Tobacco leaf and glutinous rice flour composite particle preparation method and aroma enhancement application of tobacco leaf and glutinous rice flour composite particle to filter tip

A technology of composite granules and glutinous rice flour, applied in the application, preparation of tobacco, smoke oil filter and other directions, can solve the problems of complex procedures, hidden dangers of product safety, insufficient particle strength, etc., and achieves good taste, low cost and simple preparation process. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

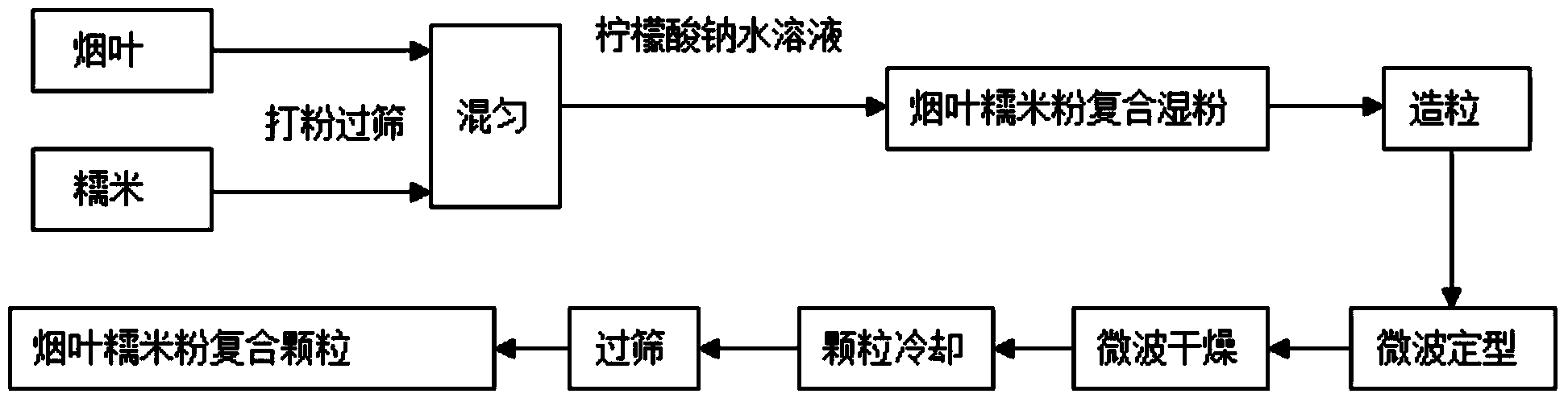

Method used

Image

Examples

Embodiment 1

[0023] C1F Tobacco leaves are powdered and passed through a 40-mesh sieve to take 10g, mix with 100g glutinous rice flour for later use, weigh 0.1g sodium citrate and dissolve in 120g water, stir magnetically to dissolve completely, then spray it evenly into the mixed powder and mix well, press to make it moist The mixed powder is granulated through a 20-mesh sieve. Under the closed state of the above-mentioned composite particles (without dehumidifying state), put them into a microwave oven at 10 kW / m 2 The microwave power density was divided into three treatments for a total of 6 minutes for setting; then open the sealing membrane (dehumidification state), and use 10 kW / m 2 A total of 8 minutes of microwave power density treatment is used to dry tobacco leaf glutinous rice flour composite particles, and the above microwave treatment should control the temperature not to exceed 120 °C. The obtained product is crushed and passed through 20-mesh and 40-mesh standard sieves res...

Embodiment 2

[0025] Take 25g of C2F powdered tobacco through a 40-mesh sieve, mix it with 100g of glutinous rice flour for later use, weigh 0.1g of sodium citrate and dissolve it in 130g of water, stir it with a magnetic force to dissolve completely, then spray it evenly into the mixed powder and mix well, press to make it moist The mixed powder was passed through a 20-mesh drying net to obtain granulation. Put the above-mentioned composite particles into a microwave oven, and in the state of non-dehumidification, use 10 kW / m 2 The microwave power density was divided into three treatments for a total of 5 minutes for setting; then in the dehumidified state, the 2 A total of 10 minutes of microwave power density treatment composite particles is used to dry tobacco leaf glutinous rice flour composite particles, and the above microwave treatment should control the temperature not to exceed 120°C. The obtained product is crushed and passed through 20-mesh and 40-mesh standard sieves respectiv...

Embodiment 3

[0027] Take 40g of C3F tobacco powder through a 40-mesh sieve, mix it with 100g of glutinous rice flour for later use, weigh 0.2g of sodium citrate and dissolve it in 140g of water, stir it with a magnetic force to dissolve completely, then spray it evenly into the mixed powder and mix well, press to make it moist The mixed powder was passed through a 20-mesh drying net to obtain granulation. Put the above-mentioned composite particles into a microwave oven, and in the state of non-dehumidification, use 10 kW / m 2 The microwave power density was divided into three treatments for a total of 6 minutes for setting; then in the dehumidified state, the 2 A total of 12 minutes of microwave power density treatment composite particles is used to dry tobacco leaf glutinous rice flour composite particles, and the above microwave treatment temperature should be controlled not to exceed 120°C. The obtained product is crushed and passed through 20-mesh and 40-mesh standard sieves respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com