Patents

Literature

110results about How to "No wrinkle" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

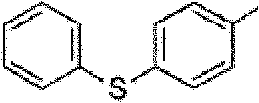

Photosensitive composite containing photoinitiator of diphenyl sulfide based ketoxime esters and application thereof

ActiveCN101923287AGood storage stabilityHigh short wavelength sensitivityOptical filtersPhotomechanical apparatusOptical transparencyPentaerythritol

The invention relates to a photosensitive composite which contains a specific ketoxime ester compound used as a polymerization initiator, an alkali-soluble resin, DPHA (Dipentaerythritol Hexaacrylate) and a colorant. The composite has good storage stability and also has high exposure sensitivity, good developing performance, no wrinkle on formed pattern surfaces and excellent solidifying effect when used for making black matrixes (BM) and RGB (Red Green Blue) of a color filter. The invention also relates to the application of the photosensitive composite in the production of the color filter, and the filter made from the photosensitive composite has high optical transparency and no light leakage.

Owner:CHANGZHOU TRONLY NEW ELECTRONICS MATERIALS

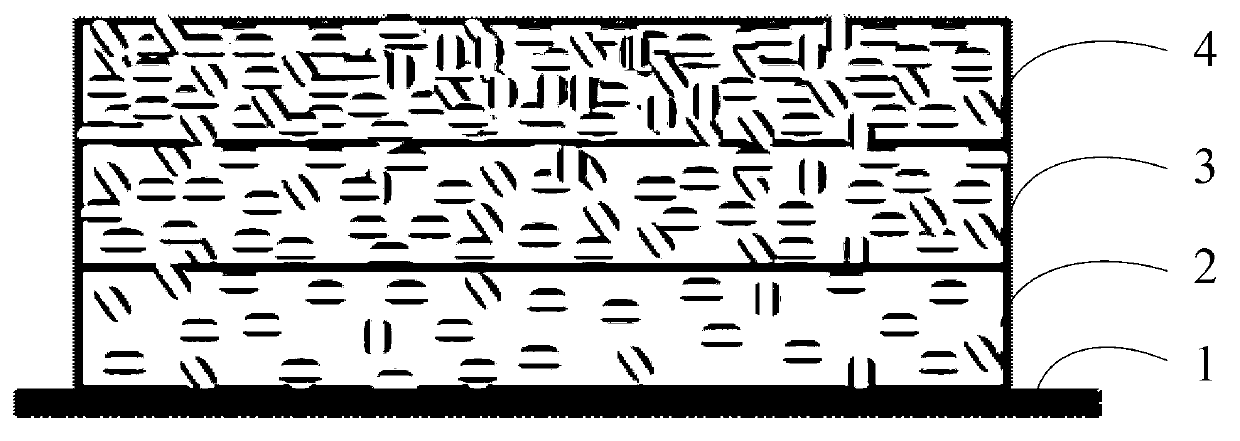

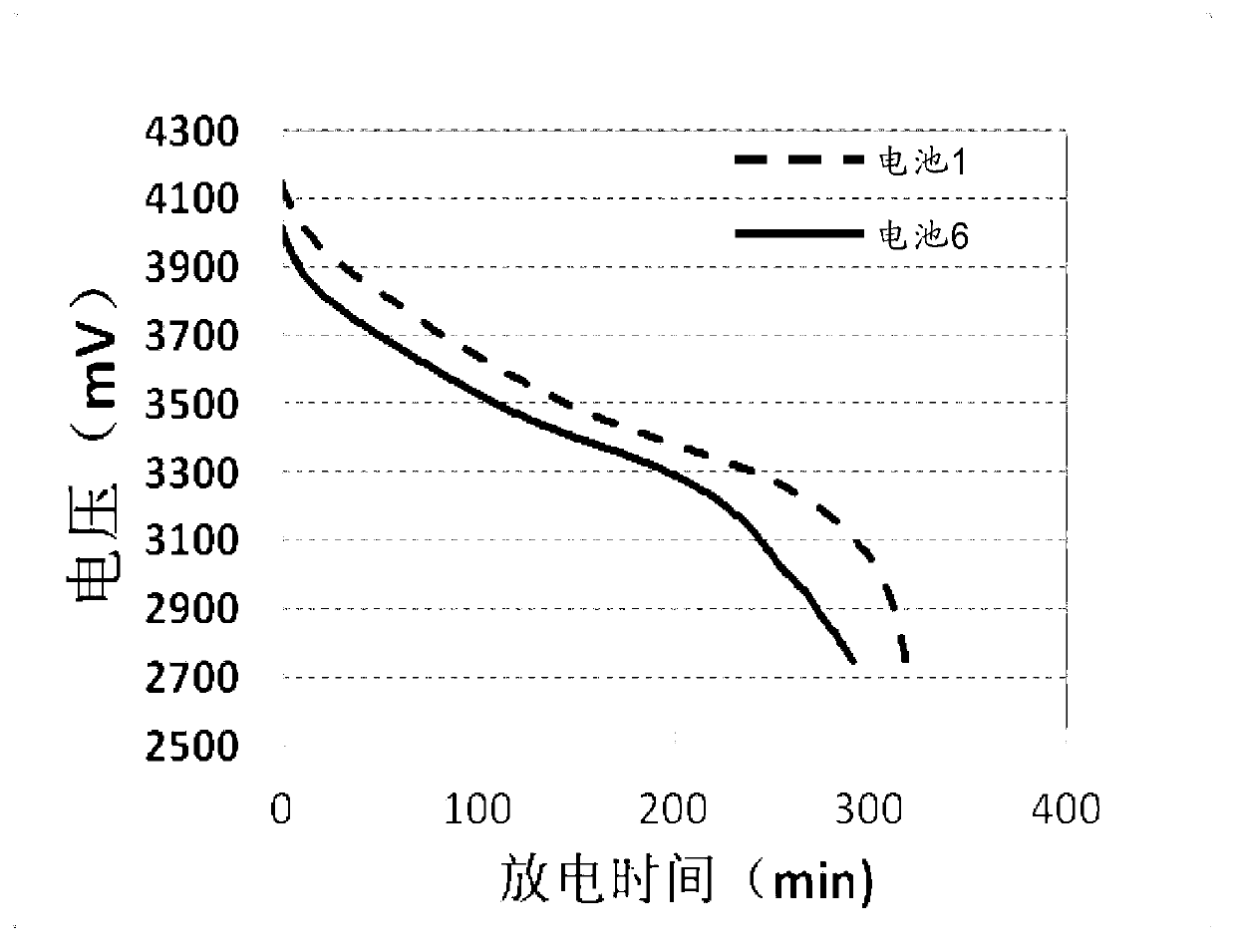

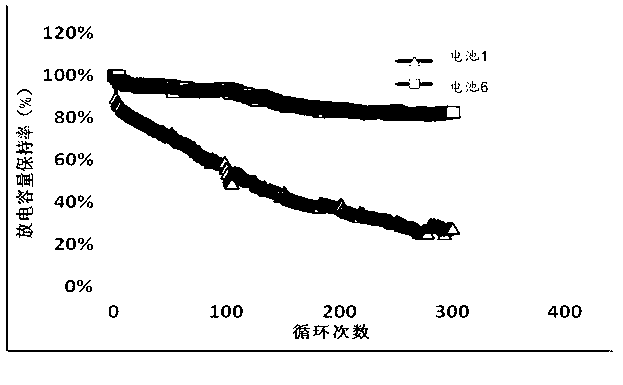

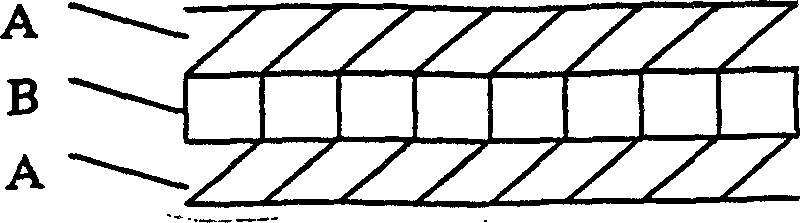

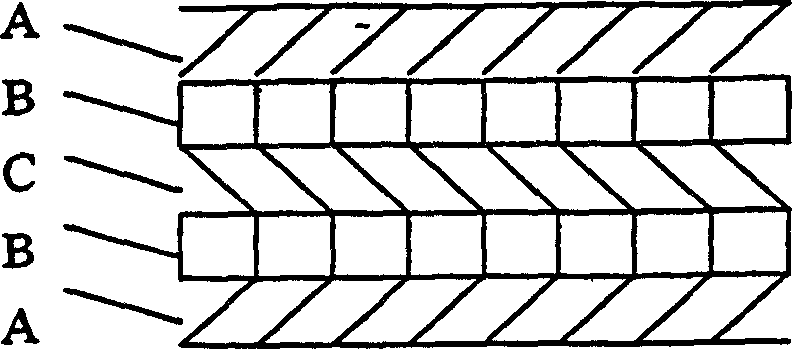

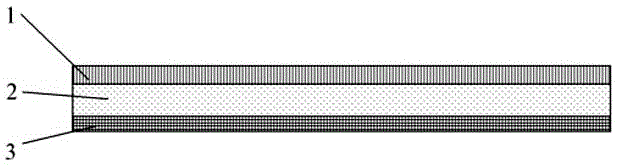

Gradient cathode piece and lithium ion battery preparation method with same

The invention provides a gradient cathode piece and a lithium ion battery preparation method with the same. The gradient cathode piece is prepared by sequentially coating a first size layer, a second size layer and a third size layer on a copper foil, wherein active components in the first size layer, the second size layer and the third size layer increase gradually. A lithium ion battery is prepared with the gradient cathode piece. The gradient cathode piece is easy to industrialize. Inner stress, generated during lithium insertion and lithium removing, of alloy materials of the gradient cathode piece in the lithium ion battery can be controlled effectively, damage, caused by expansion stress, of the gradient cathode piece is lowered greatly, and accordingly wrinkle and breakage of the gradient cathode piece are avoided, and performances such as multiplying power and capacity retention ratio of the lithium ion battery are increased effectively.

Owner:韩志娟

Foodstuff packaging membrane and its manufacturing method

InactiveCN1736813AHigh transparencyGood air resistanceFlexible coversWrappersPolymer sciencePolyolefin

The invention discloses a production of food packaging film and the method for preparation, specifically a degradable complex film prepared with degradable nanometer PA polymer as the obstruct material. Said complex film has a layer structure containing at least two outer layers and one interlayer, at least one layer among which is the obstruct layer, the obstruct layer being made up of degradable nanometer PA polymer, and others being made up of degradable polyolefin or polyolefin. Compared with the high-obstruct film prepared with PVDC, the invention overcomes the shortcomings that the manufacture is hard, the cost is high, environmental pollution is serious, and the recovery is hard. And the high-obstruct packaging film prepared mainly with nanometer PA has identical obstruct effect with PVDA film.

Owner:朱春英

Carving and molding process of leather

InactiveCN102642437AReduce processing costsSimple and fast operationDecorative surface effectsWater coolingUltimate tensile strength

The invention relates to a treatment process of leather, in particular to a carving and molding process of leather with a concave-convex arabesquitic pattern structure. The process comprises the following steps of: 1), manufacturing a corresponding plastic absorbing mold according to a selected stereoscopic figure or pattern; 2), putting the leather above the plastic absorbing mold in a vacuum plastic absorbing device, folding the leather with the plastic absorbing mold after the leather is heated to 90-120 DEG C, sealing four sides of the leather with four sides of the plastic absorbing mold, and applying vacuum, so that the leather is clung on the surface of the plastic absorbing mold to be molded; and 3), cooling the molded leather through an air cooling or water cooling way, and carrying out demolding to obtain a leather product with a concave-convex carved and molded structure. By using the carving and molding process, the plastic absorbing carving and molding are adopted; the whole flow is simple and convenient; the operation cost is low; the plastic adsorbing mold only needs one mold; moreover, a material does not need quite high strength; and thus, the carving and molding process is also lower in the machining cost of the mold.

Owner:东莞市顺琦手袋实业有限公司

Compound water-based inorganic anticorrosive paint and preparation method

InactiveCN104877402ANo changeNon-foamingAnti-corrosive paintsElectrically-conductive paintsSilicic acidPotassium silicate

The invention relates to an anticorrosive paint, particularly to a compound water-based inorganic anticorrosive paint with the functions of cathode protection and anti-static electricity and a preparation method. The compound water-based inorganic anticorrosive paint comprises the following components in mass percent: 0.1-4% of oxidized graphene, 22-34% of zinc powder, 1-3% of attapulgite AT, 15-18% of potassium silicate, 11% of iron oxide red, 30-45% of distilled water and 0.2-0.8% of sodium polyacrylate. The anticorrosive paint has the characteristics that oxidized graphene and zinc powder are used as the main raw materials of the anticorrosive paint, the use amount of zinc powder is greatly reduced, the electrical conductivity and hardness of the paint are improved, the technology is simple, the anticorrosive paint is green, environment-friendly and good in corrosion resistance, and can be applicable to anticorrosive painting of various metal pipelines and metal members.

Owner:CHANGZHOU UNIV

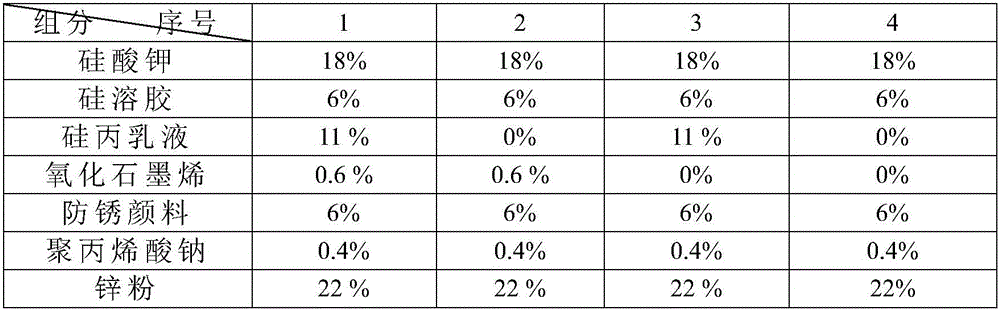

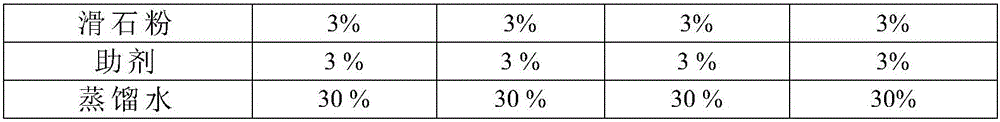

Silicone acrylate emulsion and graphene oxide-modified inorganic paint and preparation method thereof

InactiveCN106634320ANo spotsNon-foamingAnti-corrosive paintsElectrically-conductive paintsMechanical propertyAlkali metal

The invention provides a silicone acrylate emulsion and graphene oxide-modified inorganic paint and a preparation method thereof. The paint is an anticorrosion priming paint which takes an alkali metal aqueous solution as a film forming substance, takes graphene oxide and zinc dust as a main filling material, and takes the silicone acrylate emulsion as a modifier. The silicone acrylate emulsion is obtained by the processes that an appropriate auxiliary agent is added in an organosilicon monomer containing an unsaturated bond as well as an acrylic acids monomer, and the materials are polymerized through a core-shell coating polymerization technology; flexibility of a film is improved when the emulsion is added in the inorganic paint, and Van der Waals force of a coating on a base material is increased. and the graphene oxide has excellent conductive performance and mechanical property. The experiment proves that flexibility, salt fog resistance, adhesive force and conductivity of the paint are obviously increased.

Owner:CHANGZHOU UNIV

Moisture-curing polyurethane epoxy coal-tar bitumastic

InactiveCN101760135AUniform thicknessNo effect on cure speedAnti-corrosive paintsPolyurea/polyurethane coatingsEpoxyCyclohexanone

The invention relates to a moisture-curing polyurethane epoxy coal-tar bitumastic. The invention adopts a technical scheme that: the bitumastic is formed by a component A and a component B in a weight ratio of 1:1-1:2; and the preparation method comprises the following steps of: placing 37 to 40 parts of polymethylene polyphenyl isocyanate, 11 to 13 parts of polyether 330 or 3,030, 2 to 3 parts of polyether 635 or 450, 8 to 9 parts of DOP or DBP, 3 to 4 parts of epoxy resin, 0.002 to 0.003 part of phosphoric acid and 33 to 37 parts of solvent No.S10,000 or industrial xylene in a reaction kettle at the temperature of between 81 and 86 DEG C, preserving the heat for 2 hours, and cooling the raw materials to obtain the component A; and placing 62 to 66 parts of coal-tar, 9 to 10 parts of cyclohexanone, 10 to 11.5 parts of toluene, and 7 to 8 parts of solvent No.S1,000or industrial xylene in the reaction kettle at the temperature of between 115 and 120 DEG C, preserving the heat for 2 hours, and cooling the raw materials to obtain the component B. The coating applied by the bitumastic is waterproof and long in life time and can further protect equipment and pipes.

Owner:孙锡宁

Modified polyurethane asphalt corrosion-resistant coating

InactiveCN101906266AGood moisture permeabilityGood temperature resistanceAnti-corrosive paintsPolyurea/polyurethane coatingsSolventPolyphenyl isocyanate

The invention relates to a modified polyurethane asphalt corrosion-resistant coating. In the adopted technical scheme, the corrosion-resistant coating is prepared by mixing a component A and a component B in weight ratio of 1:0.5-1.5, wherein polymethylene polyphenyl isocyanate, isophorone diisocyanate, acrylate, polyether 3031K, polyether 450, dioctyl ester, epoxy resin, phosphate, solvent No.S1000 or industrial xylene are put into a reaction kettle, and react for 0.5 hour at the temperature of 40-42 DEG C, the temperature is raised to 80-82 DEG C, the heat is preserved for 2 hours, the temperature is decreased, and then the component A is prepared; and petroleum asphalt, coal tar asphalt, cyclohexanone, toluene, solvent No.S1000 or industrial xylene and epoxy rein are put into the reaction kettle, the heat is preserved for 2 hours at the temperature of 135-140 DEG C, and the temperature is decreased to room temperature; then, aluminum triphosphate, strontium chromate, mica powder and glass flake are added, grounded, and dispersed, and then the component B is prepared. The coating adopting the invention has the advantages of strong adhesive force, no moisture permeation, strong corrosion resistance, and long service life.

Owner:索慈利

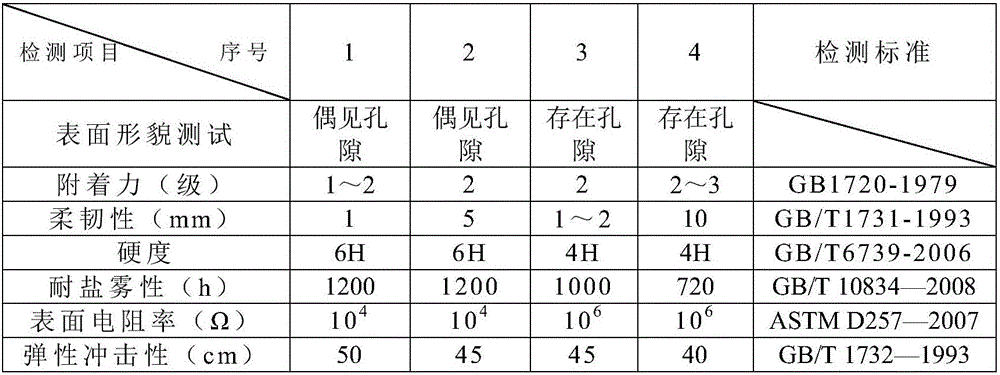

Low temperature resistant winter epoxy coal tar pitch coating

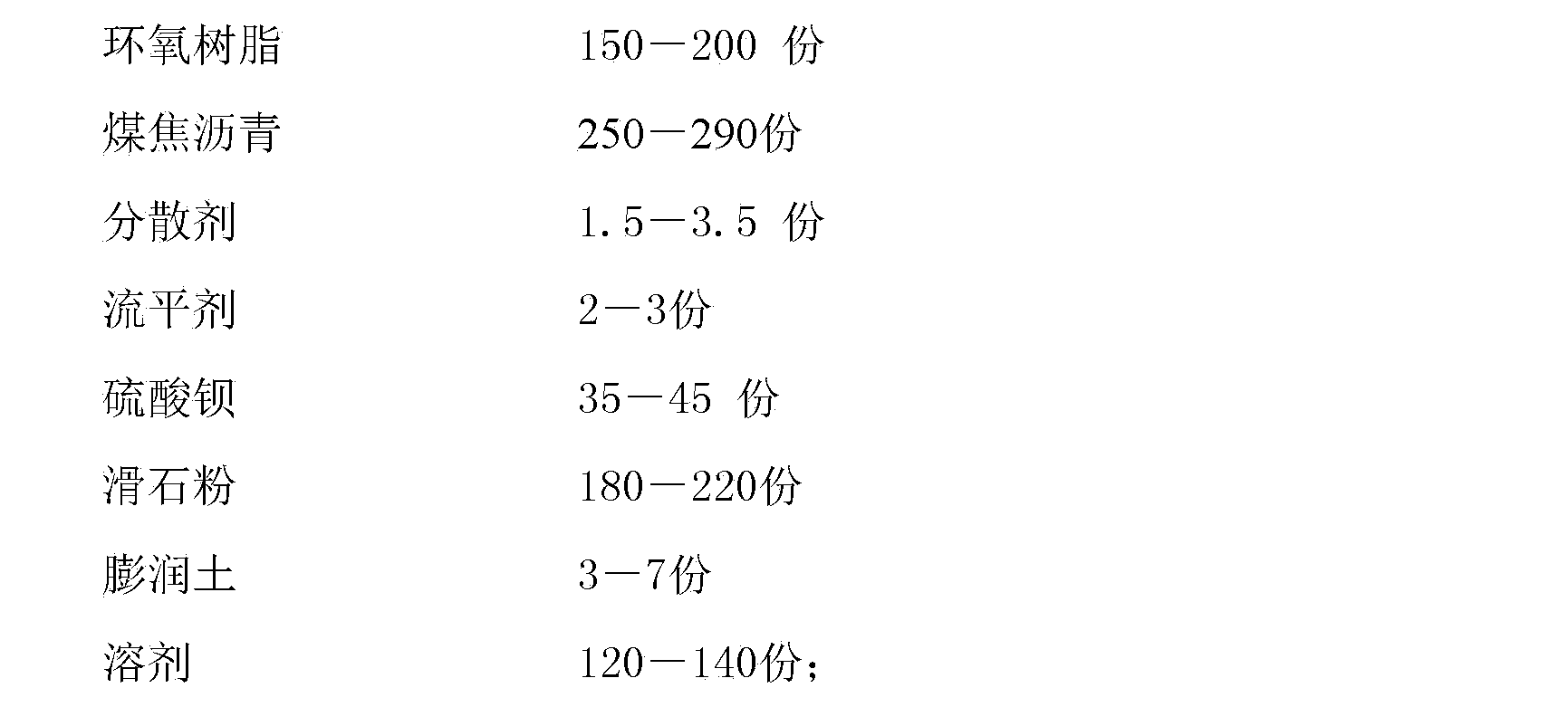

InactiveCN103360948AGood film formingImprove corrosion resistanceAnti-corrosive paintsEpoxy resin coatingsEpoxyBituminous materials

The invention provides a low temperature resistant winter epoxy coal tar pitch coating comprising a component A and a component B according to a weight ratio of 5-7:1. The component A is prepared from an epoxy resin, coal tar pitch, a dispersing agent, flatting agents, barium sulfate, a talcum powder, bentonite, and solvents in parts by weight; the component B comprises polyamide and xylene according to a weight ratio of 1:1. With combination of the epoxy resin and the coal tar pitch, not only excellent film-forming and corrosion resistance properties of the epoxy resin are exerted, but also the problems of high temperature flow and low temperature cold brittleness of a pitch material are better solved, the coating layer is resistant to low temperature and can be used in winter, and the service life of the coating is prolonged.

Owner:TIANCHANG YINHU PAINT

Mobile phone and manufacturing method of surface decorative layer of appearance piece thereof

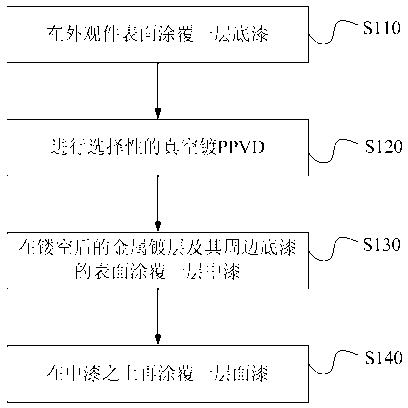

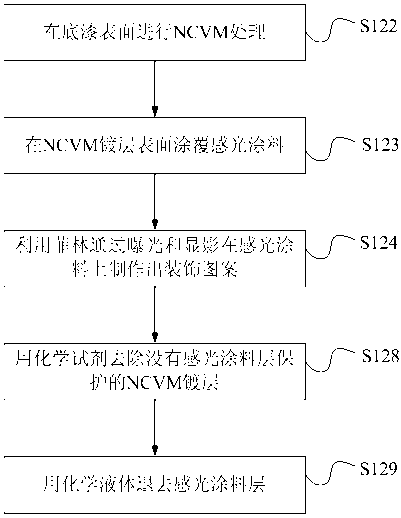

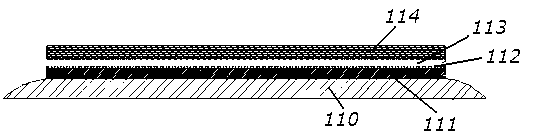

ActiveCN102843447AIncrease metallicEnhance the three-dimensional decorative effectTelephone set constructionsMetal coatingLaser etching

The invention discloses a mobile phone and a manufacturing method of a surface decorative layer of an appearance piece thereof. The manufacturing method comprises the following steps of: applying a priming paint layer on the surface of the appearance piece of the mobile phone; making a metal coating with needed pattern on the surface of the priming paint; applying a middle paint layer on the surface of the metal coating and the surface of the priming paint at the periphery of the metal coating; and applying a finish layer on the surface of the middle paint. With the PPVD (Patterned Physical Vapor Deposition) technology, the NCVM (Non-conductive Vacuum Metallization), the screen printing film and the spraying technology are combined together, the manufactured decorative layer has stereo decorative effects with high metallic characteristics, the grade of the products is improved, and the decorative layer is free from limitation of the shape of products and can be manufactured on the surface of a curve appearance piece; in comparison with gold stamping, the manufacturing method can manufacture the complex patterns which have thin lines and are not prone to fracture, and the metal layer cannot be corrugated, cannot bubble and has strong adhesive force; in comparison with the laser etching, the decorative layer manufactured by the manufacturing method has no carving trail, and provides no handfeel when being touched; and moreover, the equipment cost is low, and the production efficiency is high.

Owner:CHITWING DONGGUAN TECH

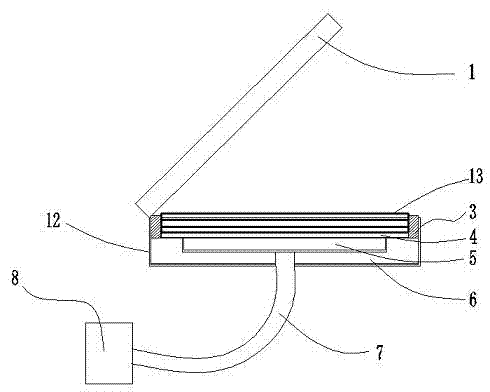

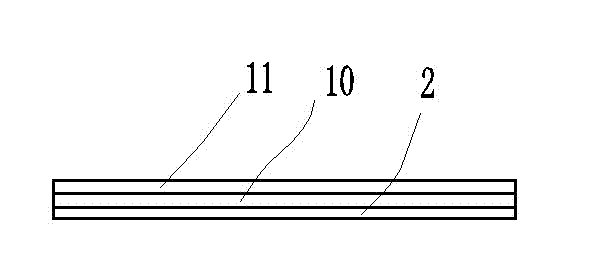

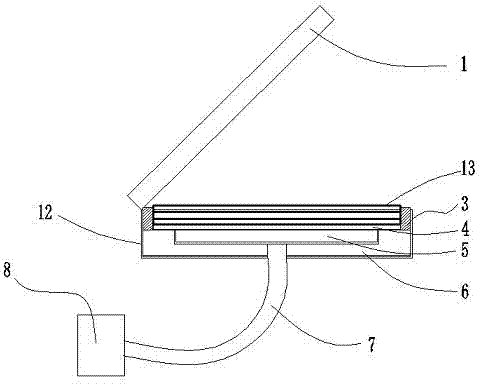

Polarization membrane and manufacturing method thereof, polarizer and optical laminate

Provided is a polarizing film which has few voids and is free of wrinkles and a method for manufacturing the same, and to provide a polarizing plate and an optical laminate. The polarizing film is obtained by treating a polyvinyl alcohol film in order of swelling treatment, dyeing treatment, boric acid treatment and rinse treatment, subjecting the film to uniaxial stretching in a boric acid treatment step and / or a step before the same and further alleviating the stretching of the film by 1 to 5% in the stretching direction in the at least one step after the stretching treatment. The polarizing plate is obtained by pasting a protective film to the at least one surface of the polarizing film. The optical laminate is obtained by pasting at least one kind selected from a retardation plate, a viewing angle improving film and a translucent reflection plate to the polarizing plate pasted with the protective film on the at least one surface.

Owner:SUMITOMO CHEM CO LTD

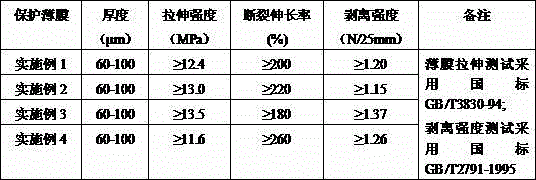

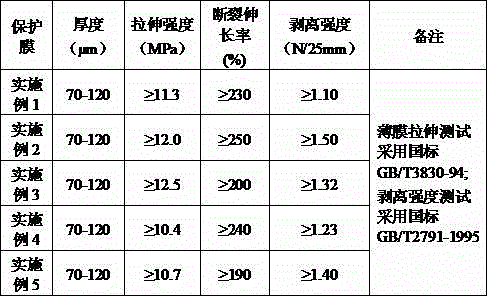

Manufacturing method of heat-shrinkable auto-adhesive vacuum plating protective film

ActiveCN104788867AViscosity stabilityGood adhesionFlat articlesFilm materialEnvironmentally friendly

The invention discloses a manufacturing method of a heat-shrinkable auto-adhesive vacuum plating protective film. The manufacturing method comprises the following steps: (1) firstly, synthesizing polyvinyl polyacrylate; (2) then, performing melt blending on the polyvinyl polyacrylate, polyethylene resin, a first initiator and an antioxidant according to a weight proportion, extruding and granulating, and finally performing extrusion film blowing and UV curing to obtain the heat-shrinkable auto-adhesive vacuum plating protective film. The manufactured protective film wraps a local part, required to be protected, of a vacuum plating component in a heat shrinkage way; in a vacuum plating process, the surface of the film does not crease and deform, the adhesion force is stable, the attachment property is good, the re-peeling performance is excellent, the phenomenon of adhesive residue is avoided, and the barrier and mechanical properties are excellent; the heat-shrinkable auto-adhesive vacuum plating protective film is an excellent vacuum plating protective film material which is non-toxic, environmentally-friendly, safe and practical.

Owner:WUXI HAITE NEW MATERIAL RES INST

Textile dyeing and finishing process capable of replacing yarn dyeing

InactiveCN101994194ATo achieve the effect of yarn-dyedBidirectionalWoven fabricsLiquid/gas/vapor textile treatmentYarnPolyester

The invention provides a textile dyeing and finishing process capable of replacing yarn dyeing. The process comprises steps of preparing, weaving, dyeing and finishing; and the yarn dyeing effect is achieved by matching cotton yarn and polyester staple fiber necked yarn and reasonably matching yarn density, textile density and arrangement and combination of weft and warn yarns. The process has a simple procedure, low cost and diverse dyed colors; meanwhile, the woven textile has the characteristics of high elasticity and resilience, strong fabric, crease resistance, high conformality and strength, durability and high light fastness.

Owner:WANG TAI CHINA

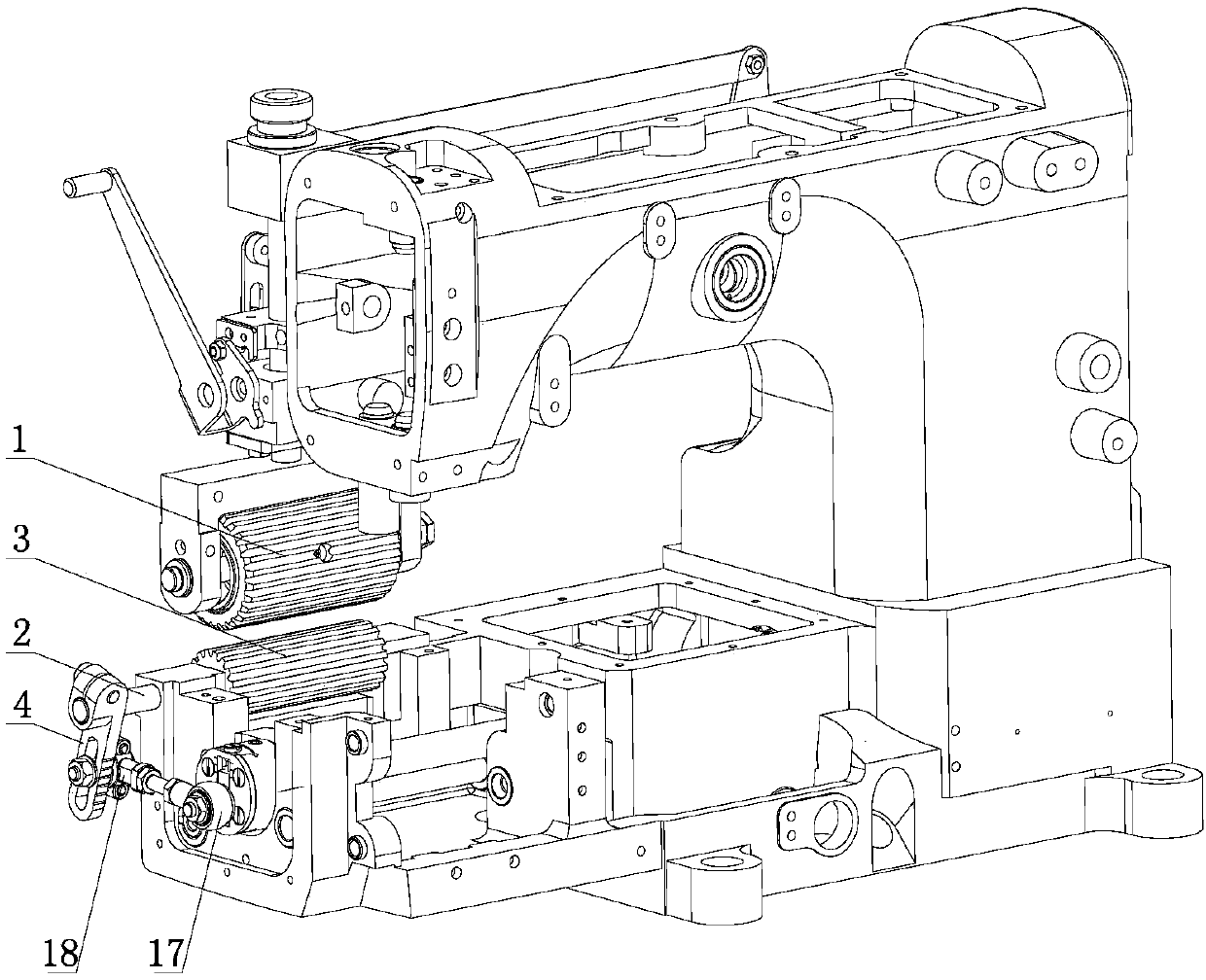

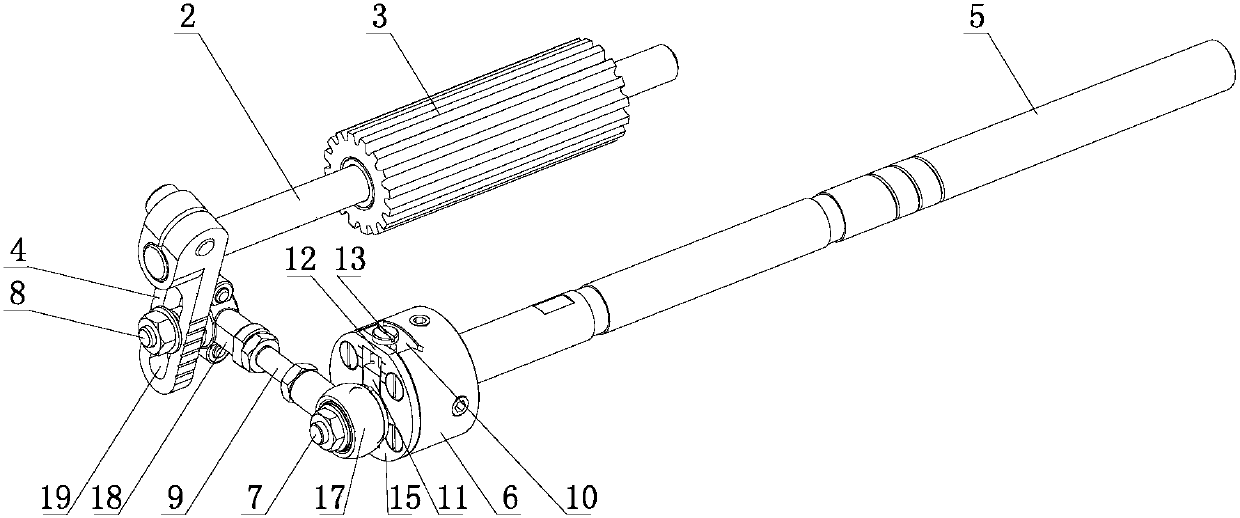

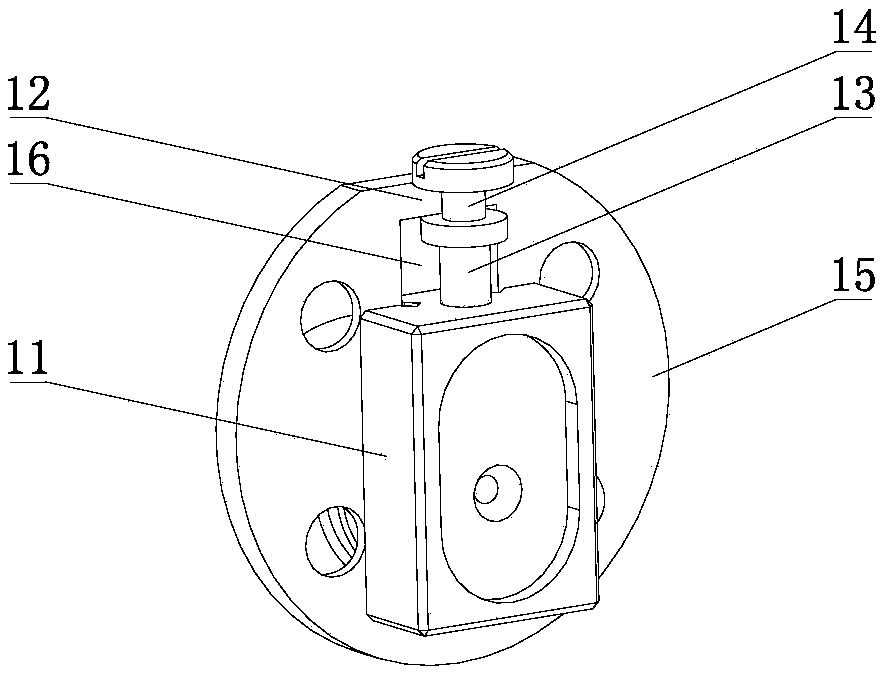

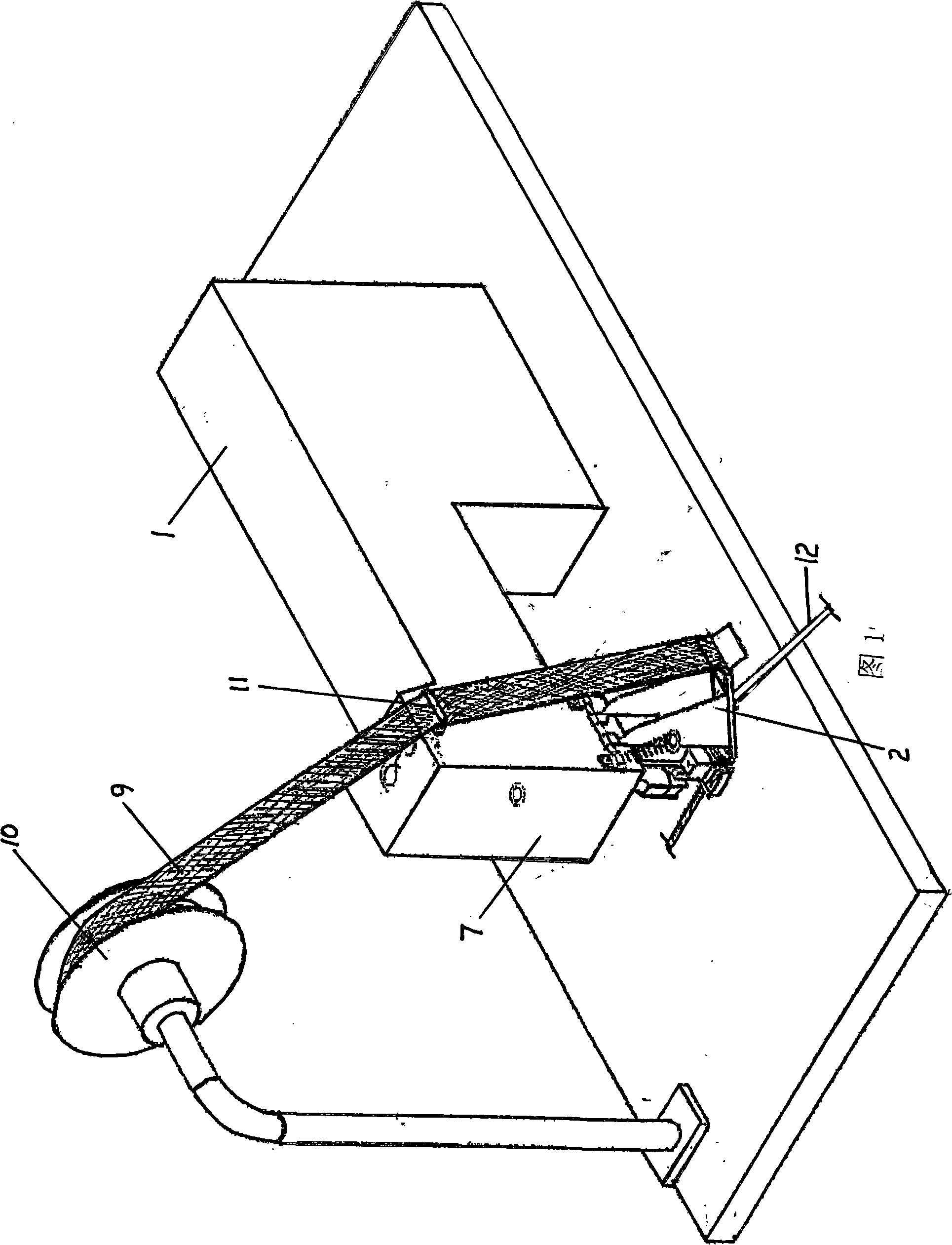

Synchronous feeding structure of lower traction wheel

ActiveCN107805889AAdjustable swing angleNo wrinkleWork-feeding meansSewing-machine control devicesEngineeringMultiple layer

The invention provides a synchronous feeding structure of a lower traction wheel, and belongs to the technical field of sewing machines. The problem that an existing sewing machine only uses upper andrear traction wheels for feeding, and accordingly when multiple layers of sewing materials are conveyed, the upper and lower layers of sewing materials are always staggered. The synchronous feeding structure of the lower traction wheel structurally comprises a rotating shaft and the lower traction wheel, the rotating shaft penetrates through a workbench of the sewing machine and is parallel to the upper traction wheel, the rotating shaft is coaxially sleeved with the lower traction wheel, the lower traction wheel is located under the upper traction wheel and opposite to the upper traction wheel, a swing rod is fixed to the rotating shaft, a transmission assembly used for driving the swing rod to swing when a main shaft rotates is arranged between the swing rod and the main shaft of the sewing machine, and a one-way assembly used for limiting the lower traction wheel to rotate in one direction all the time when the swing rod swings is arranged between the rotating shaft and the lower traction wheel. The synchronous feeding structure has the advantages that the structural design is reasonable, the application range is wide, and the sewing materials are not staggered or wrinkled whenmultiple layers of sewing materials are sewn.

Owner:JACK SEWING MASCH CO LTD

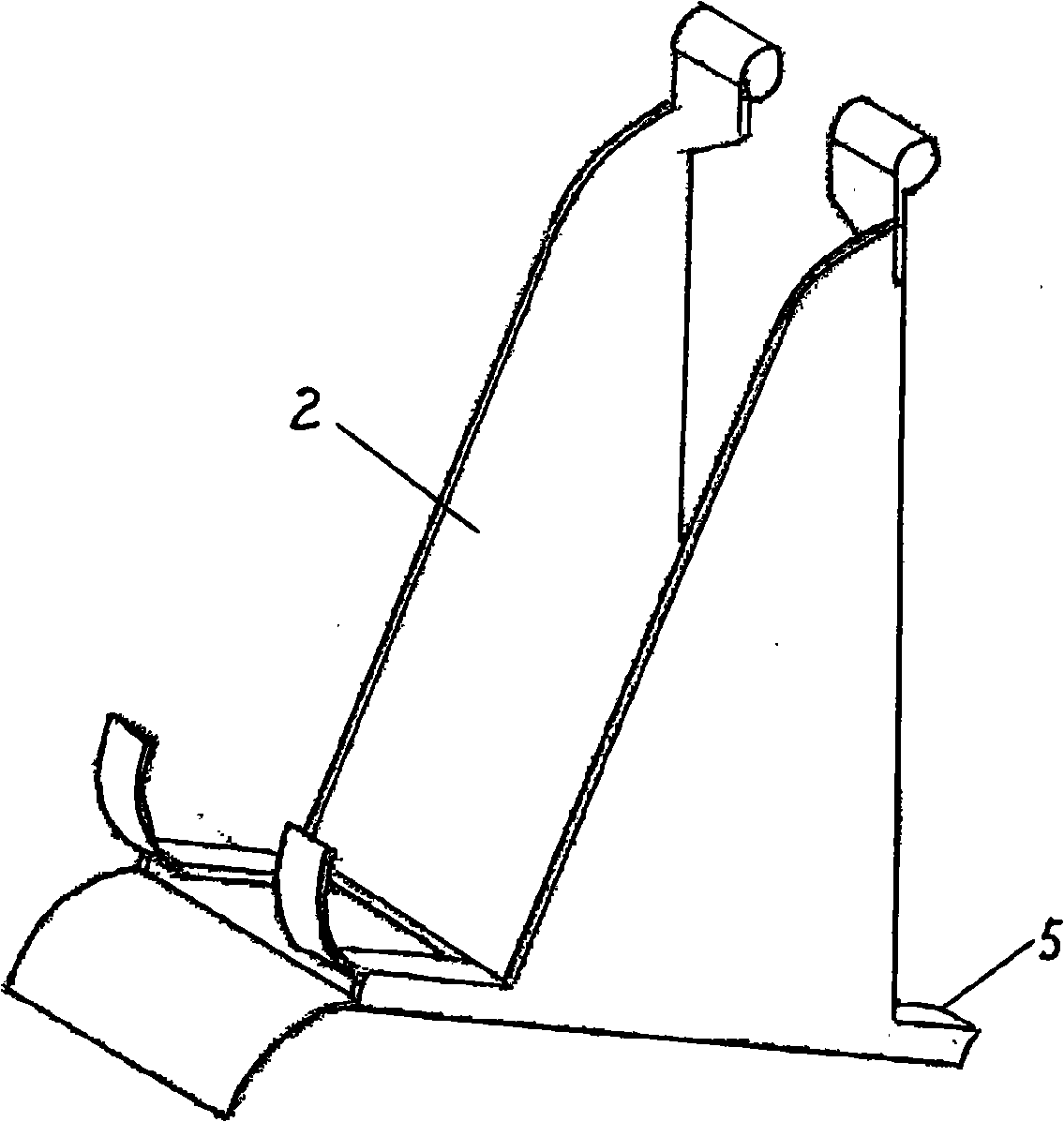

Sewing machines for threading and string drawing on waist of garment

InactiveCN101280489AEasy to processNeat stitchesWork-feeding meansPressersTechnical standardEngineering

The invention relates to a threading sewing machine on the upper and middle waste of clothing, which comprises a double needle flat bed sewing machine, a threading belt transmission rack linked with the nose of the double needle flat bed sewing machine and a threading hole used for the threading and arranged on the bottom of the threading belt transmission rack. The lower end of the threading belt transmission rack and a holding foot of the double needle flat bed sewing machine are correspondingly provided with a belt mouth. Both ends of the pressure foot are provided with a check block, and the space between two check blocks is equal to the width of the belt. With the adoption of the invention, the process of threading is much simpler and easier, in which the regular trails and the uniformity without wrinkles are achieved. Therefore, the technical standards are ensured, and the work efficiency is improved by more than 3 times.

Owner:JIHUA 3502 PROFESSIONAL GARMENT

Antibacterial radiation-proof fabric

InactiveCN105774084AImprove antibacterial propertiesReduce exposureLayered productsClothingsFiberYarn

The invention discloses an antibacterial radiation-proof fabric which comprises an outer layer and an inner layer, wherein the outer layer and the inner layer are both made of wraps and wefts in an interwoven manner; the wraps and the wefts of the outer layer are all composite yarns; the composite yarns take spandex yarns as core yarns; the core yarns are wrapped by nano titanium dioxide catalyst antibacterial fiber; the inner layer is of a plain knitting structure; the wraps and the wefts of the inner layer are twisted yarns; the twisted yarns comprise modal, wool yarns, Lycra and silver fiber which are twisted together. The nano titanium dioxide catalyst antibacterial fiber of the outer layer of the antibacterial anti-radiation fabric has an excellent antibacterial effect and can reduce contact between bacteria and skin; the silver fiber of the inner layer has a remarkable anti-radiation effect and can enhance the resistance; meanwhile the antibacterial anti-radiation fabric is relatively good in warm keeping property and air permeability, and free of wrinkle and deformation.

Owner:JURONG XINGYUN TEXTILE CO LTD

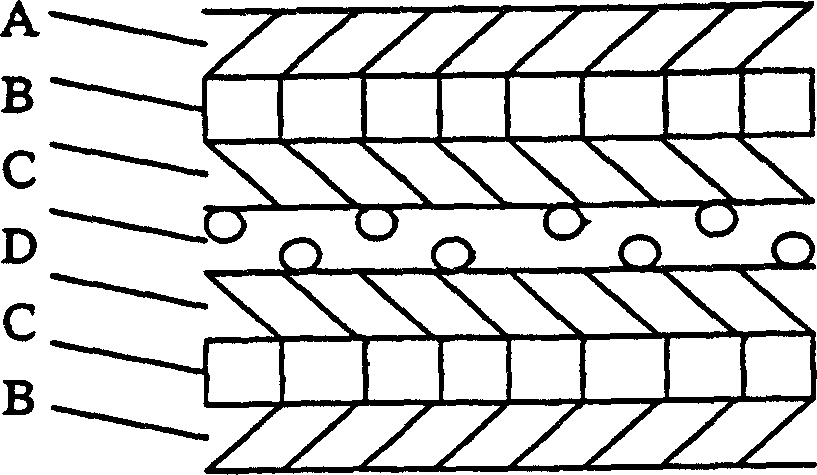

Broken elastic filament elastic yarn elastic fabric

The invention belongs to the field of spinning and provides a new elastic fabric and in particular provides a broken elastic filament elastic yarn elastic fabric. The elastic fabric is mainly characterized by using broken elastic filament elastic yarns as wefts, using common fiber yarns as warps or using broken elastic filament elastic yarns as wefts and warps to weave the elastic fabric with various patterns. The elastic fabric has the beneficial effects that the elastic fabric is convenient to weave; the fabric cover does not have wrinkles or flaws; the patterns are clear; the elastic fabric has soft hand feel and bones; compared with the existing polyurethane core-spun elastic yarn elastic fabrics, the elastic fabric further provided by the invention has comfortable elasticity, resilience and shape maintaining property; and the grade and quality of the elastic fabric are improved.

Owner:HENAN XINYE TEXTILE

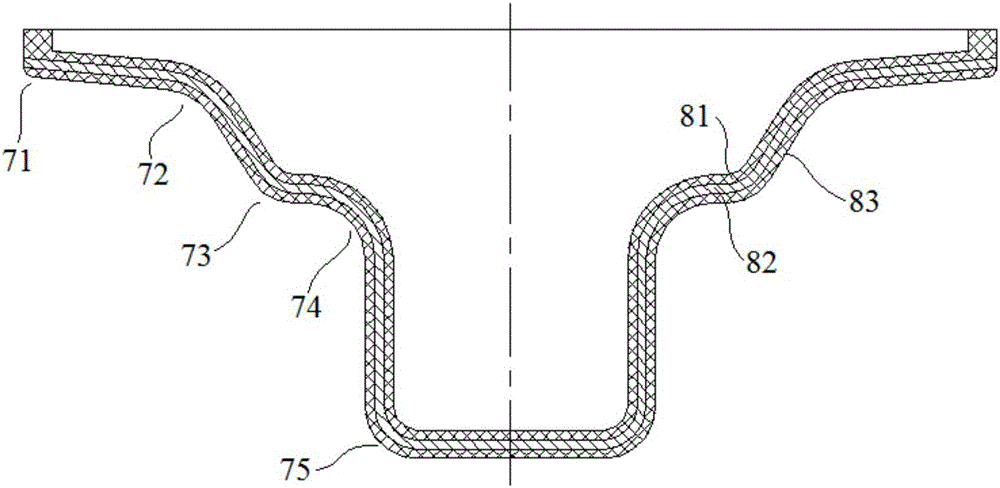

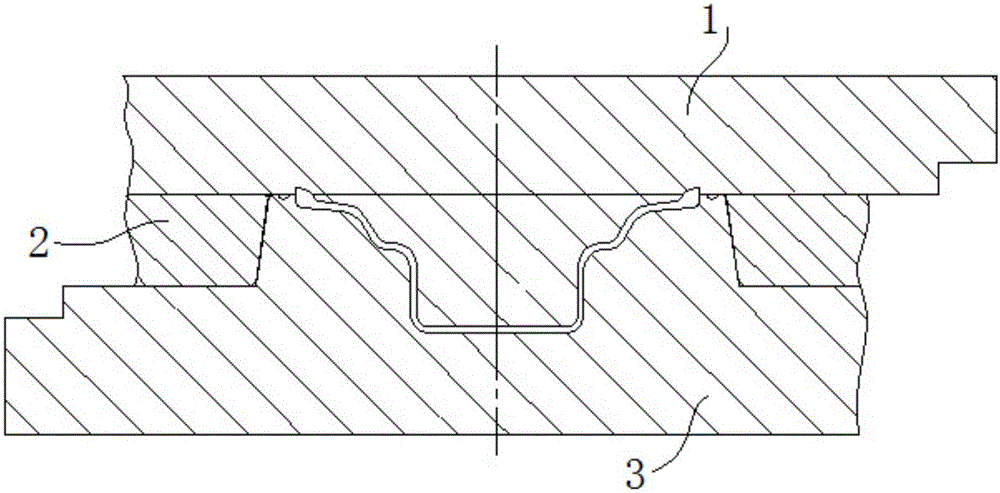

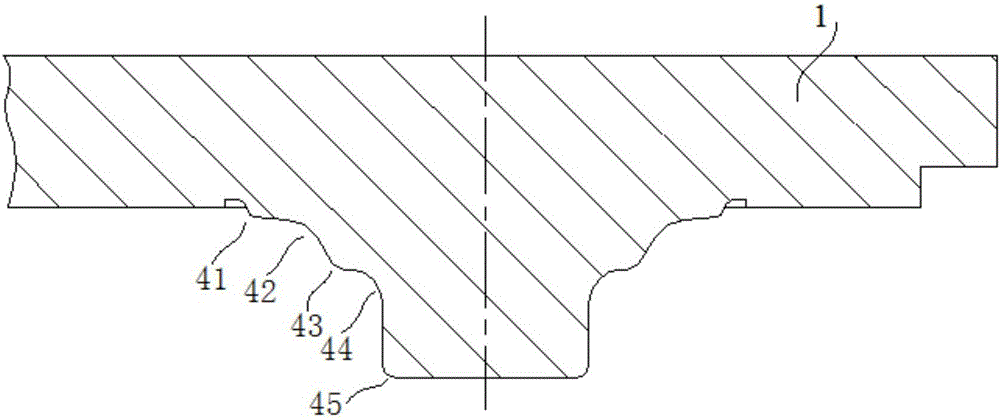

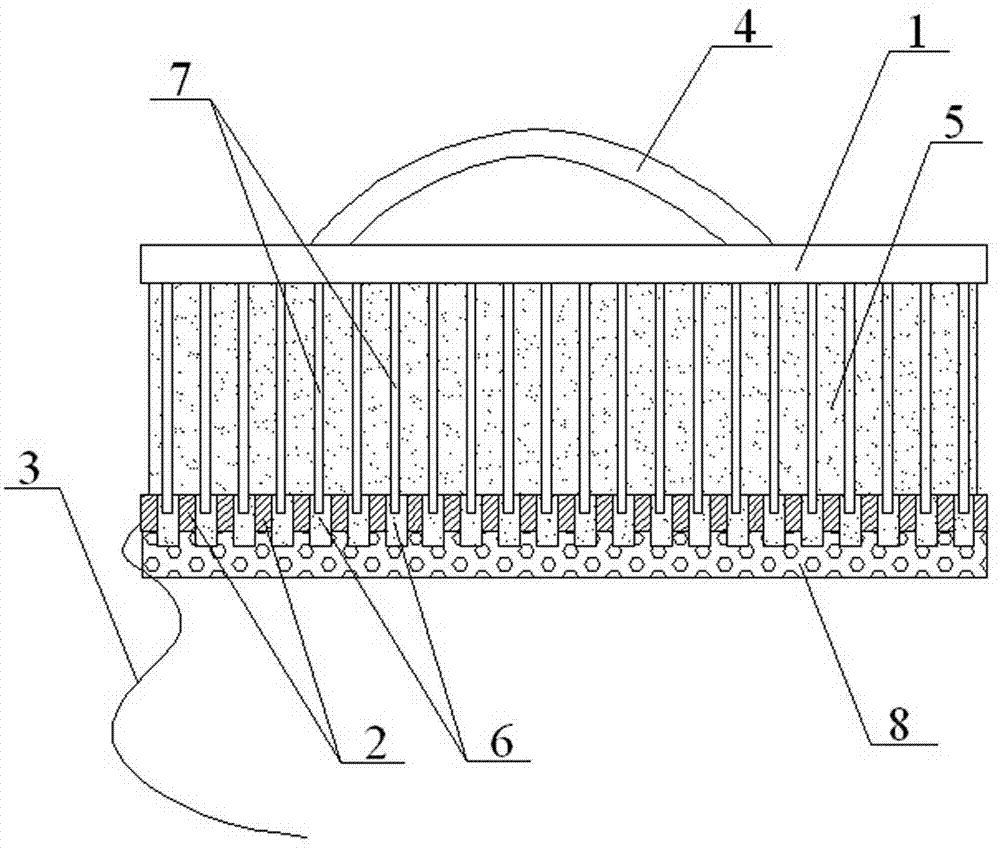

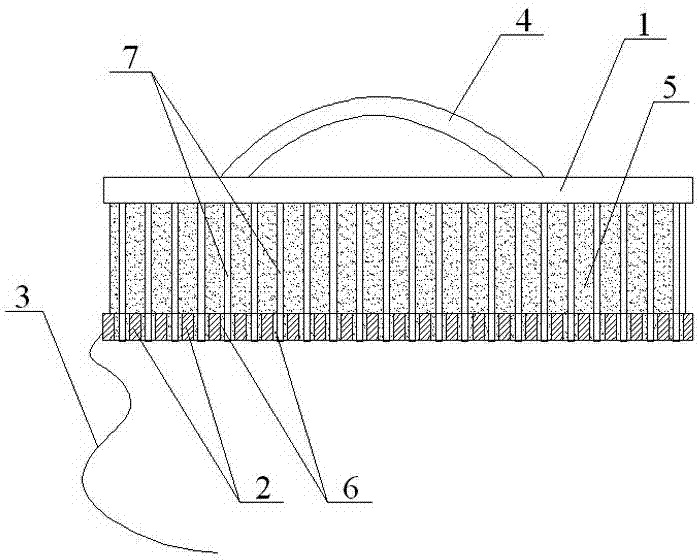

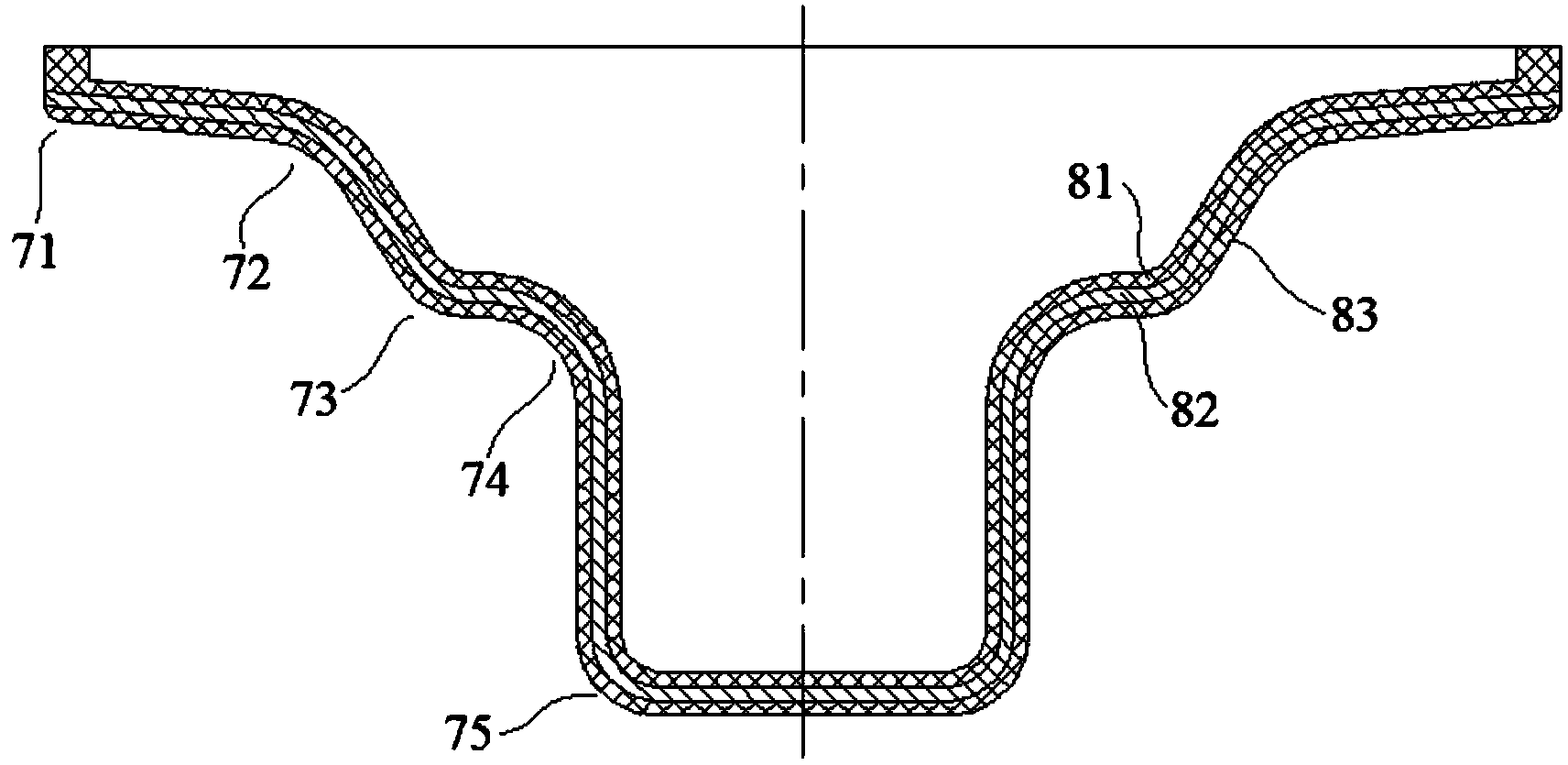

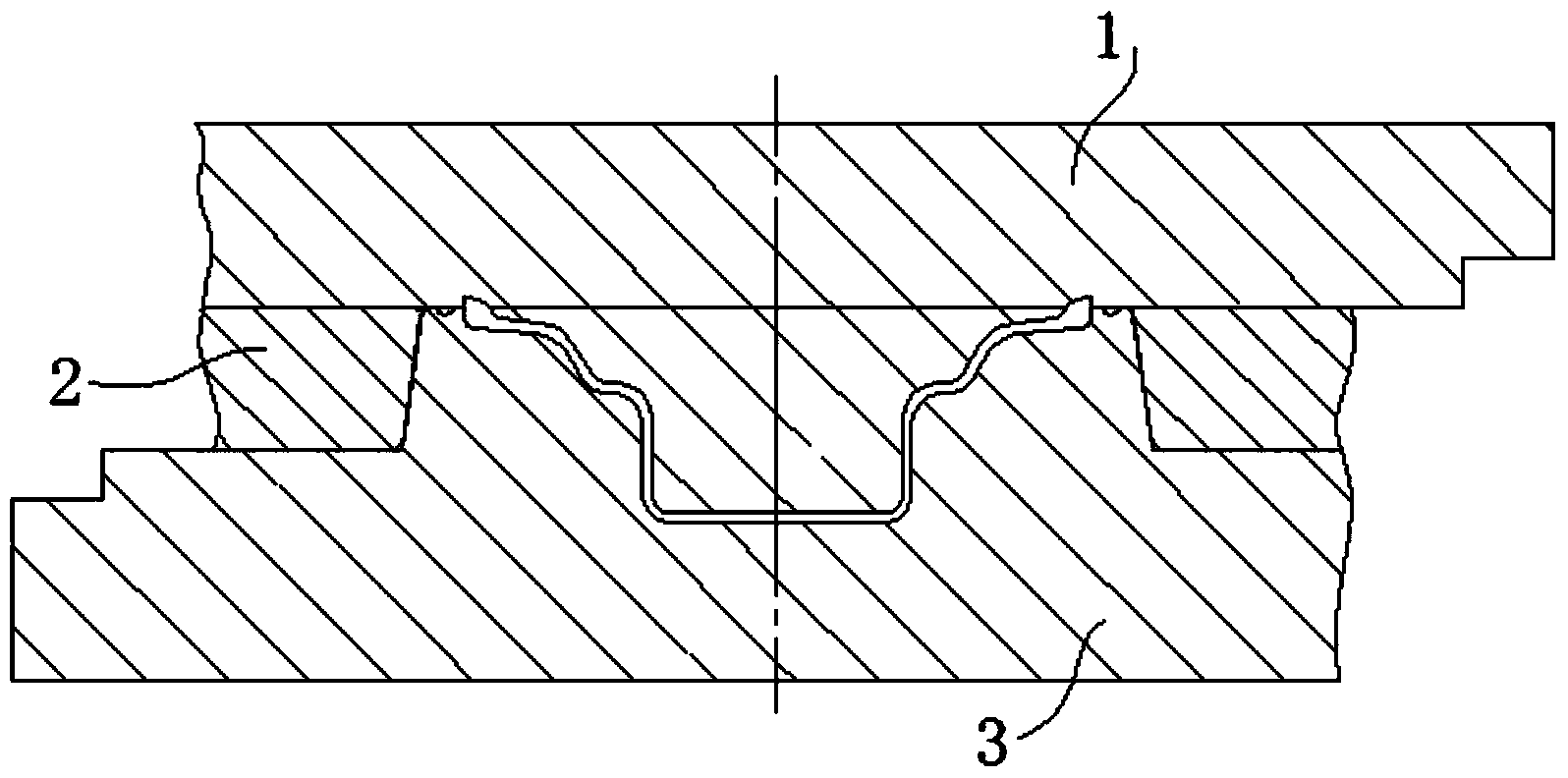

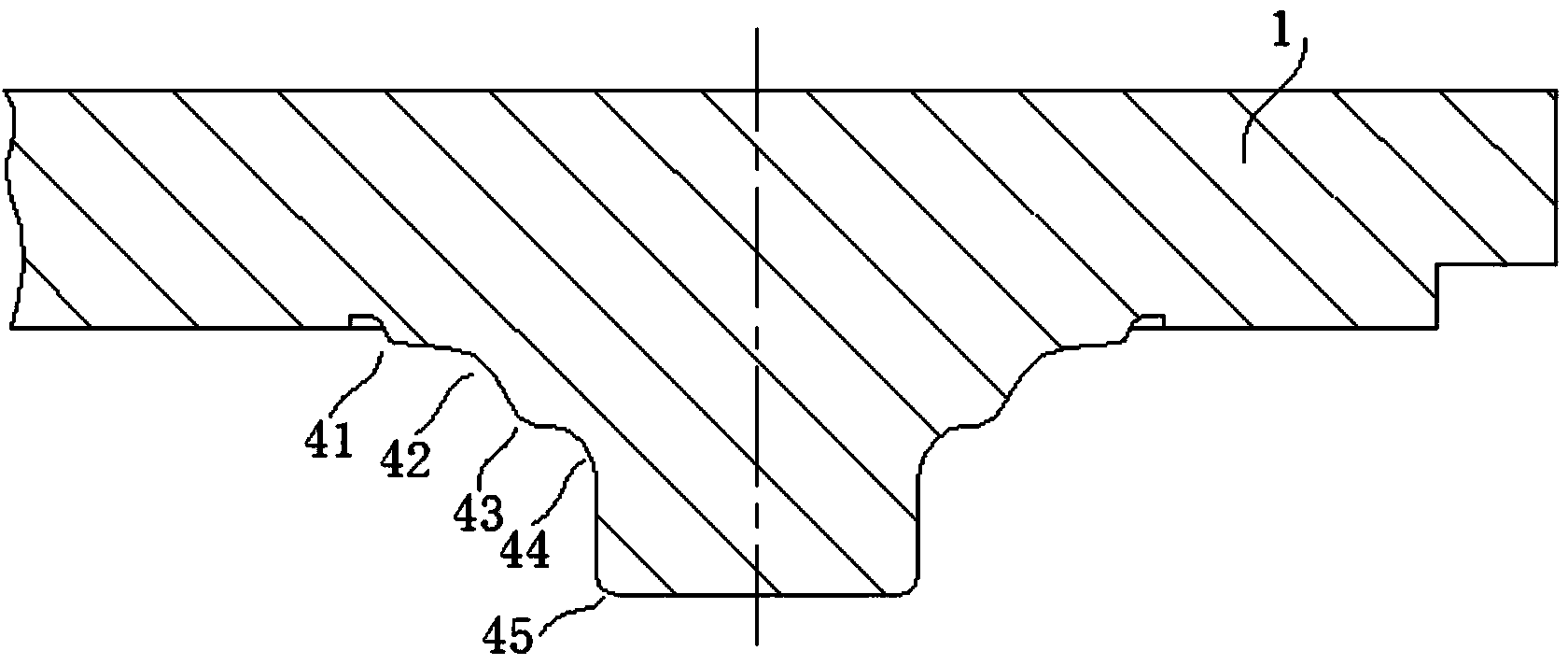

Method for manufacturing specially-shaped saturated butadiene-acrylonitrile rubber-fiber diaphragm

The invention discloses a vulcanization forming mold and manufacturing method of a specially-shaped saturated nitrile rubber laminated cloth diaphragm, and belongs to the technical field of rubber laminated cloth products. The vulcanization forming mold comprises an upper die of the mold, a middle die of the mold and a lower die of the mold, wherein a rotary body protruding outwards is arranged at the lower part of the upper die of the mold; a trapezoidal hole in a vertical direction is formed in the middle die of the mold; an arc section is formed on the bottom of the side surface of the trapezoidal hole; a round table body protruding outwards is arranged at the upper part of the lower die of the mold; the periphery of the round table body of the lower die of the mold is sleeved with the middle die of the mold; the middle die of the mold is in clearance fit with the lower die of the mold; a concave die cavity is formed inside the round table body; the structure of the die cavity is matched with the rotary body of the upper die of the mold. The manufacturing method comprises the following manufacturing steps: preparing sizing materials of fabric cloth and a diaphragm body; pressing the fabric laminated cloth by the middle die of the mold, and tightening the fabric laminated cloth; and vulcanization and forming. By adopting the vulcanization forming mold and the manufacturing method thereof, the problems of wrinkling of the specially-shaped saturated nitrile rubber laminated cloth diaphragm product and fracture of the laminated cloth are solved, and the qualified rate of the specially-shaped saturated nitrile rubber laminated cloth diaphragm is increased.

Owner:南京金三力高分子科技有限公司

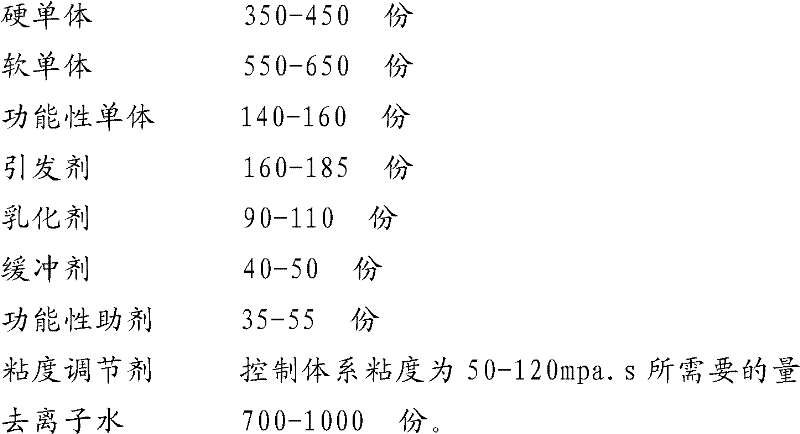

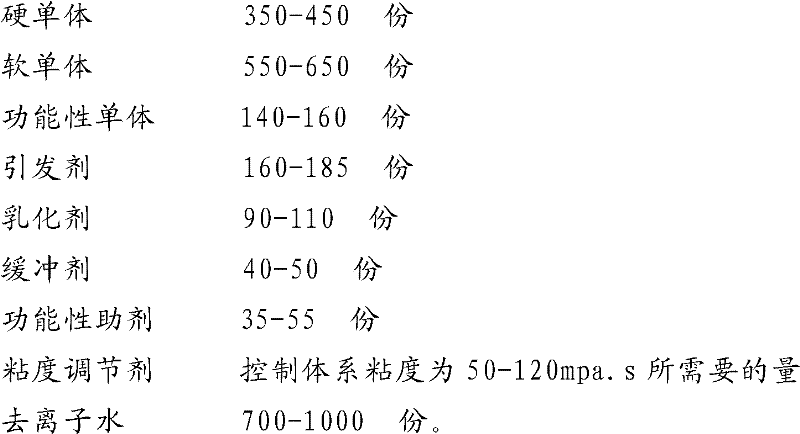

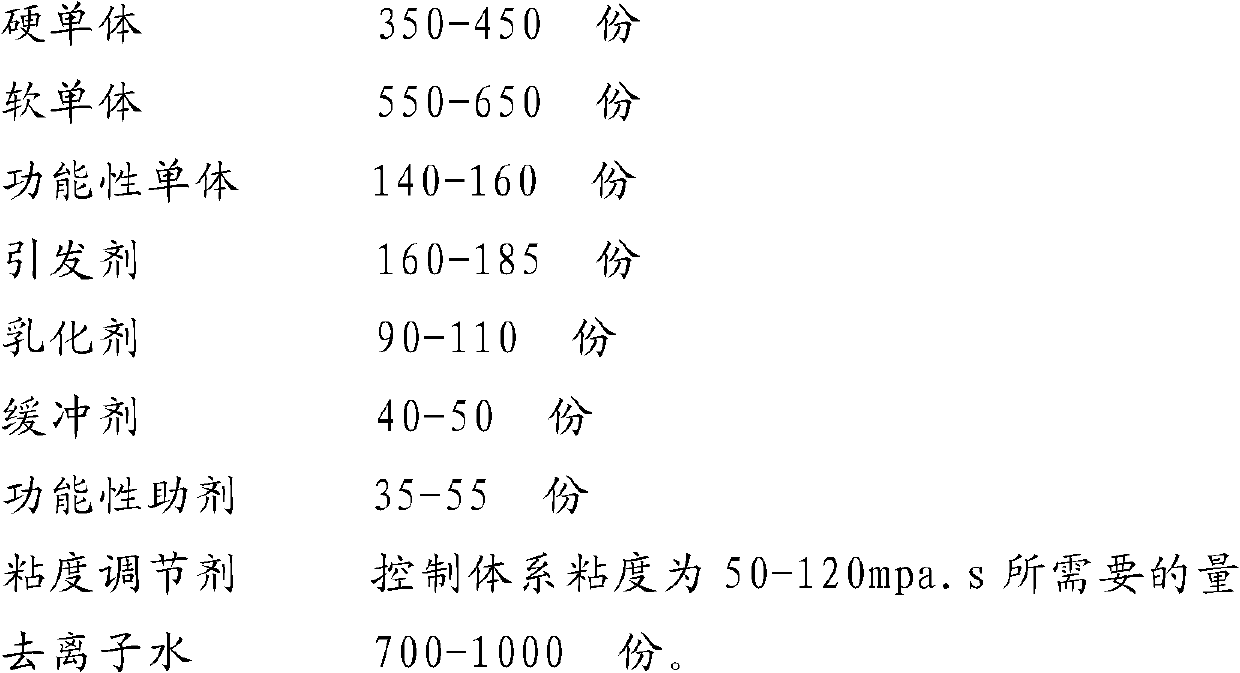

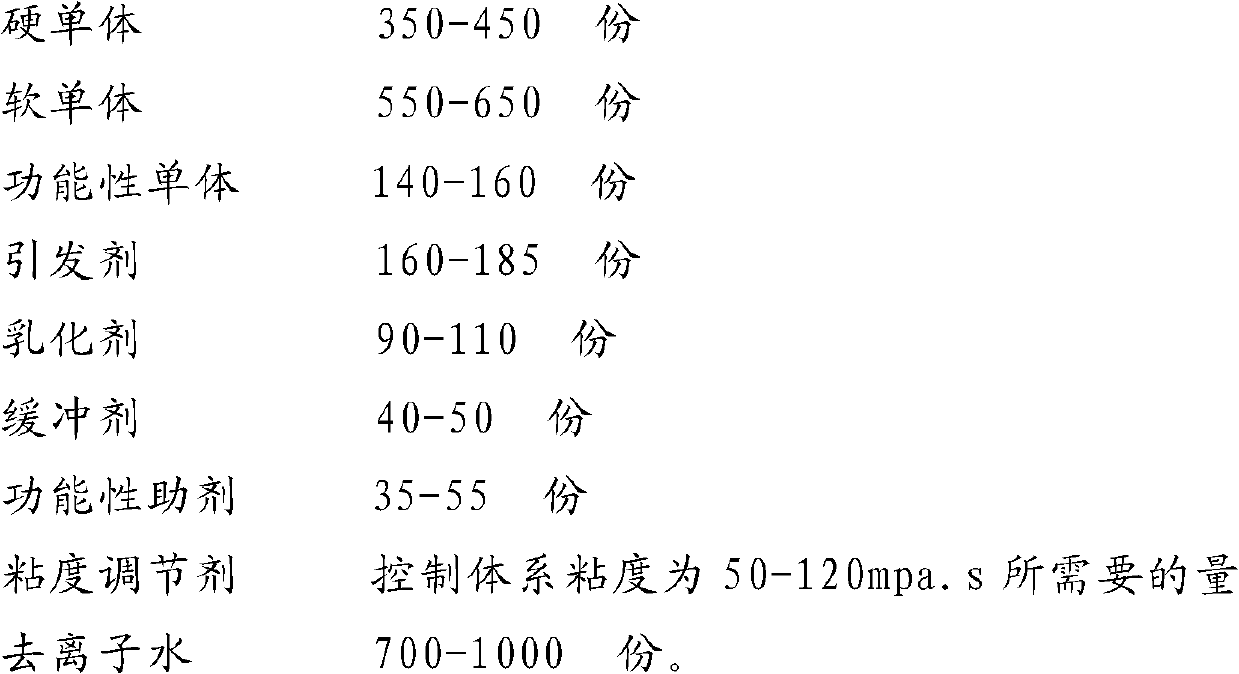

Fine pasting glue and preparing process thereof

ActiveCN102559103AFast dryingHigh production efficiencyAmide/imide polymer adhesivesEster polymer adhesivesFunctional monomerBuffering agent

The invention relates to fine pasting glue, which is polymerized by the following raw materials of a hard monomer, a soft monomer, a functional monomer, an initiating agent, an emulsifying agent, a buffering agent, a functional auxiliary agent, a viscosity regulator and deionized water. The fine pasting glue and a preparing process thereof also provides a process for preparing the fine pasting glue. The fine pasting glue and the preparing process thereof have the advantages in that the fine pasting glue is of green environmental protection and good for health and contains no bad odor and harmful substances such as phthalic acid esters plasticizer, heavy metals and the like; as the fine pasting glue has high solid content and high tenacity, products pasted are wrinkle-free and uneasy to deform under the normal temperature, and the fine pasting glue is rapid in drying, high in yielding efficiency, and good in scouring and cleaning. The adhesive residue on the facing can be easily cleaned by a wet cloth so that an attractive appearance of a substrate facing is kept; the coating is good in performance so that the glue can achieve rapid leveling and coating on the substrate; and finally the pasted products have a good bonding strength and can keep the glue-bonded surface solid and durable.

Owner:上海奇想青晨新材料科技股份有限公司

Manufacturing method of self-adhesive protective film for vacuum plating

The invention discloses a manufacturing method of a self-adhesive protective film for vacuum plating. The manufacturing method comprises the following steps: weighing the following raw materials in parts by weight: 100 parts of polyethylene resin, 2-15 parts of acrylate monomer, 0.2-5.0 parts of a first processing additive, and 0.2-1.0 part of a second processing additive; firstly, dissolving the acrylate monomer and the first processing additive in a solvent to obtain a solution, then uniformly mixing the solution with polyethylene resin and the second processing additive in a blender, realizing in-situ grafting and extrusion granulation in an extruder, finally film-forming the prepared grafted granules through a blow molding or tape-casting method directly. The manufacturing method is simple in process; the manufactured protective film is vacuum-plated in a local position, needing to be protected, of a part; during vacuum plating, the surface of the film has no wrinkle and no deformation, is stable in adhesion, good in attachment property and re-peeling performance, has no residue phenomenon; the protective film is excellent in barrier and mechanical properties, non-toxic, environment-friendly, safe and practical, and is an excellent vacuum-plated protective film material.

Owner:WUXI HAITE NEW MATERIAL RES INST

Thermal insulation coating for building exterior wall

InactiveCN104592854AIncreased durabilityNot easy to fall offAnti-corrosive paintsEmulsionThermal insulation

The invention discloses a thermal insulation coating for a building exterior wall. The thermal insulation coating for the building exterior wall is prepared from the following raw materials in parts by weight: 7-9 parts of a white emulsion, 5-6 parts of magnet powder, 7-9 parts of white lime, 10-12 parts of titanium dioxide, 10-12 parts of sodium sulfate, 9-12 parts of bauxite, 12-19 parts of phenolic resin, 5-6 parts of ethyl silicate and 12-19 parts of kaolin. The thermal insulation coating for the building exterior wall disclosed by the invention has excellent thermal insulation property after being constructed, and has good adhesiveness and anti-corrosion property.

Owner:王红玉

Paper ironing machine

InactiveCN104120632AConsistent drying speedGood cooperationOld paper after-treatmentWater storage tankWetting

A paper ironing machine comprises a water storage box and a heating ironing plate. A heating device is arranged in the heating ironing plate. The top of the water storage box is provided with an operation handle and a water injection opening. The heating ironing plate is a rectangular plate with a plurality of through holes. A sponge layer is arranged between the water storage tank and the heating ironing plate, and the bottom of the sponge layer is provided with a plurality of extension parts that can stretch out the through holes. The lower end surface of the water storage tank is provided with a plurality of small holes, each small hole is connected to a communicating pipe, each communicating pipe is arranged in a through hole after going through the sponge layer and the extension part, and when the sponge layer is in an uncompressed state, the position of the lower opening of each communicating pipe is higher than that of the lower end surface of the heating ironing plate. The paper ironing machine can quickly absorb water from wet paper to dry the paper, then press and recover the paper by utilizing the sponge's characteristics of water absorbing ability, breathability, and good deformability. Moreover, the paper ironing machine can flatten wrinkled paper by wetting, heating, and pressing the paper. The paper processed by the machine is flat and wrinkle resistant, and has a good recovery degree.

Owner:LUOYANG INST OF SCI & TECH

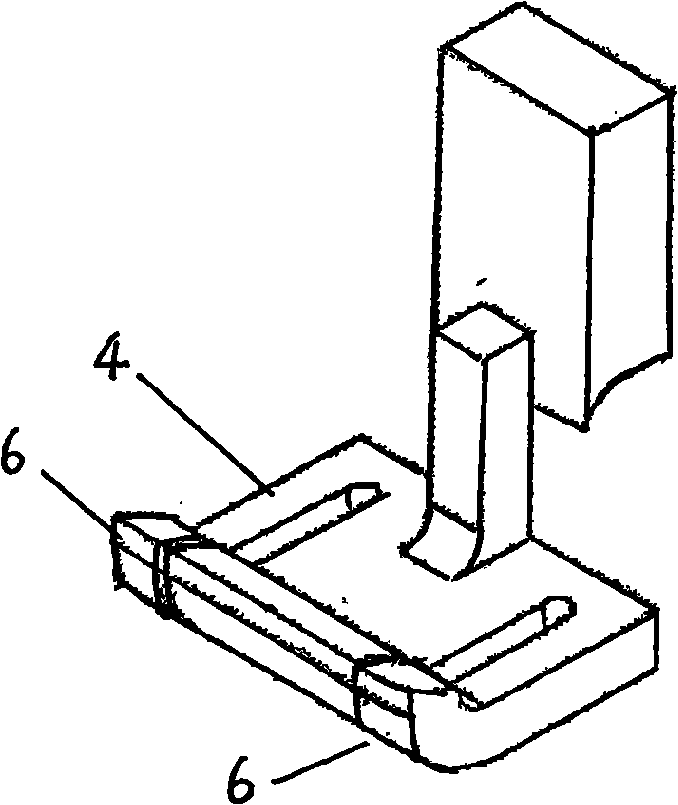

Vulcanization forming mold and manufacturing method of specially-shaped saturated nitrile rubber laminated cloth diaphragm

The invention discloses a vulcanization forming mold and manufacturing method of a specially-shaped saturated nitrile rubber laminated cloth diaphragm, and belongs to the technical field of rubber laminated cloth products. The vulcanization forming mold comprises an upper die of the mold, a middle die of the mold and a lower die of the mold, wherein a rotary body protruding outwards is arranged at the lower part of the upper die of the mold; a trapezoidal hole in a vertical direction is formed in the middle die of the mold; an arc section is formed on the bottom of the side surface of the trapezoidal hole; a round table body protruding outwards is arranged at the upper part of the lower die of the mold; the periphery of the round table body of the lower die of the mold is sleeved with the middle die of the mold; the middle die of the mold is in clearance fit with the lower die of the mold; a concave die cavity is formed inside the round table body; the structure of the die cavity is matched with the rotary body of the upper die of the mold. The manufacturing method comprises the following manufacturing steps: preparing sizing materials of fabric cloth and a diaphragm body; pressing the fabric laminated cloth by the middle die of the mold, and tightening the fabric laminated cloth; and vulcanization and forming. By adopting the vulcanization forming mold and the manufacturing method thereof, the problems of wrinkling of the specially-shaped saturated nitrile rubber laminated cloth diaphragm product and fracture of the laminated cloth are solved, and the qualified rate of the specially-shaped saturated nitrile rubber laminated cloth diaphragm is increased.

Owner:南京金三力橡塑有限公司

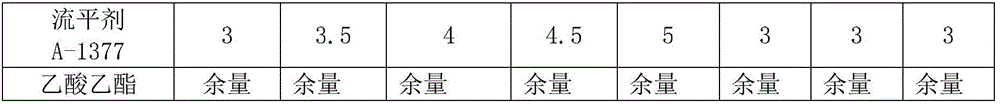

Preparation method of antirust paint for power distribution cabinet

InactiveCN106010238AImprove adhesionHigh hardnessAntifouling/underwater paintsPaints with biocidesEthyl acetateUltrasonic dispersion

The invention relates to a preparation method of a metal antirust paint, and in particular, relates to the preparation method for the antirust paint for a power distribution cabinet, wherein the method comprises the following steps: (1) adding chlorinated rubber, a film-forming auxiliary agent, a filler, a paint film self-cleaning agent and a defoaming agent into an ethyl acetate solution, heating to 40-50 DEG C, carrying out ultrasonic dispersion, adding inositol hexaphosphate and dipropylene glycol dibenzoate, and stirring for 20-30 min; (2) rising the temperature to 50-60 DEG C, adding modified alkyd resin, fluorocarbon resin and glass resin, and stirring for 40-50 min; and (3) adding a leveling agent, stirring, and dispersing to obtain the antirust paint. The prepared antirust paint has the advantages of wide use scope, high adhesive force, excellent weatherability, high hardness after curing, good wear resistance, no discoloring, no wrinkling, difficult peeling, sun-scorching and rain-drenching resistance, good decoration, and excellent anti-rust and self-cleaning effects; and the preparation method is simple, low in cost, and suitable for mass production.

Owner:仪征恒运电器有限公司

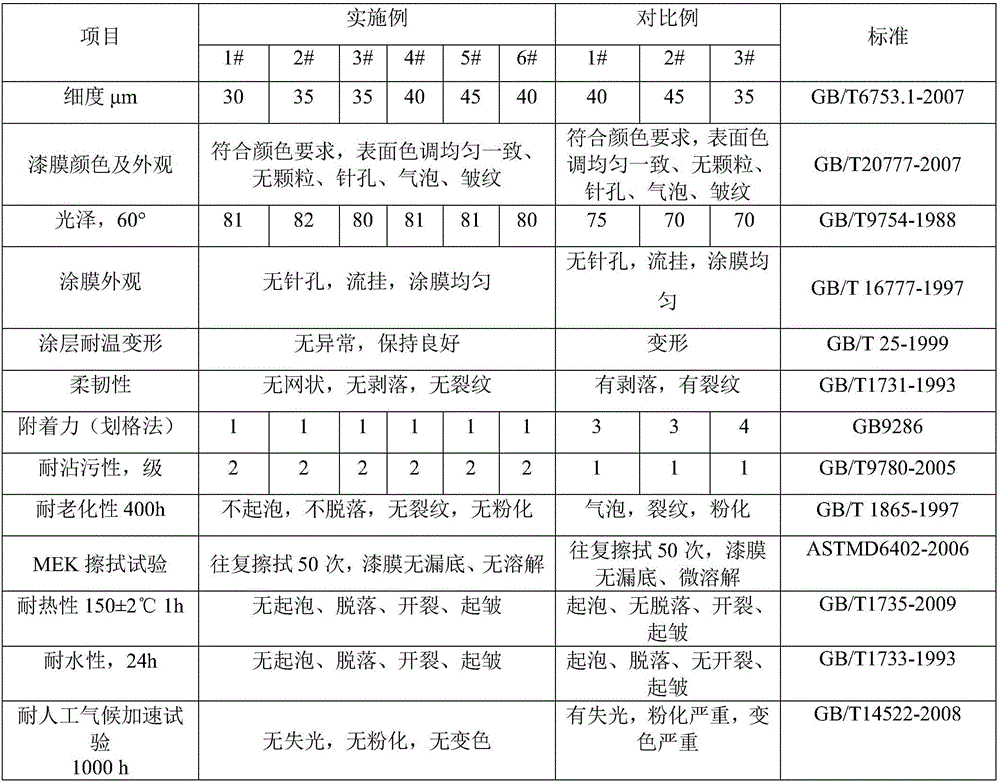

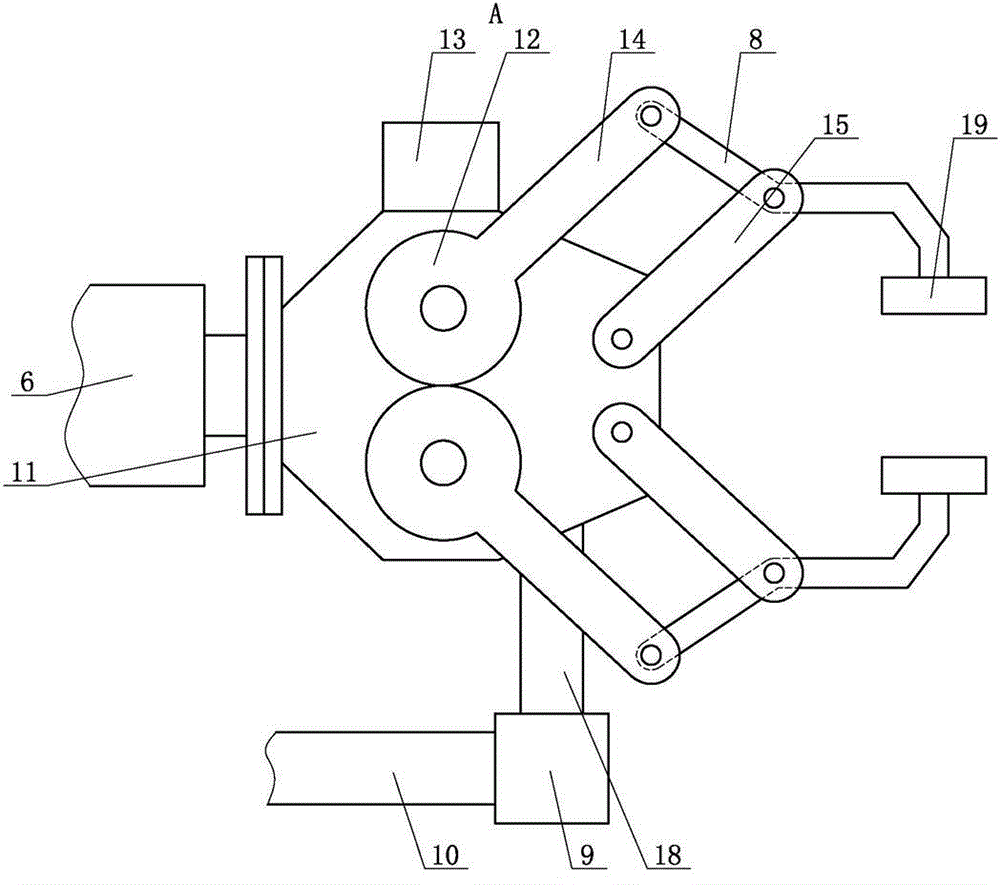

Obstacle removal and weeding robot for electric equipment fence

ActiveCN104798761APrevent short circuit to groundAvoid damagePolyurea/polyurethane coatingsWeed killersForeign matterEngineering

The invention relates to an obstacle removal and weeding robot for an electric equipment fence. The obstacle removal and weeding robot comprises a trolley, wherein a controller, a water tank and a water pump are arranged on the trolley; a remote receiving module is arranged on the controller; a weeding spraying agent is arranged in the water tank; a fixing seat is arranged at the front end of the trolley; a second motor is arranged at the fixing seat; a fixing plate is arranged at an output shaft of the second motor; two engaged gears are arranged on the fixing plate; first connecting plates are respectively arranged on the gears; each first connecting plate is hinged to one end of a mechanical arm; a clamping sheet is arranged at the other end of each mechanical arm; a second connecting plate is hinged to the middle part of each mechanical arm. The obstacle removal and weeding robot has the advantages that by utilizing remote controlling, the trolley is moved within the range of the electric equipment fence; by controlling the mechanical arms to do reciprocating movement, the function of removing foreign matters is realized; by controlling the water pump, the weeding spraying agent in the water tank is sprayed out through a spray nozzle, so the weeds in the electric equipment fence can be removed, and the short-circuiting of high-voltage equipment to ground is avoided.

Owner:STATE GRID CORP OF CHINA +1

Processing method of fluoride-coated antibacterial film material

InactiveCN103965494AFlat and smooth appearanceHas a bactericidal effectCoatingsPolymer scienceNitrile rubber

The invention belongs to the machine manufacturing field and specifically relates to a processing method of a fluoride-coated antibacterial film material. The fluoride-coated antibacterial film material is formed by using a polytetrafluoroethylene thin film, a nitrile rubber gasket and an antibacterial compound; the polytetrafluoroethylene thin film is activated previously, and then coated with the antibacterial compound in a working chamber at a temperature of 20-28 DEG C and relative air humidity of less than 65%, next, the coated polytetrafluoroethylene thin film is held down and pasted to the surface of the nitrile rubber gasket, air between the pasted layers is removed, and finally, the nitrile rubber gasket pasted with the polytetrafluoroethylene thin film is dried in a drying oven at a temperature of 90 DEG C for 10 minutes. The processing method is high in production efficiency, and also high in product percent of pass, and thus wide in application prospect.

Owner:WUXI HAITE NEW MATERIAL RES INST

Low-cost internal-external wall porcelain-imitated coating

A low-cost enamel-like paint for internal and external walls is prepared from polyvinyl alcohol fluorescent whitening agent, thickening agent, ultramarine, light calcium carbonate, urea, heavy calcium carbonate and water. Its advantages are smooth surface, high film hardness, high adhesion, high resistance to acid and alkali corrosions, and low cost.

Owner:周华海

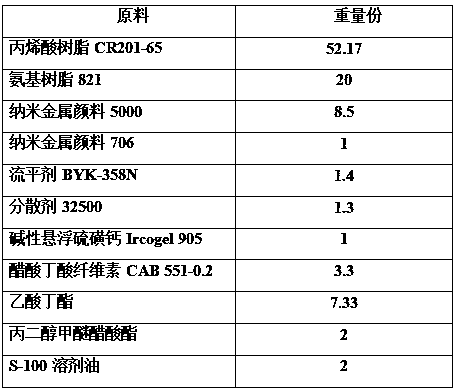

One-step coated film-formed high-gloss automobile metal wheel hub paint and preparation method thereof

ActiveCN109486306AMeet the requirements of one-time coating processHigh hardnessAnti-corrosive paintsAcrylic resinDiluent

The invention belongs to the technical field of coatings, and particularly relates to one-step coated film-formed high-gloss automobile metal wheel hub paint and a preparation method thereof. The paincomprises 40-55 parts of acrylic resin, 20-26 parts of amino resin, 8.0-13 parts of nano-metal pigments, 4.0-7.0 parts of auxiliaries and 10-15 parts of diluents. The acrylic resin reacts with the butyl ether amino resin, and the one-step coated film-formed high-gloss automobile metal wheel hub paint with high-temperature resistance, good adhesive force and high additional values can be obtainedby the aid of the metal pigments. Moreover, an original triple-coating triple-baking or triple-coating one-baking preparation process is changed into a one-coating one-baking paint preparation process, and the paint has better performances such as high gloss and salt fog resistance. The method is simple in preparation process and suitable for industrial production.

Owner:ZHANGZHOU XIN ZHAN WANG CHEM IND

Digital ink-jet printing heat transfer printing membrane and preparing method thereof

ActiveCN104354489ASave wood pulpLow costDuplicating/marking methodsDefoamerSodium carboxymethylcellulose

The invention relates to a digital ink-jet printing heat transfer printing membrane and a preparing method thereof, which have low-carbon and environmental-friendly effects and a good transfer printing effect, is low in production cost, and achieve the effects of no crinkling in transfer printing process and flexible transformation of patterns. The preparing method of the digital ink-jet printing heat transfer printing membrane comprises the following six steps: mixing carboxymethyl cellulose (CMC), titanium dioxide, polyvinyl alcohol (BP-24) and starch with water respectively in a certain ratio, stirring uniformly to prepare liquid, mixing the liquid with an organic silicon defoamer in a certain ratio, and filtering through a 200-mesh sieve to prepare coating glue; then uniformly coating the surface of a PET film with the coating glue through a coating machine; and drying and trimming to prepare the digital ink-jet printing heat transfer printing membrane.

Owner:陈裕逢

On-line automatic refined pasting glue and preparation method thereof

InactiveCN103102852AFast dryingHigh production efficiencyEster polymer adhesivesPolymer scienceFunctional monomer

The invention discloses on-line automatic refined pasting glue which is prepared by polymerizing the following raw materials: a monomer, a soft monomer, a functional monomer, an initiator, an emulsifier, a buffering agent, a functional aid, a viscosity modifier and distilled water. The invention further provides a preparation method of the on-line automatic refined pasting glue. The glue is green, environment-friendly, beneficial for heath, free of bad odor and free of harmful substances such as phthalic acid ester plasticizers, heavy metals and the like, and has high solid content and high toughness, so that pasted products are free of wrinkle and unlikely to be deformed; the glue is rapid to be dried at normal temperature, high in yield efficiency and good in stain reduction and cleaning capability; the residual glue on a decorative surface can be easily swept off by using a wet rag, thereby maintaining the attractiveness of the decorative surface of a base material; due to good coating property, the glue can be rapidly flattened and coated on the base material; and a final pasted product is excellent in binding strength, and glued surfaces are kept solid and durable.

Owner:上海奇想青晨新材料科技股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com