Energy-saving distilling apparatus for wine

The technology of a distillation device and a distillation tank, which is applied to the field of wine distillation devices, can solve the problems of poor control of heating temperature, large energy consumption, burnt smell and the like, and achieves easy control of heating temperature, good energy saving effect, and improved wine quality. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

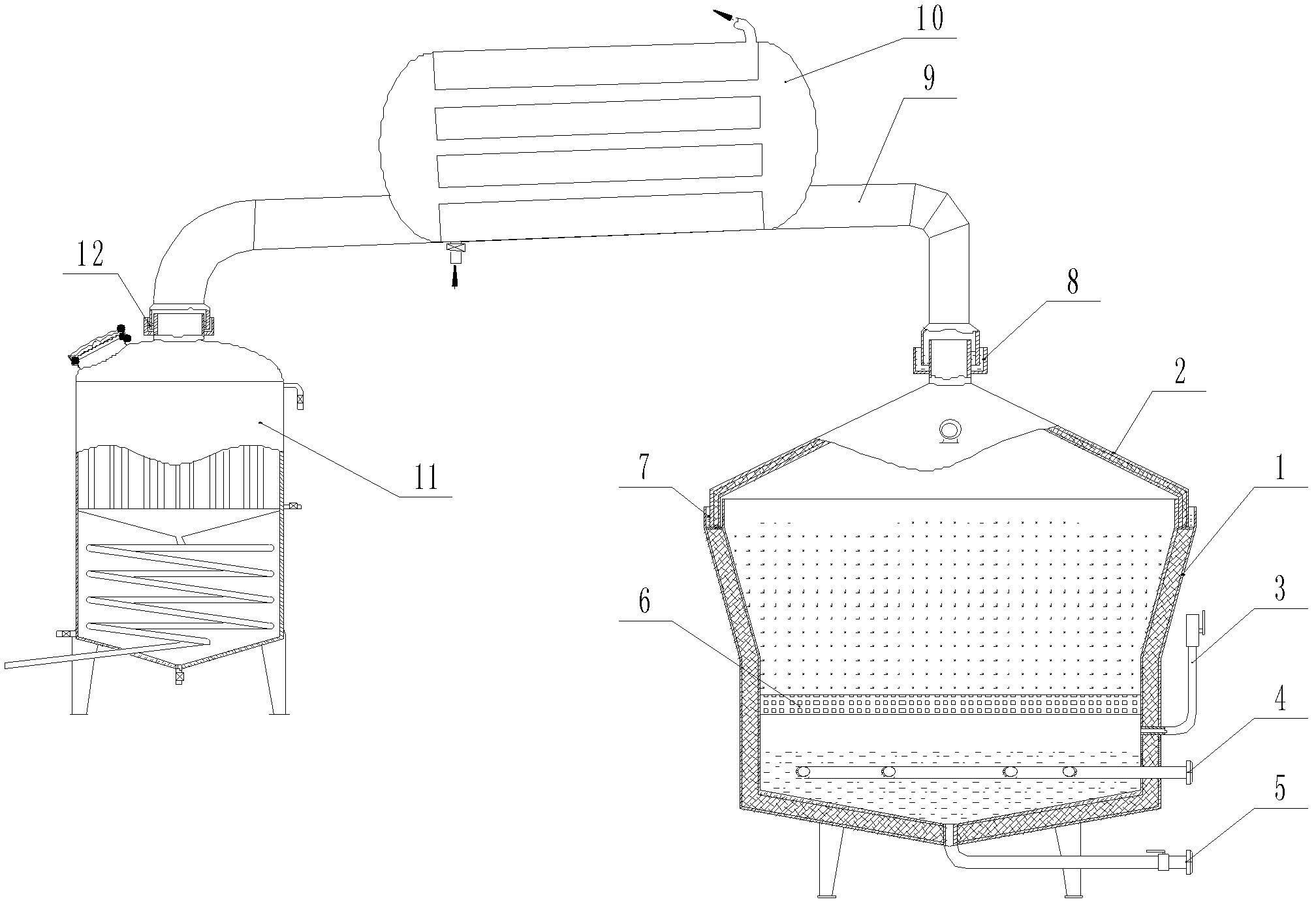

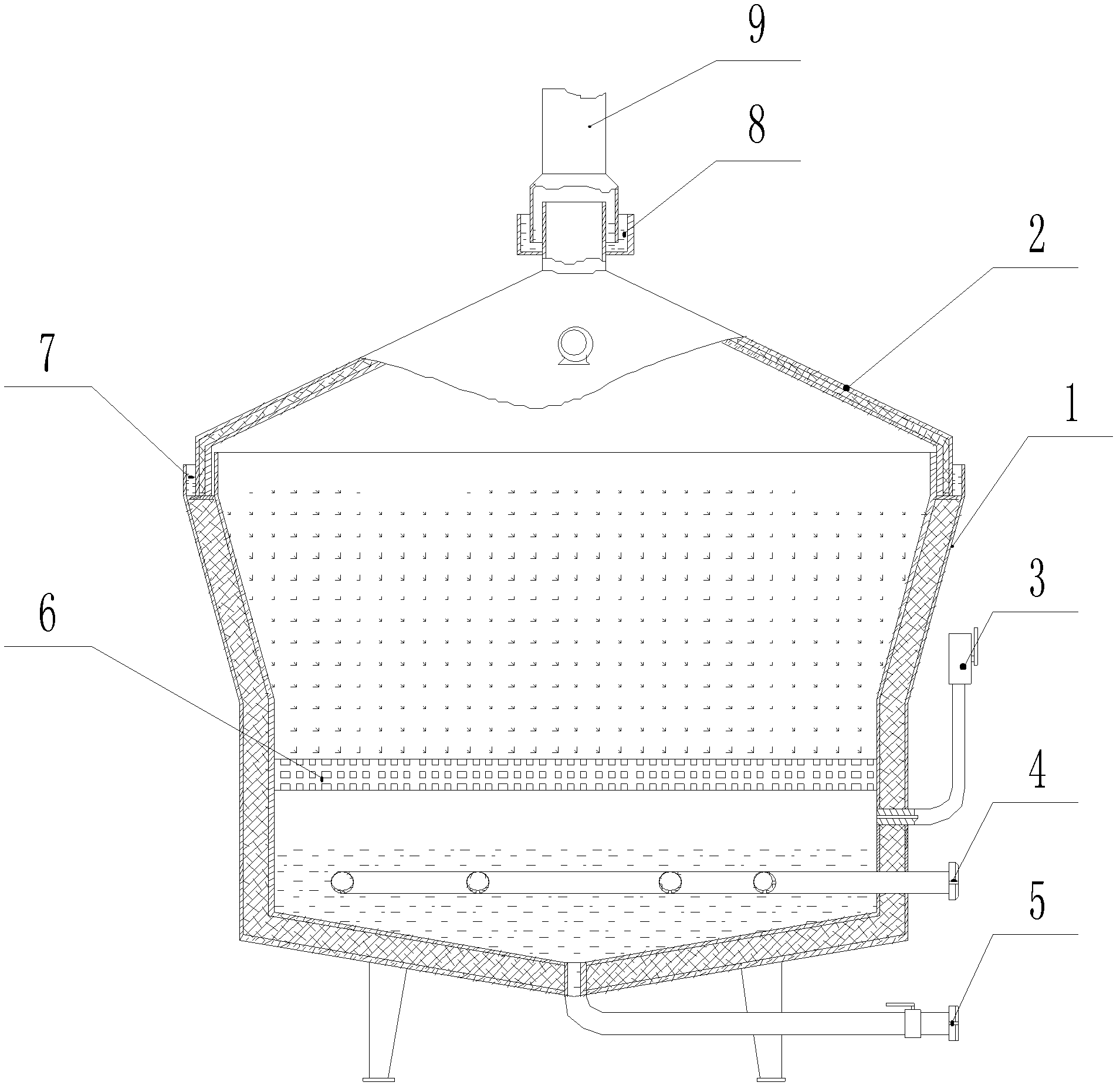

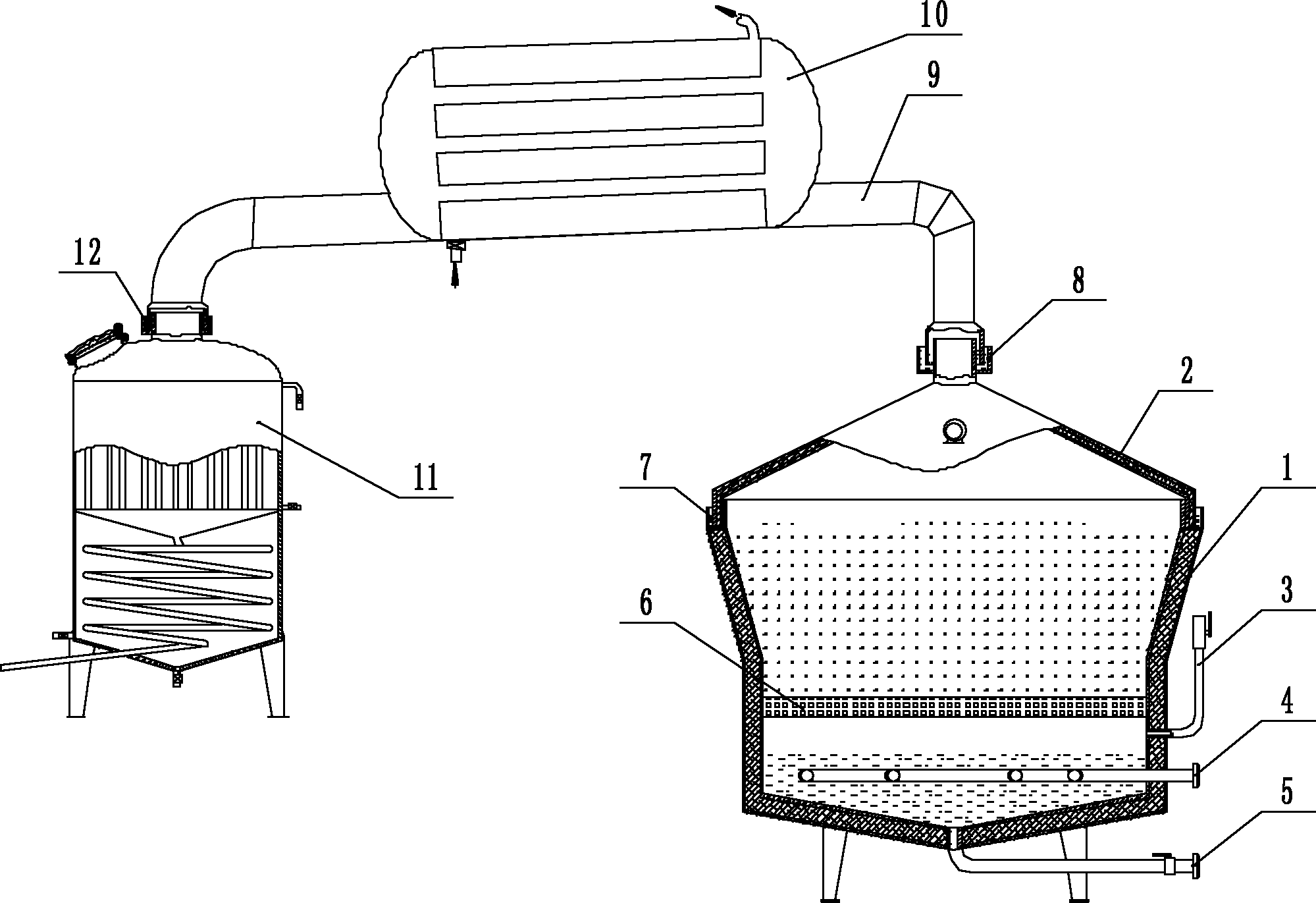

[0009] Such as figure 1 , figure 2 As shown, an energy-saving distillation device for wine is composed of a distillation tank 1, a connecting pipe 9 and a cooling tower 11; in the distillation tank 1, a heat conducting partition 6 is arranged to separate the distillation tank 1 into a material area and a heating area; The heating zone of the tank 1 is connected with a water inlet pipe 3, a steam pipe 4 and a sewage discharge pipe 5; at the mouth of the retort 1, there is a water seal groove 7 for the retort, and the cover edge of the tank cover 2 is inserted in the water seal groove 7 of the retort; The connecting pipe interface of the tank cover 2 is provided with a tank cover water sealing groove 8; the connecting pipe interface of the cooling tower 11 is provided with a cooling tower water sealing groove 12; the two ends of the connecting pipe 9 are respectively inserted in the tank cover water sealing groove 8 And cooling tower water seal tank 12; Reflux tank 10 is house...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com