Patents

Literature

68 results about "Yield efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Yield | efficiency |. is that yield is (obsolete) payment; tribute while efficiency is the extent to which time is well used for the intended task.

Degumming technology of mulberry bark

InactiveCN101638811AImprove production rateAvoid damageVegetable materialBacteriological rettingFiberCellulase

Owner:YANCHENG INST OF IND TECH

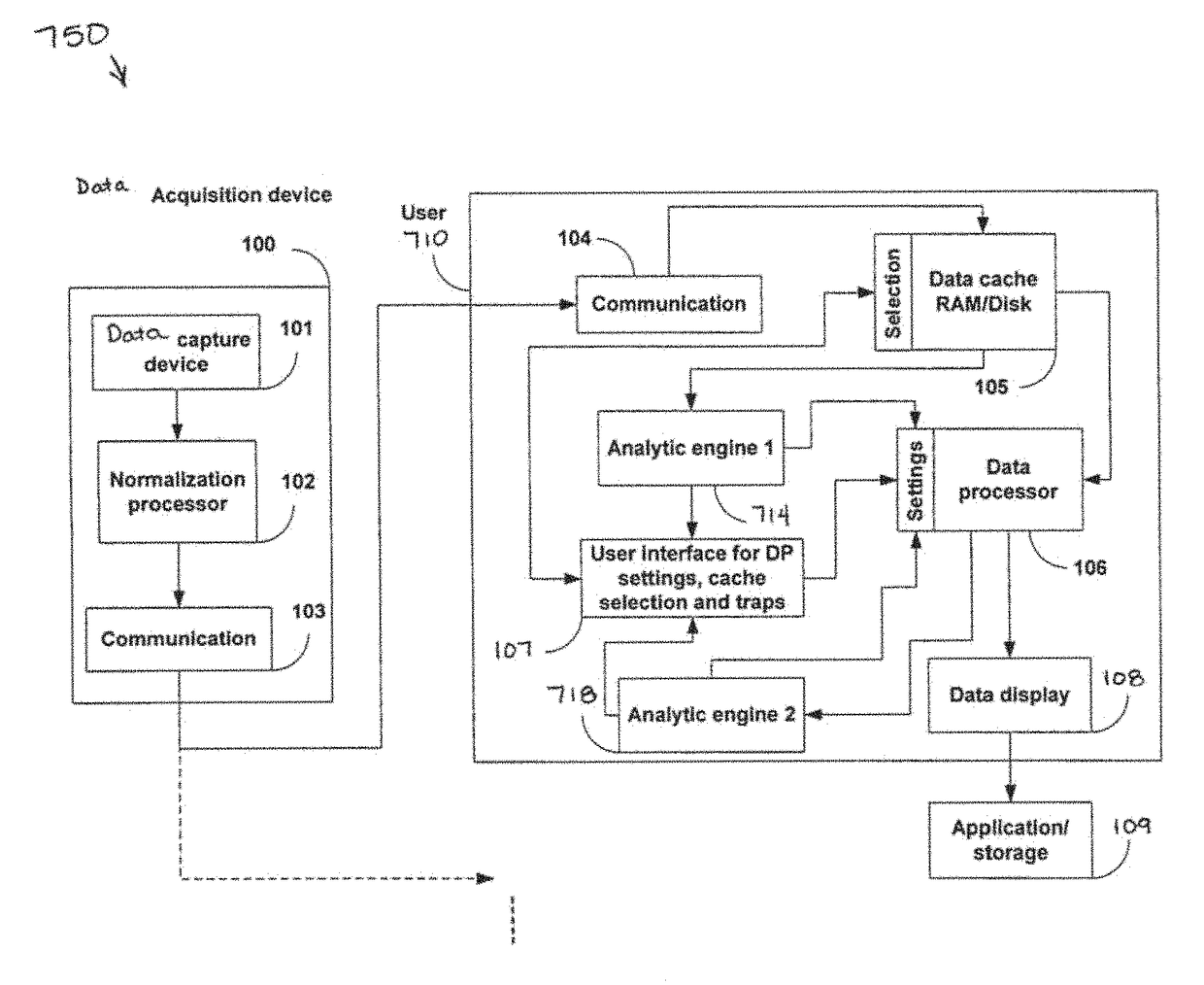

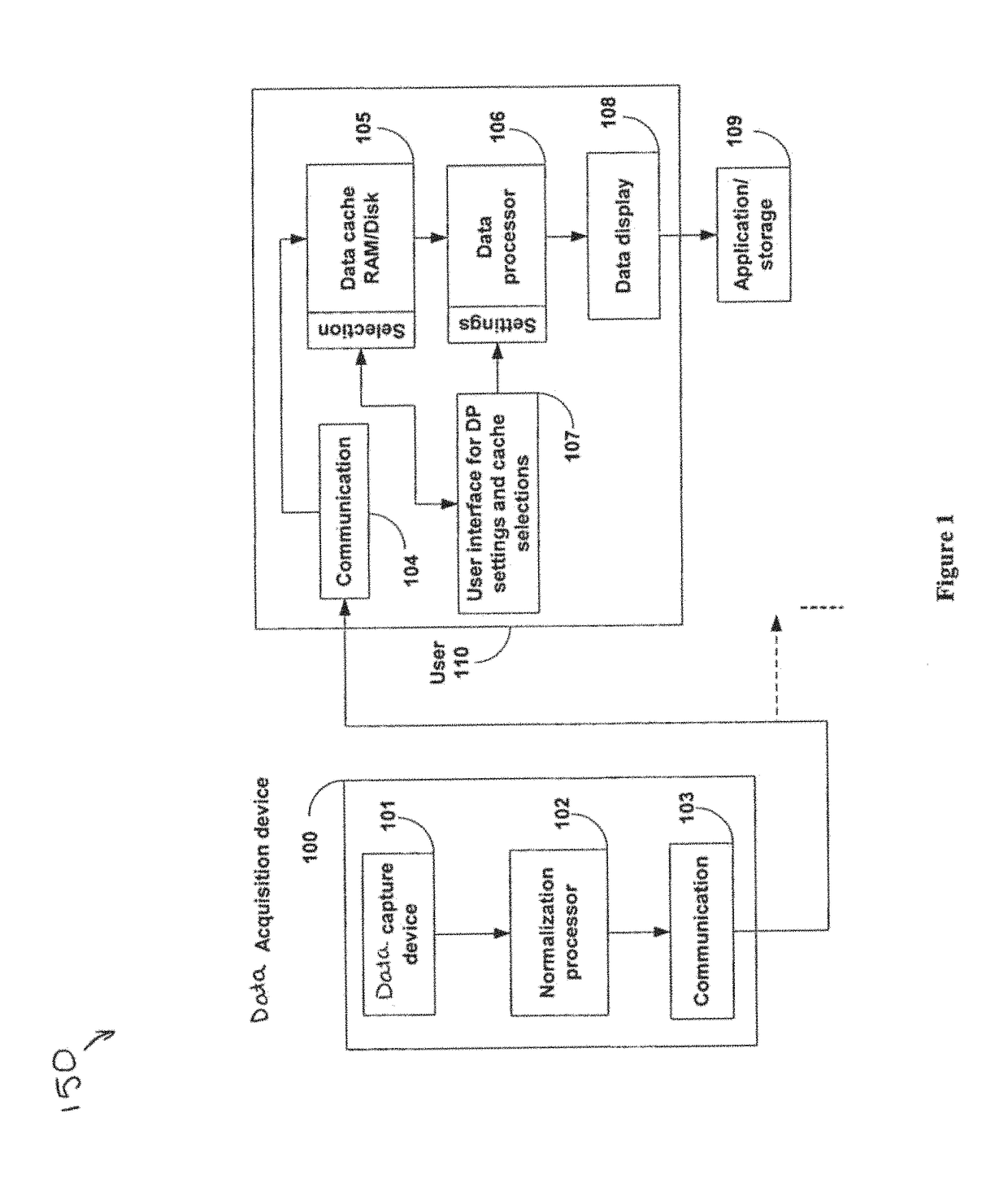

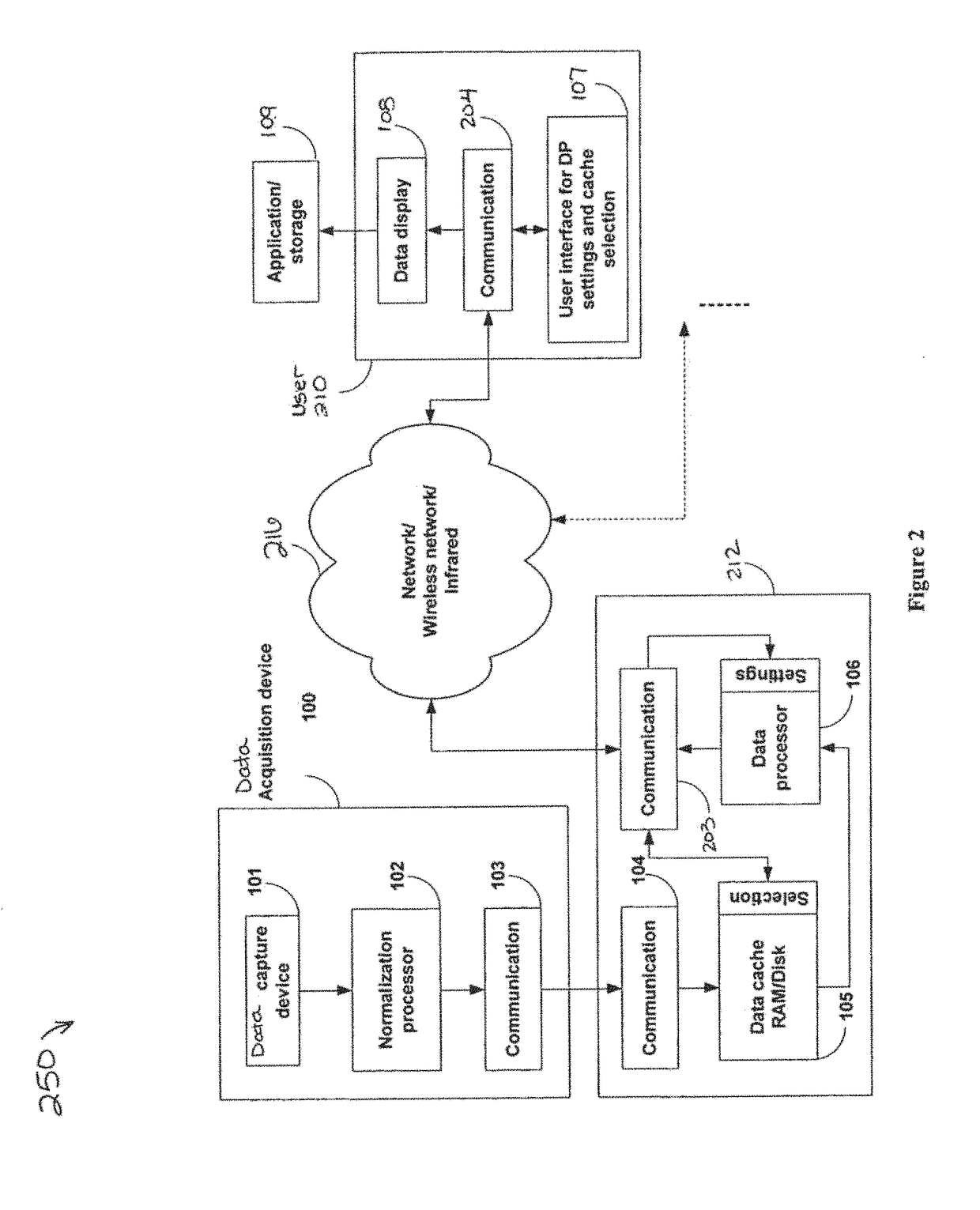

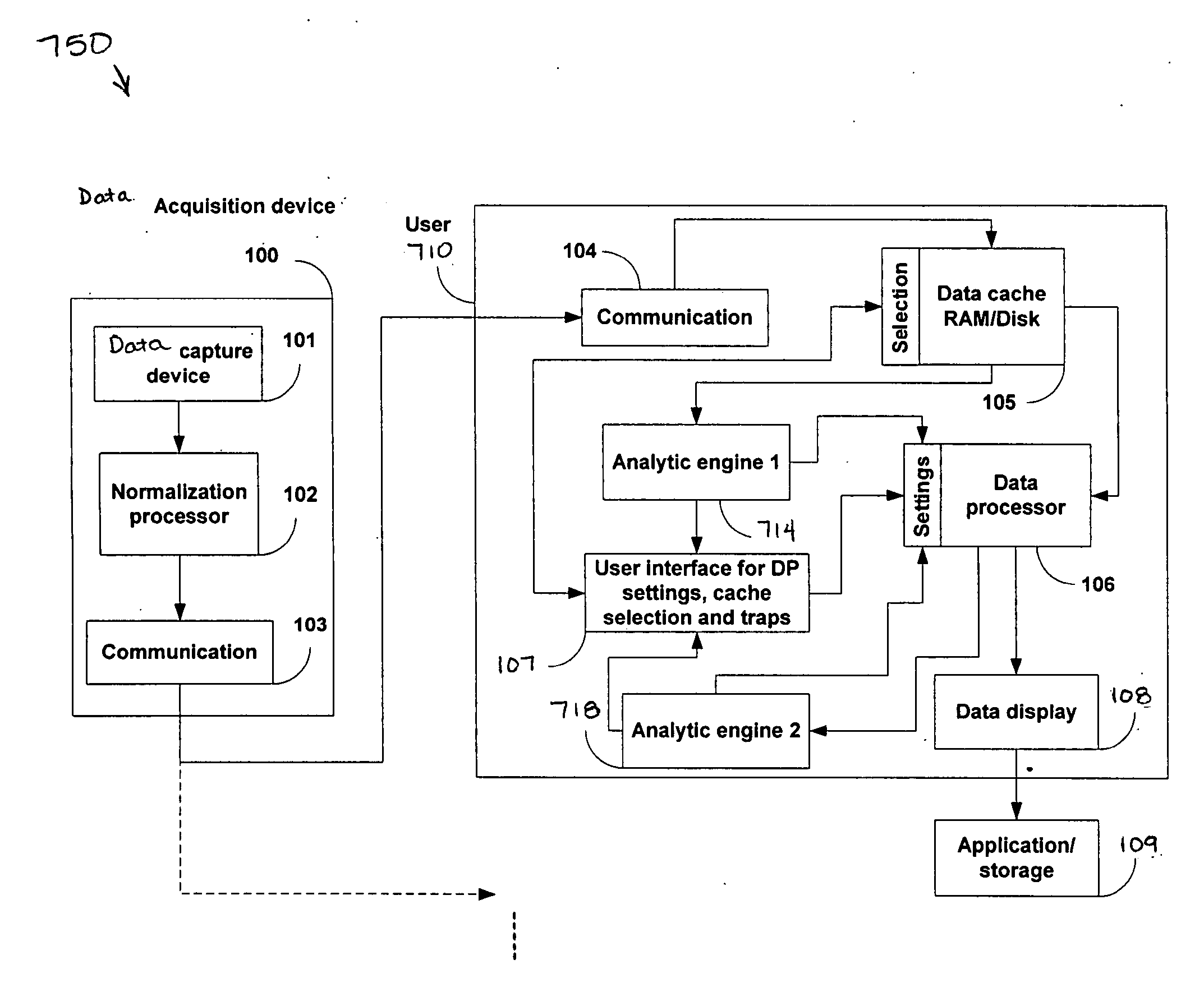

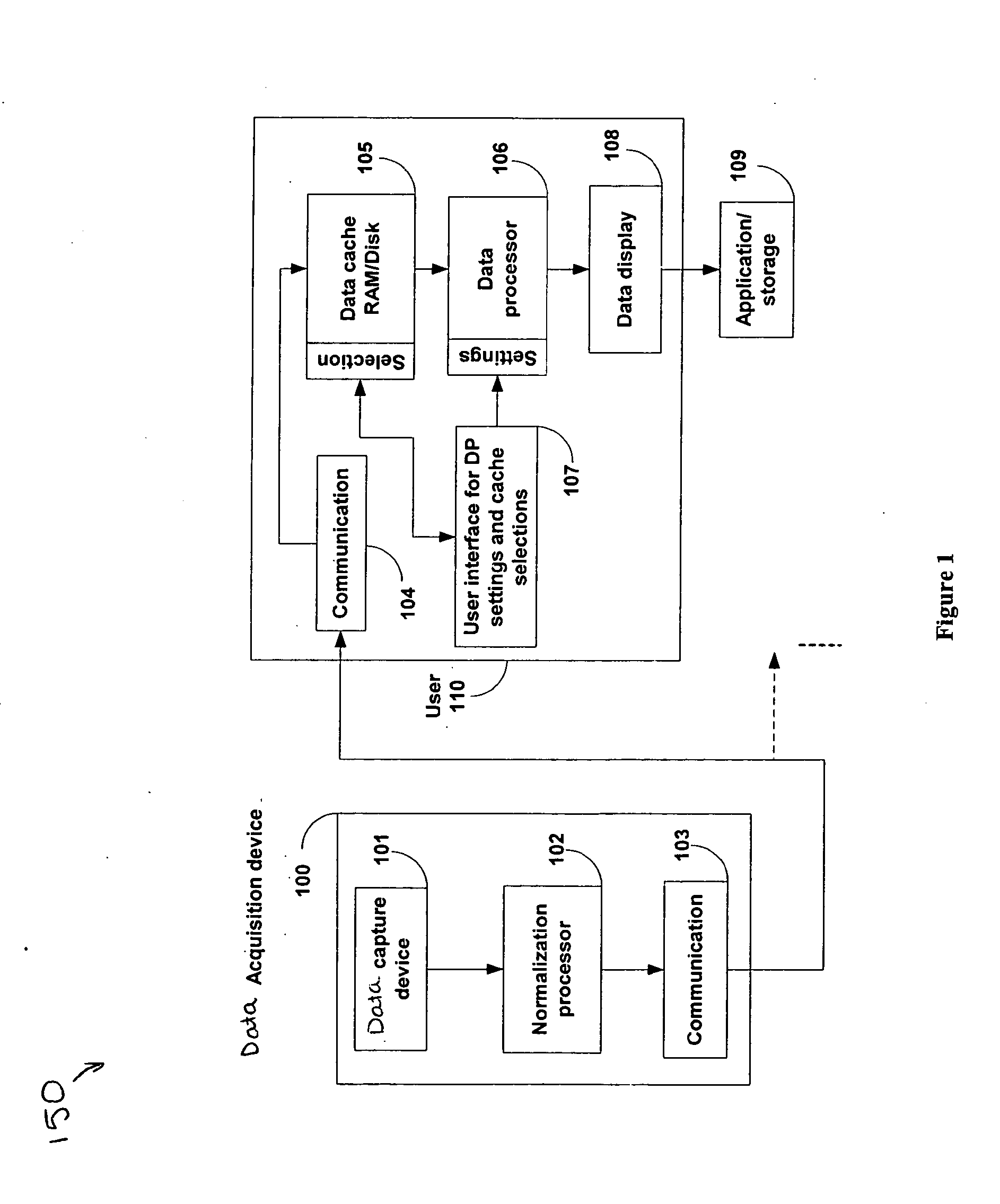

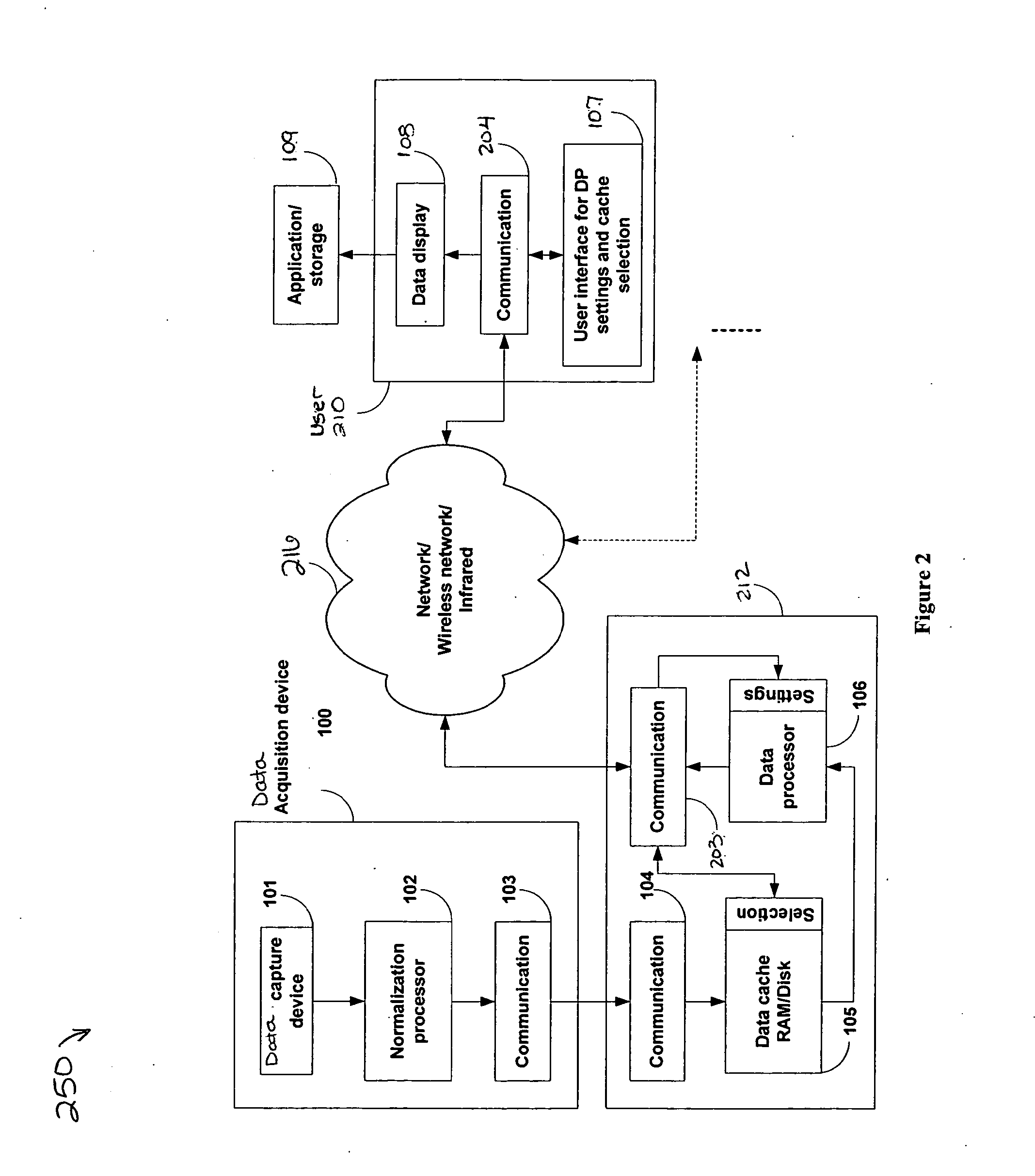

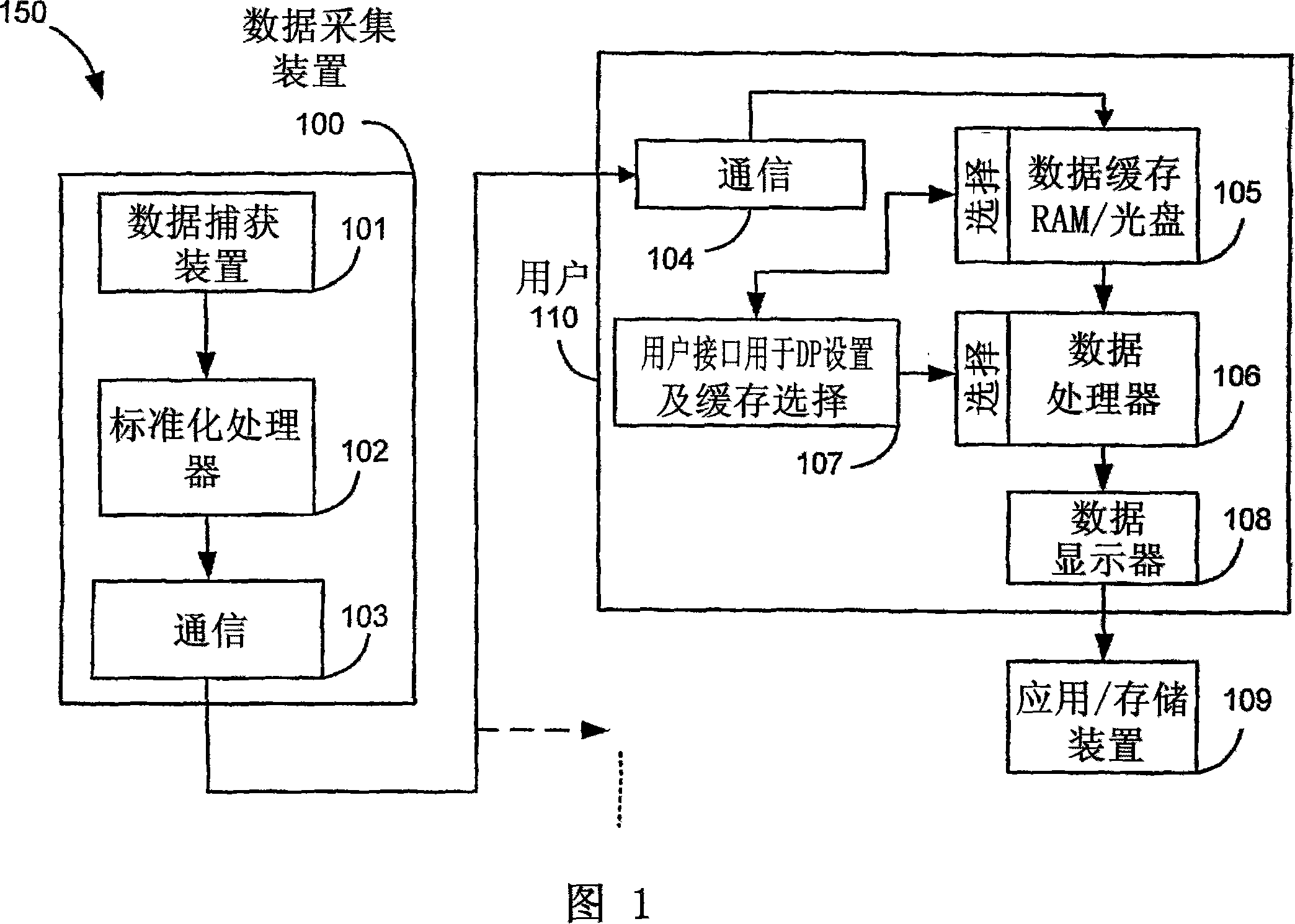

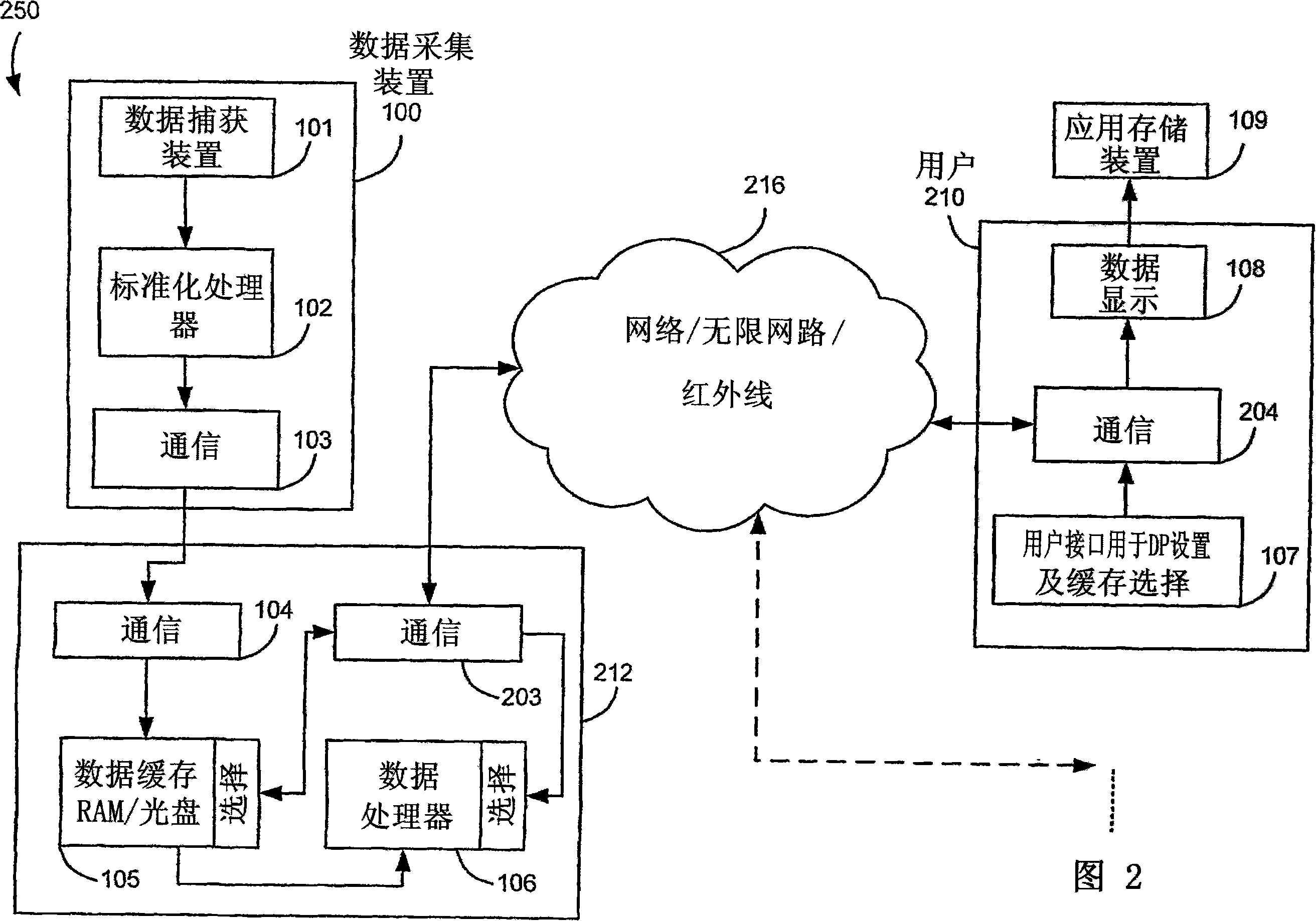

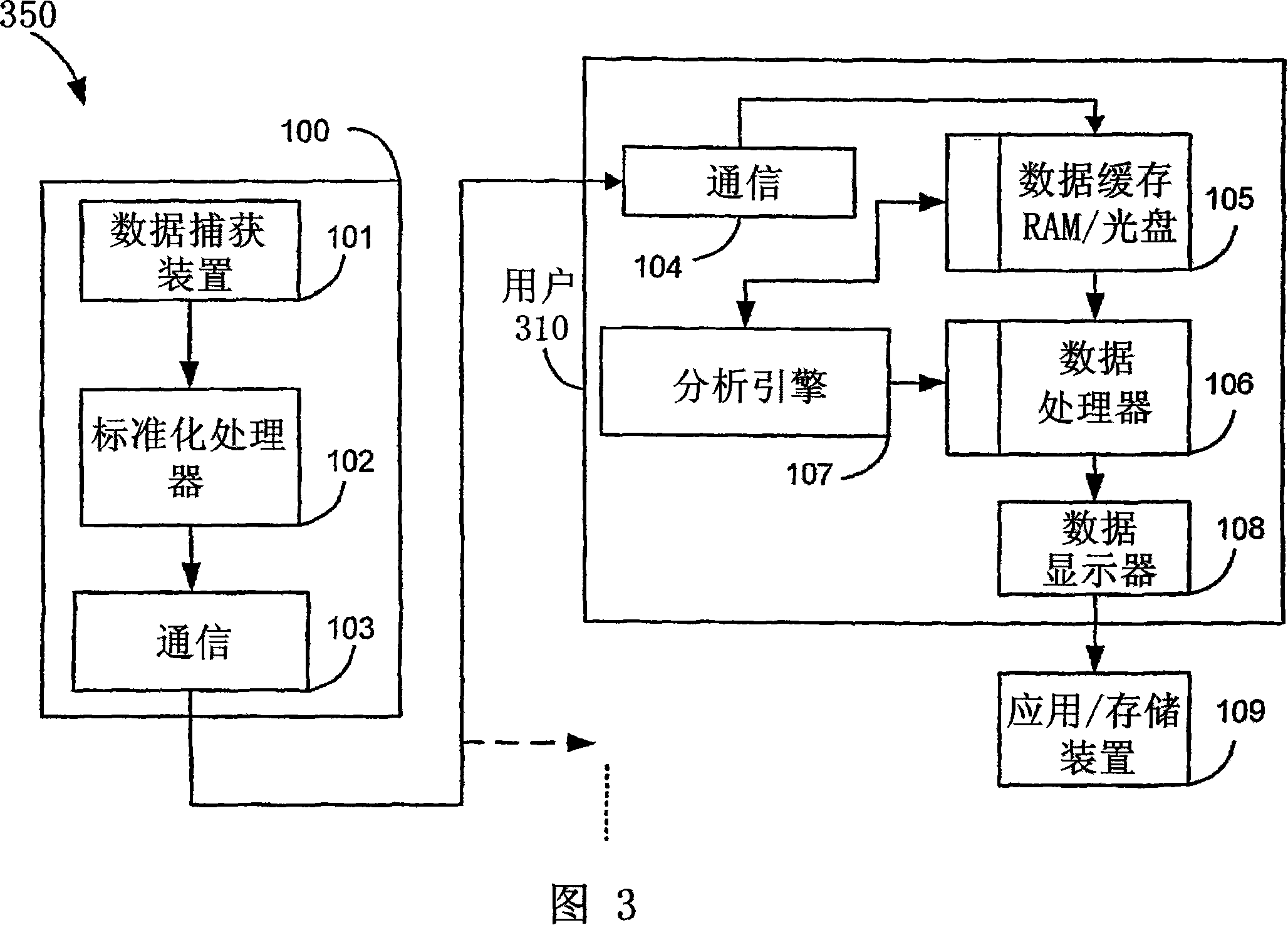

Systems and methods of processing scanned data

ActiveUS9769354B2Data augmentationAdvantages with regard to speedCharacter and pattern recognitionVisual presentationDigital dataNon real time

Owner:KOFAX

Systems and methods of processing scanned data

ActiveUS20130251280A1Data augmentationAdvantages with regard to speedImage enhancementCharacter and pattern recognitionNon real timeDigital data

An efficient method and system to enhance digital acquisition devices for analog data is presented. The enhancements offered by the method and system are available to the user in local as well as in remote deployments yielding efficiency gains for a large variety of business processes. The quality enhancements of the acquired digital data are achieved efficiently by employing virtual reacquisition. The method of virtual reacquisition renders unnecessary the physical reacquisition of the analog data in case the digital data obtained by the acquisition device are of insufficient quality. The method and system allows multiple users to access the same acquisition device for analog data. In some embodiments, one or more users can virtually reacquire data provided by multiple analog or digital sources. The acquired raw data can be processed by each user according to his personal preferences and / or requirements. The preferred processing settings and attributes are determined interactively in real time as well as non real time, automatically and a combination thereof.

Owner:KOFAX

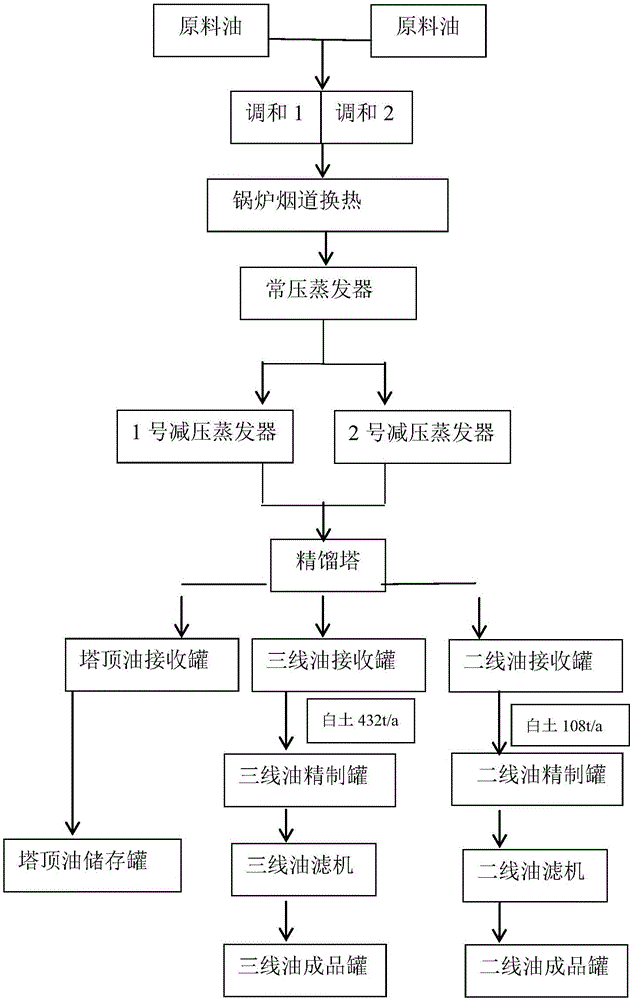

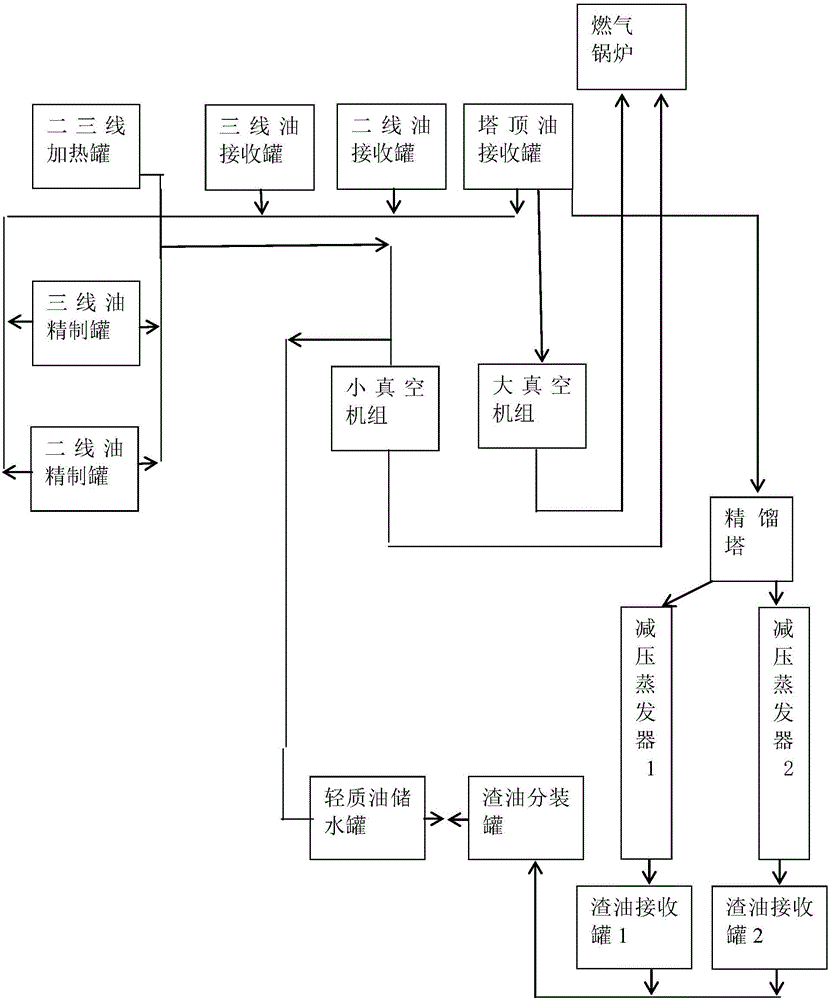

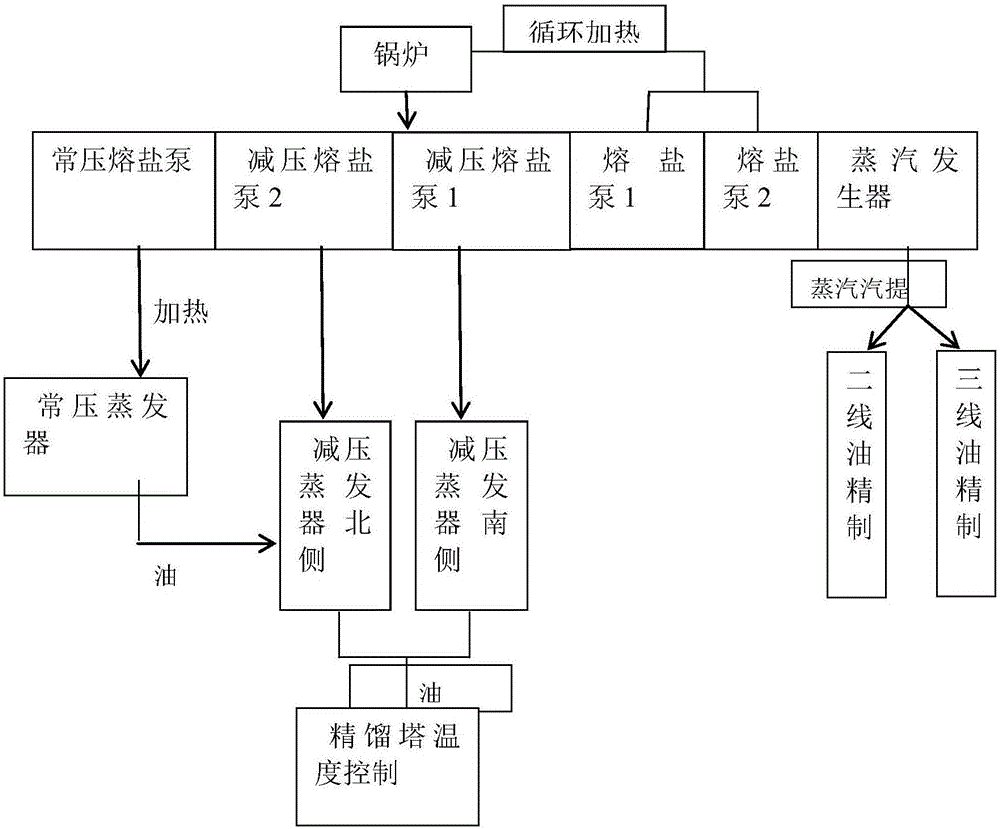

Refining technique of base oil regenerated from used lubrication oil

Disclosed is a refining technique of base oil regenerated from used lubrication oil, and the refining technique comprises the following steps of 1, removing solid waste, which includes removing solid waste from used lubrication oil by centrifugation; 2, solvent pretreatment, which includes extracting mixed impurities and moisture through a solvent and obtaining raw oil after removing upper oil; 3, flocculation treatment, which includes turning mixtures obtained from step 2 into a mixture of flocculation; 4, atomospheric distillation; 5, carrying out reduced pressure distillation; 6, carrying out rectification; 7, solvent refining: putting oil produced from a rectifying column into a treatment tank and when the height of the oil level in the treatment tank reaches 65%-75% of the height of the treatment tank, adding by mass 10%-40% of 1-Methyl-2-pyrrolidinone, and carrying out solvent refining. The refining technique of base oil regenerated from used lubrication oil has the advantages of low investment and high yield efficiency, meanwhile, the refining technique accords with the requirement of environmental protection, reduces vacuum residuum by 15%, improves product yield, facilitates the overhauling of equipment, prolongs the production period, largely improves production efficiency and appearance quality of minus line oil, and helps to obtain high quality regenerated base oil.

Owner:济南亿诺再生资源有限公司

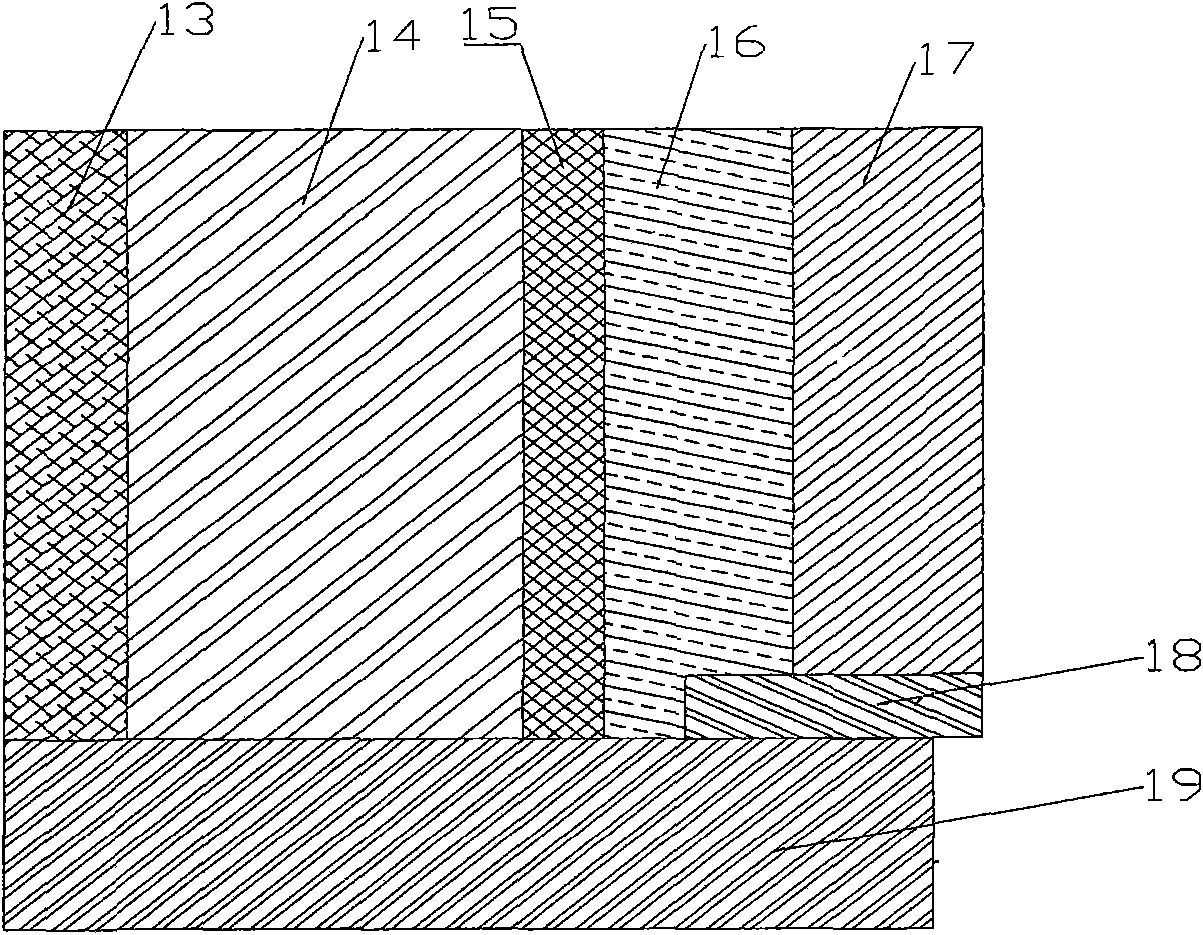

Crystallizer copper tube with transitional chromium coating and hard chromium coating and production process thereof

The manufacture technique for a crystallized copper tube with transient Cr-plating layer and hard Cr-plating layer comprises: cleaning the base copper tube to remove dust and oil; reverse nicking treatment before plating; preparing electroplate liquid; plating; cleaning; then, arranging transient plating layer with medium thermal-expansion coefficient and hardness between the base tube inner wall and surface hard plating layer. This invention ensures the tube resistance to high temperature, wear and corrosion, and endows the plating layer resistance peel, and has high yield efficiency with stable quality and low cost.

Owner:张喜成 +1

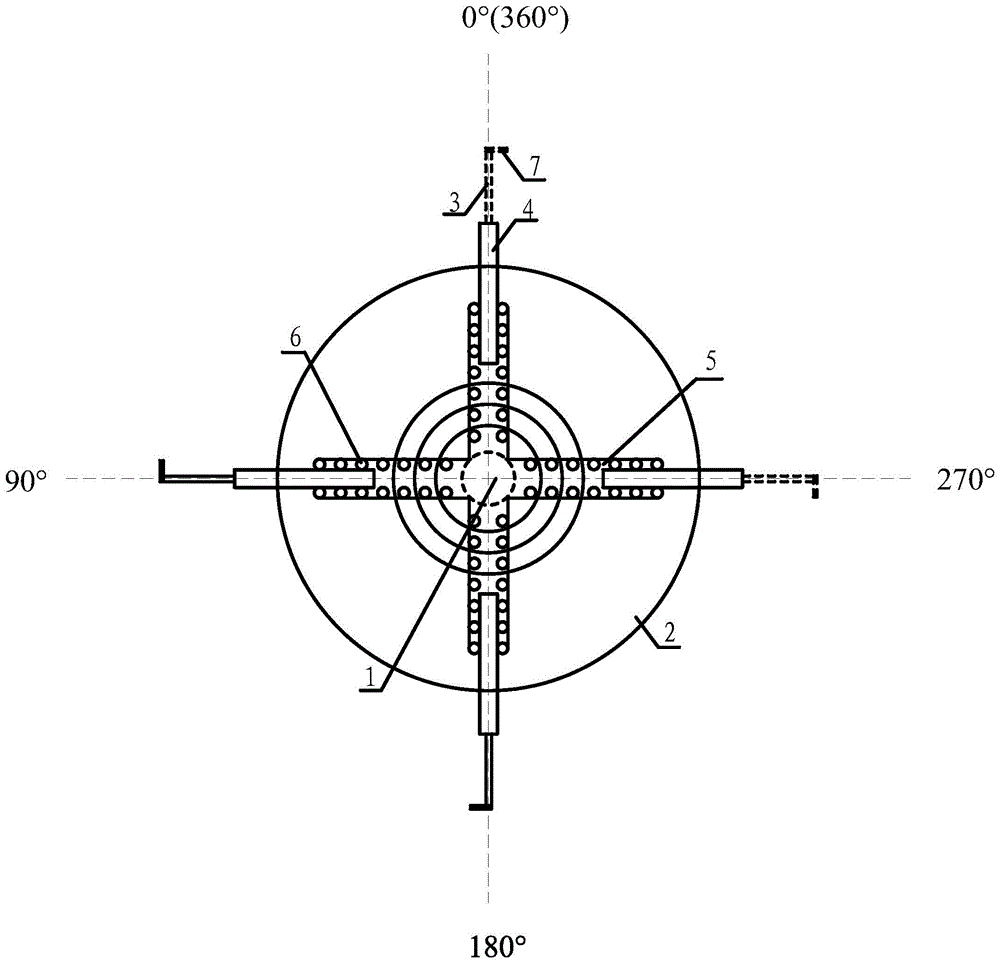

Retractable blade vertical-axis tidal turbine

InactiveCN104696139AGood energy gathering effectImprove energy harvesting efficiencyHydro energy generationReaction enginesSubmarineYield efficiency

The invention discloses a retractable blade vertical-axis tidal turbine, which comprises a rotating shaft, a turntable, blades, retractable support arms, eight guide rails, guide rail wheels, baffle plates, a controller and a support part, wherein the guide rails are positioned in the turntable, and are divided into two layers, and each layer comprises four guide rails; the guide rails are uniformly welded on the rotating shaft at intervals of 90 degrees; the guide rail wheels are mounted on the inner surfaces of the guide rails; a retractable support arm is mounted in each guide rail; the support arms are retractably and movably connected with the guide rails through the guide rail wheels; the blades are mounted at the ends, far away from the turntable, of the support arms; the blades are rectangular, and are positioned on the same planes as the upper and lower layers of retractable support arms; the baffle plates are fixedly mounted at the ends, far away from the turntable, of the blades, and are in right-angled connection with the blades; the blades slide in the guide rails through the retractable support arms, and are controlled by the controller to retractably move. According to the retractable blade vertical-axis tidal turbine with such a retractable design, the energy yielding efficiency of the vertical-axis turbine is improved, the size of the whole device is reduced, convenience in transportation and considerable market prospect are achieved, and the submarine mounting cost is reduced.

Owner:ZHEJIANG OCEAN UNIV

System and method of processing scan data

An efficient method and system to enhance digital acquisition devices for analog data is presented. The enhancements offered by the method and system are available to the user in local as well as in remote deployments yielding efficiency gains for a large variety of business processes. The quality enhancements of the acquired digital data are achieved efficiently by employing virtual reacquisition. The method of virtual reacquisition renders unnecessary the physical reacquisition of the analog data in case the digital data obtained by the acquisition device are of insufficient quality. The method and system allows multiple users to access the same acquisition device for analog data. In some embodiments, one or more users can virtually reacquire data provided by multiple analog or digital sources. The acquired raw data can be processed by each user according to his personal preferences and / or requirements. The preferred processing settings and attributes are determined interactively in real time as well as non real time, automatically and a combination thereof.

Owner:柯法克斯影像产品公司

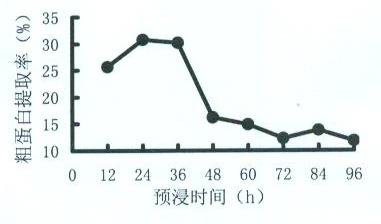

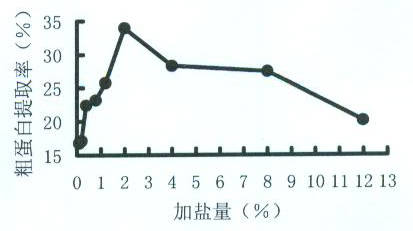

Method for extracting leaf protein from alfafa hay

InactiveCN102178026AReduce extraction timeReduce investmentAnimal feeding stuffAccessory food factorsWater bathsTime limit

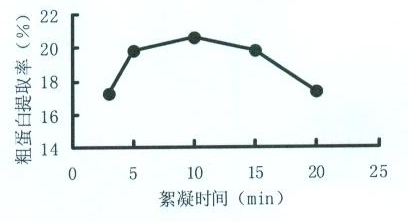

The invention relates to a method for extracting leaf protein from alfafa hay, aiming at providing a preparation method which can realize mass production and has the advantages of no time limit, simple process, low cost and high efficiency. In the method provided by the invention, leaf protein is extracted by acidification heating method and salt treatment. The method comprises the following steps of: smashing air-dried or kiln-dried alfalfa, adding appropriate amount of sodium pyrosulphate, adding water in the ratio of material to water being 1: (10-40), preimpregnating for 12-36 hours and then beating for 5 minutes, filtering (or centrifuging) with a 120-mesh filter cloth to obtain green juice, adjusting pH value to 2-7 by utilizing 2% sodium hydroxide and 0.5 mol / L hydrochloric acid solution, rapidly heating to the temperature of 40-80 DEG C in a boiling water bath, and then flocculating for 3-20 minutes in a constant-temperature water bath at the same temperature; and rapidly cooling to room temperature with cold water (normal temperature), standing for 1 hour, filtering (or centrifuging) to obtain leaf protein paste, and finally drying in a drying oven at the temperature of 60-70 DEG C. In the extraction method, the leaf protein is extracted from alfafa hay used as raw material; compared with the traditional method which takes fresh alfafa hay as the raw material, the cost is reduced, the yield efficiency is greatly improved, and the defect that the production time is limited by plant growth season is overcome.

Owner:SHENYANG AGRI UNIV

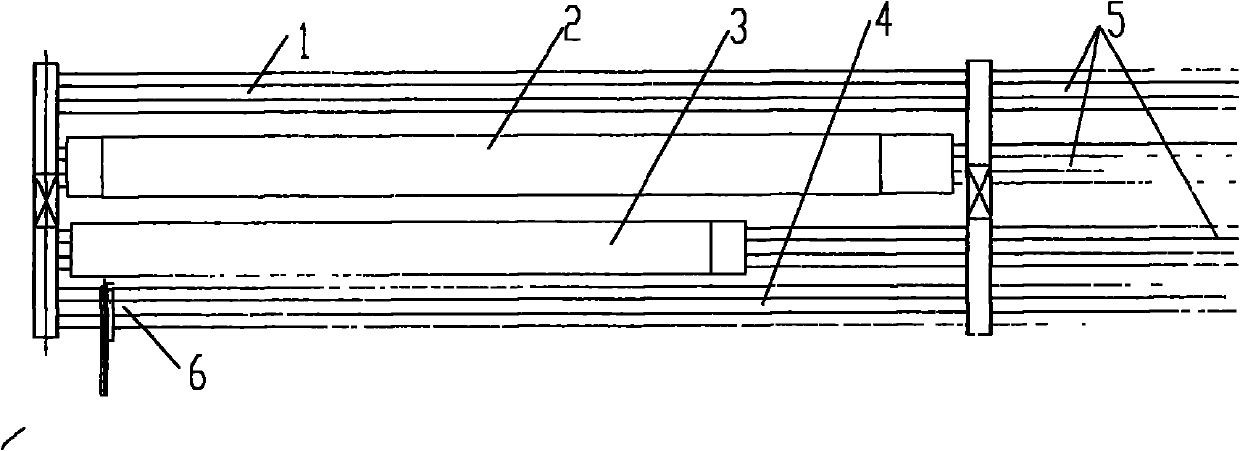

High-yield efficient tunnel kiln

The invention relates to the technical field of industrial kiln (baked brick tunnel kiln) and discloses a design scheme of a novel high-yield efficient tunnel kiln with a large section. An annual running line arrangement process is adopted, and the tunnel kiln comprises a high-yield efficiency drying kiln and a high-yield efficient calcining kiln, wherein the length of the drying kiln is 75-95 m, the inner width is 4.6-10.4 m, the inner height is 2.0-2.55 m, the kiln wall thickness is 0.37-0.49 m, and the kiln top thickness is 0.3-0.5 m; a manner of top air supply and side air supply is adopted, wherein the air supply volume is 20-40 Nm<3> / kg of water, and the air exhaust volume is 16-36 Nm<3> / kg of water; an air supply section is 60-70% of the total length, a pre-heating section is 30-40% of the total length; the total length of the calcining kiln is 100-140 m, the inner width is 4.6-10.4 m, and the inner height is 2.0-2.55 m; the thickness of a high-temperature section of the kiln wall is 1,080-1,250 mm; the thickness of the kiln top is 616-840 mm; the curve bricks protrude 0 mm from the inner wall of the kiln; 9-11 pairs of smoke discharge gate valves are arranged in a pre-heating zone; and the smoke discharge air quantity is 12,000-18,000 m<3> / h.m<2> of the kiln section area. The tunnel kiln provided by the invention has the advantages of high yield, low heat loss and small investment, is convenient in operation and is a most economical and practical kiln type in current brick making industry.

Owner:王宏伟

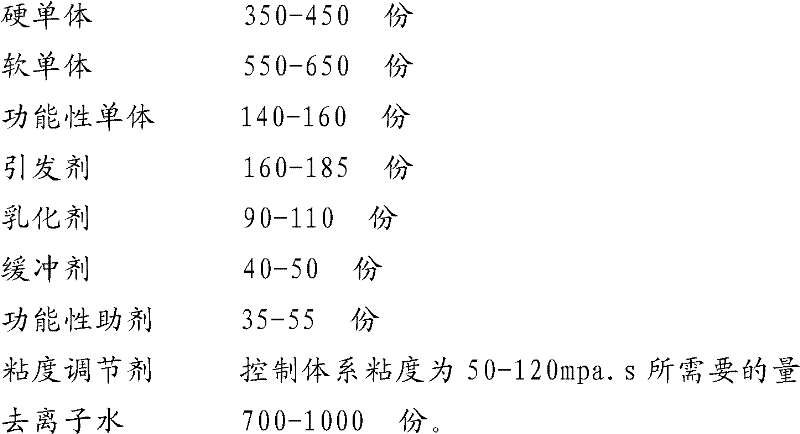

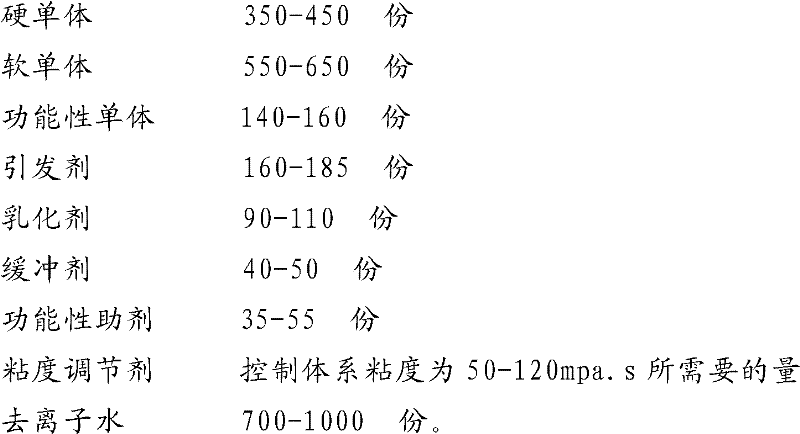

Fine pasting glue and preparing process thereof

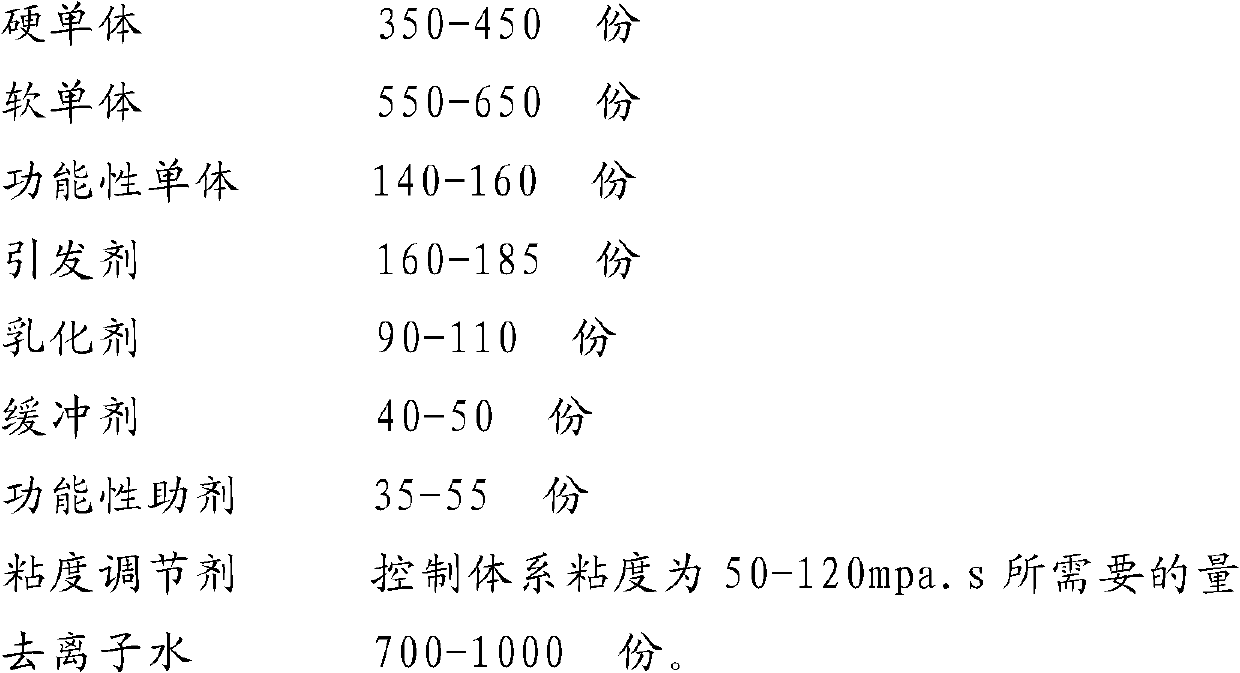

ActiveCN102559103AFast dryingHigh production efficiencyAmide/imide polymer adhesivesEster polymer adhesivesFunctional monomerBuffering agent

The invention relates to fine pasting glue, which is polymerized by the following raw materials of a hard monomer, a soft monomer, a functional monomer, an initiating agent, an emulsifying agent, a buffering agent, a functional auxiliary agent, a viscosity regulator and deionized water. The fine pasting glue and a preparing process thereof also provides a process for preparing the fine pasting glue. The fine pasting glue and the preparing process thereof have the advantages in that the fine pasting glue is of green environmental protection and good for health and contains no bad odor and harmful substances such as phthalic acid esters plasticizer, heavy metals and the like; as the fine pasting glue has high solid content and high tenacity, products pasted are wrinkle-free and uneasy to deform under the normal temperature, and the fine pasting glue is rapid in drying, high in yielding efficiency, and good in scouring and cleaning. The adhesive residue on the facing can be easily cleaned by a wet cloth so that an attractive appearance of a substrate facing is kept; the coating is good in performance so that the glue can achieve rapid leveling and coating on the substrate; and finally the pasted products have a good bonding strength and can keep the glue-bonded surface solid and durable.

Owner:上海奇想青晨新材料科技股份有限公司

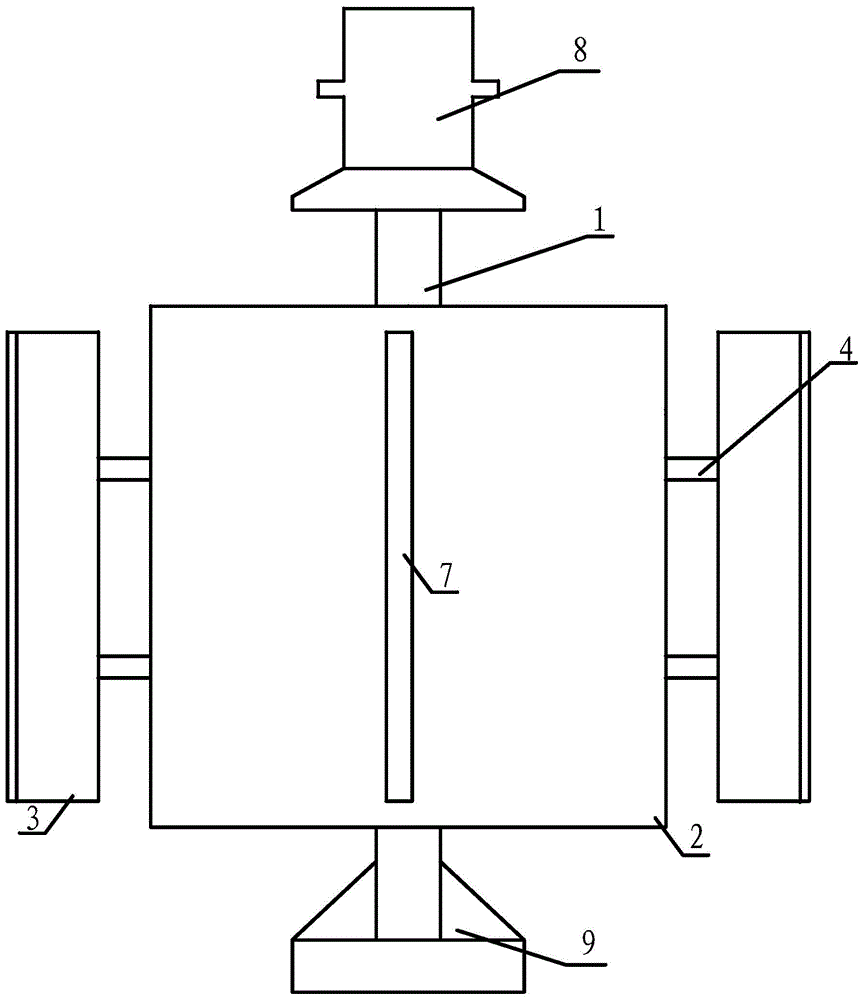

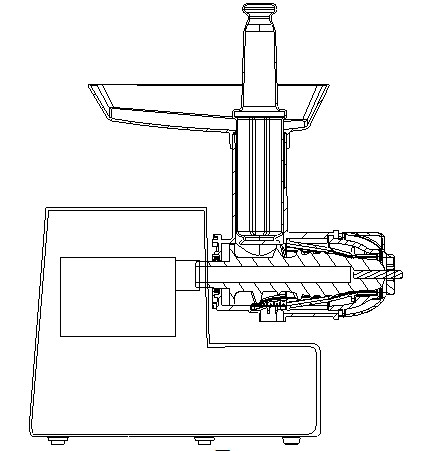

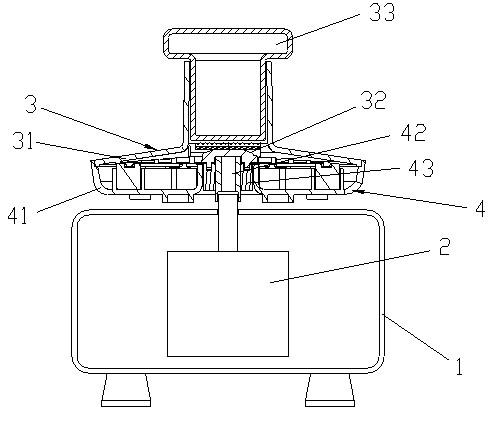

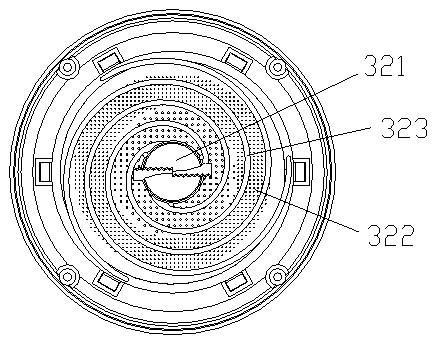

Plane squeezing type juicer

ActiveCN102599798AShorten the juice pathIncrease the juice yieldStrainersEngineeringMechanical engineering

The invention discloses a plane squeezing type juicer, which comprises a base (1), a motor (2), a juicing disc base (4) and a squeezing crushing portion (3). The motor (2) is arranged in the base (1), the juicing disc base (4) is arranged on the base (1), the squeezing crushing portion (3) is disposed on the juicing disc base (4) and comprises a juicing disc upper cover (31) and a juicing disc knife component (32), the juicing disc upper cover (31) is provided with a feeding opening, an output shaft of the motor (2) is connected with the juicing disc knife component (32), and the juicing disc base (4) is used for collecting fruit and vegetable juice squeezed out by the squeezing crushing portion (3). The plane squeezing type juicer is characterized in that the juicing disc knife component (32) is a planar structure and comprises a planar filter screen (322), a preprocessing blade (321) and a juicing strip (323), the preprocessing blade (321) and the juicing strip (323) are located on the planar filter screen (322), and the preprocessing blade (321) is disposed at the center of the juicing strip (323). The plane squeezing type juicer has the advantages of high juice yield efficiency, easiness in cleaning and the like.

Owner:MIDEA GRP CO LTD

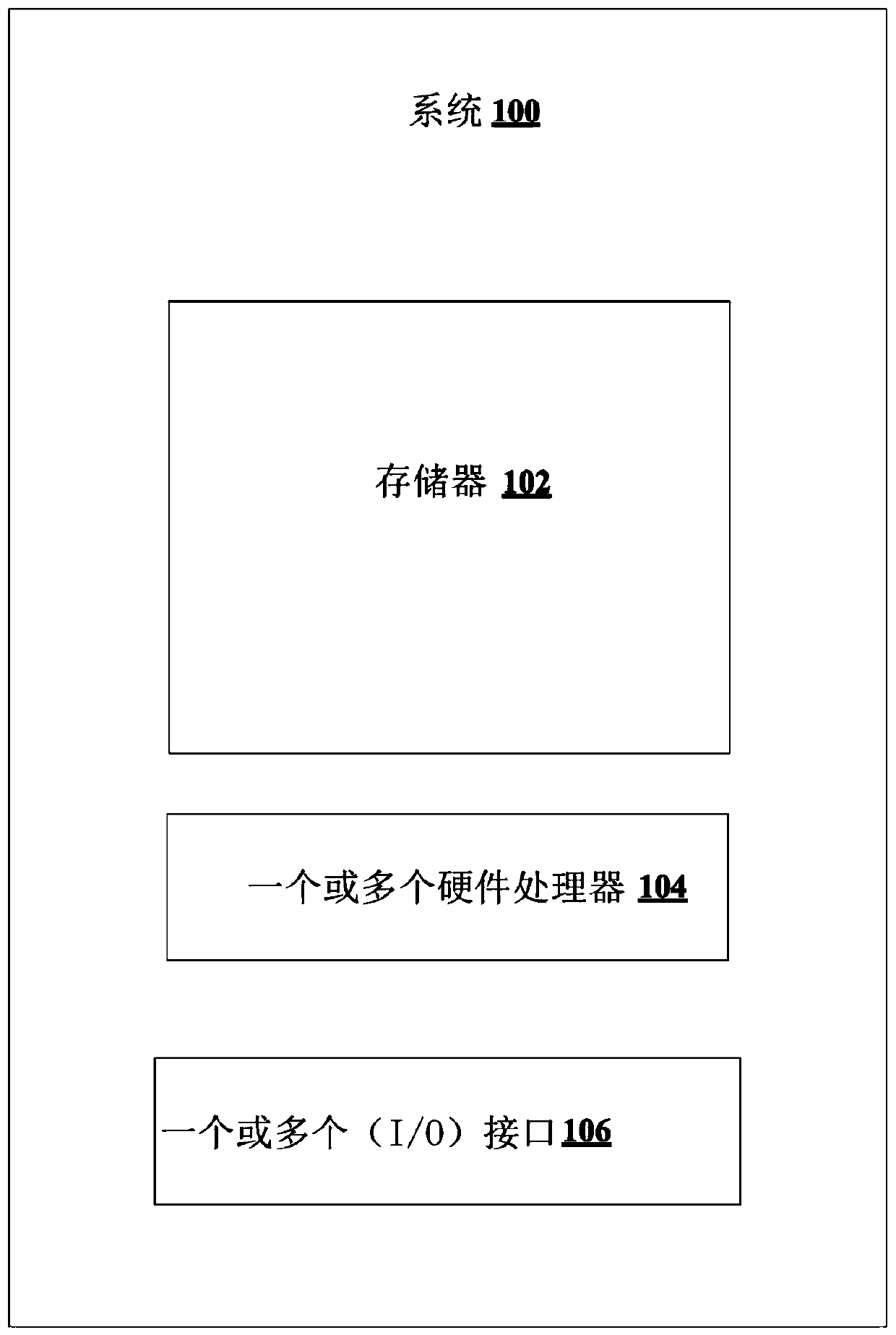

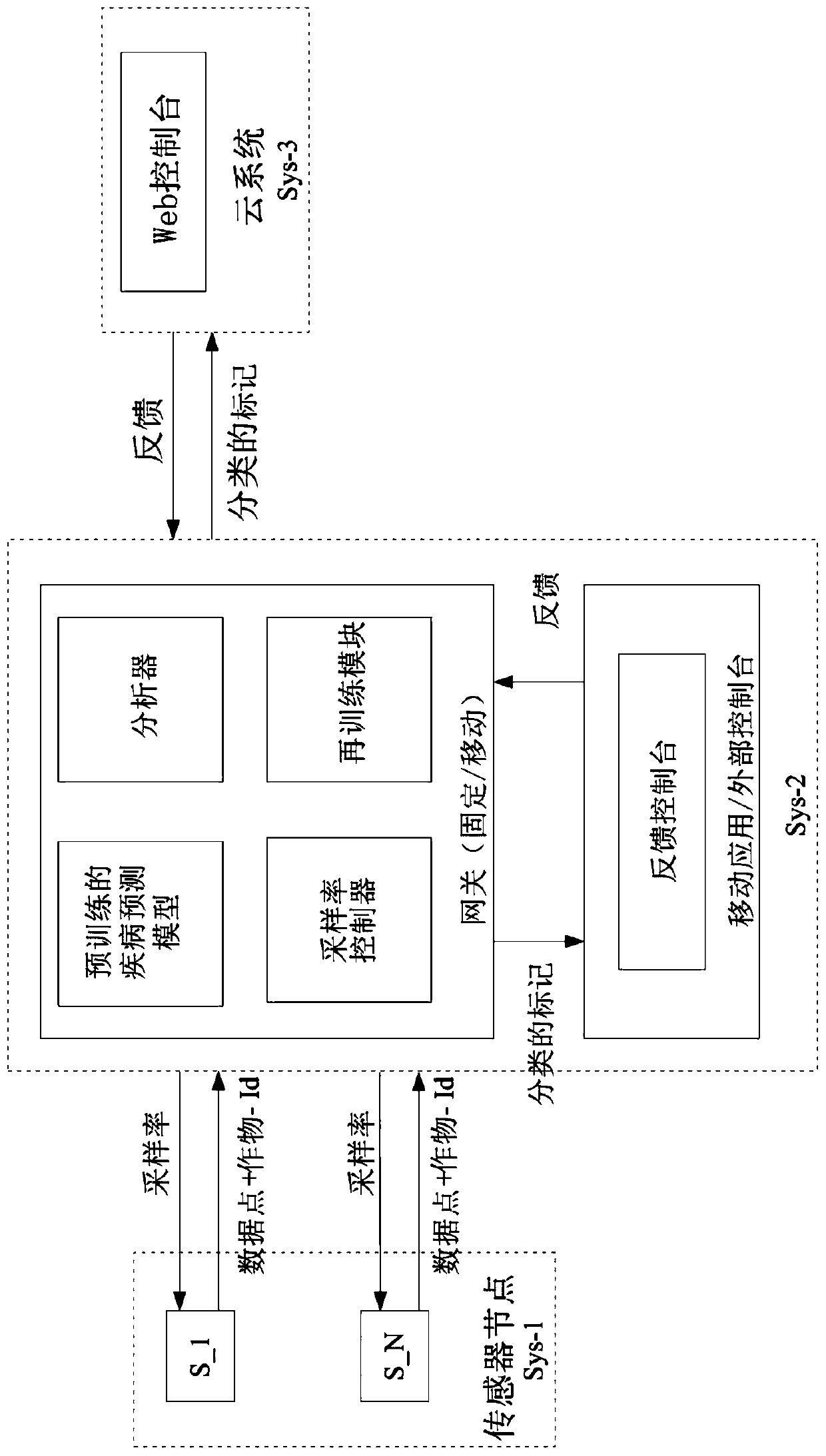

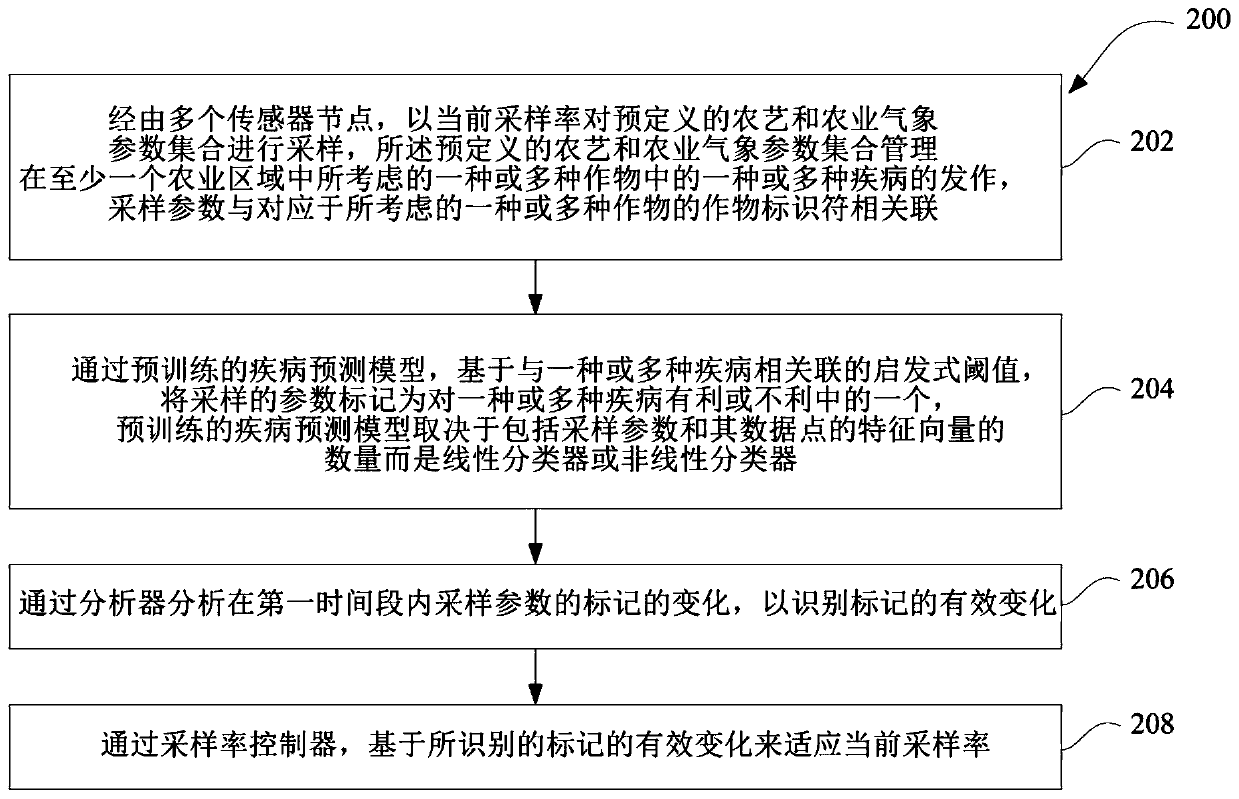

Methods and systems for adaptive parameter sampling

The invention relates to methods and systems for adaptive parameter sampling. This disclosure relates to precision agriculture that relies on monitoring micro-climatic conditions of a farm to make accurate disease forecasts for better crop protection and improve yield efficiency. Conventional systems face challenge in managing energy and bandwidth of transmission considering the humongous volume of data generated in a field through IoT based sensors. The present disclosure provides energy-efficient adaptive parameter sampling from the field by optimally configuring the parameter sampling ratethereby maximizing energy-efficiency. This helps reduce unnecessary traffic to a cloud while extending network lifetime.

Owner:TATA CONSULTANCY SERVICES LTD

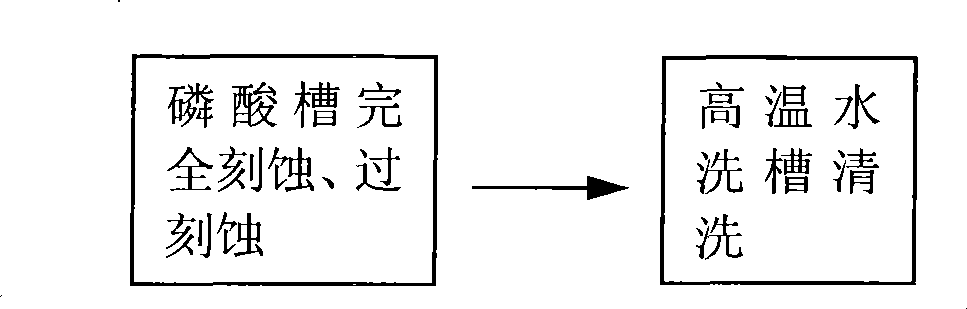

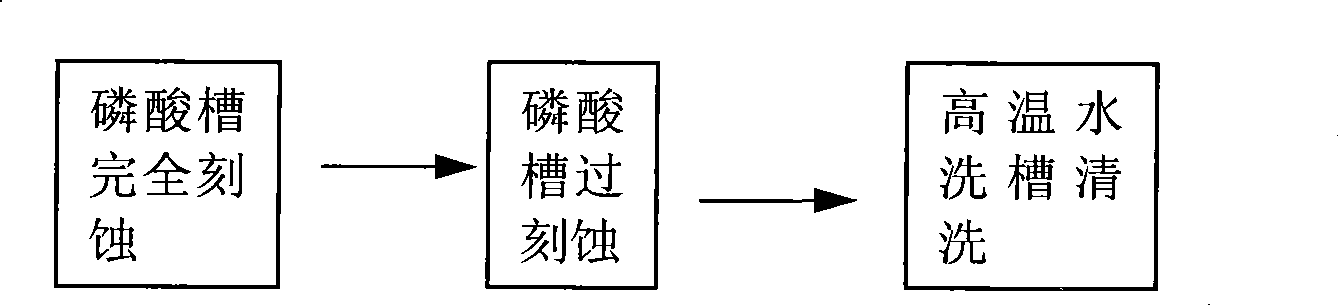

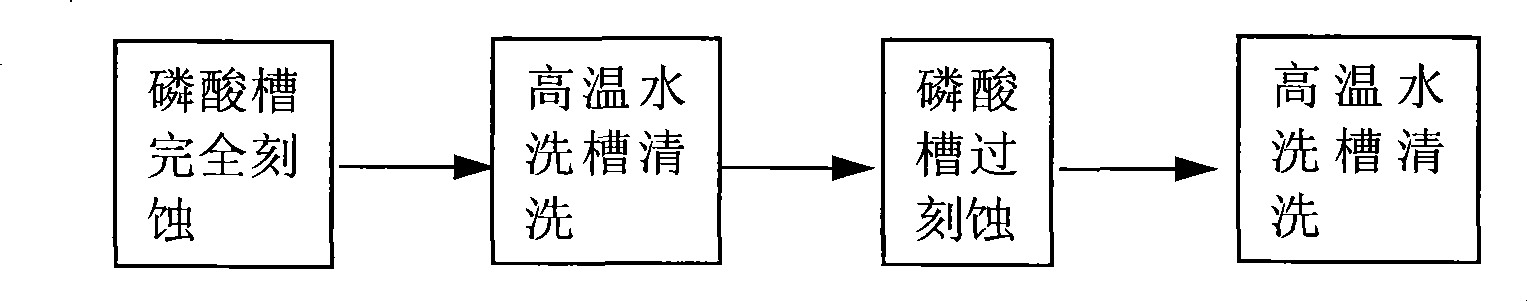

Wet method corrosion process for silicon nitride film

ActiveCN101452845ASolve the precipitation problemPrevent bringing inSemiconductor/solid-state device manufacturingPhosphoric acidYield efficiency

The invention discloses a silicon nitride film wet-method corrosion process method. The method comprises the following steps: 1, carrying out full corrosion on a silicon nitride film by using a single phosphoric acid tank; 2, cleaning the silicon nitride film by using a high-temperature rinsing tank; 3, carrying out over-etching by using the single phosphoric acid tank; and 4, cleaning the silicon nitride film by using the high-temperature rinsing tank. The method can solve the problem of low processing and yielding efficiency of equipment and can also solve the problem of precipitation of monox particles.

Owner:SHANGHAI HUAHONG GRACE SEMICON MFG CORP

Early-maturing efficient planting method for intercropping of greenhouse broad beans and garlic

InactiveCN107114098AImprove utilization efficiencyImprove output efficiencyPlant protectionShootInsect pest

The invention discloses an early-maturing efficient planting method for intercropping of greenhouse broad beans and garlic and belongs to the technical field of crop planting. The method comprises the following steps of: intercropping greenhouse broad beans and garlic, ridging and transplanting vernalized broad bean seedlings from the bottom of July to the beginning of October, and sowing garlic in the corresponding period; harvesting the broad bean green pods from the beginning of December to the Spring Festival, harvesting garlic sprouts from the first ten-day period of October to the Spring Festival, and retaining garlic without harvesting the garlic sprouts to the coming year to harvest young garlic shoots and the heads of garlic, wherein 1000-1250kg of garlic sprouts are produced per mu, so that 3000-4500 yuan can be increased per mu; about 1500-2000kg of broad bean green pots are produced per mu, so that the output value per mu of broad beans is about 10000 yuan. The planting method is incomplex in technology and stable in benefit, and the economical benefit is favorably increased and the income of farmers is favorably increased; the utilization efficiency and yield efficiency of land are favorably increased; sterilization and insect dispelling are facilitated, so that plant diseases and insect pests are prevented or reduced, and the cost is lowered and the effect is increased; by reducing nitrogen competition of soil, input of a nitrogen fertilizer is reduced, so that the cost is lowered.

Owner:JIANGSU COASTAL AREA AGRI SCI RES INST +2

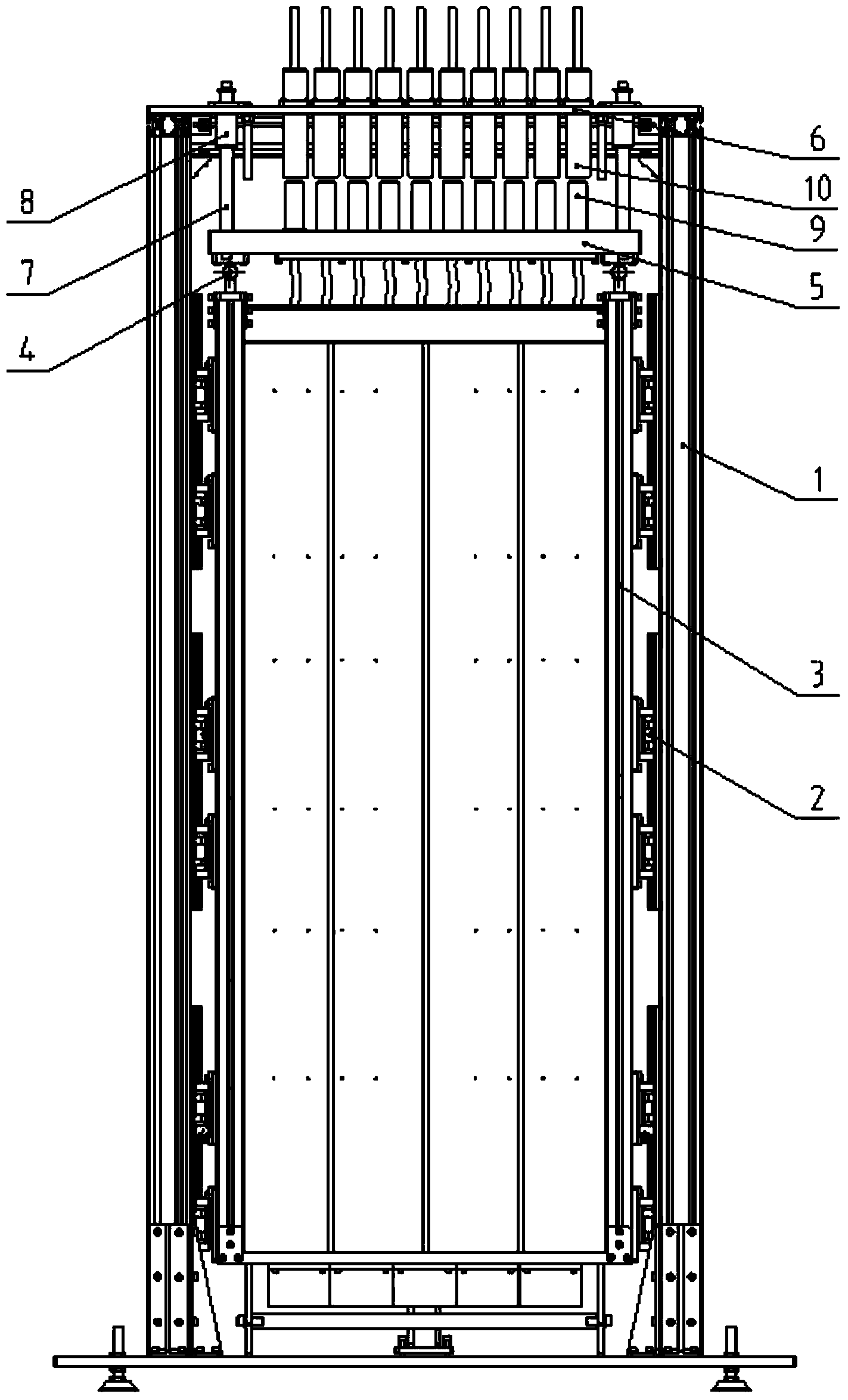

Plugging device capable of ascending and descending repeatedly

ActiveCN103531945AAvoid repeated disconnectionSimple structureCoupling device detailsEngineeringMechanical engineering

The invention discloses a plugging device capable of ascending and descending repeatedly, and relates to a plugging device in a photoelectric device. The plugging device comprises a frame and an upward / downward moving unit which is arranged on the frame and can ascend and descend, wherein the upper end of the upward / downward moving unit is provided with a plug board; the frame is provided with a socket board; the plug board and the socket board are plugged in a matching way; the plug board is provided with a plurality of plug posts; the socket body is provided with socket grooves correspondingly plugged with the plug posts. The plugging device is simple in structure, and is low in cost; the frame is provided with the upward / downward moving unit, so that a tested product can move up and down on a certain sliding track along with a guide slide block; flexible connection of the upward / downward moving unit and the plug board is realized through a floating joint, and power is transmitted to the plug board, so that plugging power is provided for the plug board. According to the plugging device, the testing batch quantity of the product can be ensured, repeated detachment and connection of a power line can be avoided, stable joint resistance is kept, and the yield efficiency can be increased.

Owner:SICHUAN CHANGHONG ELECTRIC CO LTD

Thin-skinned walnut cultivation method

The invention provides a thin-skinned walnut cultivation method. The method includes the steps of 1), after a field is divided into areas, ploughing soil deeply and subsequently applying base fertilizers, disinfectants and sterilizing agents; 2), selecting high-quality full thin-skinned walnut varieties, and allocating pollinate trees in a proportion of 8:1; 3), vertically placing seedlings in planting holes after unfreezing of the soil and before sprouting of walnuts, lifting up the seedlings for light treading after landfill of live soil, and pouring sufficient water prior to sealing; 4), pouring water sufficiently for one time after covering membranes are planted, pouring water sufficiently for one more time after 20 days, watering and spreading chemical fertilizers when young sprouts grow to more than 15cm, and timely weeding and strengthening pest control. The thin-skinned walnut cultivation method is simple, easy to operate, high in survival rate, rapid in fruit bearing, good in quality, high in fruit oil yield efficiency and especially suitable for thin-skinned walnut cultivation.

Owner:张松波

Two-stage sand removal process for livestock manure

The invention belongs to the field of biogas engineering, and particularly relates to a sand removal process for livestock manure. The sand removal process is characterized in that the livestock manure is poured into a stirring settling tank, water is added into the livestock manure to stir and dilute the livestock manure and remove sand in the livestock manure, the sand with the size larger than 0.5mm in the manure is removed, an upper layer of livestock manure diluent overflows to a hydrolytic acidification tank after stirring and sand removal, sand with the size smaller than 0.5mm is separated and removed during hydrolytic acidification, and the hydrolytic acidification tank sequentially consists of a primary hydrolytic acidification tank and a secondary hydrolytic acidification tank from a high position to a low position. The sand removal process has the advantages that by the aid of the two-stage sand removal process, the sand with various sizes in the manure are thoroughly removed, sand content in liquid entering a fermentation tank is reduced to be lower than 2%, influences of the sand to various follow-up links are greatly reduced, and stable running of biogas engineering with the livestock manure as a raw material is guaranteed. In addition, insoluble macromolecular substances in the liquid are degraded into soluble micro-molecule substances which can be easily utilized by methane bacteria, and gas yield efficiency is improved.

Owner:SHANDONG MINHE BIOTECHNOLOGY CO LTD

Method for preparing <14>NL-phenylalanine with enzyme

InactiveCN101270377AIncrease productionHigh purityMicroorganism based processesFermentationOrganic synthesisIsotope

The invention aims to provide an enzymatic preparation method of <15>NL-Phenylalanine. <15>N-ammonium sulfate and trans-cinnamic acid react to produce <15>NL-Phenylalanine under the catalyst of phenylalanine ammonia-lyase. The method of the invention has the advantages of the simple synthesis process, the higher output, compared with organic synthesis method and enzymatic method, achieving the easy substitution of N isotope, resulting in the product purity at 99 percent, the yield efficiency at 71 percent, the isotopic abundance at higher than 98 percent, the recovery rate of <15>N at 88 percent and being favorable for the large-scale production.

Owner:BEIJING UNIV OF CHEM TECH

Manufacturing technology of wooden door

InactiveCN108437144AQuality improvementExtended service lifeWood working apparatusGrinding machinesManufacturing technologyHigh volume manufacturing

The invention discloses a manufacturing technology of a wooden door. The manufacturing technology comprises the steps of raw material pretreatment, cutting, plate splicing, polishing, edge sealing andpainting. The wooden door produced through the manufacturing technology is good in quality and long in service life, moreover, the surface of the wooden door is smooth and attractive, the wooden doorconforms to the life pursuit of modern people, the manufacturing technology can carry out batch production, and the yield efficiency is effectively improved.

Owner:铜陵凯特实业有限公司

On-line automatic refined pasting glue and preparation method thereof

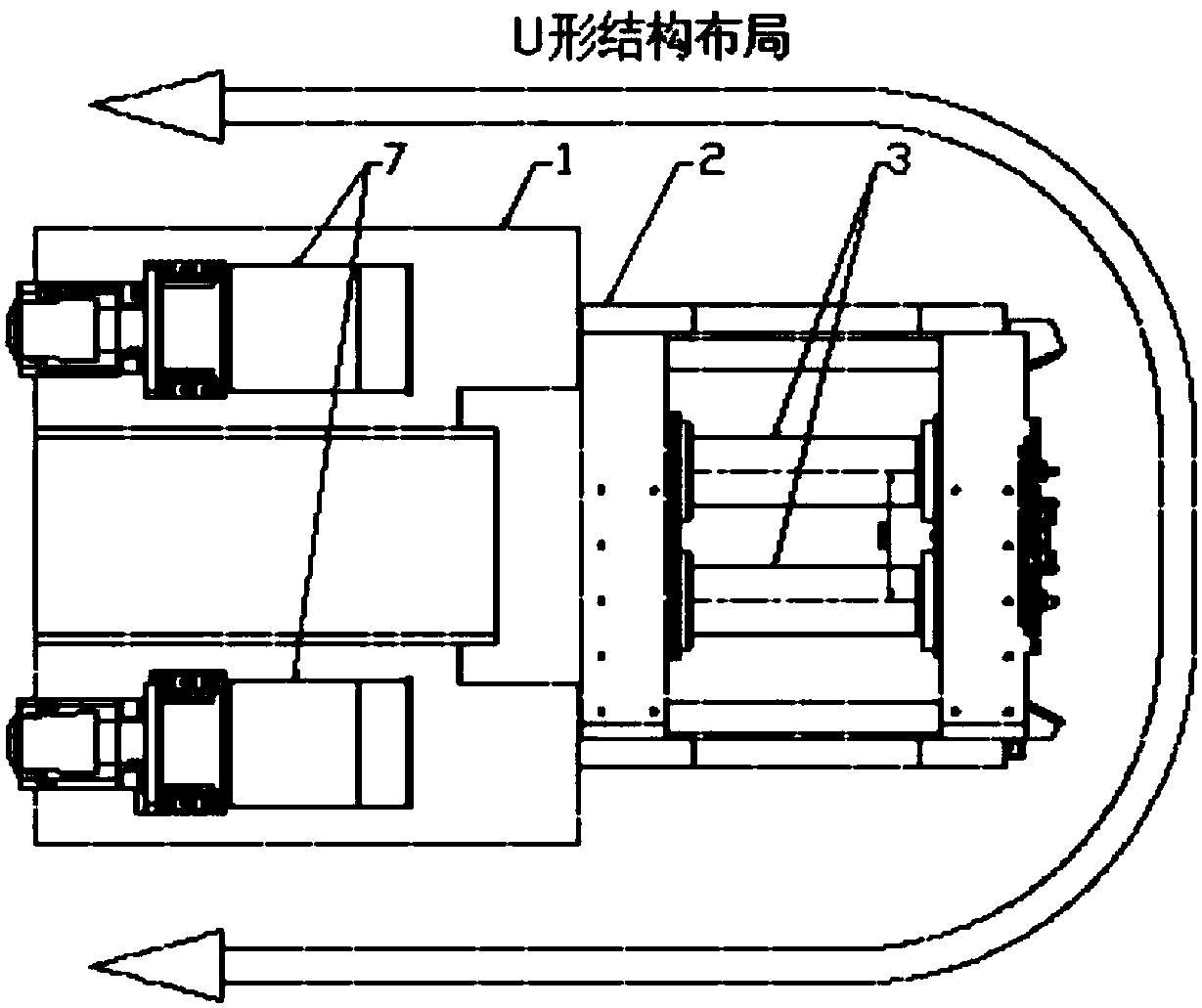

InactiveCN103102852AFast dryingHigh production efficiencyEster polymer adhesivesPolymer scienceFunctional monomer

The invention discloses on-line automatic refined pasting glue which is prepared by polymerizing the following raw materials: a monomer, a soft monomer, a functional monomer, an initiator, an emulsifier, a buffering agent, a functional aid, a viscosity modifier and distilled water. The invention further provides a preparation method of the on-line automatic refined pasting glue. The glue is green, environment-friendly, beneficial for heath, free of bad odor and free of harmful substances such as phthalic acid ester plasticizers, heavy metals and the like, and has high solid content and high toughness, so that pasted products are free of wrinkle and unlikely to be deformed; the glue is rapid to be dried at normal temperature, high in yield efficiency and good in stain reduction and cleaning capability; the residual glue on a decorative surface can be easily swept off by using a wet rag, thereby maintaining the attractiveness of the decorative surface of a base material; due to good coating property, the glue can be rapidly flattened and coated on the base material; and a final pasted product is excellent in binding strength, and glued surfaces are kept solid and durable.

Owner:上海奇想青晨新材料科技股份有限公司

Biogas fermentation initiator and preparation method thereof

InactiveCN104152494AReduce startup timeIncrease gas productionMicroorganism based processesWaste based fuelGenus MethanosarcinaStart time

The invention discloses a biogas fermentation initiator and a preparation method thereof, and belongs to the technical field of biogas preparation through a biological fermentation method. The present problems of slow start, low gas yield efficiency, and no gas yield in the fermentation process are solved. The initiator is composed of the following raw materials: sludge in fishpond, wheat straw, animal manure, ammonium bicarbonate, and bacterium strains; wherein the bacterium strains are bacteroides succinoge-nes, butyrivibrio fibrisolvens, bacillus subtilis, saccharomycetes, methanosarcina, and methanosaeta. The biogas fermentation initiator is applied to biogas fermentation, can greatly shorten the start time (biogas can be produced after one day), and is capable of increasing the biogas yield and biogas generation speed.

Owner:INST OF AGRI RESOURCES & ENVIRONMENT SHANDONG ACADEMY OF AGRI SCI

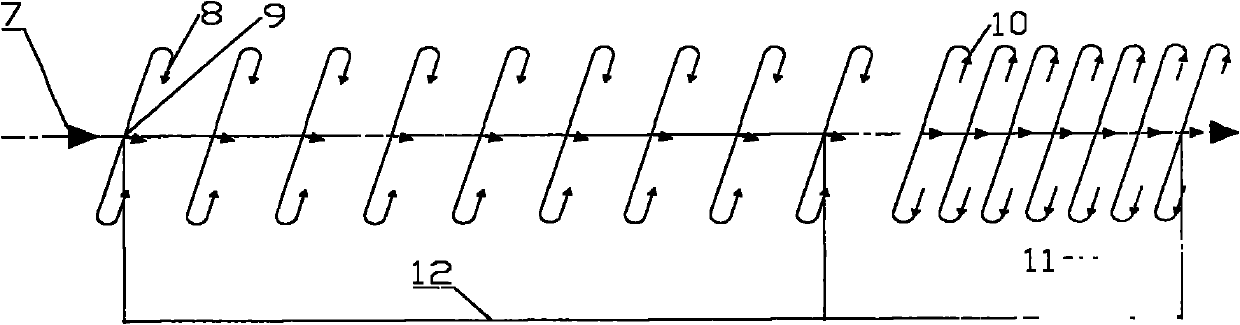

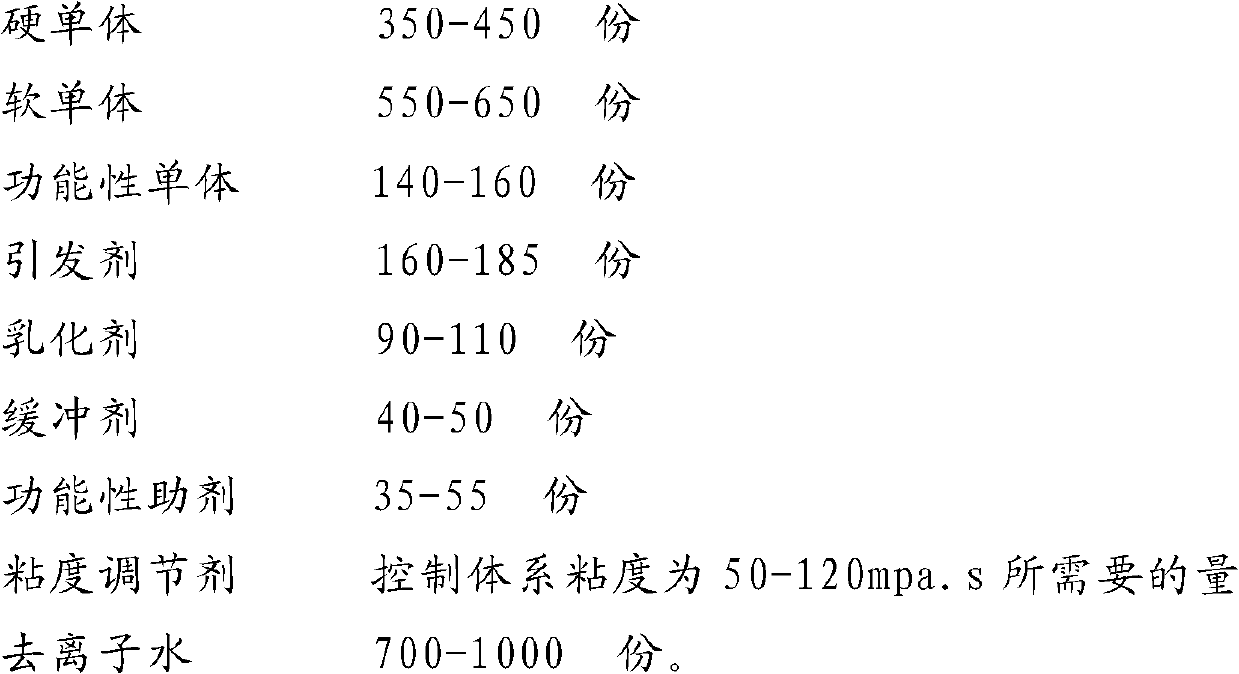

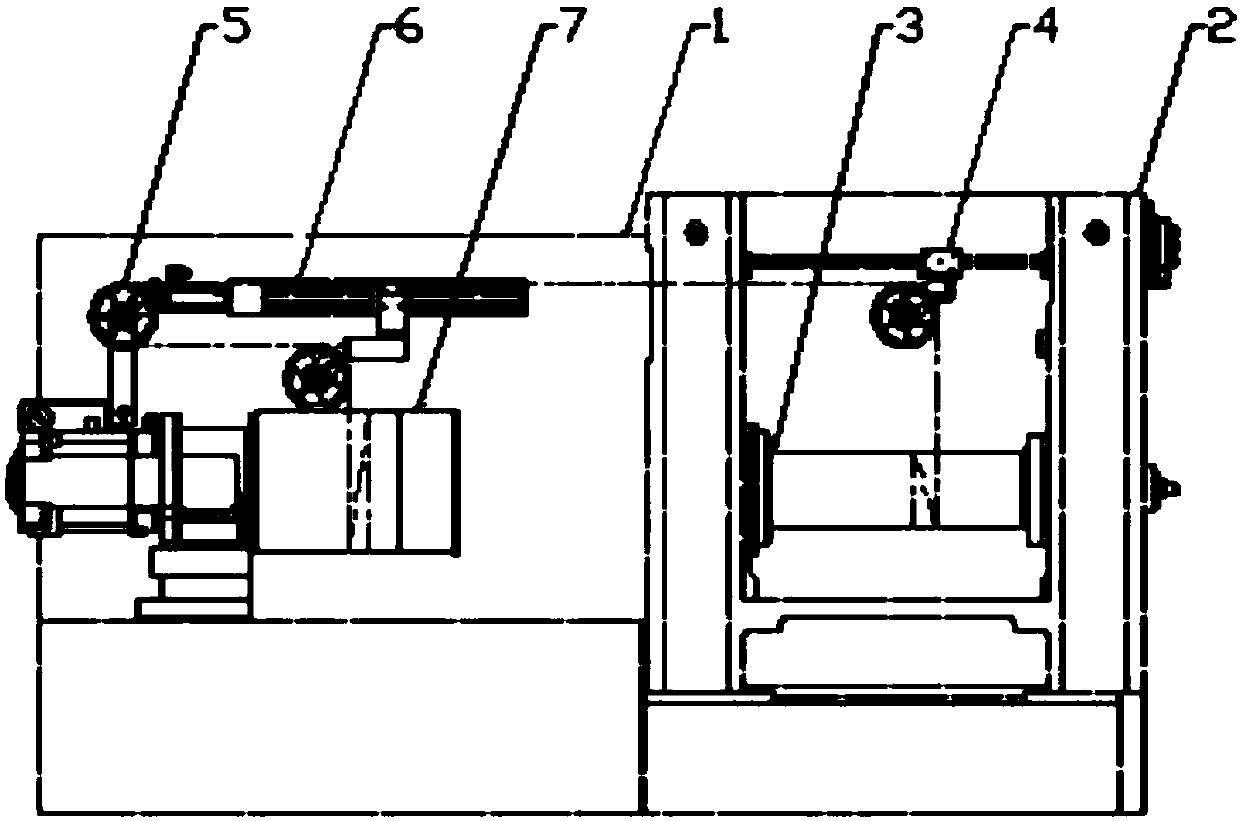

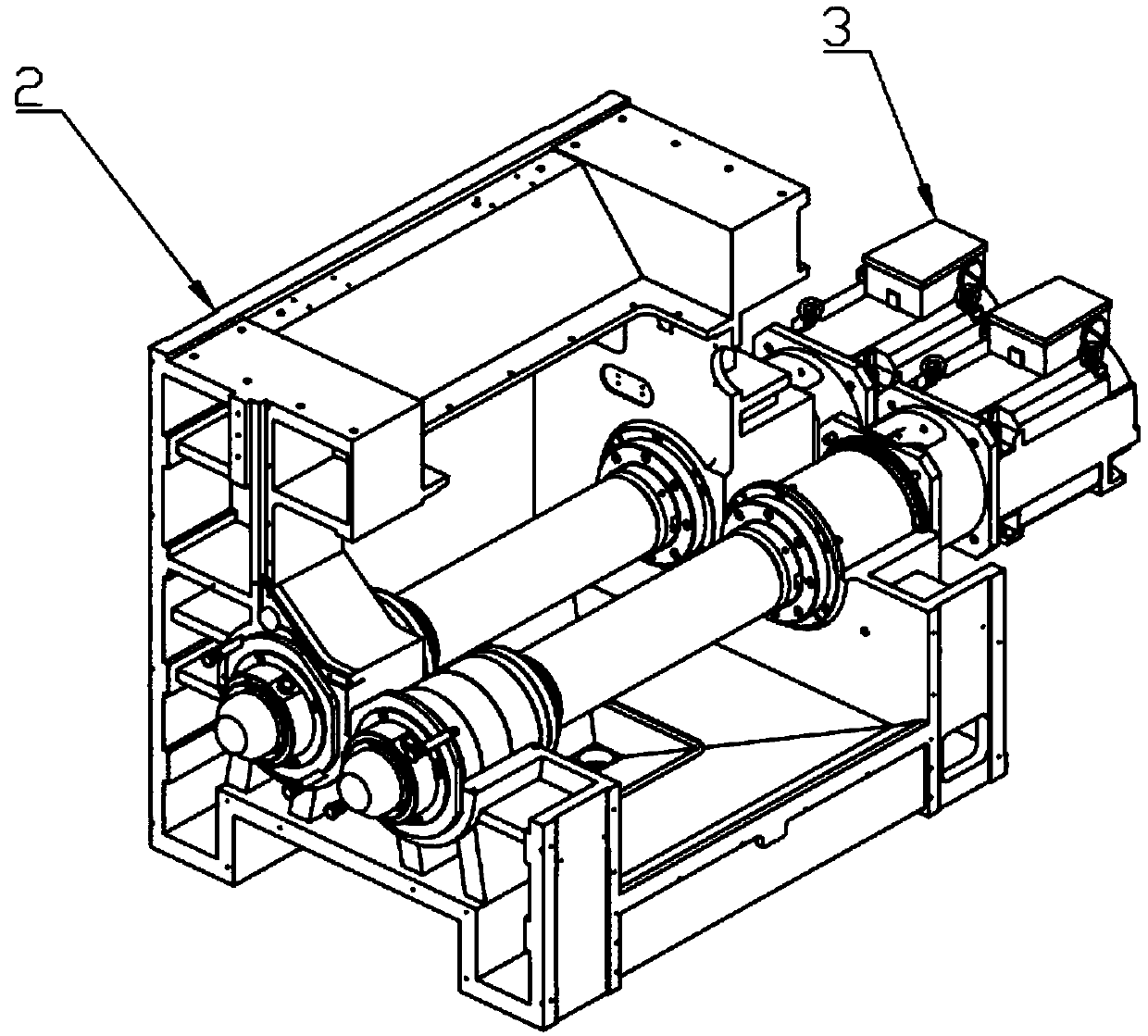

U-shaped short wheelbase high-speed and high-efficiency multi-wire cutting method

InactiveCN108044821AReduce in quantityReduce pollutionWorking accessoriesFine working devicesWire cuttingDrive motor

The invention discloses a U-shaped short wheelbase high-speed and high-efficiency multi-wire cutting method. In an overall structure of U-shaped layout, a take-up / pay-off system, a tension system anda wire arrangement system are symmetrically mounted on two sides of a rack respectively; a cutting room system is mounted on the front side of the rack; the take-up / pay-off system, the tension system,the wire arrangement system, a wire guide system and a spindle system are sequentially connected through a cutting wire, so that three operation areas of take-up, pay-off and cutting are independentof each other;the spindle system drives a roller to rotate through direct drive of a drive motor, thereby remarkably reducing influence on the cutting precision caused by the vibration resulting fromrotation of a belt wheel during high-speed cutting;traditional roller diameter as well as the center distance between two rollers are decreased, and the formation of large wire bow is reduced in a high-speed cutting process, thereby guaranteeing the cutting stability. By adopting the cutting method, the slice yield efficiency can be greatly boosted while the cost of single wire slice is lowered, and the slice yield is increased;moreover, blending of cutting fluid is not needed in the cutting of a diamond wire, and the consumable cost and the environmental pollution are reduced.

Owner:HUNAN YUJING MACHINE

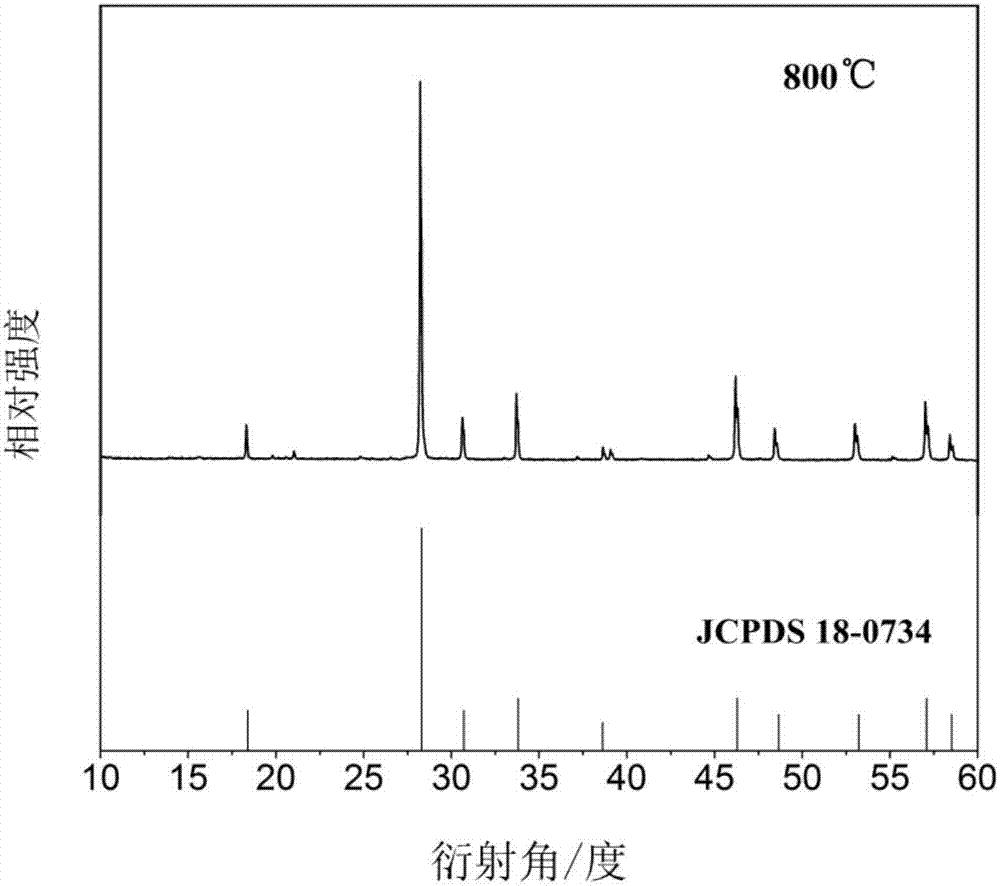

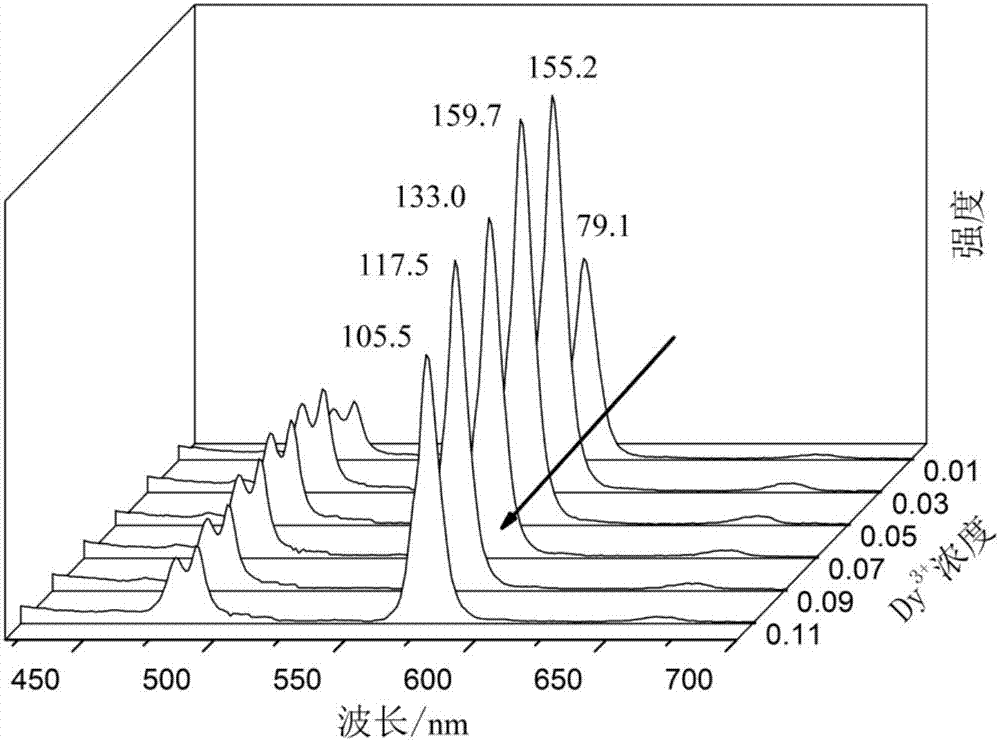

Dysprosium-doped lanthanum lithium molybdate fluorescent powder and preparation method thereof

The invention relates to dysprosium-doped lanthanum lithium molybdate fluorescent powder and a preparation method thereof. Li2CO3 powder, La2O3 powder, MoO3 powder and Dy2O3 powder are taken in the mole ratio being 1:(1-x):4:x, ground and stirred uniformly, and a reactant material is obtained, wherein x ranges from 0.01 to 0.11; the reactant material is calcined at the temperature of 750-850 DEG C for 4-6 h, and a reaction product is obtained; the reaction product is cooled, taken out to be ground and then sieved, and the dysprosium-doped lanthanum lithium molybdate fluorescent powder is obtained. The fluorescent powder adopting the pure phase substance structure is formed with a high-temperature solid phase method, raw materials are more widely sourced, the cost is relatively low, and no toxic organic matter is formed; compared with an existing wet chemistry method, the preparation method is simple, low in pollution and high in yield, no acid or alkali is used, and the yield efficiency is effectively improved.

Owner:SHAANXI UNIV OF SCI & TECH

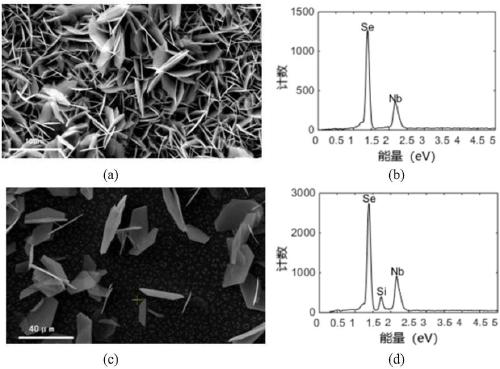

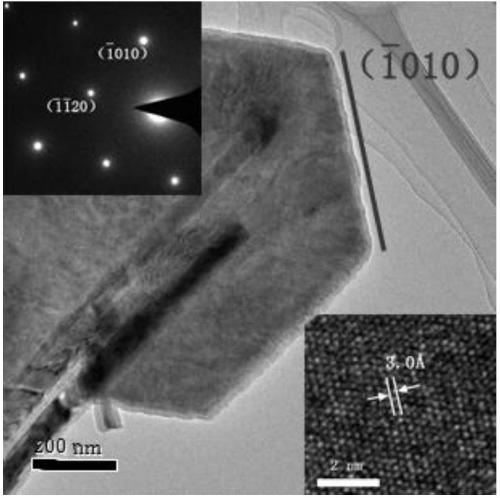

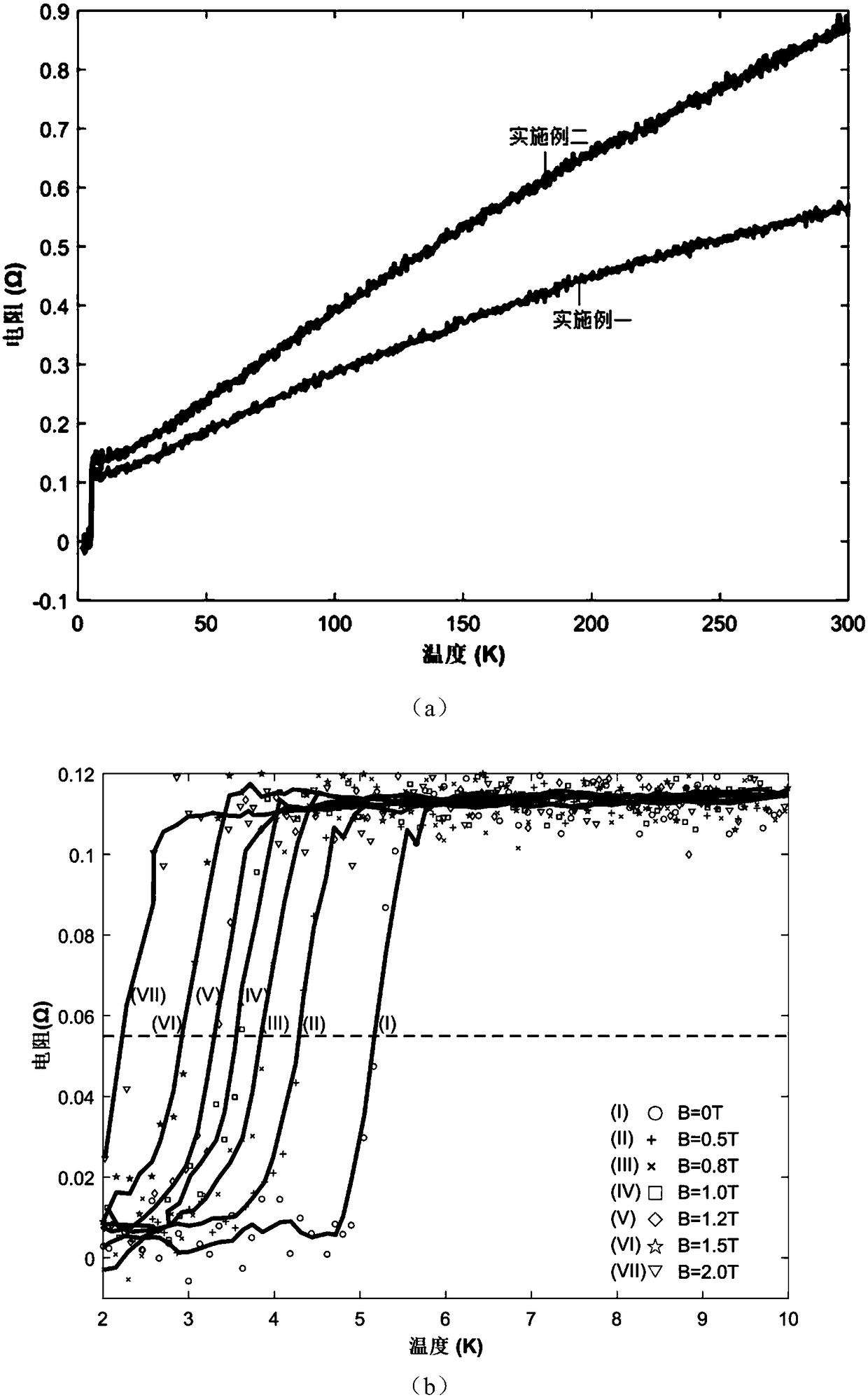

Synthesis device and synthesis method for NbSe2 monocrystal layered nanosheet

ActiveCN109440190AFree accessShorten the timePolycrystalline material growthNanotechnologyNanowireSynthesis methods

The invention discloses a synthesis device and a synthesis method for an NbSe2 monocrystal layered nanosheet. Carrier gas is used for controlling airflow, the atmosphere of a growth environment is accurately controlled, the pure NbSe2 monocrystal layered nanosheet can still be synthesized even if a carrier gas source participates in reaction in a gaseous phase conveying process; in a whole process, only a sealed quartz tube needs to be used to grow in a horizontal tube furnace, time and economic cost are greatly lowered, and a preparation method is simple; characterization results are good, practical samples can be taken and used at will, and the yield efficiency is improved by multiple orders of magnitude; control factors mainly depend on growth time and temperature, a space between a source and a deposition substrate, the shape structure of slide glass, annealing time and the like, parameters can be easily controlled, and the repeatability is good. According to the method disclosed by the invention, a great quantity of NbSe2 monocrystal layered nanosheets can be prepared, after dosage concentration is controlled through a further condition, a new scheme is provide for the growthof the NbSe2 nanosheets and other all transition metal disulfide compound nanostructures, and the synthesis device and the synthesis method have an important reference meaning.

Owner:PEKING UNIV

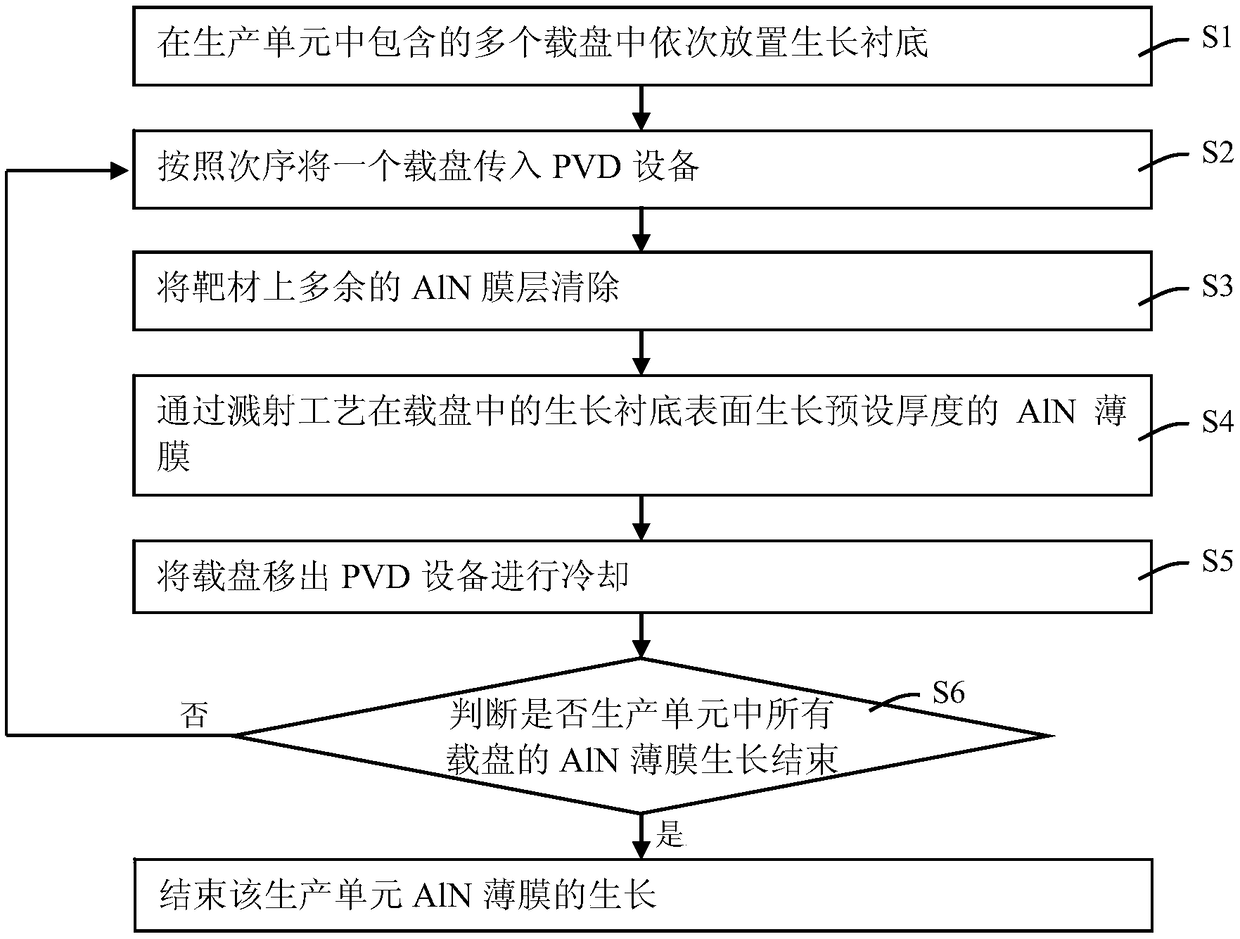

AlN film growing method

InactiveCN109326506AExtended service lifeAvoid affecting the sputtering processVacuum evaporation coatingSputtering coatingEngineeringProduction unit

The invention provides an AlN film growing method. The AlN film growing method comprises the following steps: S1, successively placing growing substrates in a plurality of carrying plates in a production unit; S2, transferring a carrying plate to PVD equipment in sequence; S3, removing a redundant AlN film layer on a target material; S4, growing an AlN film with a preset thickness on the surface of the growing substrate in the carrying plates through a sputtering process; S5, moving the carrying plates out of the PVD equipment and cooling the carrying plates; and S6, judging whether growing ofAlN films of all the carrying plates in the production unit is finished or not, if growing of the AlN films of all the carrying plates in the production unit is finished, finishing growth of the AlNfilm of the production unit, and if growing of the AlN films of all the carrying plates in the production unit is not finished, skipping to step S2. The circumstance that the follow-up sputtering process is affected due to the over-thick AlN layer on the target material is avoided effectively, continuous production can be carried out, the circumstance that the process of AlN removing and pre-settling at regular intervals is not required, the yield efficiency is greatly improved, and the stability of the process is improved.

Owner:LATTICE POWER (JIANGXI) CORP

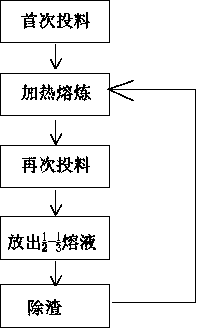

Temperature rise method for lead smelting furnace body

InactiveCN103644737AReduce CooldownReduce lossesStirring devicesCharge manipulationLead smeltingSingle cycle

The invention relates to a smelting method, in particular to a temperature rise method for lead smelting furnace body. The temperature rise method is characterized in that the feeding capacity is increased in batches, compressed air is blown from the furnace bottom, furnace burdens are mixed, so that bonded slag is prevented from bottom sitting, 1 / 2-1 / 3 of a smelting solution are poured out, then cold burdens are fed, smelting is continued, high-temperature precipitation is shortened to be 2 hours from original 4 hours, the slag is fed in batches, then feeding is continued to smelt, in each cycle, the smelting solution of the furnace body is kept to account for 1 / 2-1 / 3, and the preheating effect performed on the cold burdens can be achieved. According to the temperature rise method for the lead smelting furnace body, operation procedures are changed, a single cycle is changed to be the reciprocating cycle, cold burden preheating and hot smelting solution cooling interact mutually, energy losses are reduced, besides, smelting solution cooling time is reduced, the yield efficiency is improved, and production cost per ton is reduced.

Owner:岷山环能高科股份公司

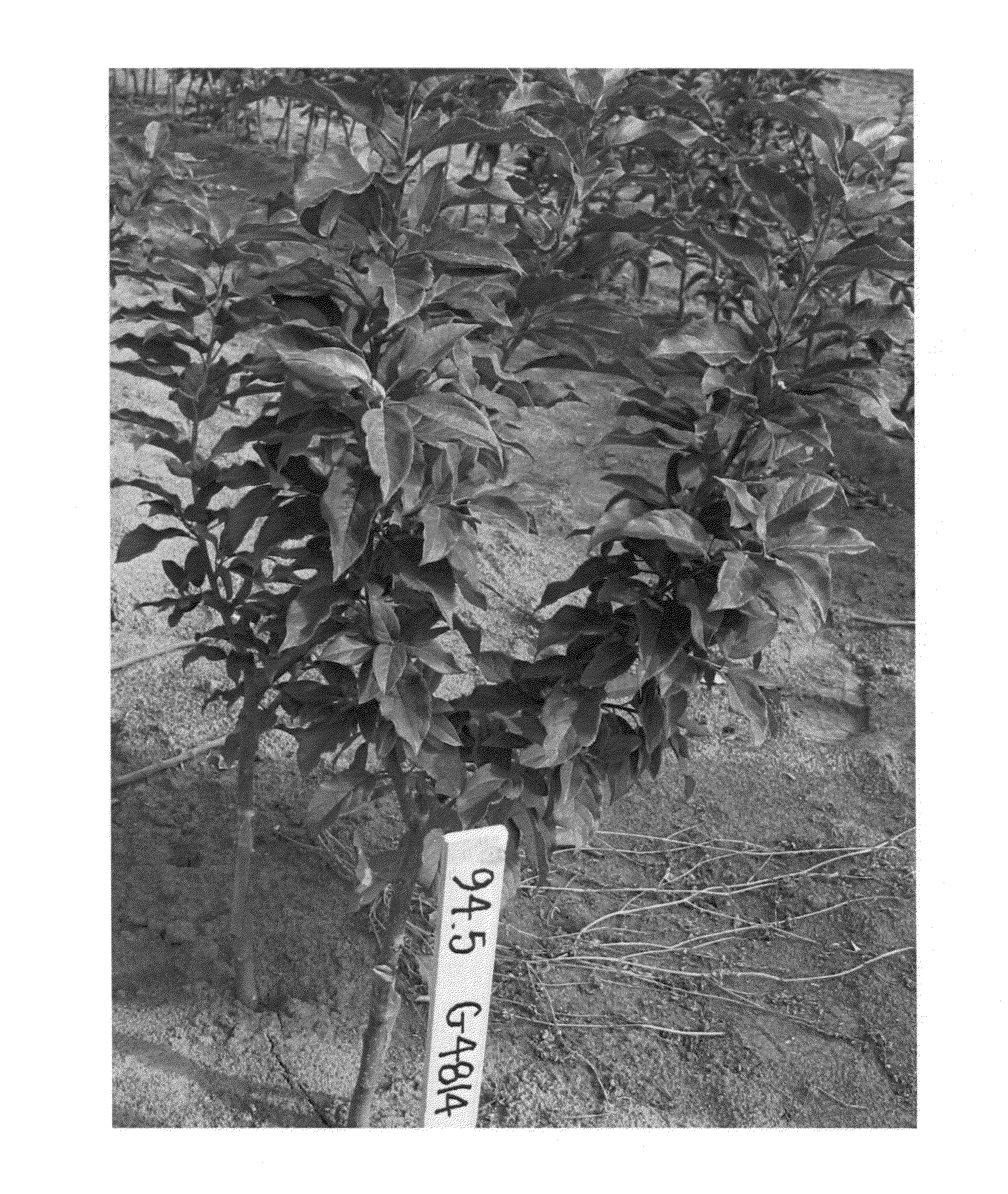

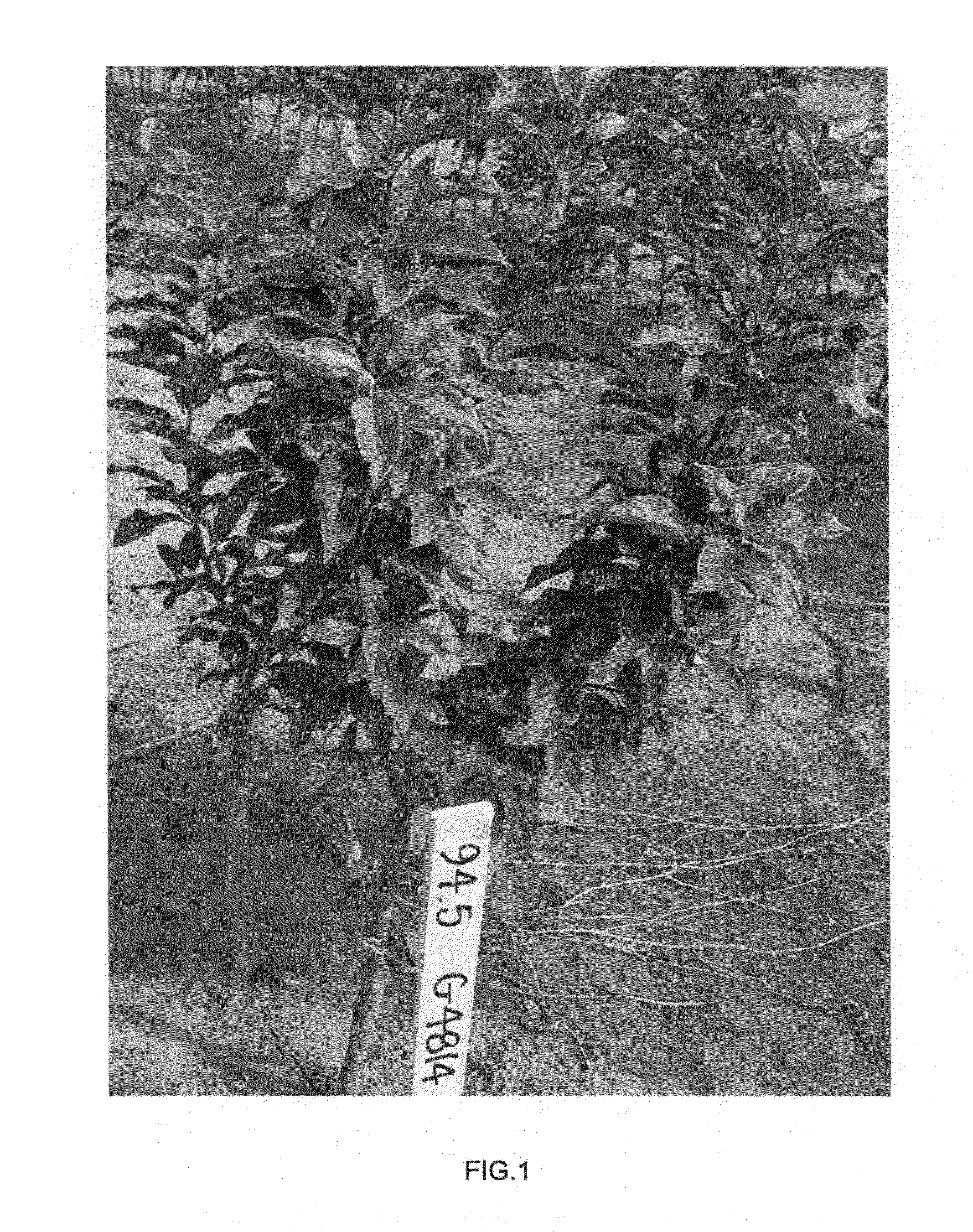

Apple tree named 'G.814'

ActiveUS20150342101P1Induces scion precocityHigh yield efficiencyAngiosperms/flowering plantsDiseaseFire blight

The present invention relates to a new and distinct variety of apple tree named ‘G.814.’‘G.814’ is useful in that it can be propagated clonally and used as a rootstock or root system for apple trees as well as for interstems of apple trees. When used as a rootstock, ‘G.814’, is: dwarfing, induces scion precocity, is cold hardy, induces scion precocity, has a high yield efficiency, is tolerant to replant disease, and is resistant to: crown and root rot (Phytophthora cactorum), fire-blight (Erwinia amylovora), and powdery mildew. ‘G.814’ is susceptible to Apple Stem Grooving Virus (ASGV) and wooly apple aphid.

Owner:US SEC AGRI +1

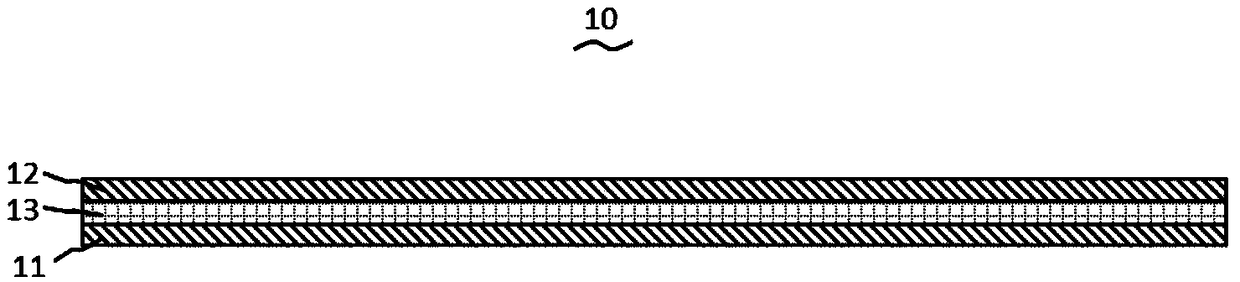

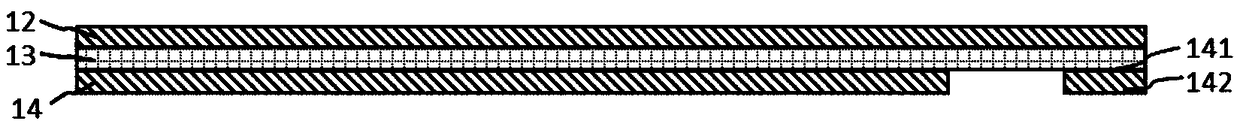

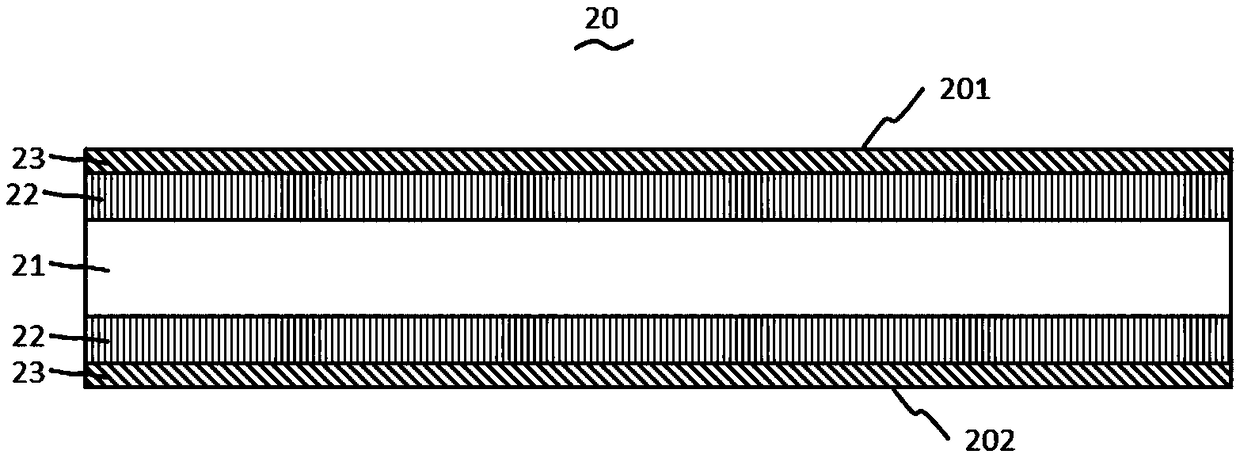

Manufacturing method of packaging substrate

ActiveCN108550531AImprove output efficiencyAchieve fine layoutSolid-state devicesSemiconductor/solid-state device manufacturingCapacitanceMedia layer

The invention relates to a manufacturing method of a packaging substrate. According to the embodiment of the invention, the manufacturing method comprises steps of providing an overlapping structure,wherein the first overlapping structure comprises a first metal layer, a second metal layer and a capacitance medium layer arranged between the first metal layer and the second metal layer; carrying out patterning processing on the first metal layer of the first overlapping structure so as to form a first circuit layer; providing a carrier plate, wherein the carrier plate comprises a first surfaceand a second surface, and the first surface is opposite to the second surface; laminating a first dielectric layer and the first overlapping structure subjected to the patterning processing on the first surface and the second surface of the carrier plate; and carrying out patterning processing on the first surface and the second surface so as to form a second circuit layer. According to the invention, precise layout of inner elements of the packaging substrate is achieved; and yield efficiency of the packaging substrate is improved.

Owner:ASE SHANGHAI

Water-based environment-friendly fine mounting glue

ActiveCN102952507ANo bad smellHigh solid contentGraft polymer adhesivesWater basedHazardous substance

The invention discloses a water-based environment-friendly fine mounting glue, which is composed of the following raw materials: a pre-emulsifier, a seed monomer, an dropping monomer, an initiator 1, an initiator 2 and a functional additive. The fine mounting glue produced by the invention is environment-friendly and healthy, does not have bad smell or contain harmful substances such as toluene, dimethylbenzene and heavy metals, and has the advantages of high solid content and high toughness. The mounting product hardly wrinkle or deform. In addition, the glue has fast drying speed at room temperature, high yield efficiency, good stain cleaning performance and coating performance, and initial adhesion and lasting adhesion reaching the process requirements for a hardcover gift box.

Owner:牛小夺

Glutamic acid high-yielding technology

The invention belongs to the technical field of amino acid fermentation, and discloses a glutamic acid high-yielding technology. Glutamic acid is prepared through fermenting glutamic acid temperature sensitive strains through a fermentation culture by adopting a temperature sensing technology. The technology has the advantages of reasonable compatibility of the fermentation medium, low cost, high acid yielding efficiency, enterprise cost saving and income increase.

Owner:HULUNBEIER NORTHEAST FUFENG BIOTECHNOLOGIES CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com