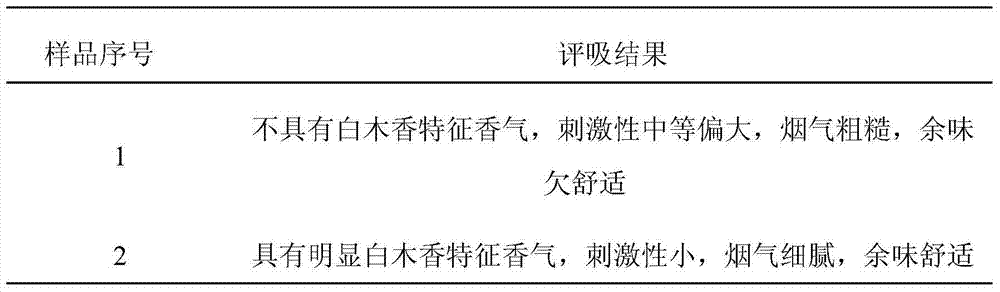

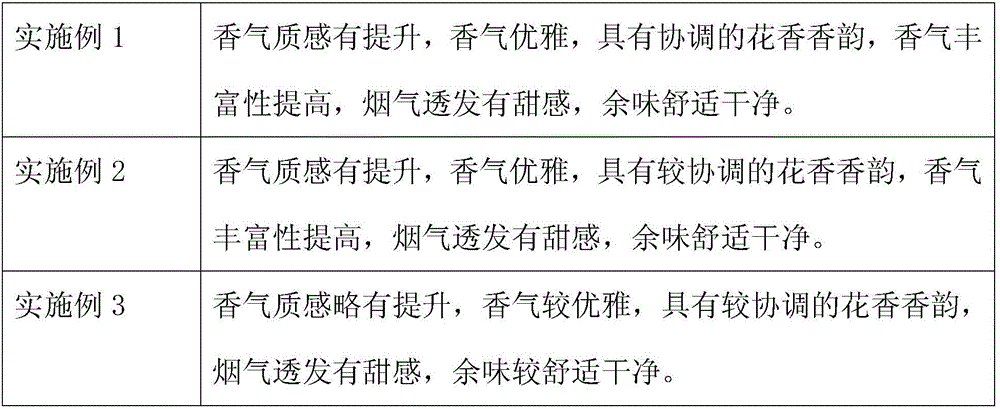

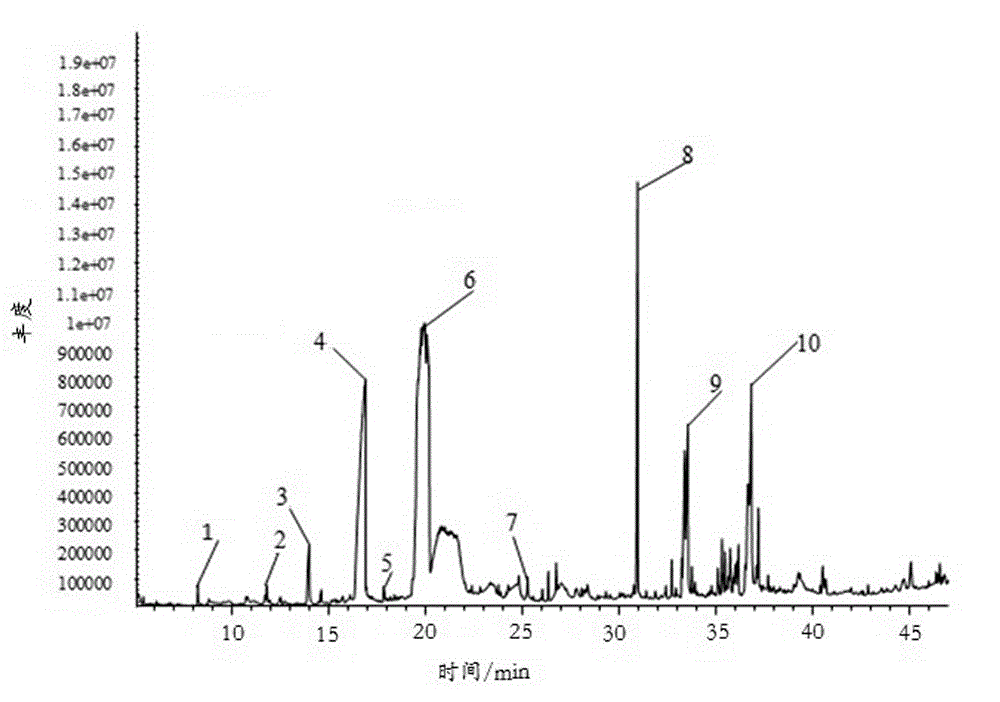

Application of supercritically-extracted aquilaria sinensis in tobacco reproduction technology with paper making method

ActiveCN103783651AEfficient use ofLess irritatingTobacco preparationTobacco treatmentAlcoholPaper manufacturing

The invention discloses the application of supercritically-extracted aquilaria sinensis in the tobacco remanufacturing technology with the paper making method. The specific preparation technology comprises the first step of extraction, wherein tobacco raw materials are mixed and added with water to be extracted; the second step of separation, wherein after extraction is finished, extracted liquid and solid raw material residues are obtained through solid-liquid separation; the third step of aquilaria sinensis supercritical extraction, wherein dried and meshed aquilaria sinensis is extracted through the supercritical carbon dioxide fluid to obtain extracts and residues, the obtained extracts are dispersed by absolute ethyl alcohol and then blended into the extracted liquid obtained in the second step, the mixture is concentrated to manufacture coating liquid, the obtained residues are blended into the solid raw material residues obtained in the second step, mixing and pulping are conducted, and tobacco piece bases are manufactured through the paper manufacturing technology with pulp; the fourth step of coating, wherein the tobacco piece bases are coated with the coating liquid, and remanufactured tobacco products are manufactured through drying and cutting. The preparation technology is simple, the cost is low, limited aquilaria sinensis resources are effectively utilized, and the sensory quality of aquilaria sinensis cigarettes is improved.

Owner:CHINA TOBACCO JIANGSU INDAL +1

Flowery flavor essence for cigarette dropping pills and application

InactiveCN106118884ASolve coordination problemsRich and comfortable aromaTobacco smoke filtersEssential-oils/perfumesFlavorFlavoring essences

The invention provides flowery flavor essence for cigarette dropping pills and application. The flowery flavor essence is prepared from the following raw materials of valerian oil, neroli essential oil, sweet osmanthus absolute, lavender essential oil, rose essential oil, violet leaf extract, isoamyl isovalerate and olive oil and is obtained by mixing and uniformly stirring the raw materials for 1 to 3 hours, then standing for 24 to 48 hours and filtering out sediment through a sieve which is 60 to 80 meshes. The flowery flavor essence can be prepared into the cigarette dropping pills by using a dropping pill machine, and then the cigarette dropping pills can be located in and applied to a cigarette holder bar. When the flowery flavor essence provided by the invention is used for preparing the dropping pills, the production stability is better, the breakage rate of the cigarette dropping pills is low, and the rate of finished products is 80 to 85 percent. During a smoke panel test of prepared cigarette, a smoker can feel that the flowery flavor in the smoking taste is obviously enhanced, the fragrance is elegant and ethereal, and the remaining taste is comfortable.

Owner:HUBEI CHINA TOBACCO IND

Smokeless tobacco product additive and preparation method and application thereof

ActiveCN101862026ARich tasteRich and delicate fragranceTobacco treatmentSmoking reducedSmokeless tobacco

The invention discloses a smokeless tobacco product additive and a preparation method and application thereof. The smokeless tobacco product additive is characterized in that the additive consists of substances extracted from any more than two raw materials of tea leaf, cocoa, coffee and tobacco through the process flows of extraction, concentration, combination and the like. Through the additive, smokeless tobacco products have richer categories and more pleasant tastes, and persons smoking the smokeless products obtain the same satisfaction of smoking cigarettes. The additive can meet the requirement of tobacco consumption crowds, can reduce the harm of smoking to the heath, and more important, can avoid the harm of smoking to the environment, reduce the possibility of sucking second-hand smoke for non-smoking crowds and achieve smoking environmental protection.

Owner:ZHENGZHOU TOBACCO RES INST OF CNTC

Tobacco extract and electronic cigarette liquid

ActiveCN104939305ASweet and deliciousRoasted aroma style Tobacco aroma is goodTobacco treatmentBiotechnologyAqueous ethanol

The invention discloses tobacco extract and electronic cigarette liquid. A preparation method of the tobacco extract comprises the following steps that (1), tobacco powder or / and tobacco shreds serve as raw materials, the raw materials are extracted with ethanol water with the volume fraction more than 75%, an extracting solution is concentrated to obtain ethanol extract, ethanol is used for dissolving the ethanol extract, then the ethanol extract is frozen, dissolved out, precipitated and filtered, and filter liquor is concentrated to obtain extract I; (2), the raw materials extracted with the ethanol are extracted with water, water extract is obtained, the water extract is leached with a solvent A, water phases are collected and then are used for leaching a solvent B, and organic phases are collected and concentrated to obtain extract II, wherein the solvent A is one or more of petroleum ether, normal hexane and cyclohexane, and the solvent B is ethyl acetate or dichloromethane; (3), the extract I and the extract II are mixed to obtain the tobacco extract. The tobacco extract keeps the tobacco aroma, the amount of aroma is full, no black residue exists after atomization, and no scorched flavor exists.

Owner:CHINA TOBACCO HUNAN INDAL CORP

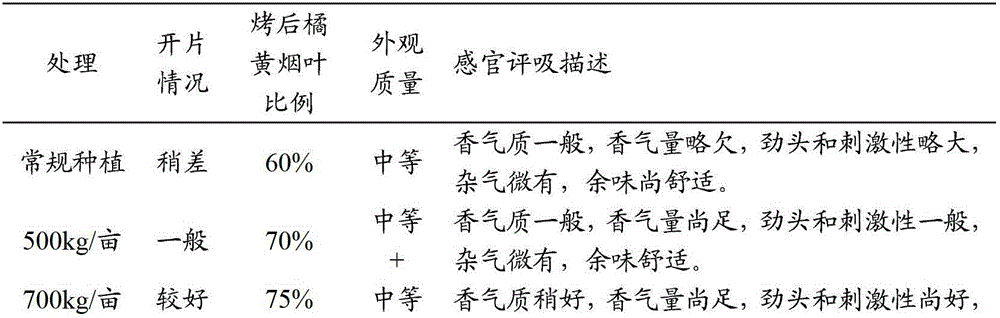

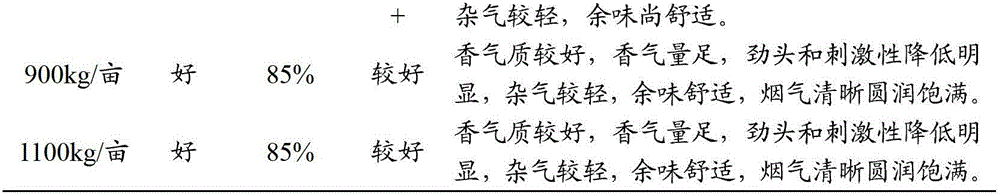

Method for improving quality and enhancing aroma of upper leaf of flue-cured tobacco

InactiveCN102939832APromote conversionPromote accumulationBio-organic fraction processingOrganic fertiliser preparationSodium molybdateSulfate

The invention provides a method for improving quality and enhancing aroma of upper leaves of flue-cured tobacco. The method comprises the following steps of: on the basis of conventional ridging fertilization of the flue-cured tobacco, additionally applying 800-1000kg of thoroughly decomposed farmyard manure per mu as base fertilizers; after the middle leaves of the flue-cured tobacco are harvested, evenly applying foliar fertilizers onto the front surfaces and the back surfaces of the upper leaves; and after normal mature harvesting time is delayed for 4-9 days, harvesting the upper leaves in one step and then curing the upper leaves. The foliar fertilizers comprise the following components in percentage by weight: 15-45 percent of borax, 15-45 percent of zinc sulfate, 15-45 percent of manganese sulfate, 3-12 percent of sodium molybdate, 1.5-4.5 percent of copper sulfate and 0-0.001 percent of jasmonic acid. In combination with measures such as additionally applying organic fertilizers in the base fertilizers, applying the foliar fertilizers after the middle leaves are harvested, delaying the harvesting time of the upper leaves and the like, the method for improving quality and enhancing aroma of upper leaves of flue-cured tobacco has the advantages that the method is simple, and the formula use value and the usability of the upper leaves can be greatly improved.

Owner:HUBEI CHINA TOBACCO IND

Preparation method of novel tea leaf volatile flavoring substance and application of novel tea leaf volatile flavoring substance in cigarettes

InactiveCN102068029AQuality improvementIncrease aromaTobacco preparationEssential-oils/perfumesDistillationAbsorption column

The invention relates to a preparation method of a novel tea leaf volatile flavoring substance and application of the novel tea leaf volatile flavoring substance in cigarette flavoring. The novel tea volatile aromatic substance is prepared with the method comprising the following steps of: taking tea leaves; distilling with vapor; collecting distillate; separating with an absorption column; and obtaining the tea leaf volatile flavoring substance. After the tea leaf volatile flavoring substance is added to tobacco shreds of the cigarettes, the cigarettes can have pleasant fresh and sweet tastes, which can improve the fragrance quality and the grade of the cigarettes, increase tobacco original fragrance, ensure rich, sweet, pure and mild smoke, suppress irritants and reduce impurities. The invention has the advantages that the technology of combining vapor distillation and absorption column separation is used for preparing the novel tea leaf volatile flavoring substance for the first time, and the substance is applied to cigarette flavoring, which obtains good expected effect, thus the invention provides a new technology for extracting and processing natural plants, provides a novel and important natural flavoring material for cigarette aromatization, and lays a certain foundation for researching various tea leaves in fragrance compensation of cigarettes.

Owner:广州华芳烟用香精有限公司

Bacillus pumilus preparation for processing tobacco stems

InactiveCN102250813AIncrease the amount of aromaIncrease pleasureBacteriaTobacco treatmentBacillus pumilusIrritation

The invention discloses a microorganism preparation for tobaccos as well as a preparation method and application thereof, belonging to the technical field of tobacco additives. A production bacterial strain liquid is fermented and cultured to obtain the corresponding microorganism preparation. The production bacterial strain is bacillus pumilus.Van35, the bacterial strain is collected in the Center for General Microorganism of China Committee for Culture Collection of Microorganisms and the collection number is CGMCC No.3411. The microorganism preparation provided by the invention can obviously improve the qualities of stems, such as fragrance amount, joviality and the like; impure gas, irritation and the like are reduced; smoke concentration and strength are reduced and remaining taste becomes more comfortable so that the doping amount of the stems in a cigarette is further increased so that aims of reducing harm, decreasing coke content and reducing the production cost of the cigarette are achieved.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD

Tobacco sheet and production method thereof

ActiveCN102972860ARich aromaGood compatibilityTobacco preparationTobacco treatmentCelluloseEngineering

The invention relates to the field of tobacco product processing, in particular to a tobacco sheet and a production method thereof. The tobacco sheet is produced from the following raw materials in parts by weight: 20-30 parts of elsholtzia, 70-80 parts of tobacco, 3-4 parts of guar gum, 1 part of liquorice cream and 8 parts of cellulose. According to the invention, the smoke concentration of the tobacco sheet can be effectively increased, the clustering feel of the tobacco sheet can be effectively improved, impurity gases and the irritation of the sheet are reduced, and the mouth feel of the rolling-process sheet is remarkably improved. The production method is simple to operate and low in production cost, and is suitable for the large-scale industrial production of the rolling-process tobacco sheet.

Owner:JILIN TOBACCO IND

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com