Application of supercritically-extracted aquilaria sinensis in tobacco reproduction technology with paper making method

A technology of reconstituted tobacco leaves and supercritical, applied in the application, tobacco, preparation of tobacco and other directions, can solve problems such as poor sensory quality, achieve the effects of comfortable aftertaste, fine smoke, and reduce production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

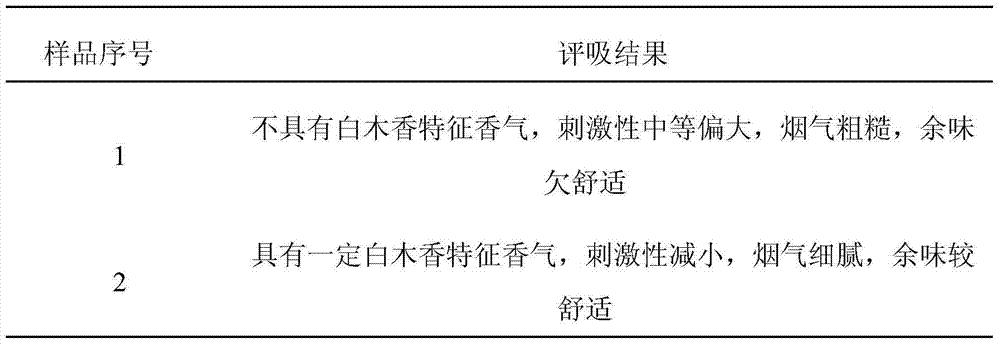

[0016] First, mix the tobacco leaf raw materials (including 30-60% tobacco stems, 10-40% chips, 10-40% tobacco powder, 10-20% wood pulp and 10-20% calcium carbonate, etc.) and add water for extraction. After the extraction is completed, After solid-liquid separation, the extract and solid raw material residues are obtained; then the dried and crushed Akiras sinensis is extracted with supercritical carbon dioxide fluid for 3 hours at an extraction temperature of 30°C and an extraction pressure of 15MPa to obtain the extract and residue. The obtained extract is dispersed with anhydrous ethanol and blended into the extract obtained after pressing and separating, and then concentrated to make a coating liquid, and the obtained residue is blended into the solid raw material residue obtained after pressing and separated, and mixed and beaten. The degree of percussion is 30°SR, and the tobacco sheet base is produced through the papermaking process. The weight of the extract and residu...

Embodiment 2

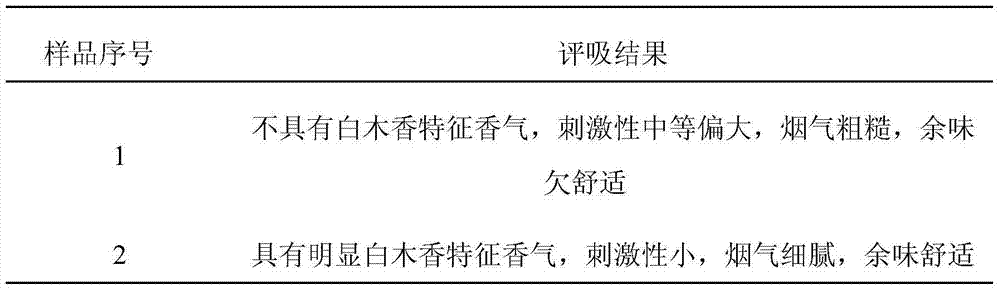

[0021] First, mix the tobacco leaf raw materials (including 30-60% tobacco stems, 10-40% chips, 10-40% tobacco powder, 10-20% wood pulp and 10-20% calcium carbonate, etc.) and add water for extraction. After the extraction is completed, After solid-liquid separation, the extract and solid raw material residues are obtained; then the dried and crushed Akiras sinensis is extracted with supercritical carbon dioxide fluid, preferably at an extraction temperature of 40°C and an extraction pressure of 20 MPa for 2 hours to obtain Extract and residue, the obtained extract is dispersed with absolute ethanol and blended into the extract obtained after pressing and separating, and concentrated to make a coating liquid, and the obtained residue is blended into the solid raw material residue obtained after pressing and separating, Mixing and beating, the beating degree of beating is 40°SR, and then the tobacco sheet base is produced through the papermaking process, wherein the added extrac...

Embodiment 3

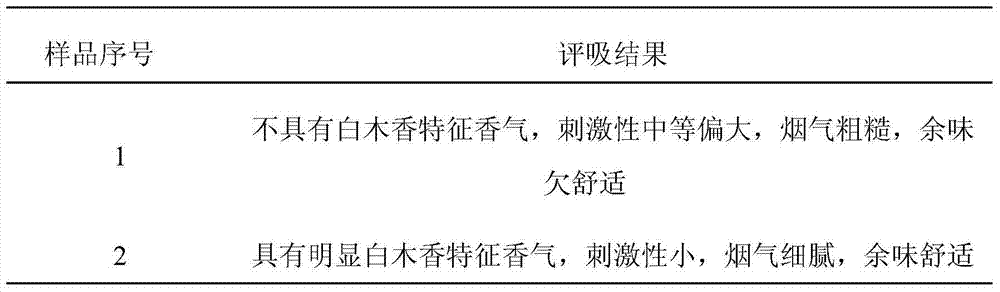

[0026] First, mix the tobacco leaf raw materials (including 30-60% tobacco stems, 10-40% chips, 10-40% tobacco powder, 10-20% wood pulp and 10-20% calcium carbonate, etc.) and add water for extraction. After the extraction is completed, After solid-liquid separation, the extract and solid raw material residues are obtained; then the dry and crushed Akiras sinensis is extracted with supercritical carbon dioxide fluid, preferably at an extraction temperature of 45°C and an extraction pressure of 15 MPa for 2 hours to obtain Extract and residue, the obtained extract is dispersed with absolute ethanol and blended into the extract obtained after pressing and separating, and concentrated to make a coating liquid, and the obtained residue is blended into the solid raw material residue obtained after pressing and separating, Mixing and beating, the beating degree of beating is 40°SR, and then the tobacco sheet base is produced through the papermaking process, wherein the added extract ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com