Fine pasting glue and preparing process thereof

A mass ratio, emulsifier technology, applied in the direction of adhesive type, amide/imide polymer adhesive, hydrocarbon copolymer adhesive, etc., can solve the problem of decreased strength of lamination film, slow drying speed, and Problems such as production speed, to achieve fast leveling and coating, excellent bonding strength, and good stain removal and cleaning performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

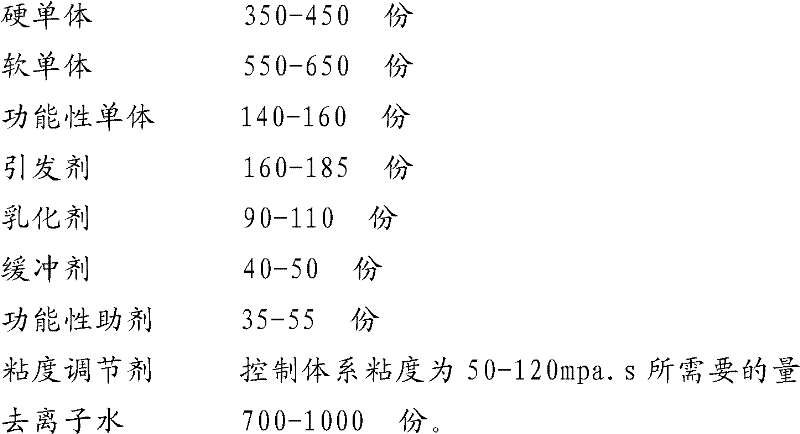

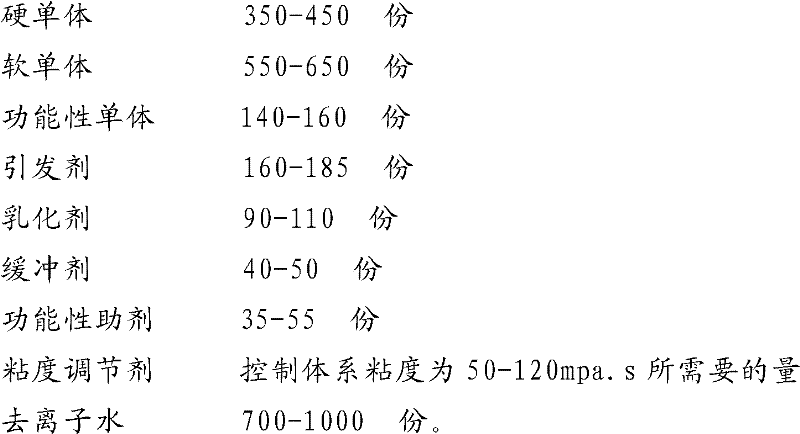

Method used

Image

Examples

Embodiment 1

[0042] With 280 parts by weight of deionized water, 16 parts by weight of emulsifier (sulfosuccinate and phenol ether sulfate are compounded in a weight ratio of 2:5), soft monomers of 600 parts by weight (450 parts by weight of acrylic acid butyl ester and 150 parts by weight of ethyl acrylate compound), the hard monomer of 360 parts by weight (84.6 parts by weight of styrene and the compound of methyl methacrylate of 275.4 parts by weight), join in the pre-emulsification tank and stir ( Rotating speed is 720rpm) 55 minutes, after being made into pre-emulsion, take the pre-emulsion of 29.16 weight parts as the bottom seed reaction solution for subsequent use;

[0043] With 500 parts by weight of deionized water, 145 parts by weight of functional monomers (hydroxyethyl acrylate and N-methylol acrylamide compounded in a weight ratio of 5.5: 1.5), 45 parts by weight of buffering agent (bicarbonate Ammonium and sodium bicarbonate are compounded in a weight ratio of 2.5:7.5), 90 p...

Embodiment 2

[0047] With the deionized water of 280 weight parts, the emulsifier of 16 weight parts (sulfosuccinate and phenol ether sulfate are compounded by the weight ratio of 2:5), the soft monomer of 650 weight parts (the acrylic acid of 487 weight parts butyl ester and 163 parts by weight of ethyl acrylate compound), the hard monomer of 400 parts by weight (the styrene of 96 parts by weight and the methyl methacrylate compound of 304 parts by weight), join in the pre-emulsification tank and stir ( Rotating speed is 680rpm) 55 minutes, after being made into pre-emulsion, take by weighing the pre-emulsion of 107 parts by weight as the bottom seed reaction solution for subsequent use;

[0048]With 500 parts by weight of deionized water, 155 parts by weight of functional monomers (hydroxyethyl acrylate and N-methylol acrylamide compounded in a weight ratio of 5.5: 1.5), 40 parts by weight of buffering agent (bicarbonate Ammonium and sodium bicarbonate are compounded by weight ratio of 2....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com