Manufacturing method of packaging substrate

A technology for encapsulating substrates and manufacturing methods, applied in semiconductor/solid-state device manufacturing, electrical components, electrical solid-state devices, etc., can solve problems such as low output efficiency, difficulty in providing, and high requirements for machine thin plate capabilities, and achieve fine layout , the effect of improving output efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] In order to better understand the spirit of the present invention, it will be further described below in conjunction with some preferred embodiments of the present invention.

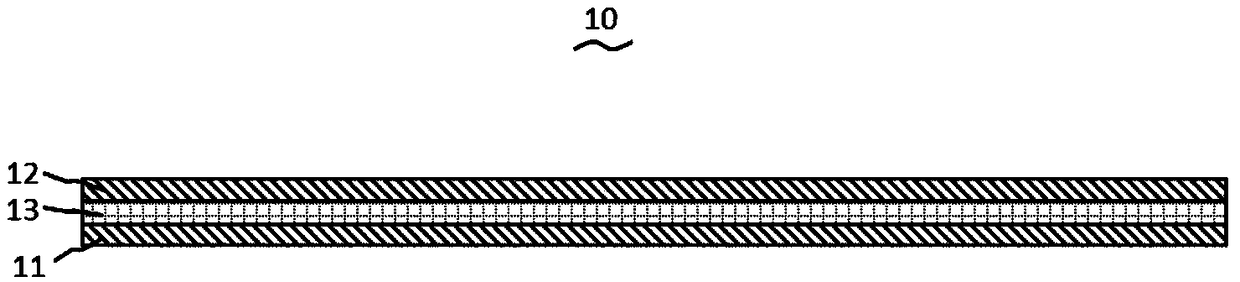

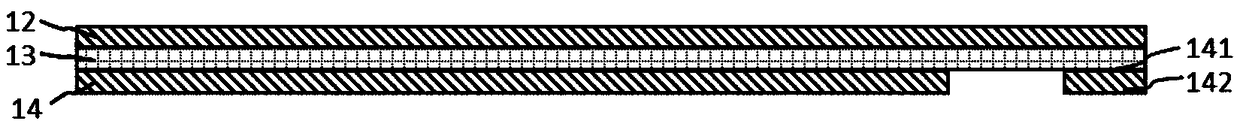

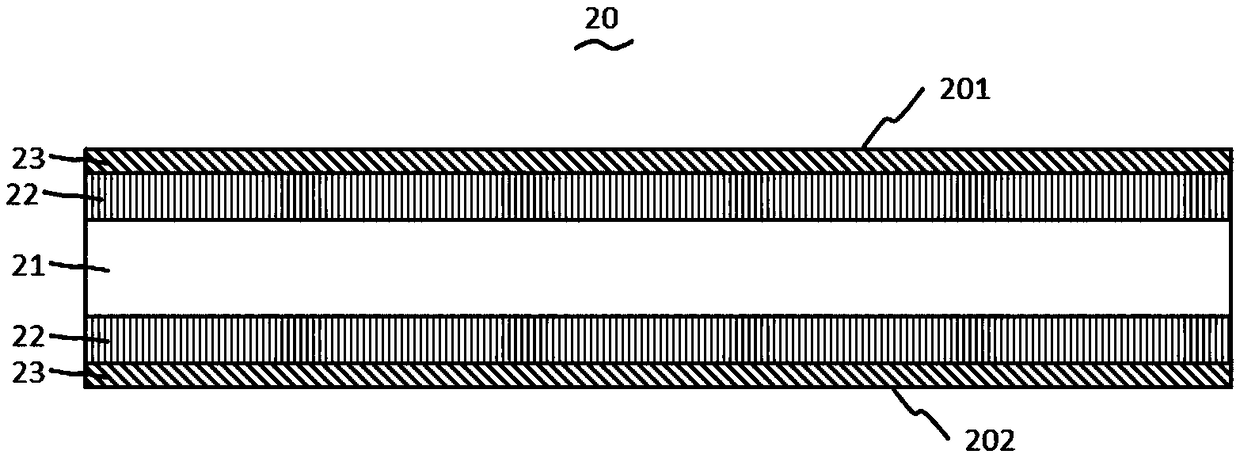

[0014] Figure 1-11 Shown is a schematic cross-sectional view of the packaging substrate in different manufacturing stages of the manufacturing process of the packaging substrate according to an embodiment of the present invention. However, those skilled in the art can fully understand based on the examples of the embodiments of the present invention Figure 11 The package substrate 100 shown can also be obtained according to other embodiments of the present invention, and is not limited to Figure 1-10 The illustrated steps. In other words, what those skilled in the art can determine based on the following disclosure is that the manufacturing process of the packaging substrate should be adjusted accordingly due to the structure or production requirements of the packaging substrate. This embodim...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com