Process for baking Hongda tobacco leaves

A technology of safflower big gold dollar and roasting process, which is applied in the fields of tobacco, tobacco preparation, application, etc., can solve the problems of poor roasting quality and low yield, and achieve good aroma, comfortable aftertaste, and significant improvement in quality and efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

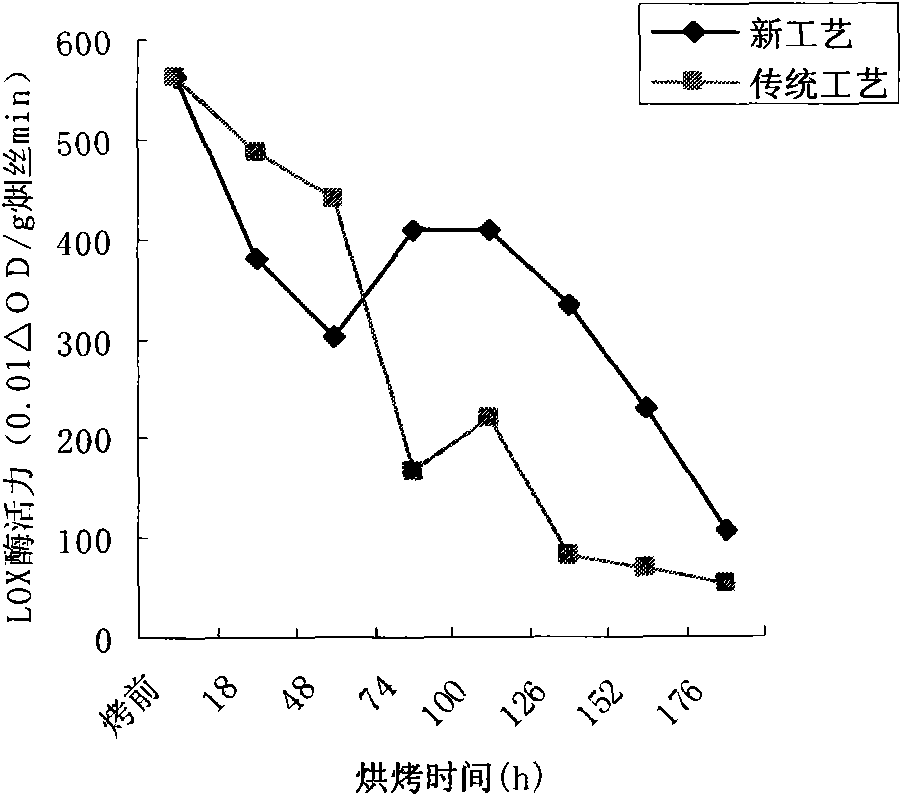

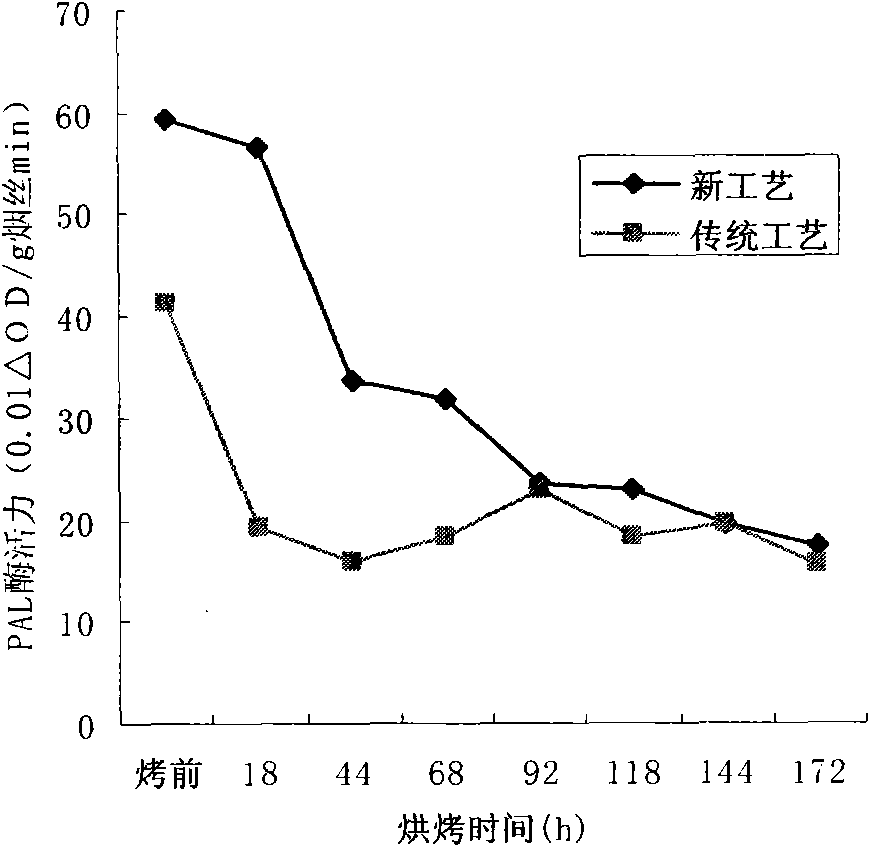

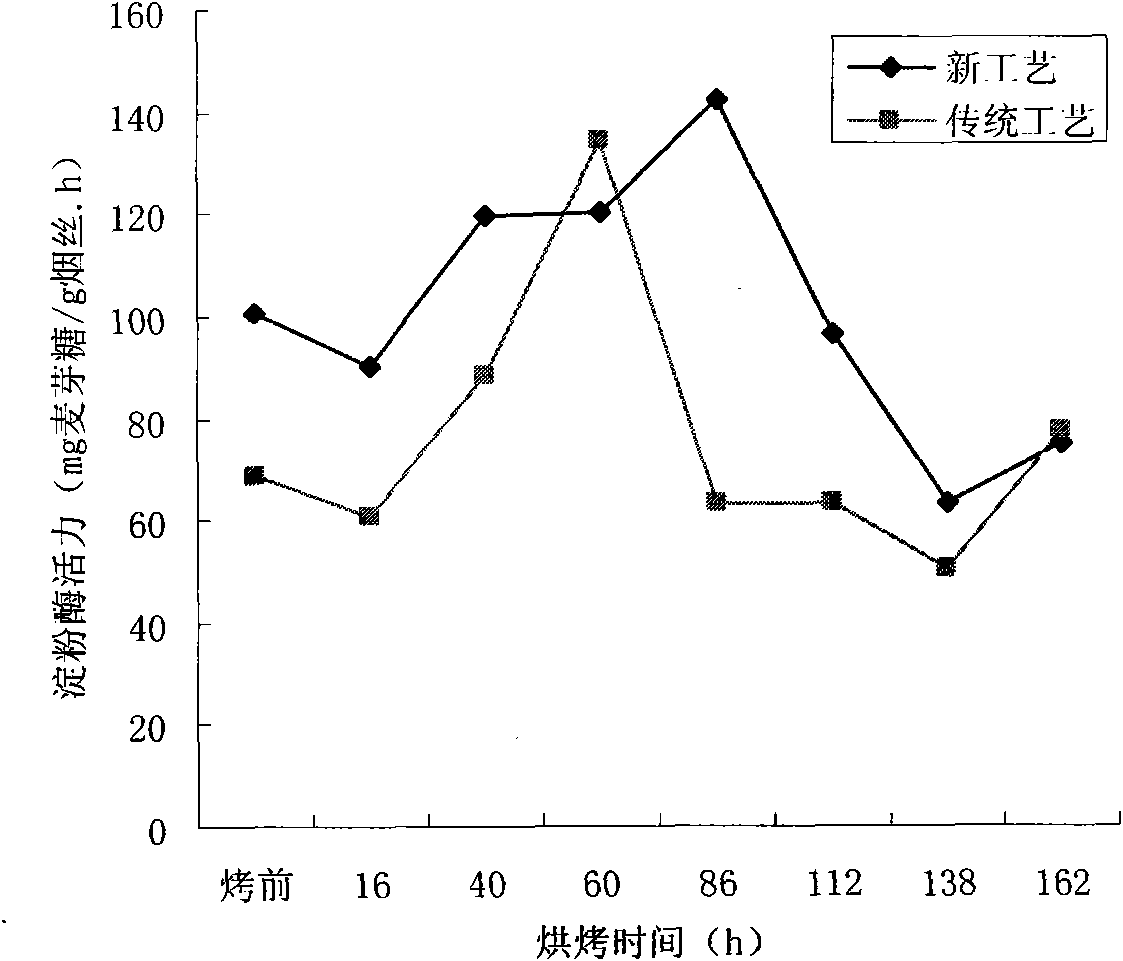

[0027] In Hongda planting township (town) of Shilin County, two representative functional curing barns were selected, respectively, according to the curing process and traditional process of the Honghua Dajinyuan variety tobacco leaves described in the content of the invention, and the standard leaf curing process was carried out at the same time. The comparative test of curing tobacco leaves (Xiaerpeng, Zhengyaoye, and Shangerpeng) was carried out to track and record the technical parameters related to curing. Track and sample the cured tobacco leaves at each stage, and detect the relevant chemical composition indicators; and evaluate the internal quality of the cured tobacco leaves of the current curing process and the old curing process, evaluate the quality of the appearance grade, and compare and analyze the curing cost, output value and benefit ; Analyze the change law of chemical composition and quality substance accumulation of tobacco leaves during the curing process, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com