Plane squeezing type juicer

A squeezing and juicer technology, which is applied to household machinery, kitchen utensils, household utensils, etc. for filtering food, can solve the impact of the cleanliness of the juicer and food safety, the inconvenience of cleaning the filter structure, the screw and the screw. Extrusion cylinder wear and other problems, to achieve the effect of improving cleanliness and food safety, improving juice extraction efficiency, and increasing use time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in detail below in conjunction with the embodiments and accompanying drawings.

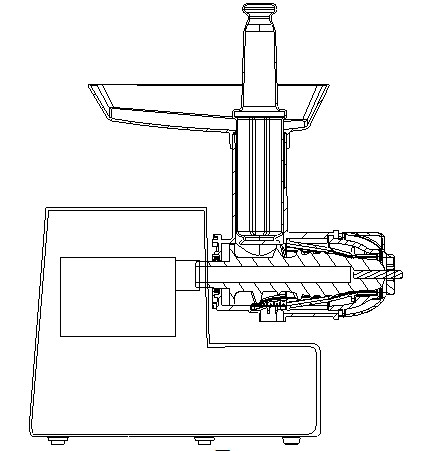

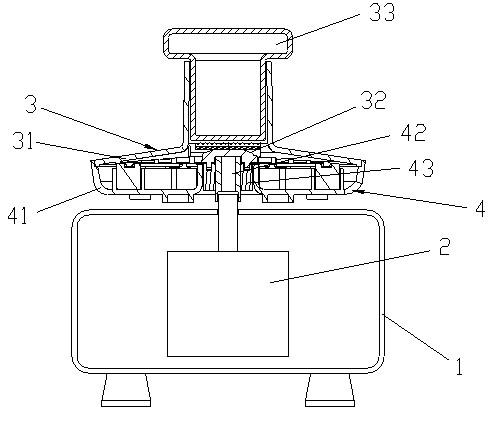

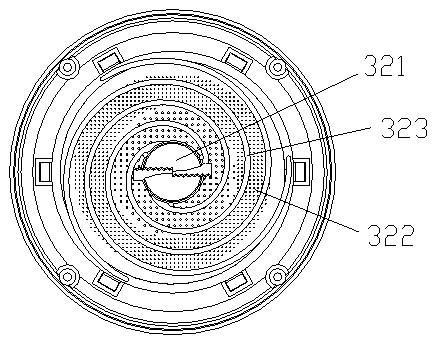

[0025] Such as Figures 1 to 4 As shown, the present invention discloses a plane squeezing juice extractor, which includes a machine base 1, a motor 2 installed in the machine base 1, a juicer plate base 4 located on the machine base 1, and a juicer plate located on the machine base 1. The squeezing and crushing part 3 on the base 4, the squeezing and crushing part 3 includes a juice squeeze plate cover 31 and a juice squeeze plate knife assembly 32, the juice squeeze plate cover 31 has a feed port, and the output shaft of the motor 2 Connected with the squeeze disc knife assembly 32, the juice squeeze disc base 4 is used to receive the fruit and vegetable juice extruded by the crushing part 3. The juice squeeze disc knife assembly 32 has a planar structure, which includes a planar filter 322 and a The pretreatment blade 321 on the flat screen 322 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com