Making method for pre-baked mashed potato bread

A production method and technology of mashed potatoes, applied in dough processing, baking, baked food, etc., can solve problems affecting bread quality, poor taste, bread temperature fluctuations, etc., and overcome easy aging, fine pores, uniform pores, etc. hook effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

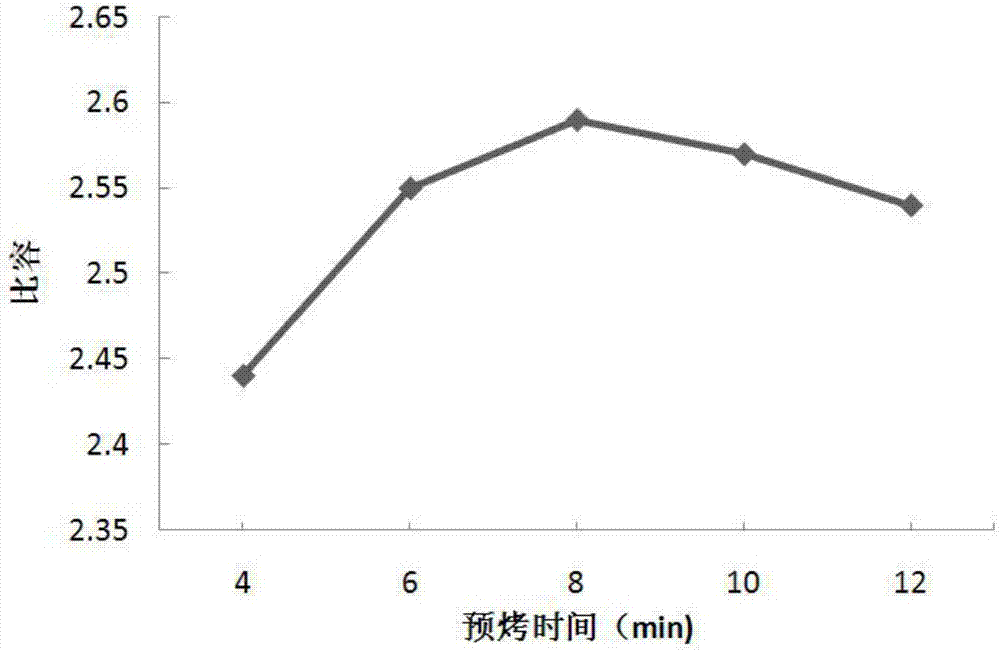

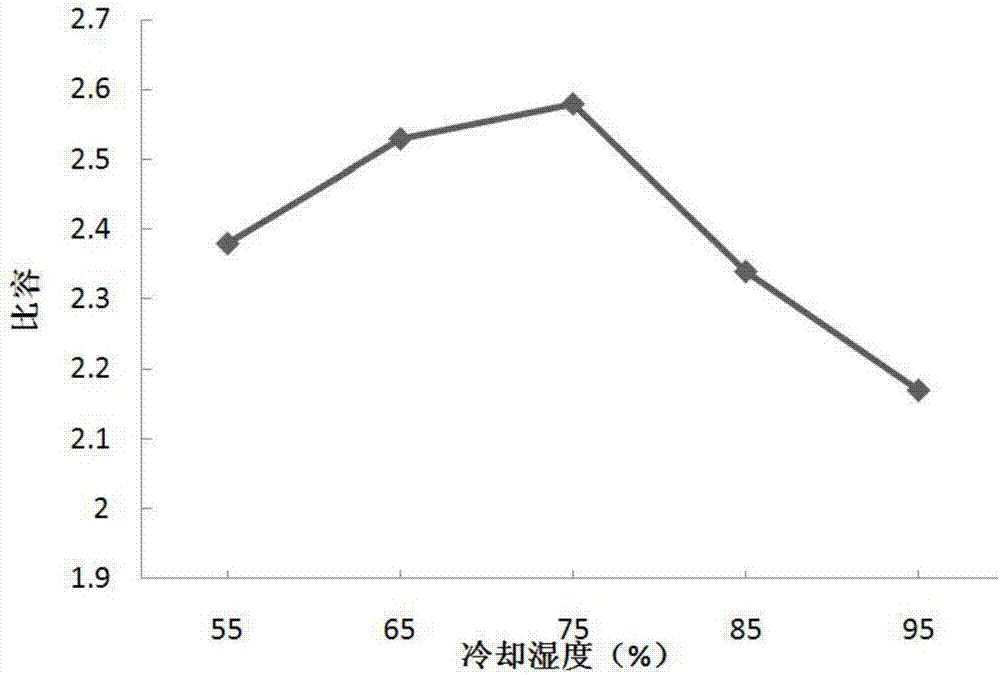

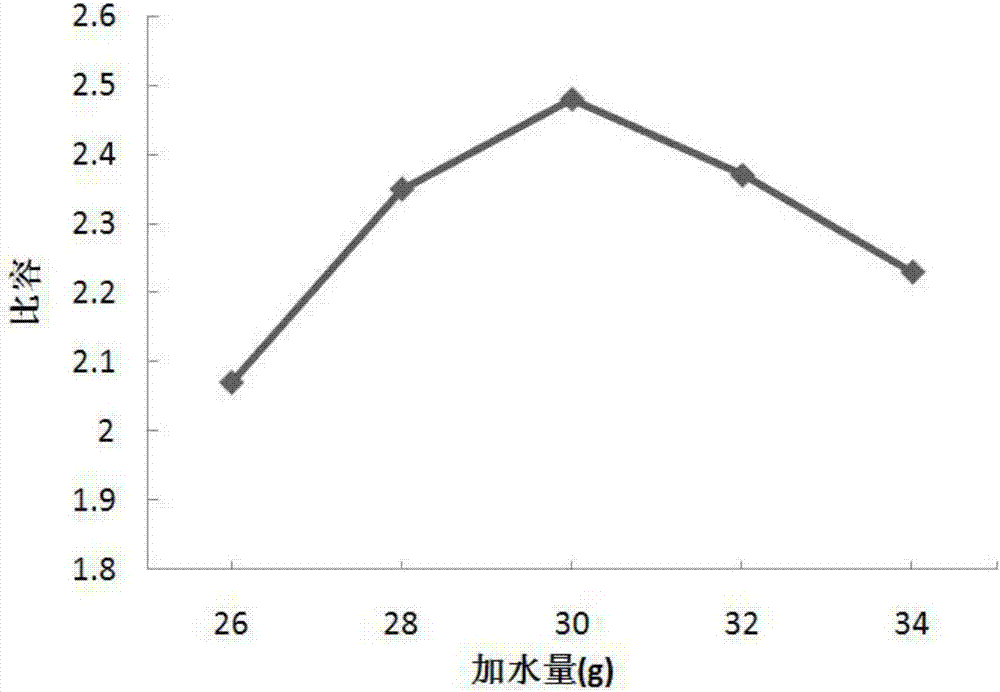

[0029] The present invention conducts experimental research on the production process parameters of pre-baked frozen bread, including: water addition, cooling humidity, pre-baked time, etc., explores the influence of different processing technology conditions on the quality of pre-baked mashed potato bread, and then determines its best Process parameters, thereby improving the quality of pre-baked mashed potato bread in terms of color, texture, flavor, and mouthfeel.

[0030] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

[0031] 1. Make mashed potatoes

[0032] Method 1: Wash and cut the bought potatoes into pieces, steam them in a pot, tear off the cooked potato skins, put the potato pieces into a basin after peeling, and squeeze them evenly into mashed potatoes with a spoon. After determination, the moisture content in mashed potatoes is about 77%.

[0033] Method 2: Mix dry potato powde...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com