Patents

Literature

54results about How to "High yield efficiency" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

LED lamp

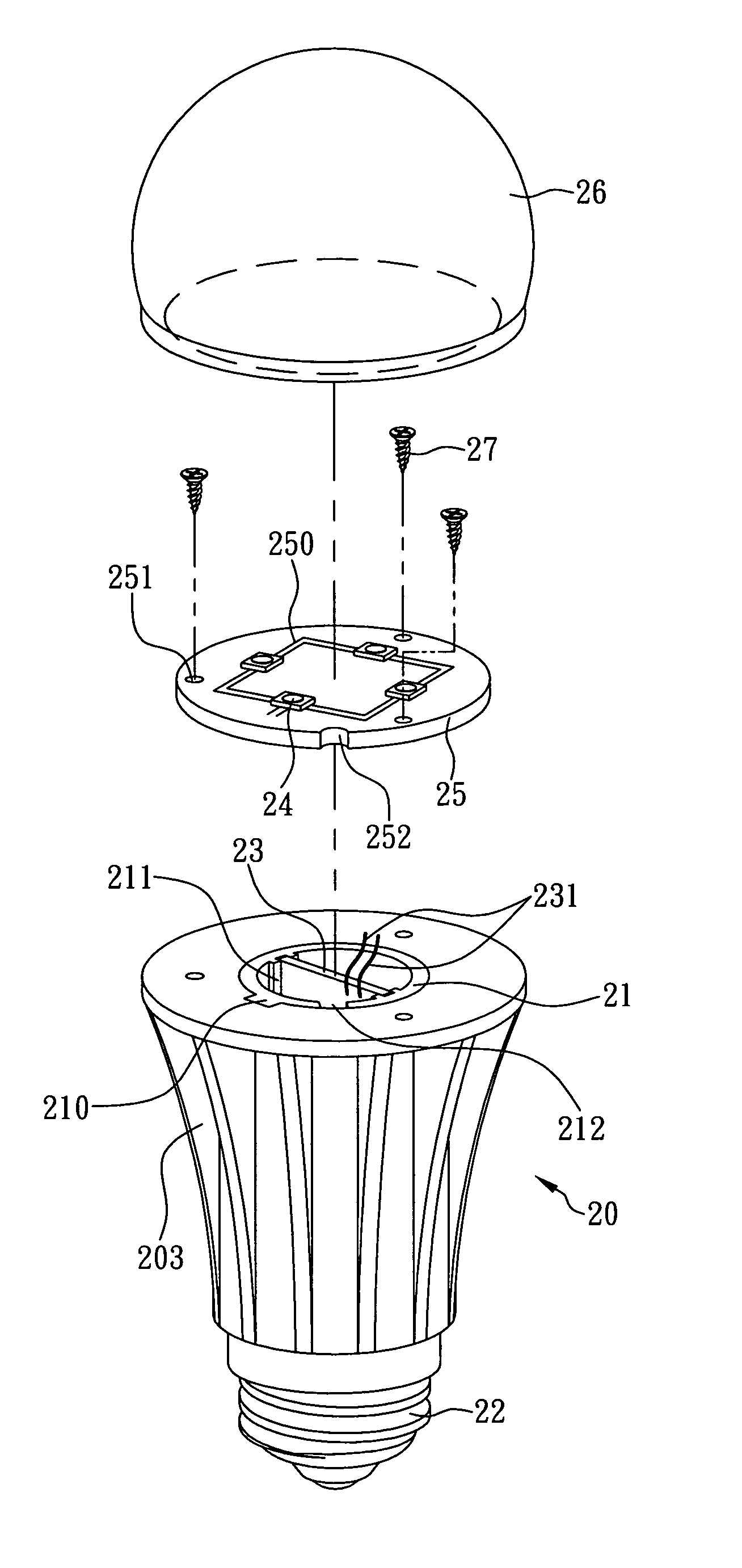

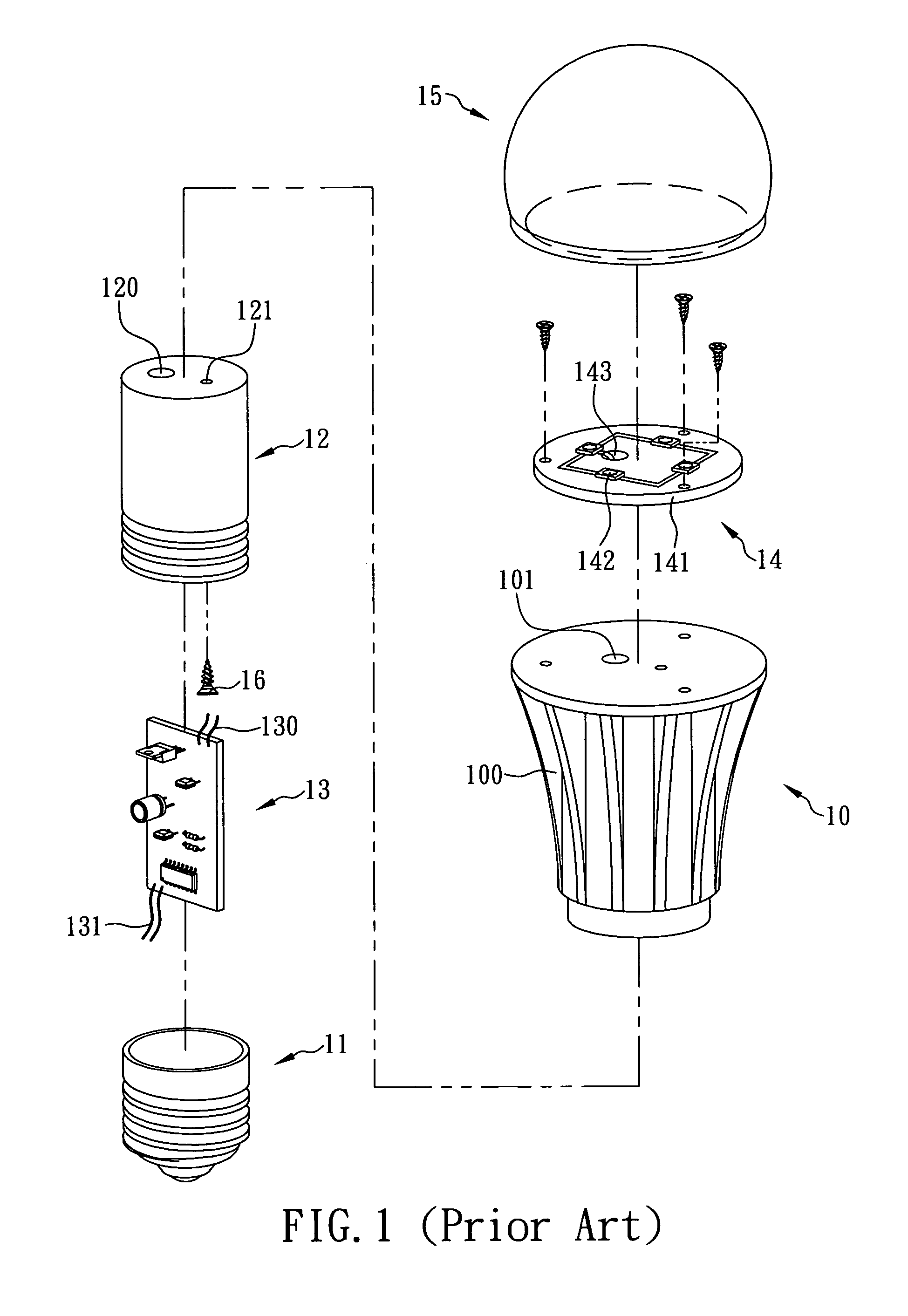

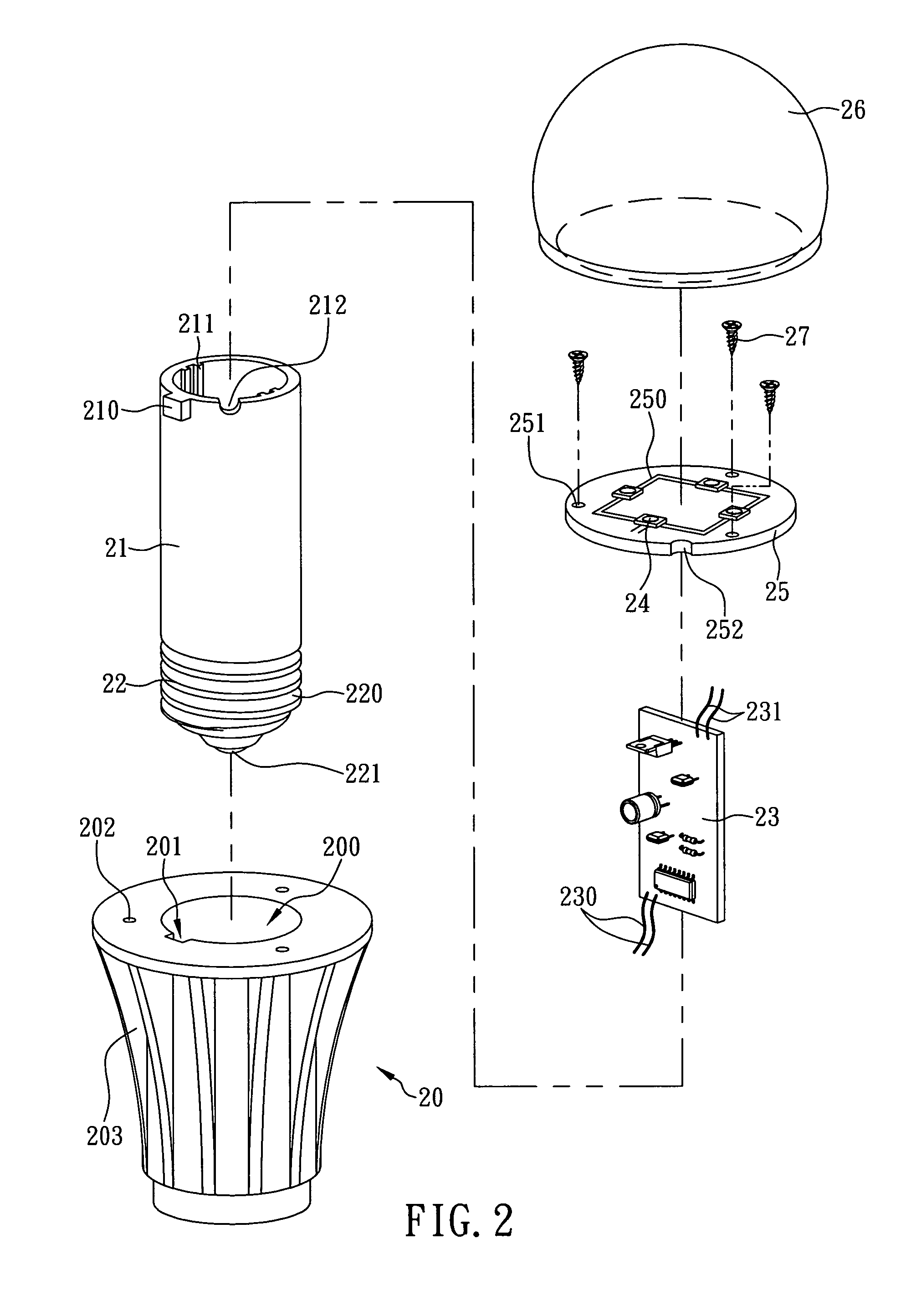

InactiveUS7965023B1Precise positioningEasy to installPoint-like light sourceElectric discharge tubesEngineeringLED lamp

The present invention is to provide an LED lamp, which comprises a heat dissipation housing formed with a receiving hole axially passed therethrough, an insulation housing, an electrode cap connected to the insulation housing, a power PCB, and an installation base plate having a first side installed with at least one LED. A manufacturer only needs to firstly insert the insulation housing along with the electrode cap into the receiving hole for allowing the electrode cap to be extended out of a lower end of the heat dissipation housing, then insert the power PCB into the insulation housing and electrically connect the power PCB to the electrode cap, and finally position a second side of the installation base plate on the upper end of the heat dissipation housing and electrically connect the installation base plate to the power PCB, so as to rapidly complete the installation of the LED lamp.

Owner:SKYNET ELECTRONICS

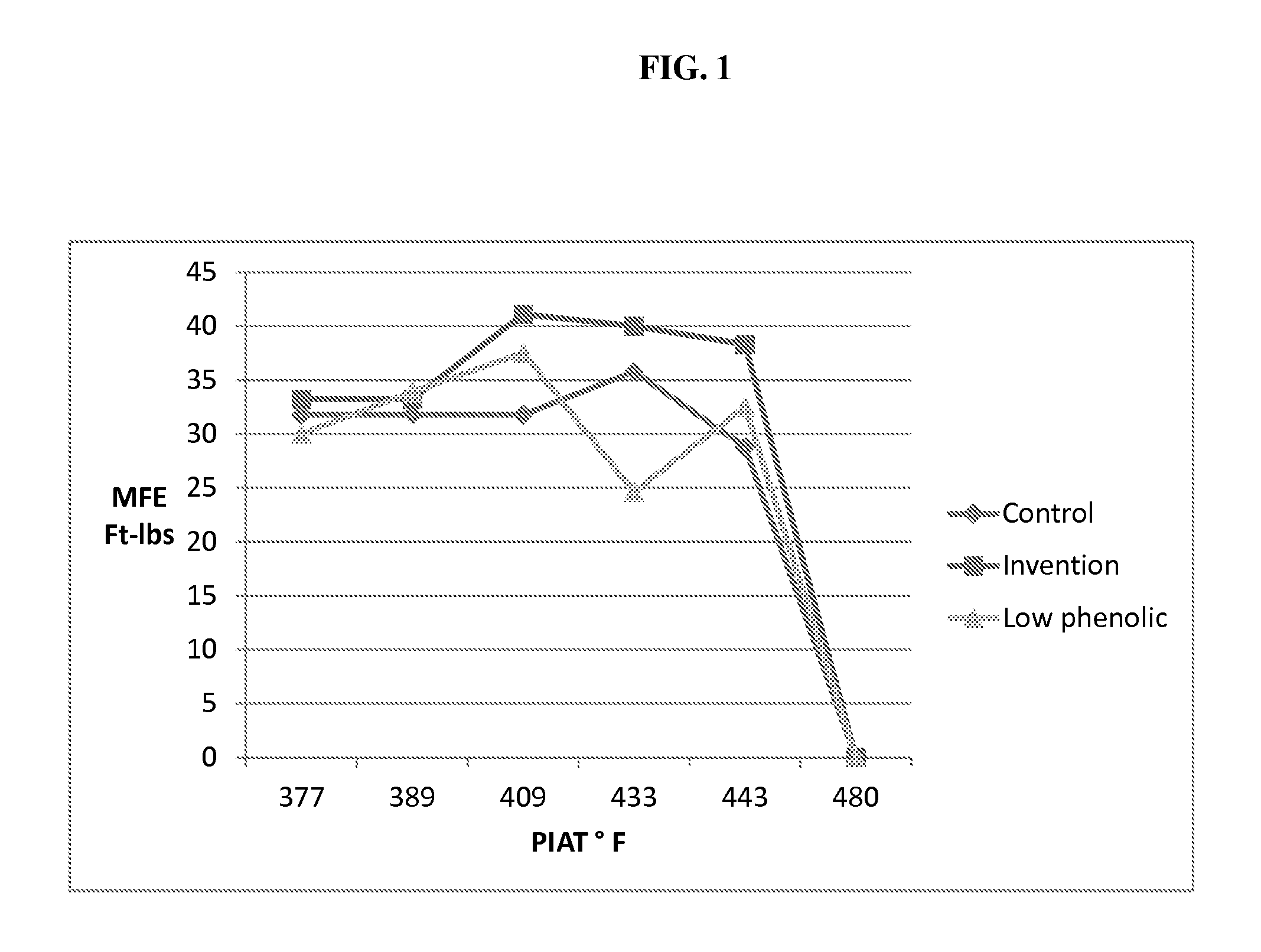

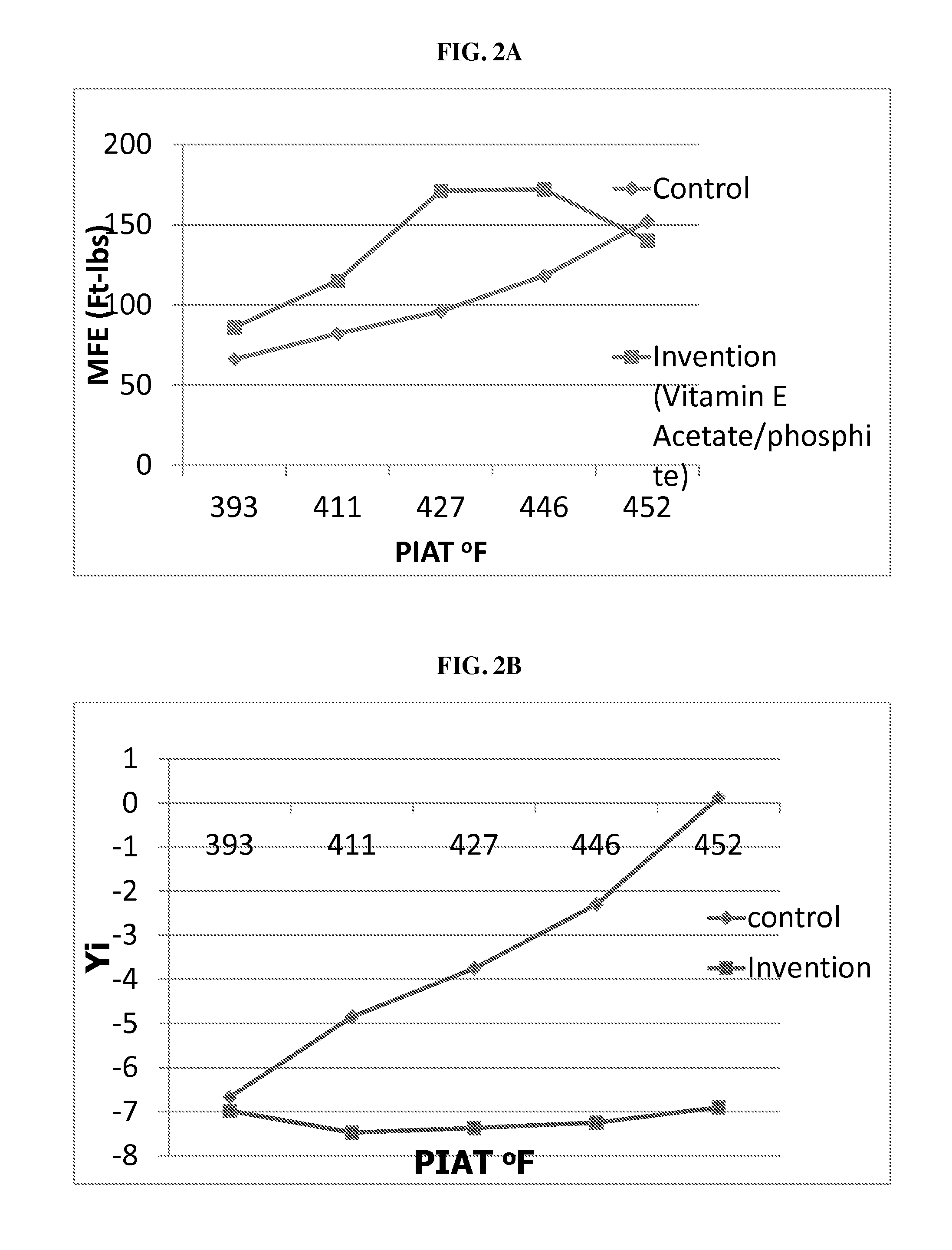

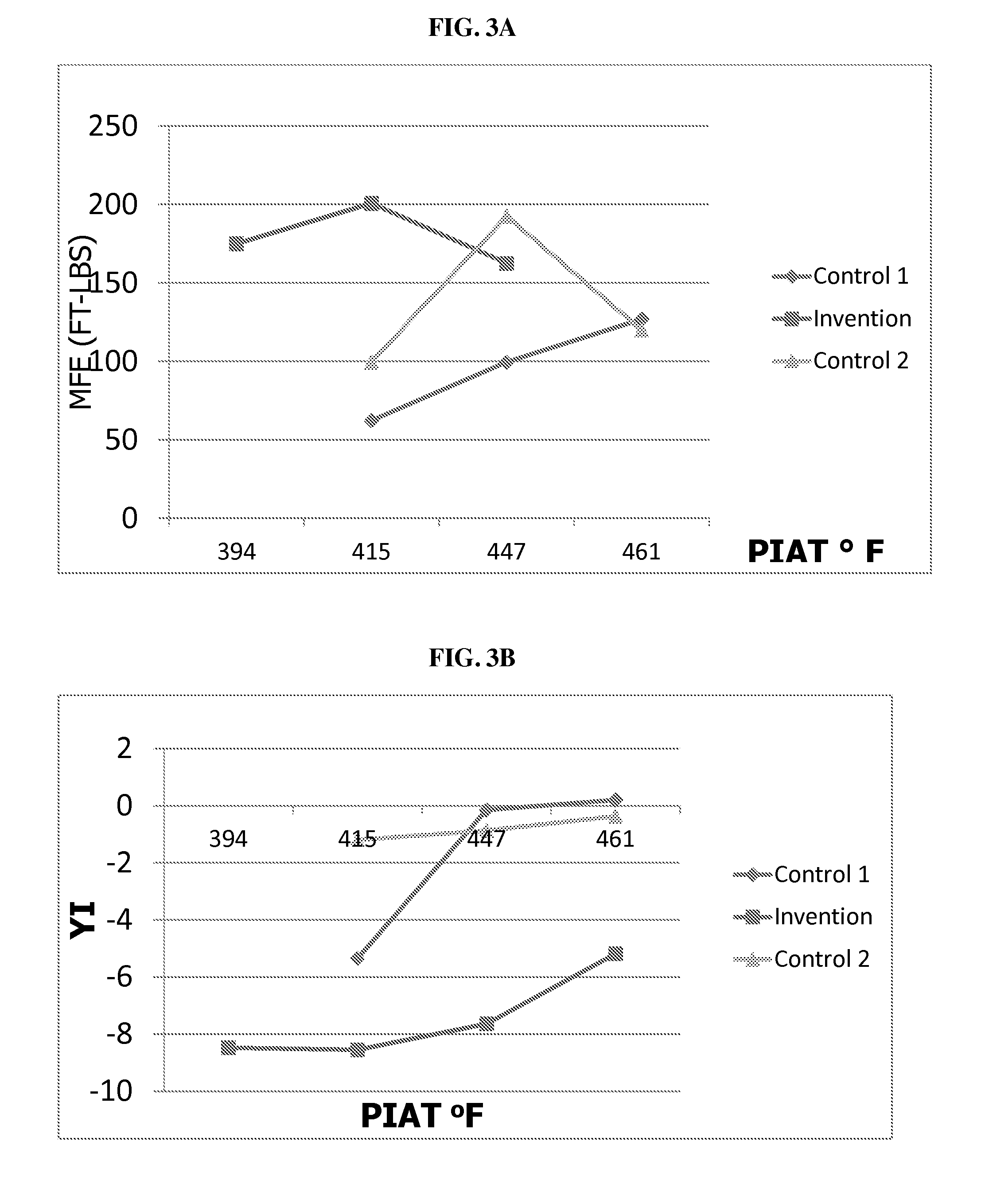

Processing additives and uses of same in rotational molding

ActiveUS20120146257A1Shorten cycle timeShorten the timeOrganic chemistryChemical industryShell moldingCycle time

The cycle time of polymer compositions subjected to a rotomolding process is improved (i.e., reduced), while the processing window is simultaneously enlarged through the use of a polymer-stabilizing amount of a processing stabilizer system having at least one chroman-based compound according to Formula V:

Owner:CYTEC TECH CORP

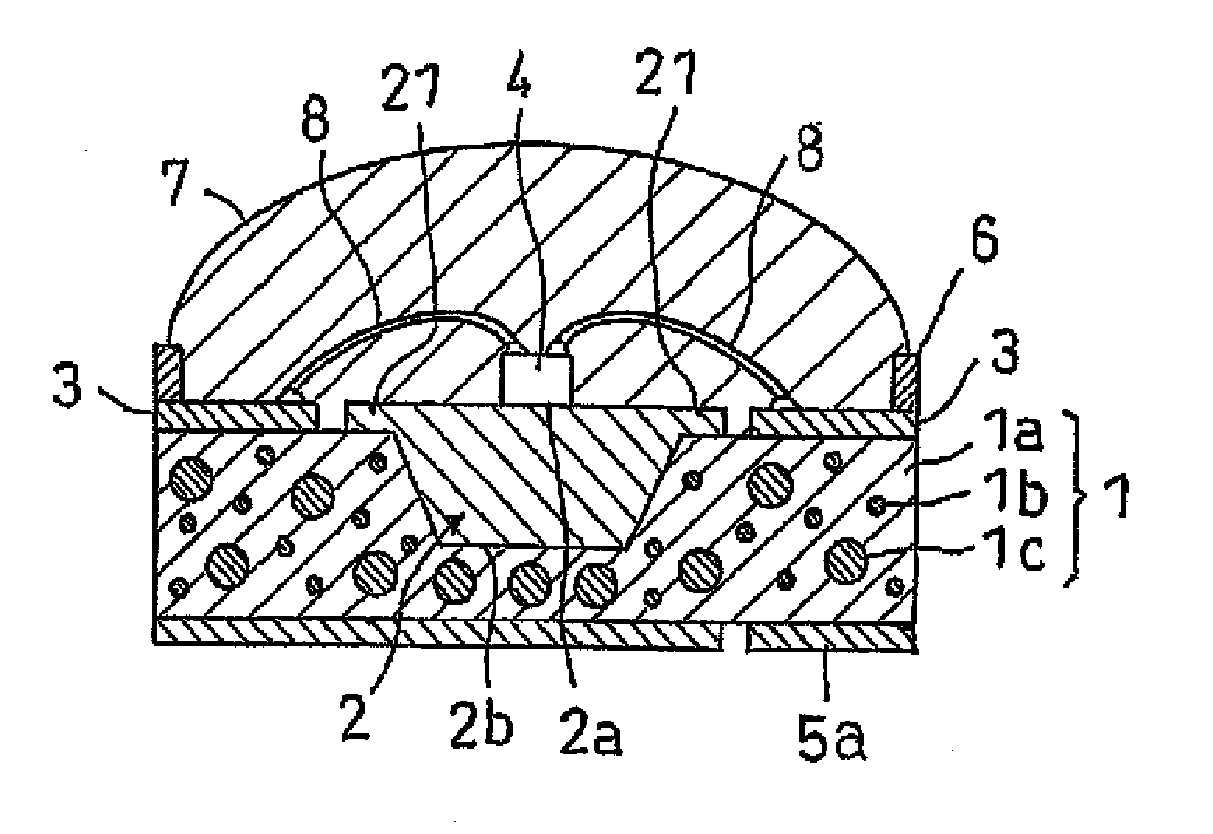

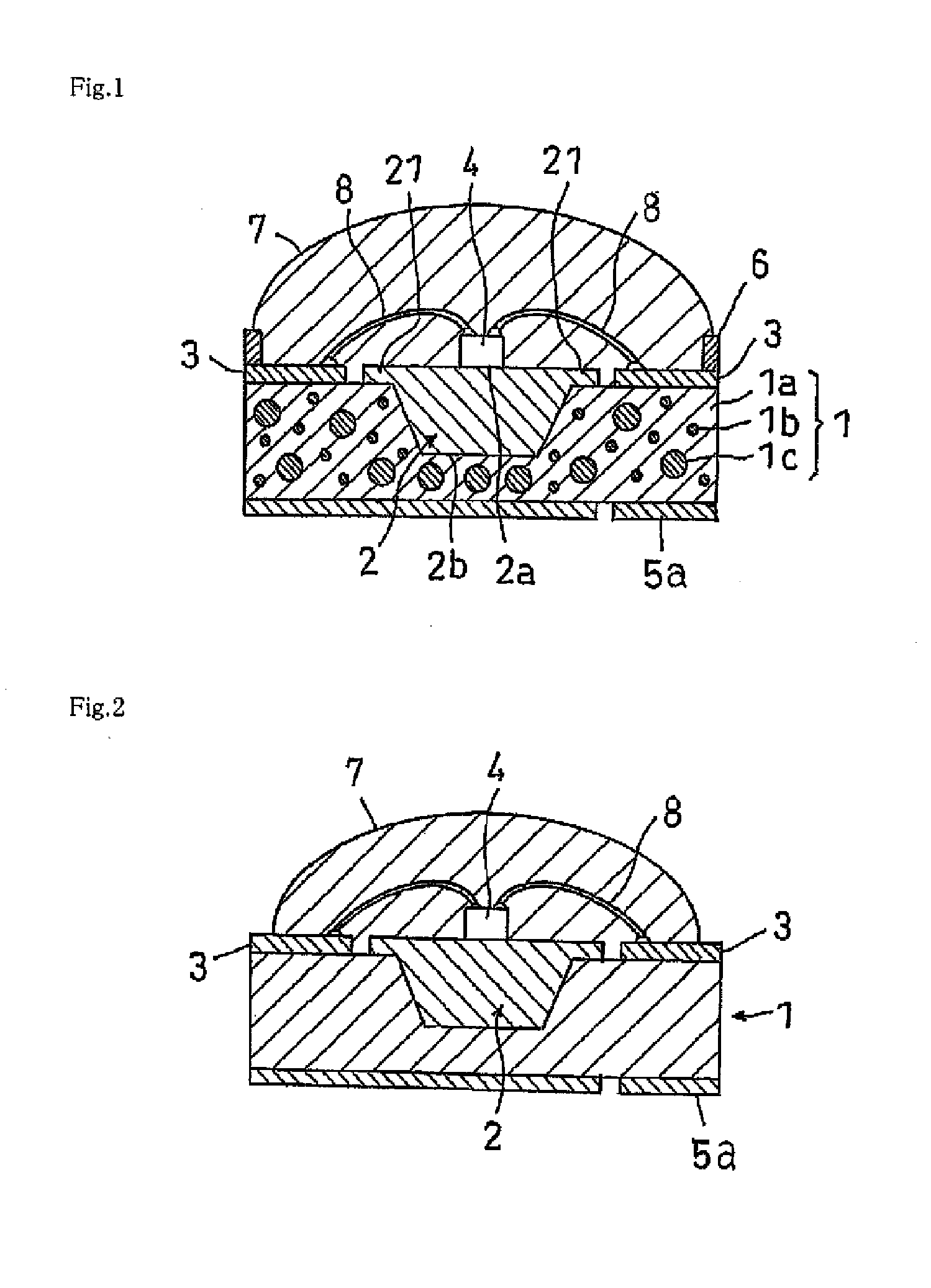

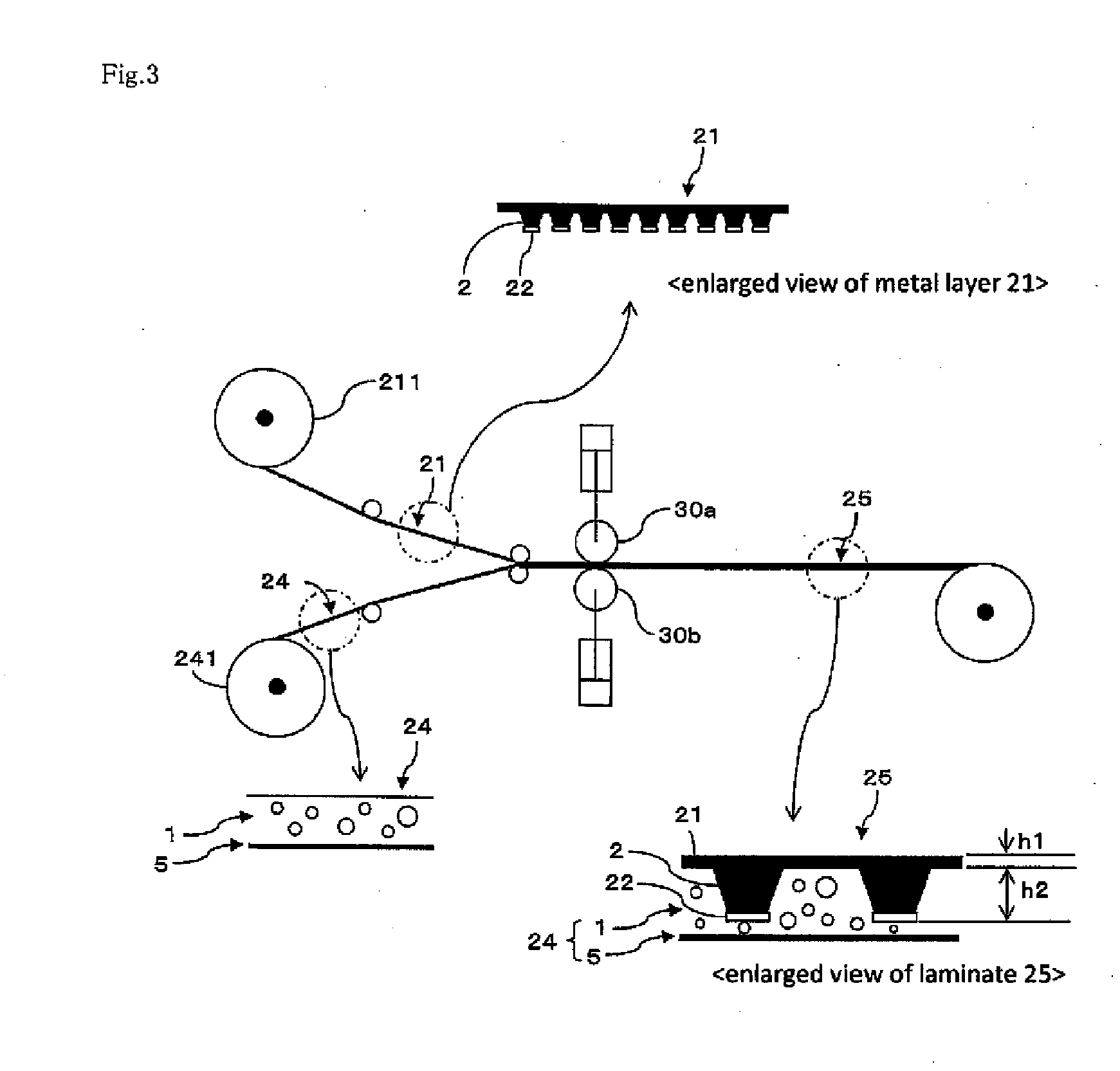

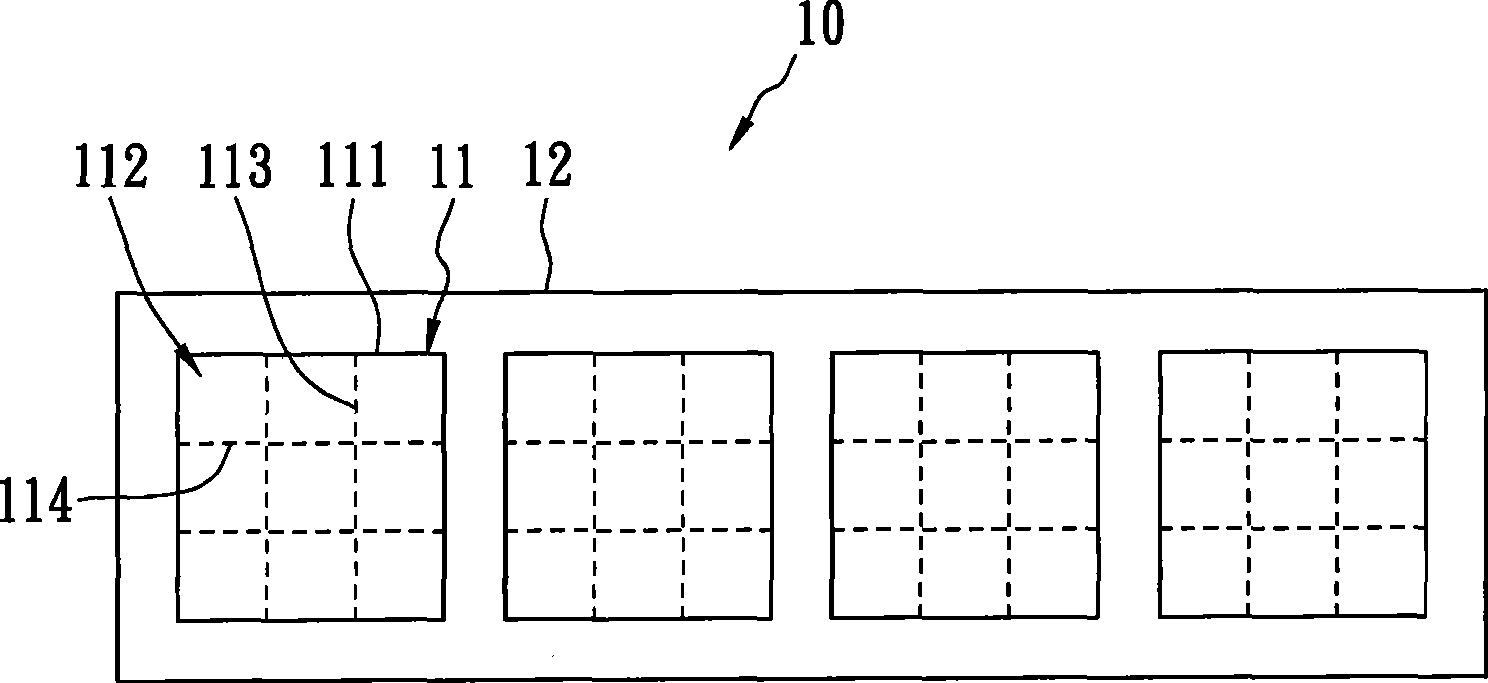

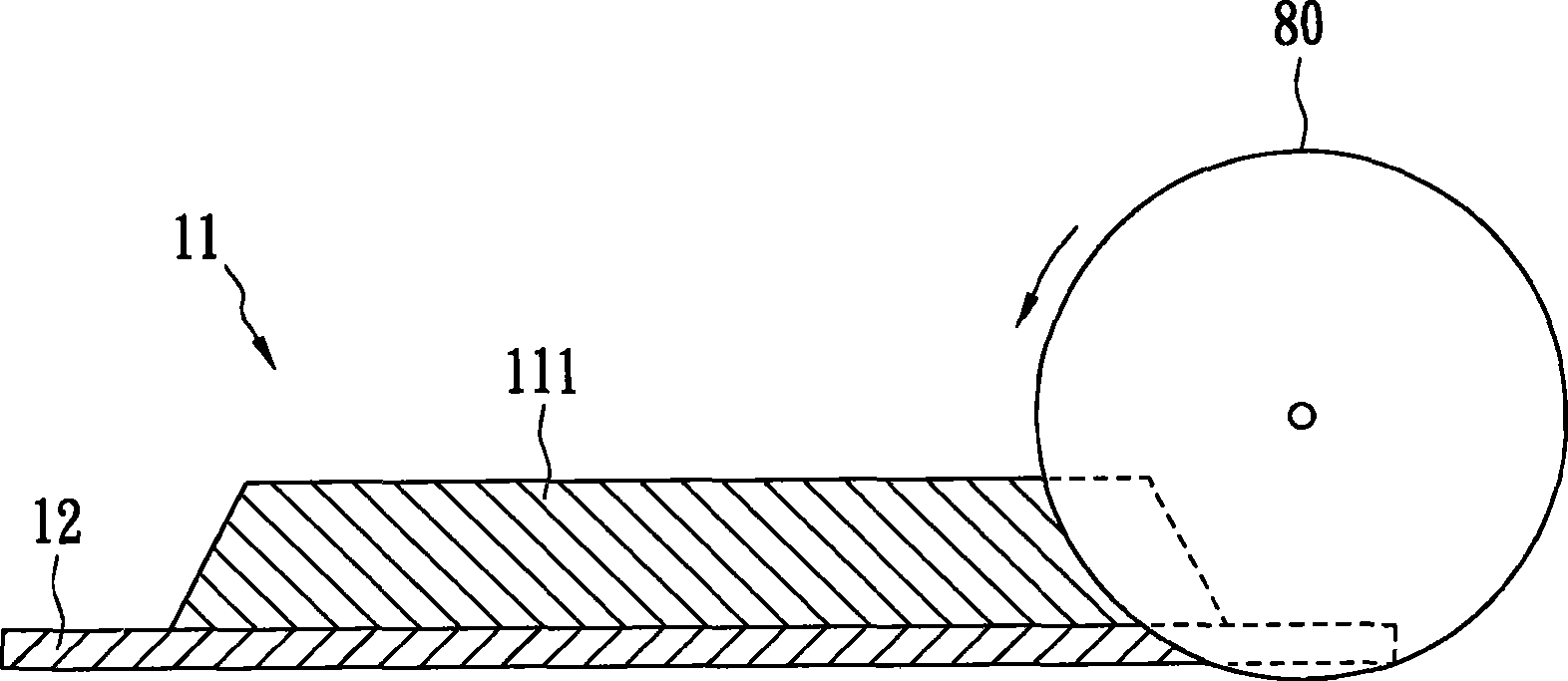

Method for manufacturing substrate for light emitting element package, and light emitting element package

InactiveUS20110311831A1Improve thermal conductivityEasy to carryPrinted circuit aspectsSolid-state devicesOptoelectronicsMetal

A method for manufacturing a substrate for a light emitting element package provided with a thick metal section formed under a mounting position of a light emitting element, having a lamination step of laminating and integrating a laminate having an insulating adhesive agent which is composed of a resin containing heat conductive fillers and has a heat conductivity of 1.0 W / mK or more and a metal layer member, with a metal layer member having a thick metal section while drawing out each member.

Owner:DENKA CO LTD

Corynebacterium glutamicum genes encoding metabolic pathway proteins

InactiveUS20060084152A1Improve production efficiencyHigh yieldBacteriaSugar derivativesAntigenAntisense nucleic acid

Isolated nucleic acid molecules, designated MP nucleic acid molecules, which encode novel MP proteins from Corynebacterium glutamicum are described. The invention also provides antisense nucleic acid molecules, recombinant expression vectors containing MP nucleic acid molecules, and host cells into which the expression vectors have been introduced. The invention still further provides isolated MP proteins, mutated MP proteins, fusion proteins, antigenic peptides and methods for the improvement of production of a desired compound from C. glutamicum based on genetic engineering of MP genes in this organism.

Owner:EVONIK DEGUSSA GMBH

Method for preparing o-chloroaniline by virtue of solvent-free catalytic hydrogenation

ActiveCN103664641ASolve the problem of hydrogenolysis and dechlorinationReduce corrosionOrganic compound preparationAmino compound preparationPtru catalystSolvent free

The invention belongs to the technical field of fine chemical engineering, and relates to a method for preparing o-chloroaniline by virtue of solvent-free catalytic hydrogenation ortho-nitrochlorobenzene. The method is characterized in that ortho-nitrochlorobenzene is adopted as a raw material to be reacted with hydrogen in the presence of a catalyst at the temperature of 70-120 DEG C and the pressure of 0.5-5.0 MPa so as to obtain o-chloroaniline through the processing after the reaction. By adopting the method, no solvent is added, the defect for adding the solvent can be overcome, the environmental pollution problem and the solvent recycling problem can be avoided, the equipment investment is reduced, the production cost is reduced, the conversion rate of the ortho-nitrochlorobenzene can reach 100 percent, the selectivity of the o-chloroaniline is more than 99.2 percent, and the dechlorinating rate is less than 0.09 percent.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for high-selectivity preparation of 3,4-dichloroaniline

ActiveCN103694124AReduce corrosionSolve the problem of hydrogenolysis and dechlorinationOrganic compound preparationAmino compound preparationPtru catalystNitrobenzene

The invention belongs to the technical field of fine chemical engineering, and relates to a method for preparing 3,4-dichloroaniline from 3,4-dichloronitrobenzene through high-selectivity catalytic hydrogenation. With 3,4-dichloronitrobenzene as raw material and in the presence of a Pt catalyst, 3,4-dichloroaniline is prepared through a catalytic hydrogenation reaction under the pressure of 1.0 MPa-3.0 MPa and at the temperature of 75-120 DEG C. With adoption of the method, the conversion rate of 3,4-dichloronitrobenzene is 100%, the selectivity of 3,4-dichloroaniline is greater than 99.6%, and the dechlorination rate is less than 0.20%. The Pt catalyst is safe to use, and has stable catalytic activity and high selectivity; a dechlorination inhibitor is not required to be added; through introduction of Fe2O3 into the Pt catalyst, a dechlorination phenomenon can be effectively inhibited, and the corrosion of dechlorination to a reaction container during reduction is reduced; and the method is not added with a solvent, overcomes the defect of the addition of the solvent, avoids the problems of pollution of the solvent to the environment and solvent recovery, reduces equipment investment, and reduces production costs.

Owner:CHINA PETROLEUM & CHEM CORP +1

Method for directly producing fiberglass yarns

The invention provides a method for directly producing fiberglass yarns. In the prior art, protofilaments are degraded and then are stranded together according to the conventional manufacturing method. Different from the conventional manufacturing method, protofilaments are drawn firstly and then are twisted and stranded together. In the traditional market, the filament drawing operation is conducted in the single drawing manner. That means, only one protofilament cylinder is drawn out of a filament drawing handpiece each time. According to the invention, the original tank-furnace filament drawing method of significant investment is applied to the crucible process of small investment, while a paraffin type impregnating compound coated with the protofilaments is modified as a starch type impregnating compound. Therefore, the production efficiency is increased and the tensile strength is improved. the number of spools is increased and the production cost is lowered. Moreover, the yarn hairiness, filoselle, breakage and other phenomena of fiberglass yarns are reduced.

Owner:通城县同力玻纤有限公司

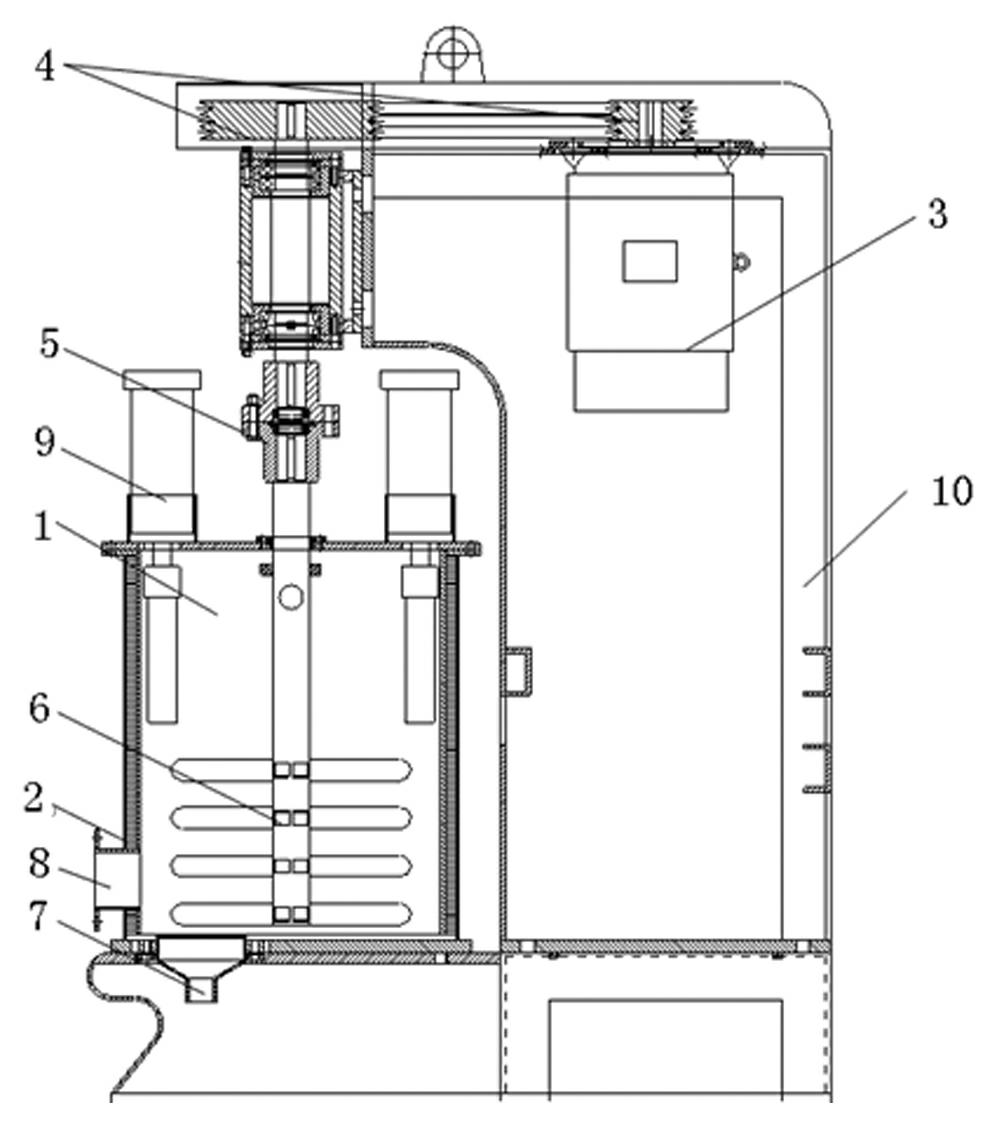

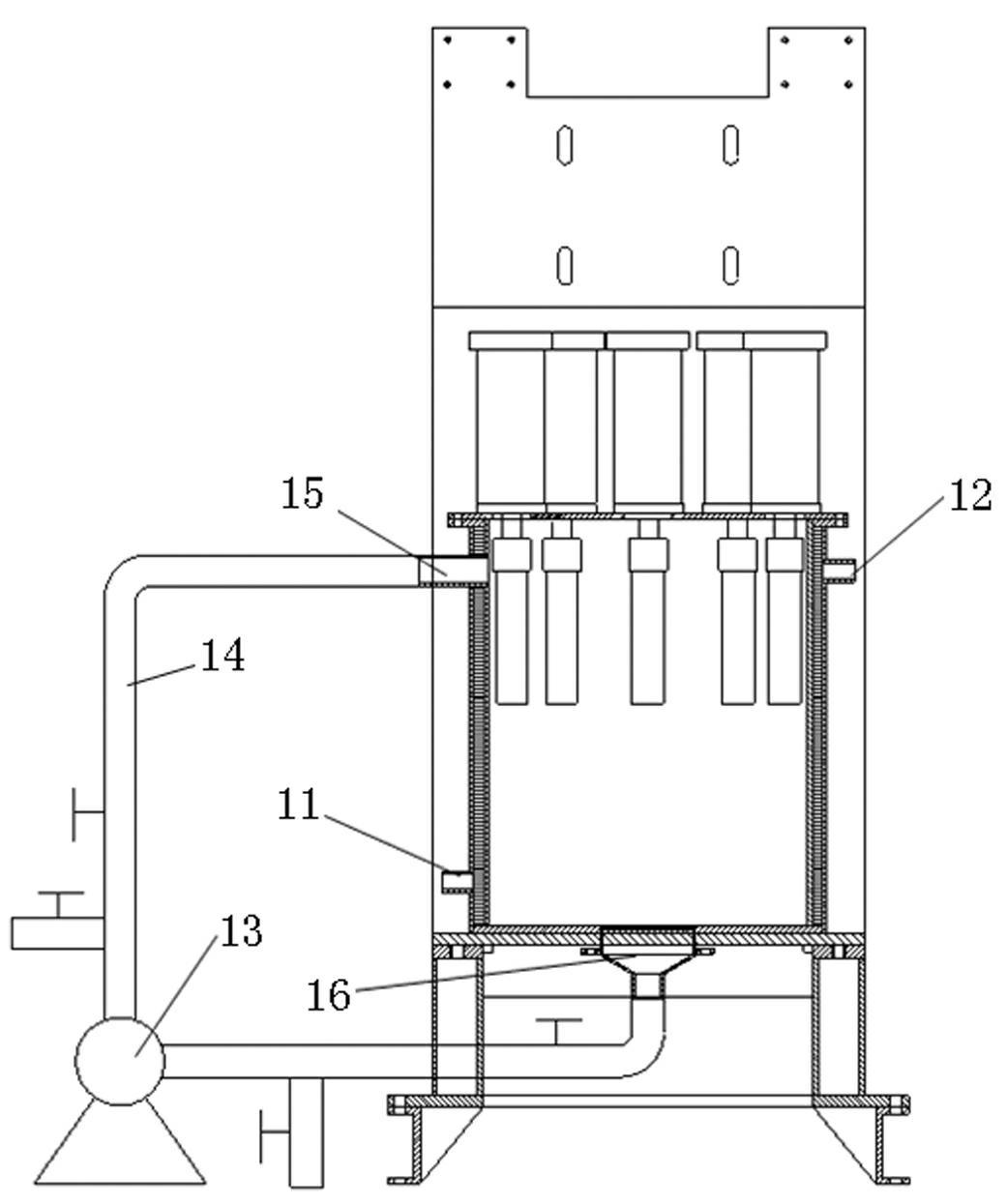

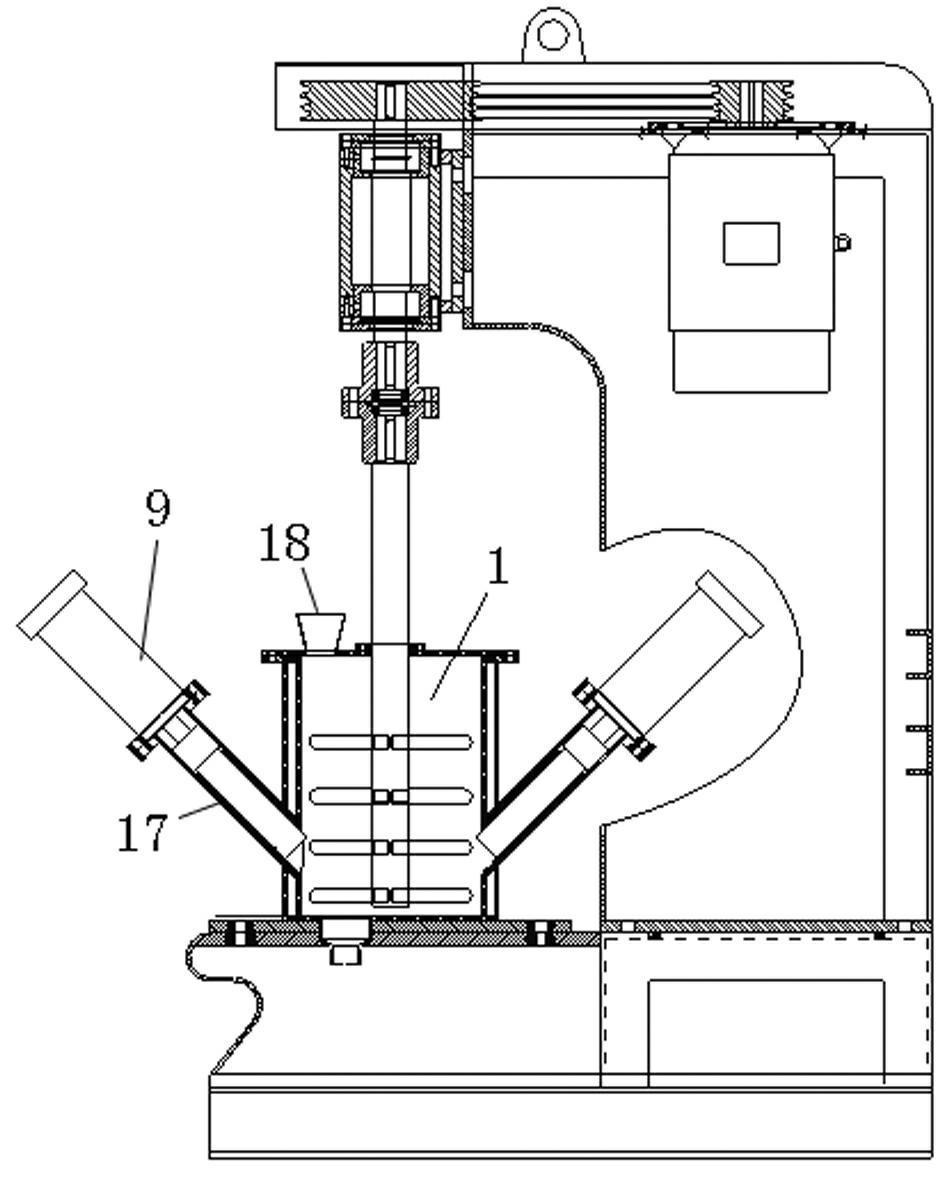

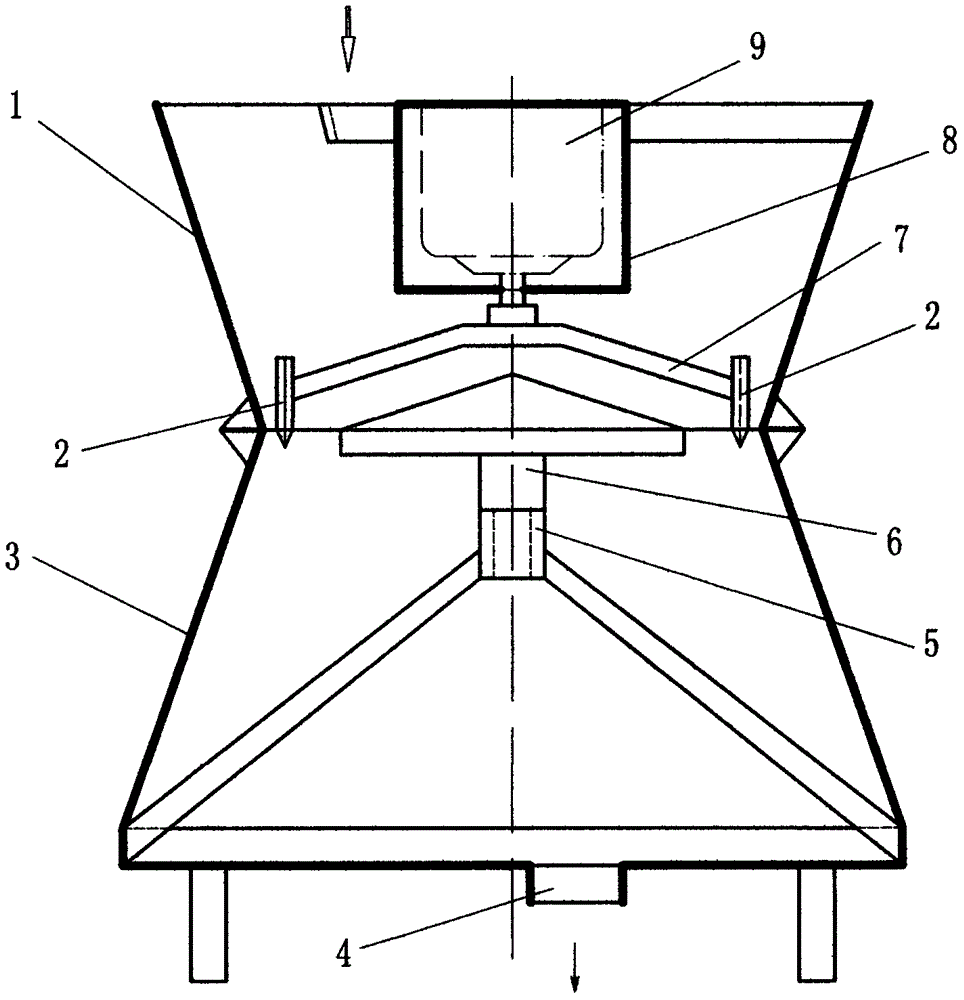

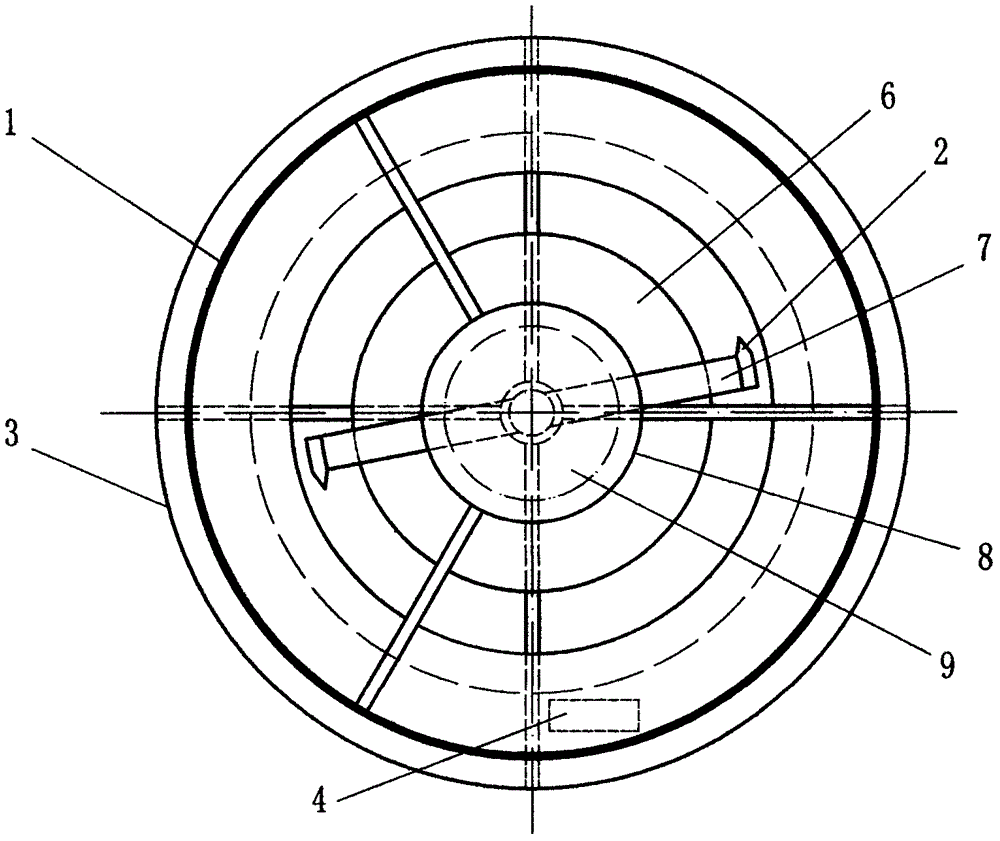

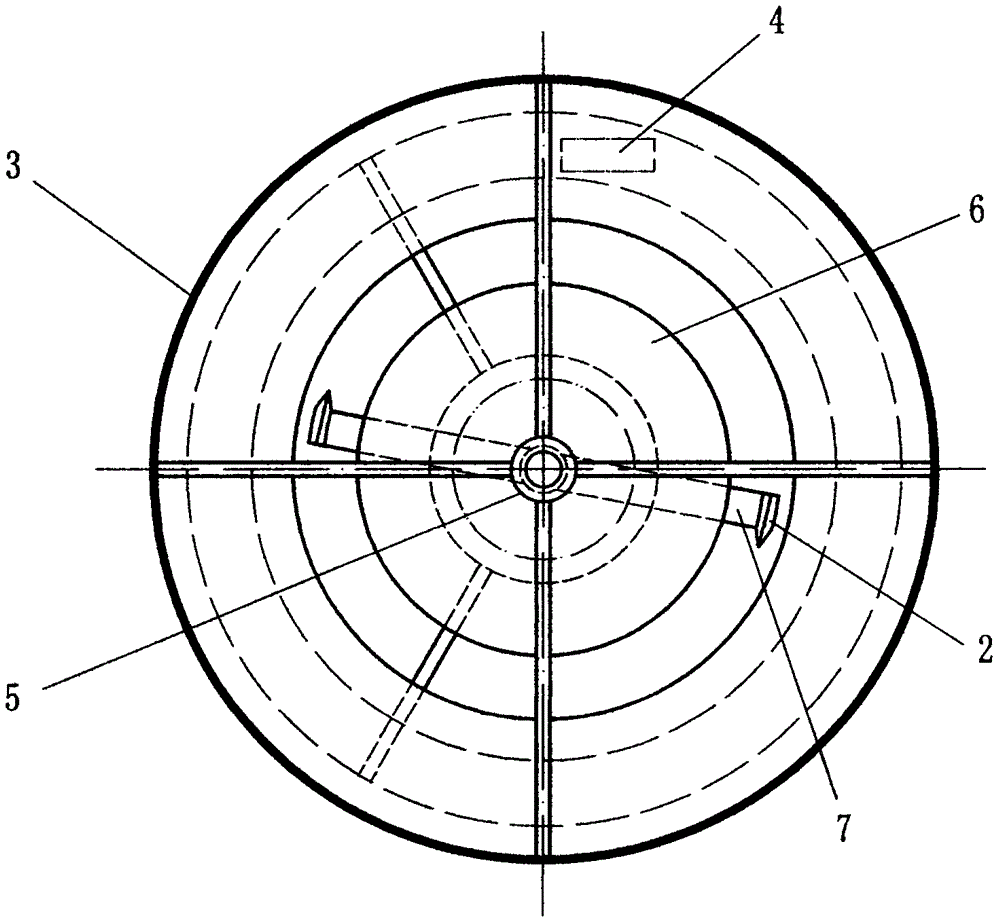

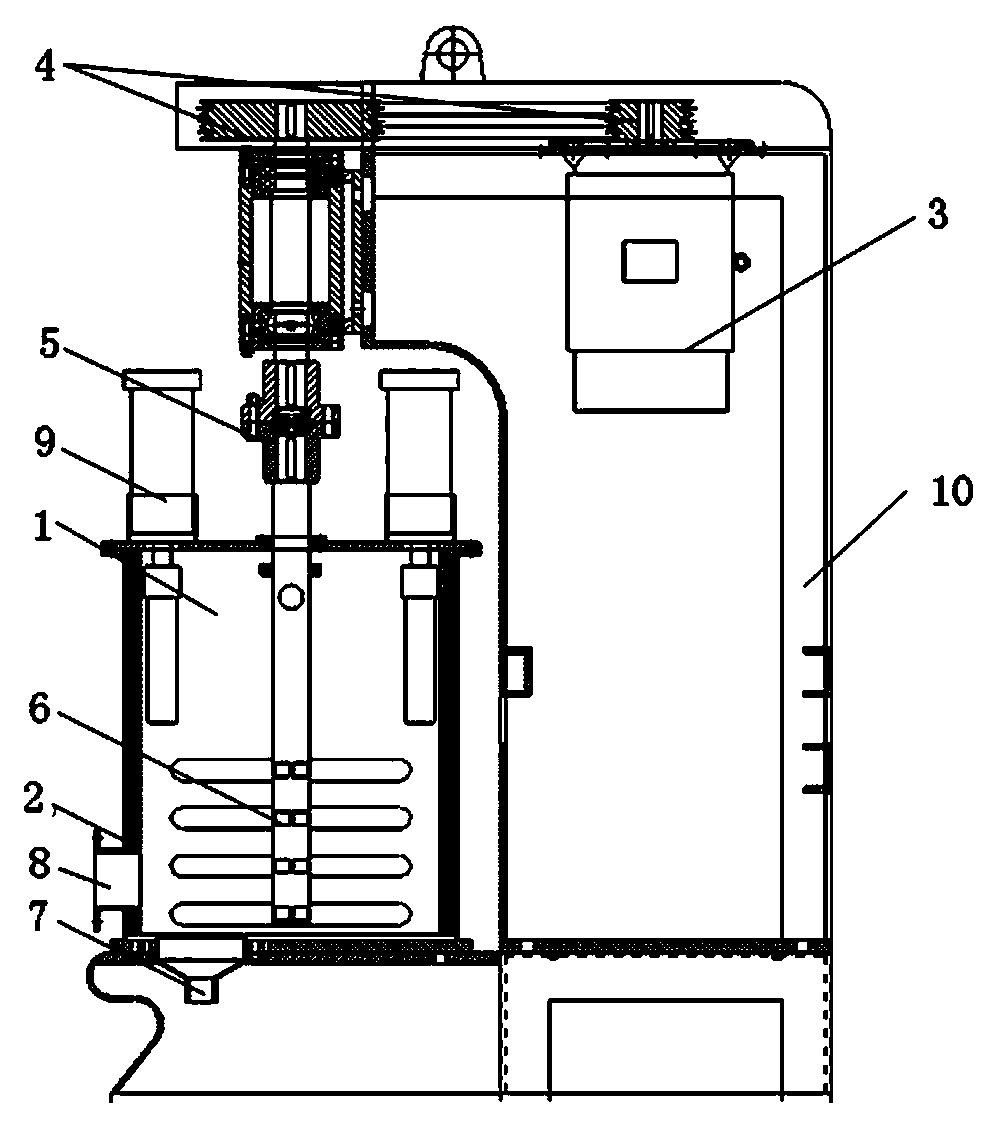

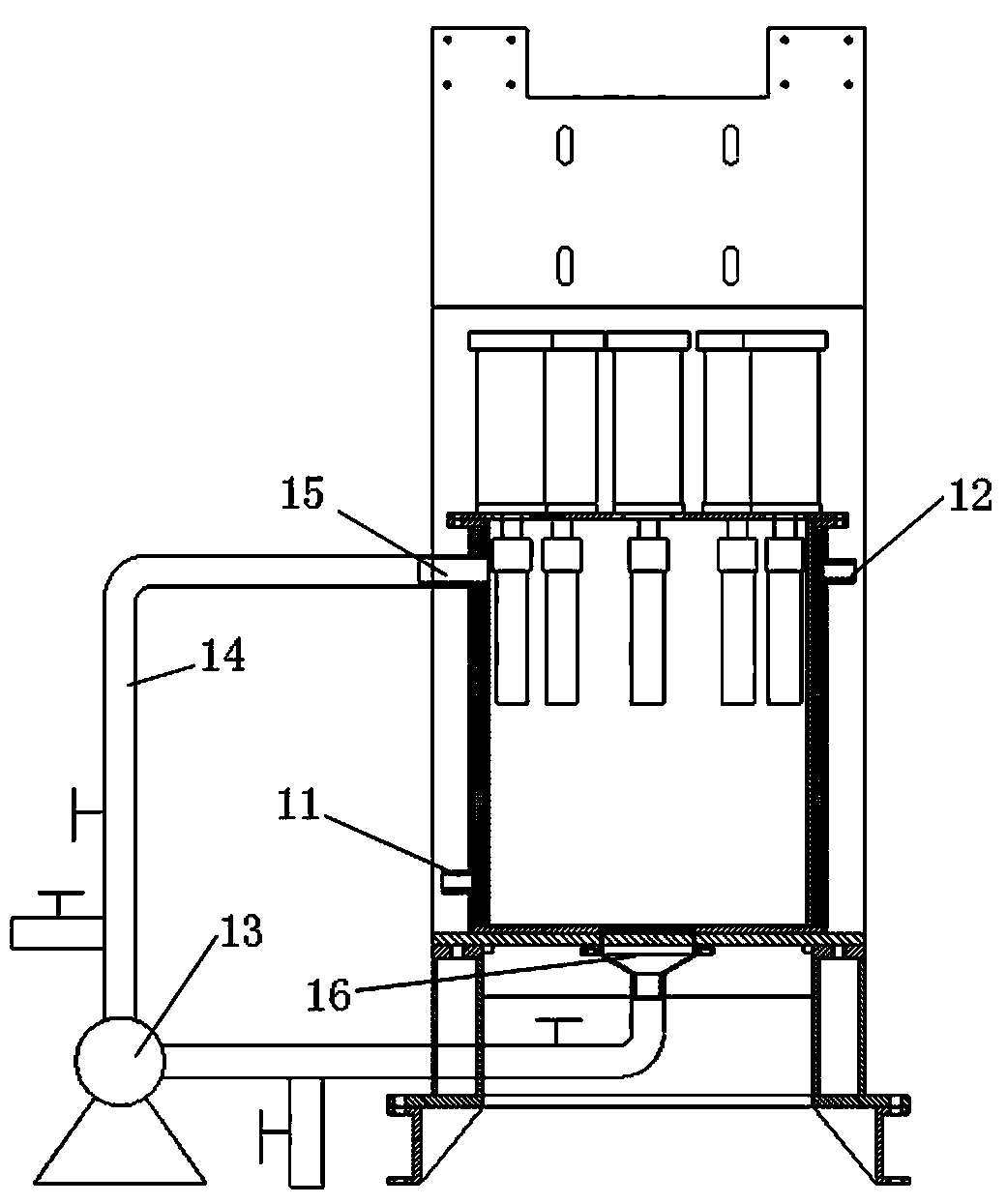

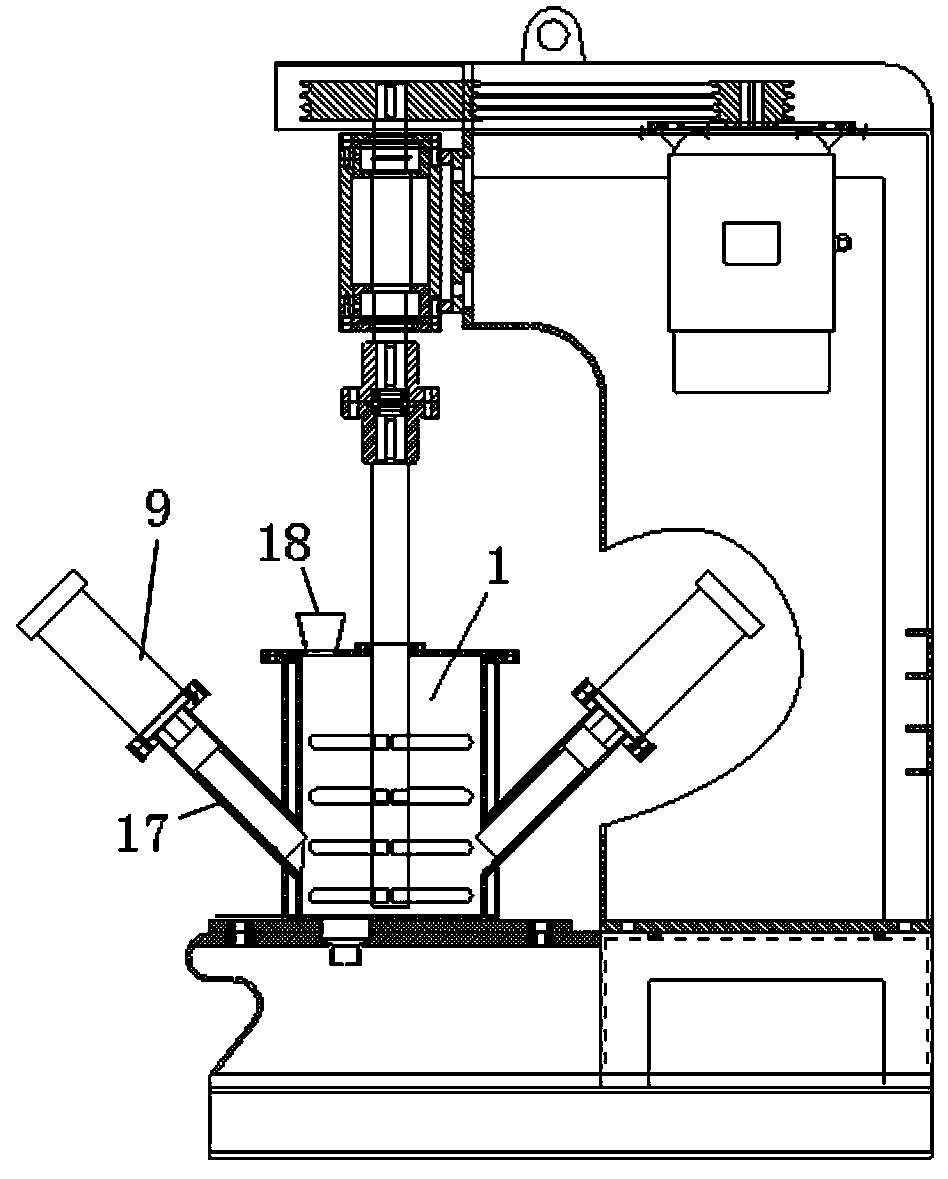

An ultrasonic ball mill

InactiveCN102284326AGet the most out of collision grindingMake full use of ultrasonic cavitation to promote collision grindingGrain treatmentsHigh densityMotor drive

The invention provides an ultrasonic ball mill pulverizer which comprises a frame, a mixing tank, a transmission motor driving a stirring shaft to rotate, the stirring shaft pushing mill balls to crush and grind a material, a material circulation system, as well as a cooling water jacket layer, a water inlet, a water outlet, a material inlet, a material outlet and a ball discharge port which are arranged on the mixing tank. The ultrasonic ball mill pulverizer is characterized in that: holes for inserting ultrasonic generators and an assembly bosses are formed on the upper cover or / and wall of the mixing tank; 1 to 12 sets of ultrasonic generators are vertically or / and obliquely inserted into the assembly bosses which are connected or welded on the cover or the wall of the mixing tank through threads or flanges; and probes of the ultrasonic generators are inserted deep into the mixing tank and contacted with the material, so that the material completely absorb strong ultrasonic energy. While performing stirring and ball milling to the material, the ultrasonic ball mill pulverizer applies strong ultrasonic field action to generate a high-density energy filed, so that micron-grade or sub-micron-grade (0.7-30mu m) powder can be crushed into nano-grade (20-600nm) powder. The ultrasonic ball mill pulverizer has the advantages of high yield and efficiency, simple process, is easy to operate and control and can eliminate local concentration unevenness, effectively prevent particle agglomeration, and is suitable for industrial production.

Owner:CHANGSHA SDLUBE SCI & TECH

Process for extracting theaflavin product

The invention discloses a process for extracting a theaflavin product, and relates to the technical field of the deep processing of tea products. In order to solve the problems of excessive oxidization and low yield caused by the uncontrolled consecutive reaction in traditional in-vitro enzymatic oxidization process for the preparation of theaflavin, the invention provides the process for extracting the theaflavin product, which comprises the following steps of: (a) the preparation of a substrate solution; (b) the preparation of an enzymatic catalyst; (c) the preparation of fermentation; (d) the separation of an ester phase; (e) the concentration and phase inversion; and (f) drying. When the process is adopted, the process control of the fermentation process is realized, the conversion rate and specification of the theaflavin product are improved, and the process cost for the follow-up refining and purification is reduced.

Owner:HANGZHOU TEA RES INST CHINA COOP

Cleaning device and a cleaning method of a fixed abrasives polishing pad

ActiveUS20120167924A1Reduce scratchesImprove production efficiencyGrinding drivesBelt grinding machinesCleaning methodsEngineering

A device for cleaning a fixed abrasive polishing pad includes a main body having a surface facing the polishing pad, an inlet coupled to an end of the main body and configured to supply a cleaning liquid, an inject orifice coupled to the inlet for injecting the cleaning liquid and being provided on the surface of the main body, an outlet coupled to the end of the main body, and a recycle orifice coupled to the outlet, and being provided on the surface of the main body.

Owner:SEMICON MFG INT (SHANGHAI) CORP

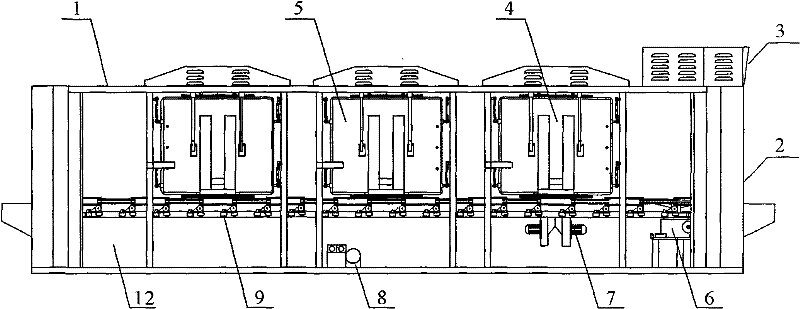

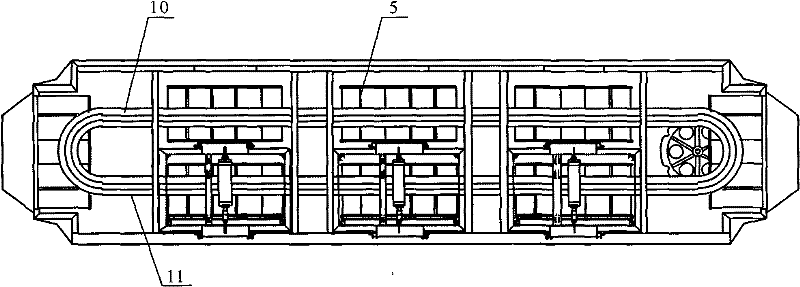

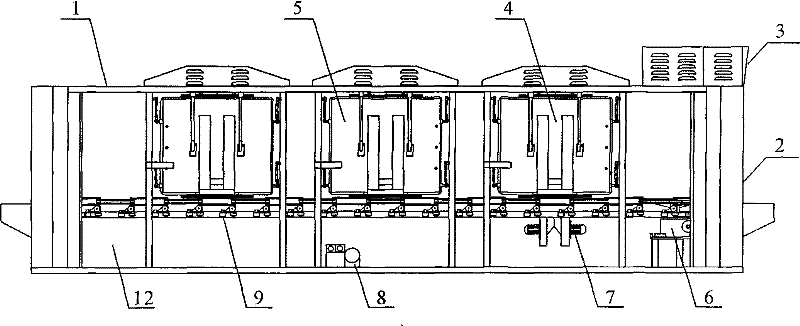

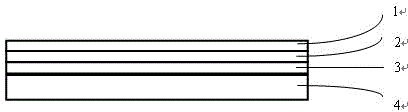

High-efficiency energy-saving rail type lithium battery oven

InactiveCN102455118AUniform return air circulationSolve the technical problem of uneven dryingCell electrodesDrying machines with progressive movementsFiberTemperature control

The invention discloses a high-efficiency energy-saving rail type lithium battery oven which consists of an oven body, a sealing door, a temperature control device, vacuum tanks, a heating device, a variable-frequency transmission motor, blowers, a vacuum pump, a guide wheel, a rail, a chain driving band and a bracket, wherein the carbon fiber heating device is arranged at the inner walls at left and right sides of the oven body, the electrodeless temperature control device is arranged at the front side of a panel at the upper end of the sealing door, a plurality of temperature cycle blowers are arranged in the middle of the lower end of the oven body, a plurality of temperature air-exhaust devices are arranged in the middle of the upper end of the oven body. The high-efficiency energy-saving rail type lithium battery oven is characterized in that: the inside of the oven body is in a rail type and adopts the chain driving band, the guide wheel is fixedly arranged at the upper end of the bracket, and then the rail and 4-8 vacuum tanks are fixedly arranged on the rail. The high-efficiency energy-saving rail type lithium battery oven has the advantages that the oven has high efficiency and quick temperature rise, is energy-saving and environmentally-friendly, is provided with the electrodeless temperature control device, thoroughly solves the technical problem that the oven dries non-uniformly, saves time and labor and occupies small area, and can dry one time through automatic limitation without manual touch of workers for landing, so as to increase the quality stability, performance and cycle life of an electric piece.

Owner:楼瞻浩

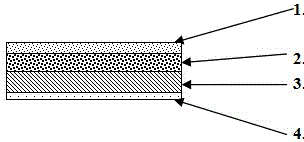

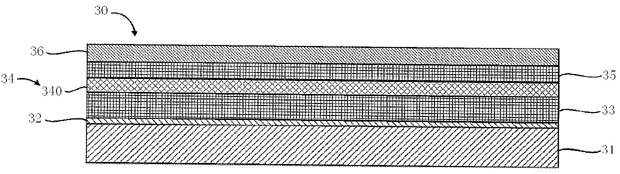

Transfer coating ink-jet printing high-gloss photographic paper

ActiveCN105970724AGood ink absorptionGood color fixing effectWater-repelling agents additionDuplicating/marking methodsEmulsionPolyvinyl acetate

The invention relates to a paper and especially relates to a transfer coating ink-jet printing high-gloss photographic paper. The paper comprises a surface coating, a base coating, a raw paper layer and a back coating. The surface coating is an ink absorption water-resistant gloss coating. The base coating is an ink absorption fixation coating. The back coating is a water-resistant coating for balancing two surface tensions of a photographic paper. The base coating comprises light calcium carbonate, a sodium polycarboxylate dispersant, a polyvinyl acetate emulsion adhesive, a polyvinyl alcohol glue solution and a fixer. The surface coating comprises aqueous silica sol and a polyvinyl alcohol glue solution. The back coating comprises polyvinyl alcohol. The photographic paper surface is a high-gloss mirror surface, images obtained by color ink-jet printing have plump colors and realizes real restoration and ink absorption and fixing performances are good.

Owner:ZHEJIANG JUNMA DIGITAL TECH

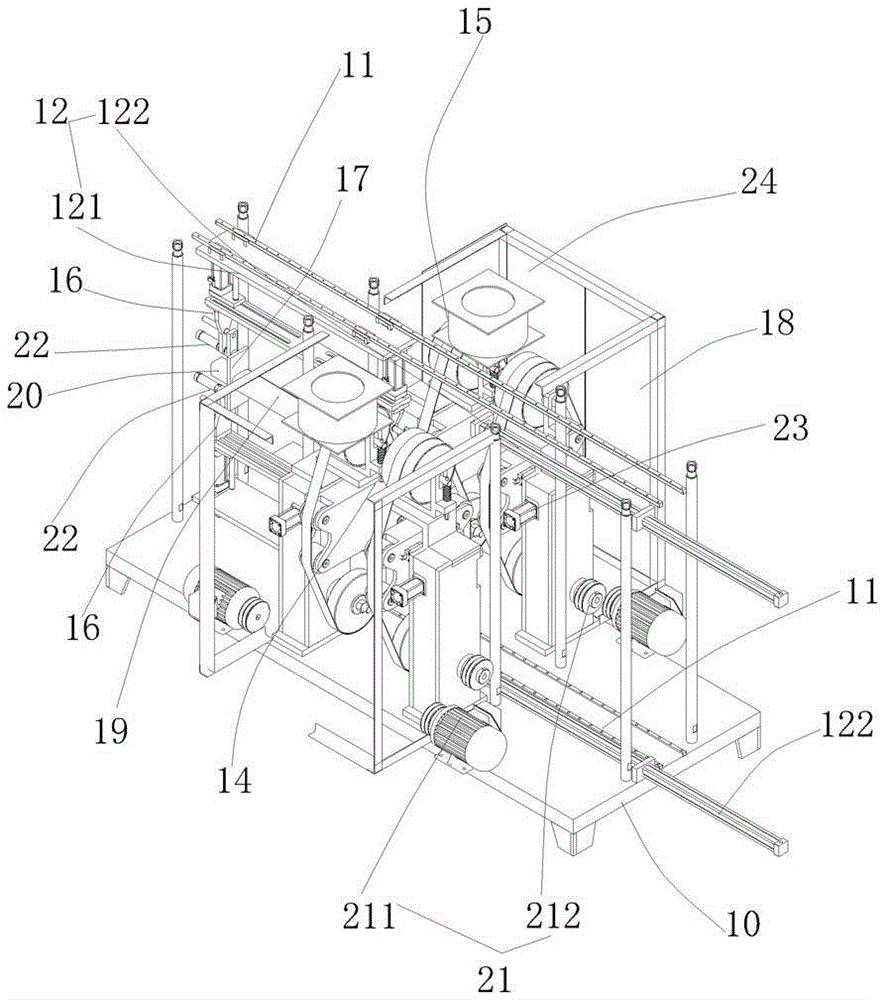

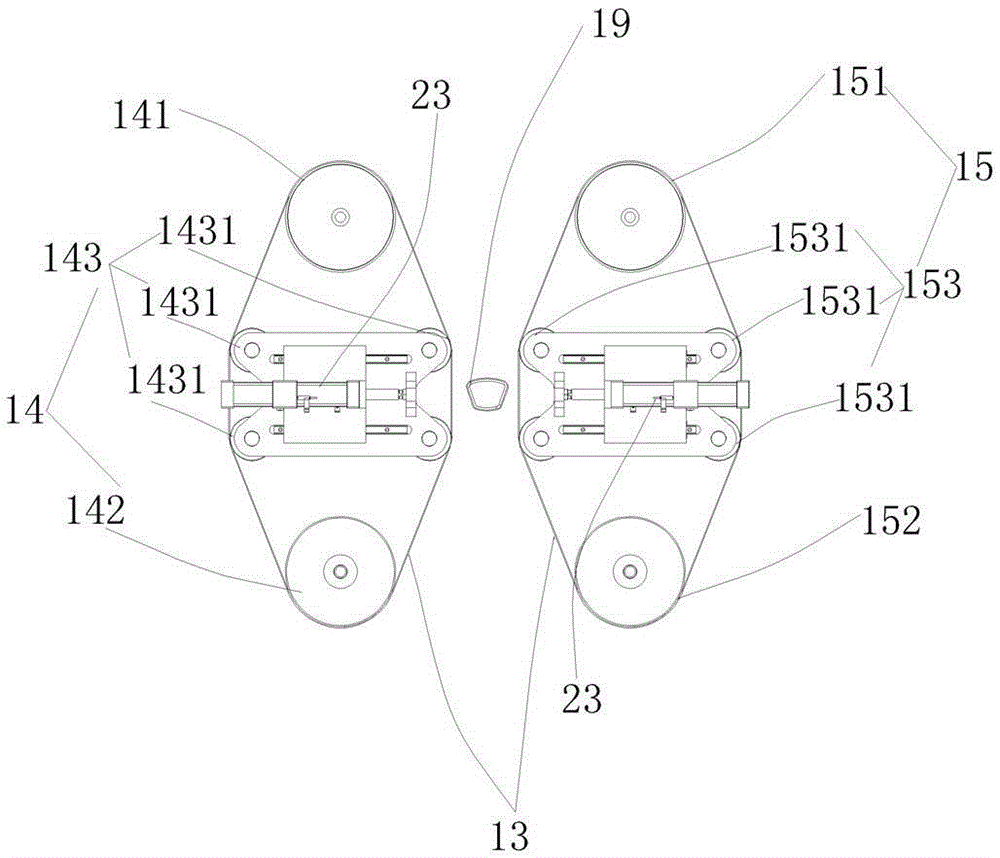

Automatic adhesive belt grinding machine and grinding method thereof

ActiveCN105234779AHigh yield efficiencyAchieve the effect of automatic grindingBelt grinding machinesGrinding work supportsHydraulic motorAdhesive belt

The invention discloses an automatic adhesive belt grinding machine and a grinding method thereof. The grinding machine comprises a rack, sliding rails, a plurality of first roller sets, a plurality of second roller sets, displacement sets, jacking lifting sets, a first fixing plate, a second fixing plate, an oil pressure motor and a jacking cylinder. The first roller sets and the second roller sets are symmetrically distributed, and a clamping space used for clamping the pipe material outer periphery in the longitudinal direction is formed in the center of an adhesive belt between the first roller sets and the second roller sets. The two transverse ends of a pipe material are clamped between the first fixing plate and the second fixing plate. Pressure maintaining cylinders are arranged on the first roller sets and the second roller sets respectively. The automatic adhesive belt grinding machine has the characteristics of being reasonable in design, good in grinding effect, high in yield, low in labor intensity and low in labor cost.

Owner:深圳市钜达机械设备有限公司

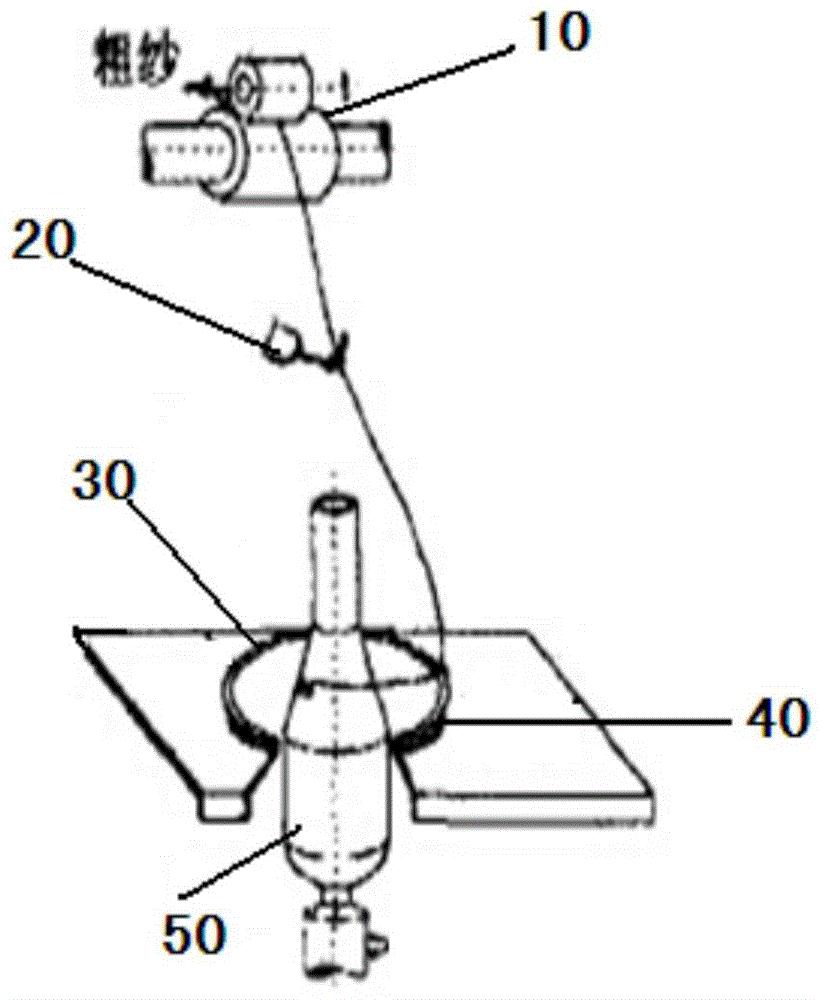

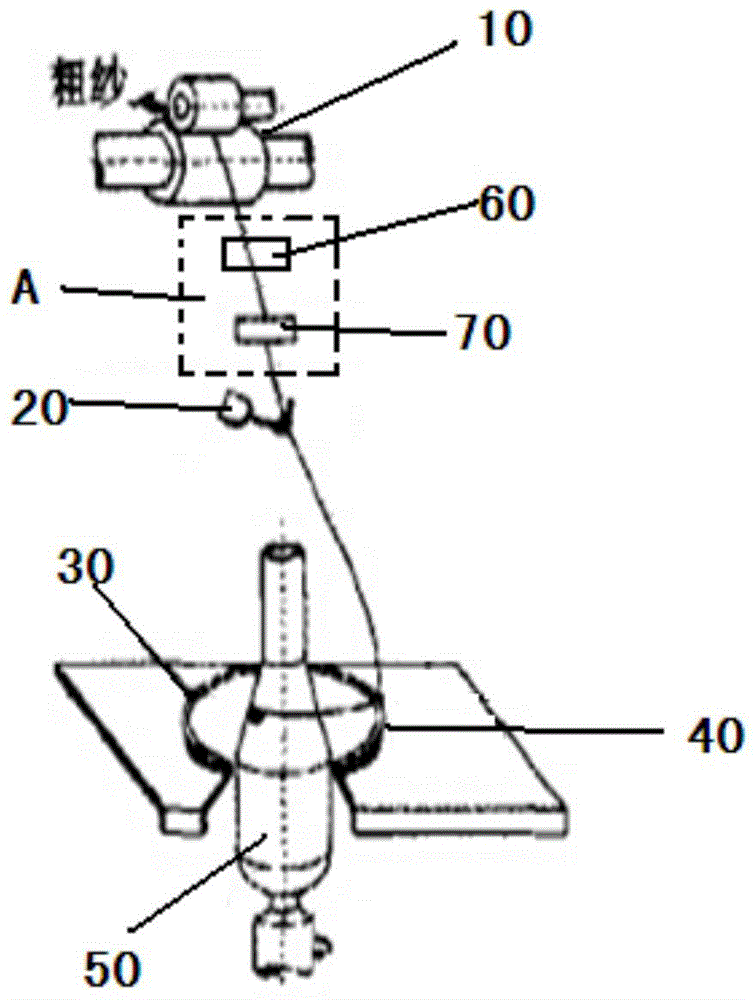

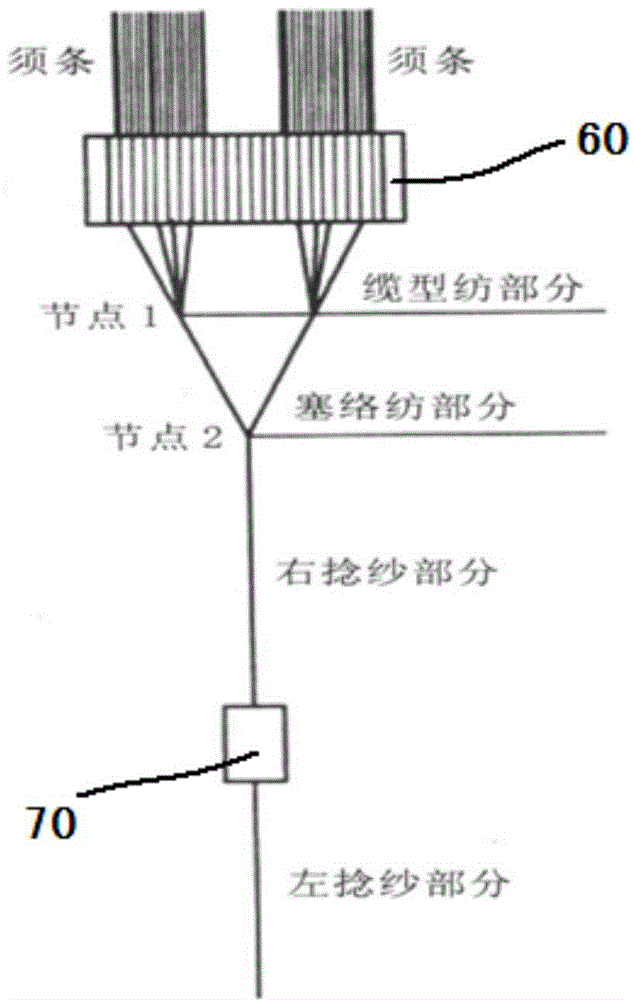

Low-torque spinning process

The invention discloses low-torque spinning process. The process comprises following steps: (1) firstly, a spinning frame adopts a double-roving feeding method, two rough yarns are drafted to form fiber strands through a drafting device of the spinning frame and fiber strands coming out of a front jaw of the spinning frame after drafting are conveyed to be installed at a fiber arraying and adjusting device between a front roller and a yarn-guide hook; (2) the fiber arraying and adjusting device is used for cutting fiber strands into at least two strands of fiber bundles, the fiber bundles firstly wind around the itself rotary center under effect of twisting force and are combined to wind around again the center of the fiber bundles to be twisted to be solospun single yarns and then two solospun single yarns are combined to twisted as right-laid single yarns; (3) the right-laid single yarns are subjected to false-twisting operation through a false twister, left-laid single yarns formed by false twisting operation are conveyed to steel collars and steel travelers for twisting and finally are wound to be finished yarns. The low-torque spinning process has following beneficial effects: without decreasing yarn strength of low-torque spinning process, yarns featuring lower twisting force, fewer fibers and higher strength can be spun than conventional ring-spun yarns; and cost of yarns remains unchanged.

Owner:SHANGHAI SHUIXING HOME TEXTILE

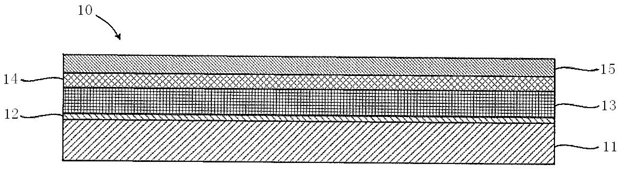

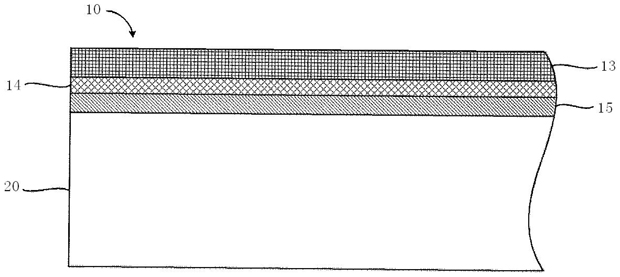

Transfer film structure

InactiveCN102059871AImprove structural strengthPrevent infiltrationDuplicating/marking methodsSynthetic resin layered productsOptoelectronicsUltimate tensile strength

The invention relates to a transfer film structure. The transfer film structure is characterized by comprising a base film layer, a release layer, a first hardened film layer, a decorative grain layer, a second hardened film layer and an adhesive film layer, wherein the release layer is arranged on the upper surface of the base film layer; the first hardened film layer is arranged on the upper surface of the release layer; the decorative grain layer is arranged on the upper surface of the first hardened film layer; the second hardened film layer is arranged on the upper surface of the decorative grain layer; and the adhesive film layer is arranged on the upper surface of the second hardened film layer. The second hardened film layer is arranged between the decorative grain layer and the adhesive film layer, and the second hardened film layer can block the glue of the adhesive film layer from permeating into the decorative grain layer to prevent ink patterns from being damaged and reinforce the structural strength of the film layer so as to achieve the effect of promoting the processing qualification rate of the transfer film.

Owner:琨诘电子(昆山)有限公司

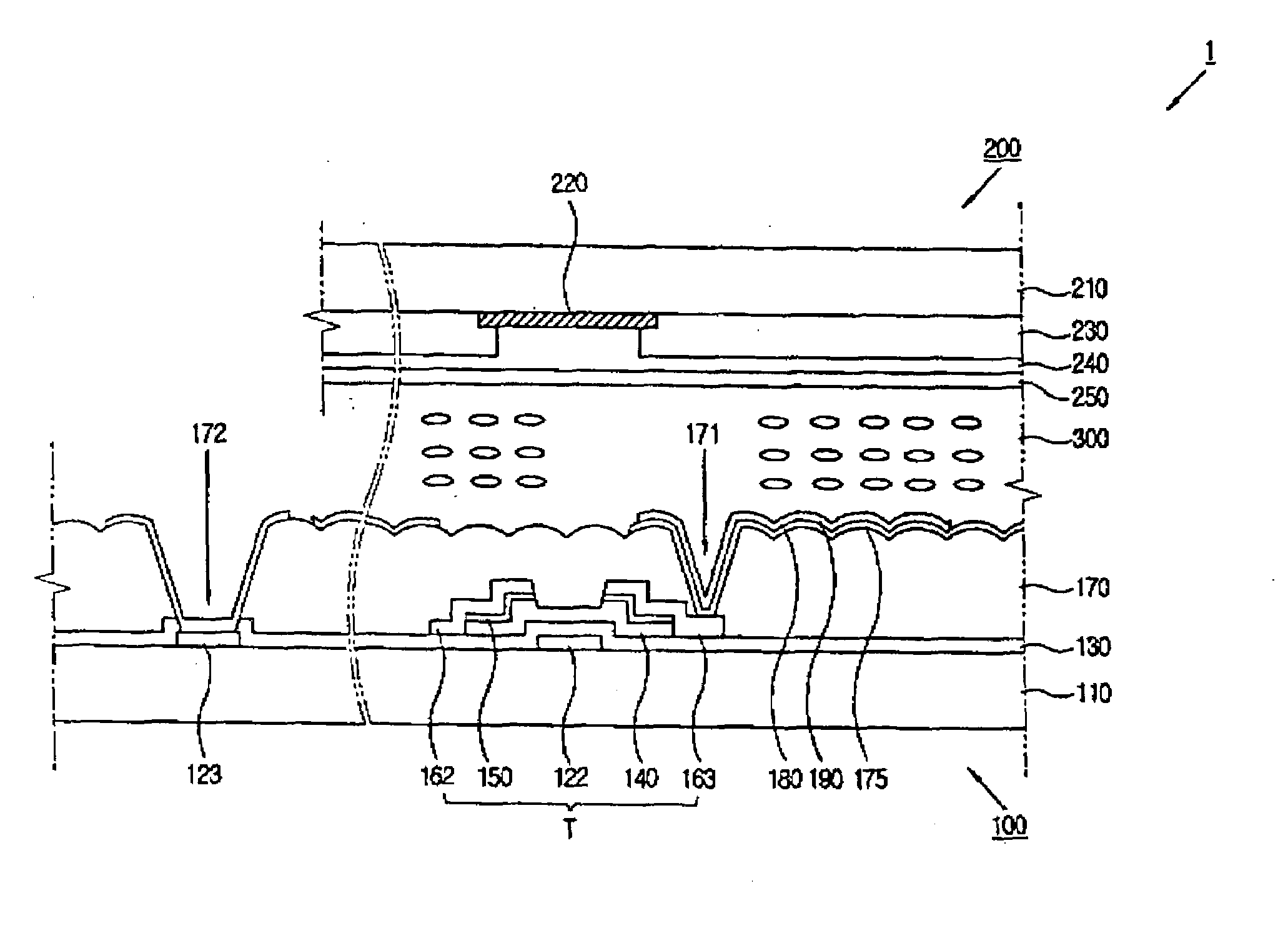

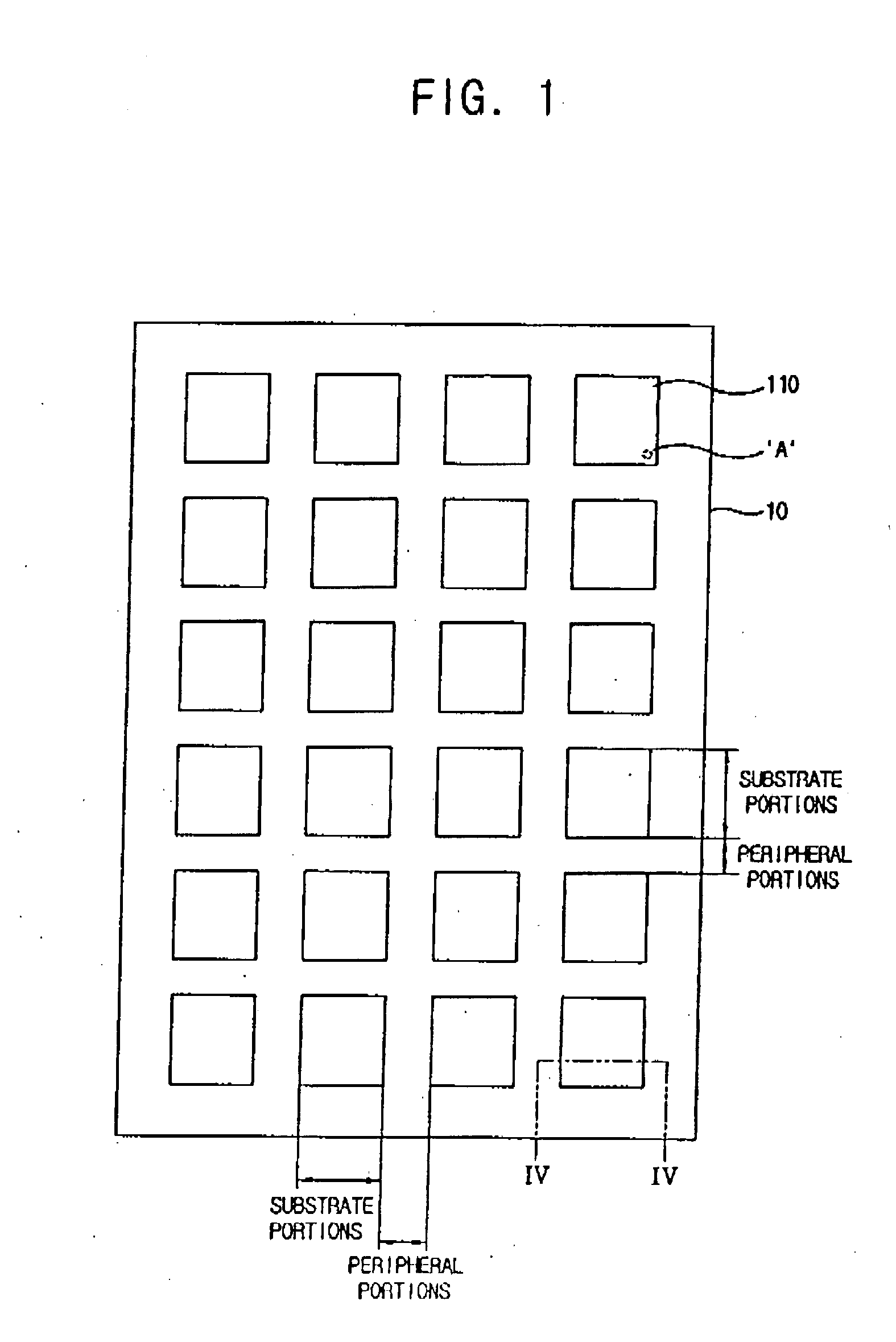

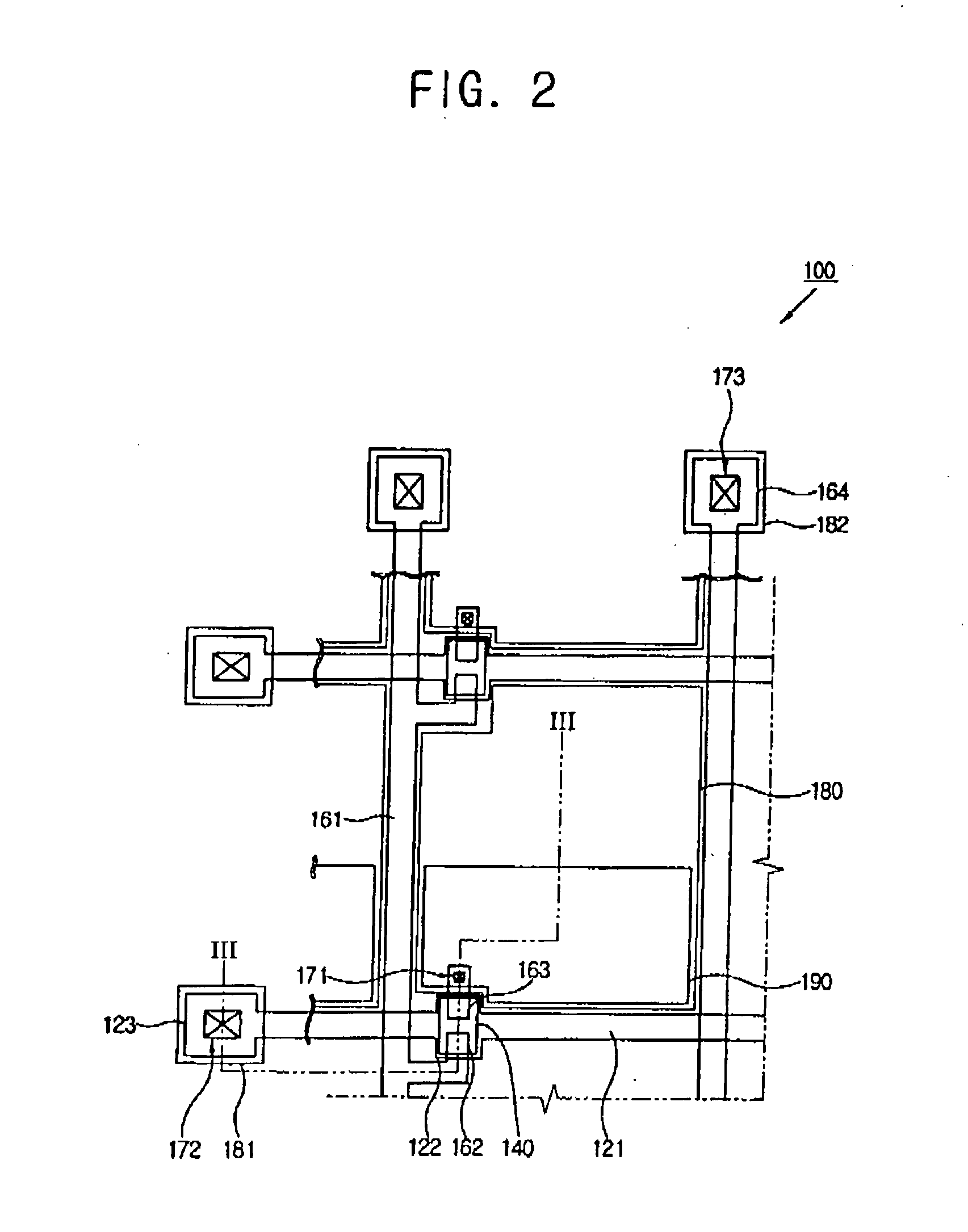

Manufacturing method of liquid crystal display

InactiveUS20080286889A1Improve reflection efficiencyHigh yield efficiencySolid-state devicesPhotomechanical apparatusLiquid-crystal displayEngineering

A method of manufacturing a liquid crystal display at a reduced cost is presented. The method entails: preparing an insulating substrate; forming a gate line and a data line on the insulating substrate to define a pixel area; forming a thin film transistor at an intersection of the gate line and the data line; forming A passivation layer on the thin film transistor; positioning a mold having a concavo-convex pattern on the organic passivation layer, pressing the mold, and forming the concavo-convex pattern on the surface of the organic passivation layer. A pixel electrode on the organic passivation layer is formed.

Owner:SAMSUNG DISPLAY CO LTD

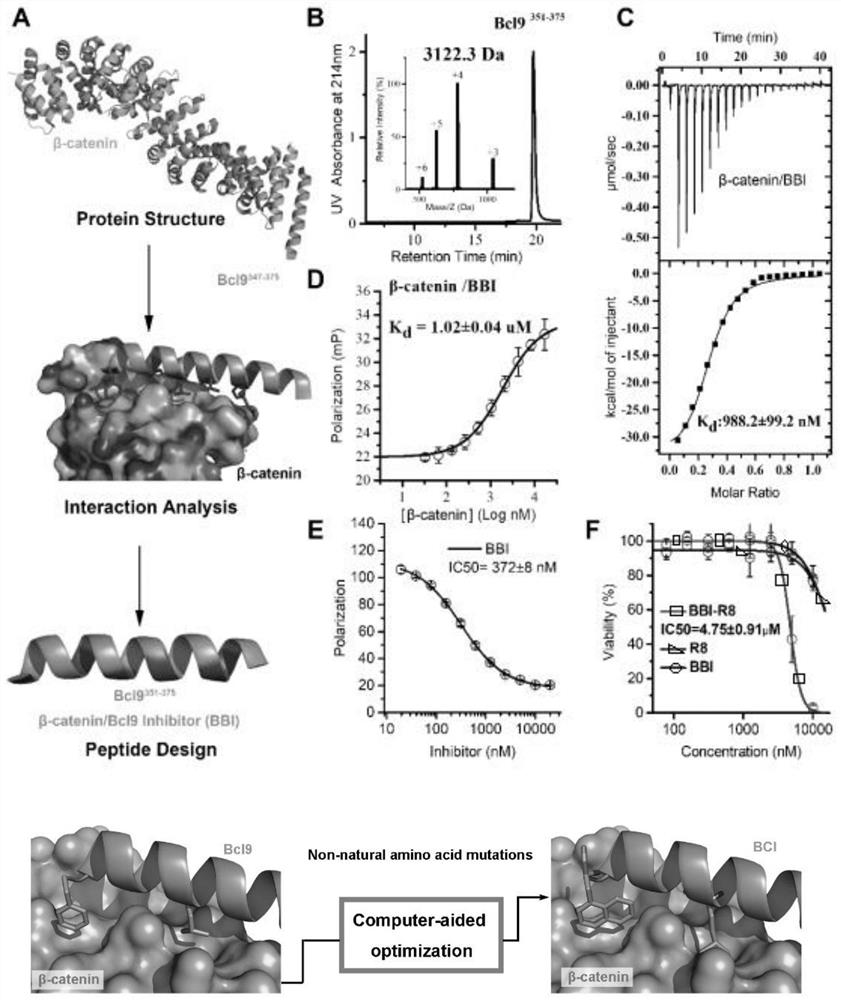

Polypeptide specifically combined with beta-catenin protein with high affinity, and application and synthesis method of polypeptide

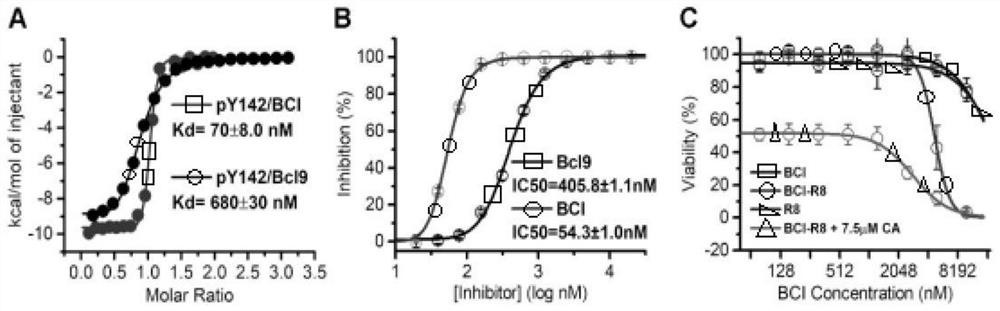

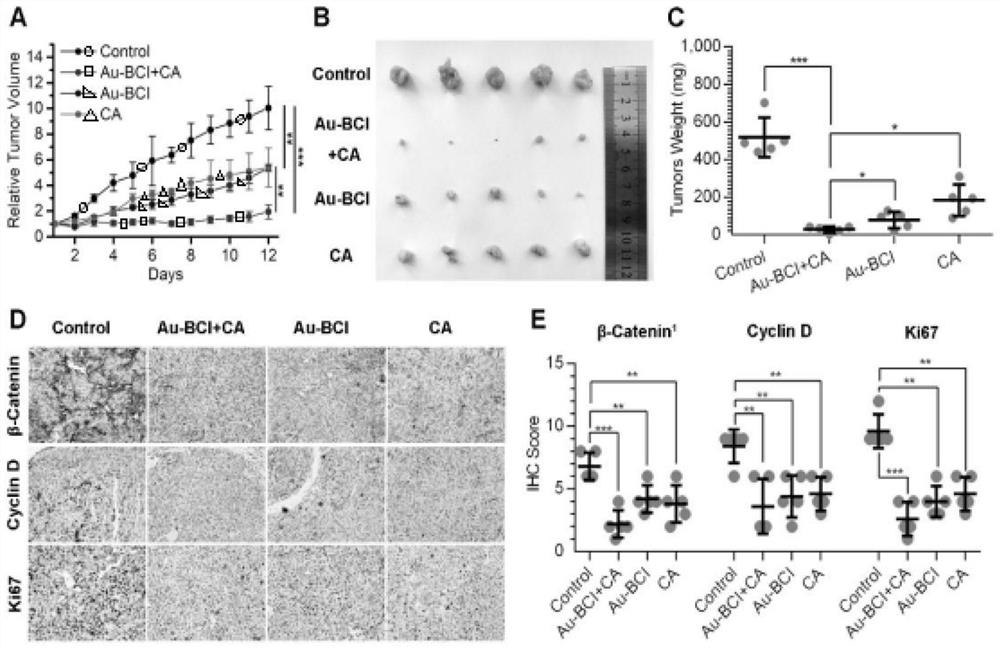

ActiveCN111909242AThe synthesis method is simple and easy to obtainInhibit onPeptide/protein ingredientsPeptidesDiseaseCancer cell

The invention discloses a polypeptide specifically combined with beta-catenin protein with high affinity, and application and a synthesis method of the polypeptide. The amino acid sequence of the polypeptide is LEHRERSLQT(X1)RDIQRML(X2)P, wherein X1 is leucine, norleucine or homoleucine, and X2 is phenylalanine, 1-naphthyl alanine, 2-naphthyl alanine, 2-anthryl alanine or 9-anthryl alanine. The polypeptide is used for inhibiting growth of cancer cells. By the polypeptide, various tumor treatment targets can be achieved. The polypeptide inhibits opening of a beta-catenin protein-mediated Wnt signal pathway by inhibiting mutual combination of the beta-catenin protein and BCL9 in the cancer cells, so that growth of tumors is inhibited, self-apoptosis of the cells is induced, and the tumor disease treatment targets are achieved. The synthesis method of the polypeptide is simple and easy to implement, and the final product has high yield efficiency, has mass production potential, and has great drug clinical transformation potential.

Owner:THE FIRST AFFILIATED HOSPITAL OF MEDICAL COLLEGE OF XIAN JIAOTONG UNIV

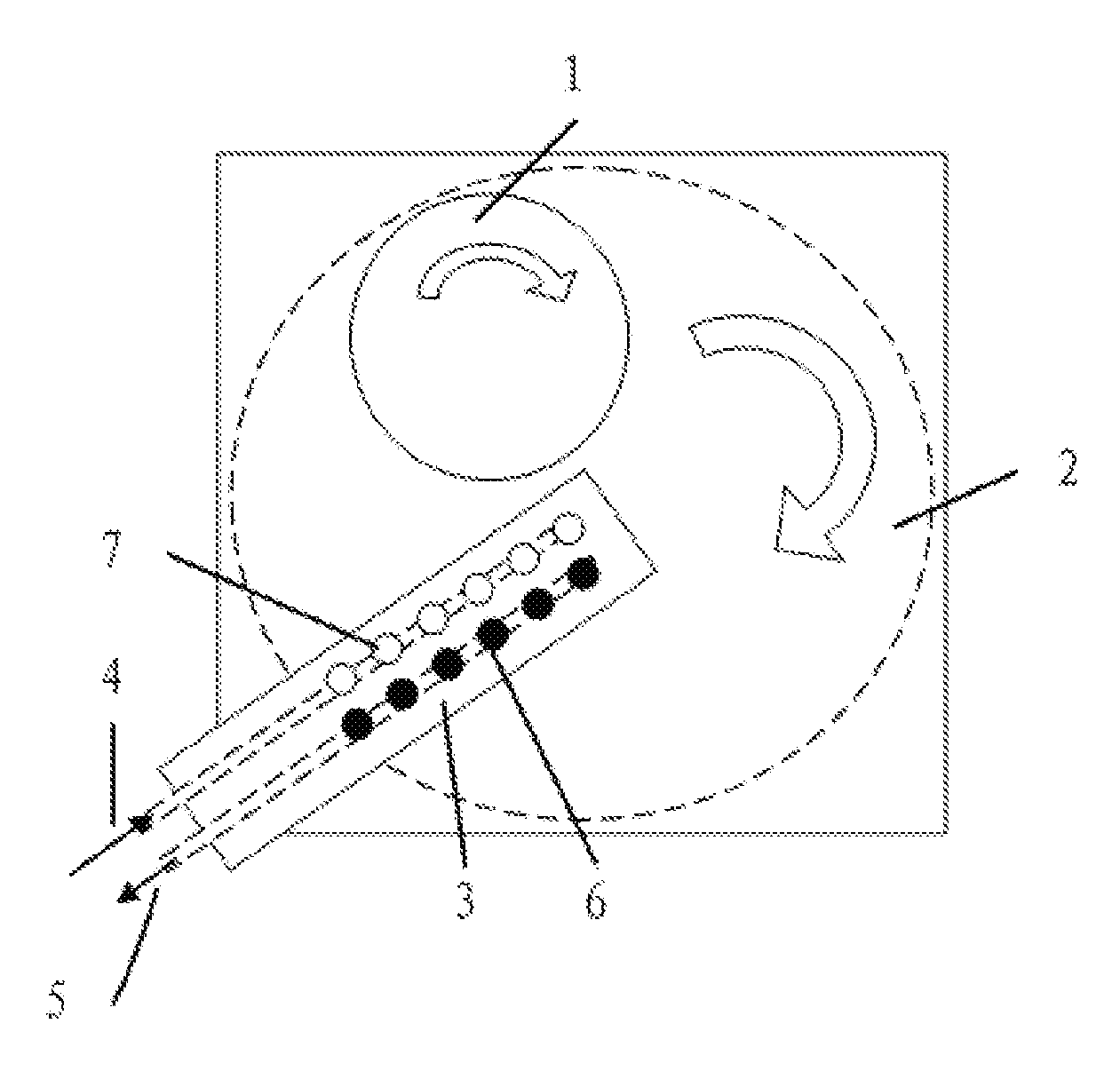

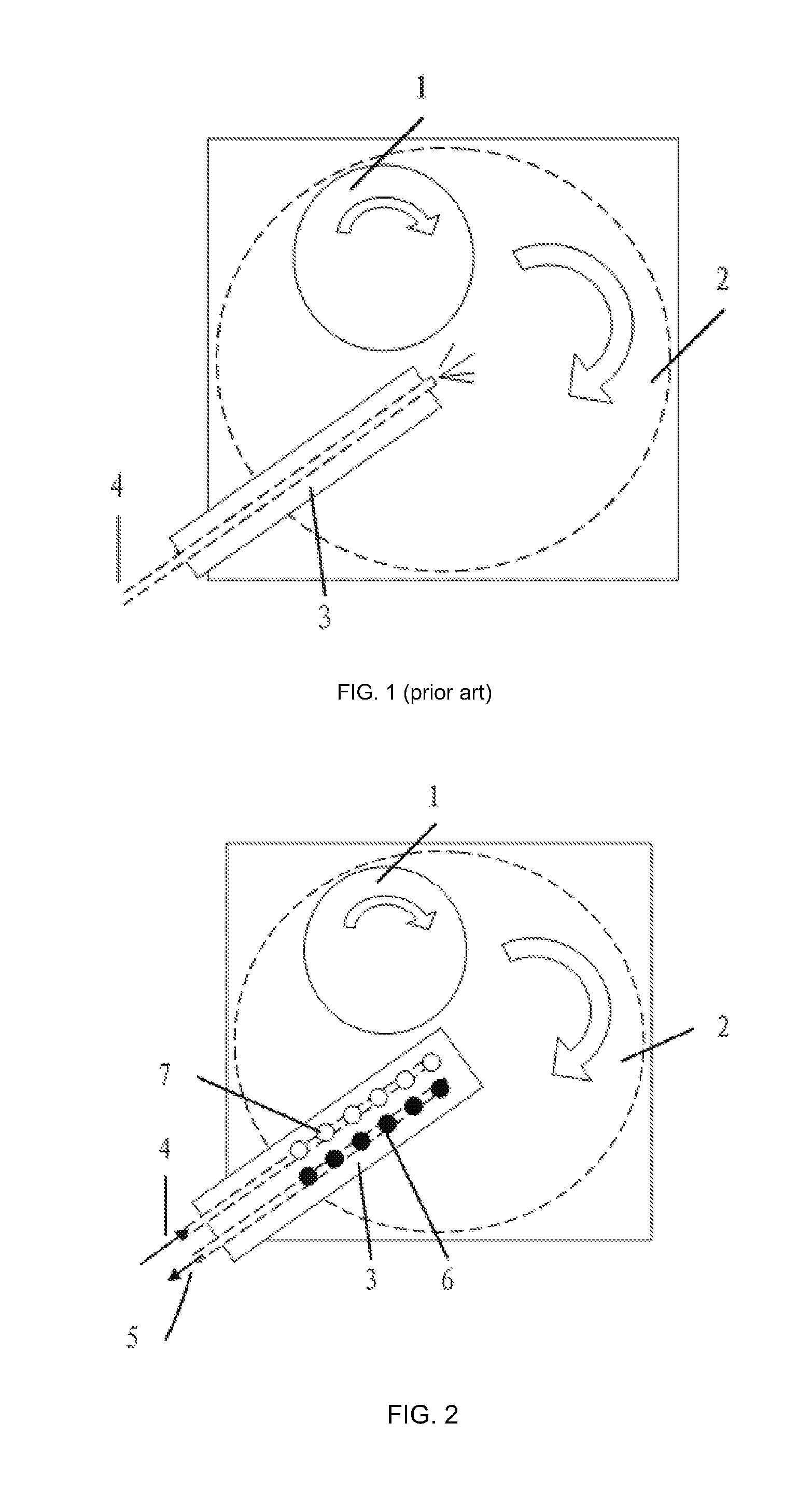

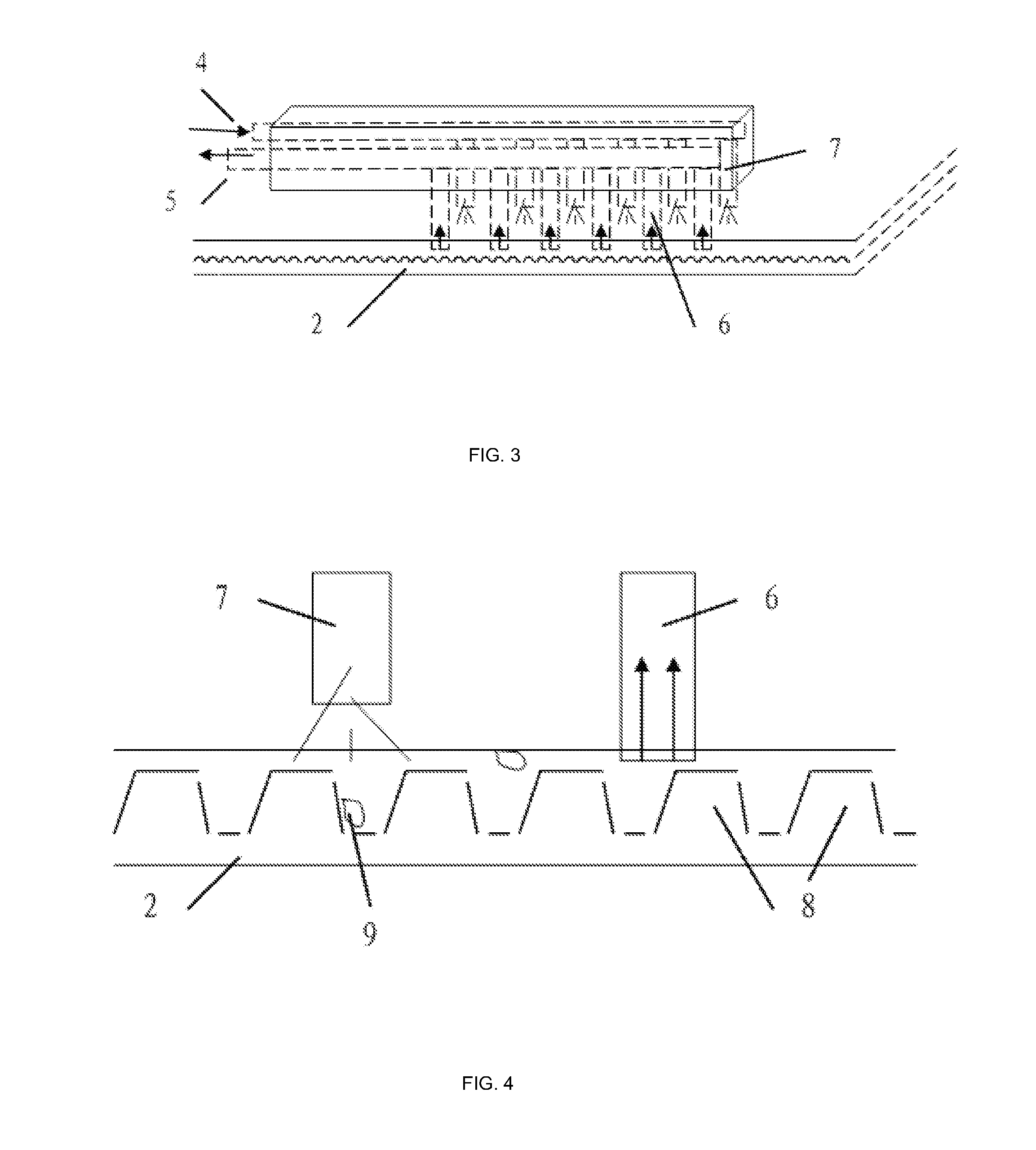

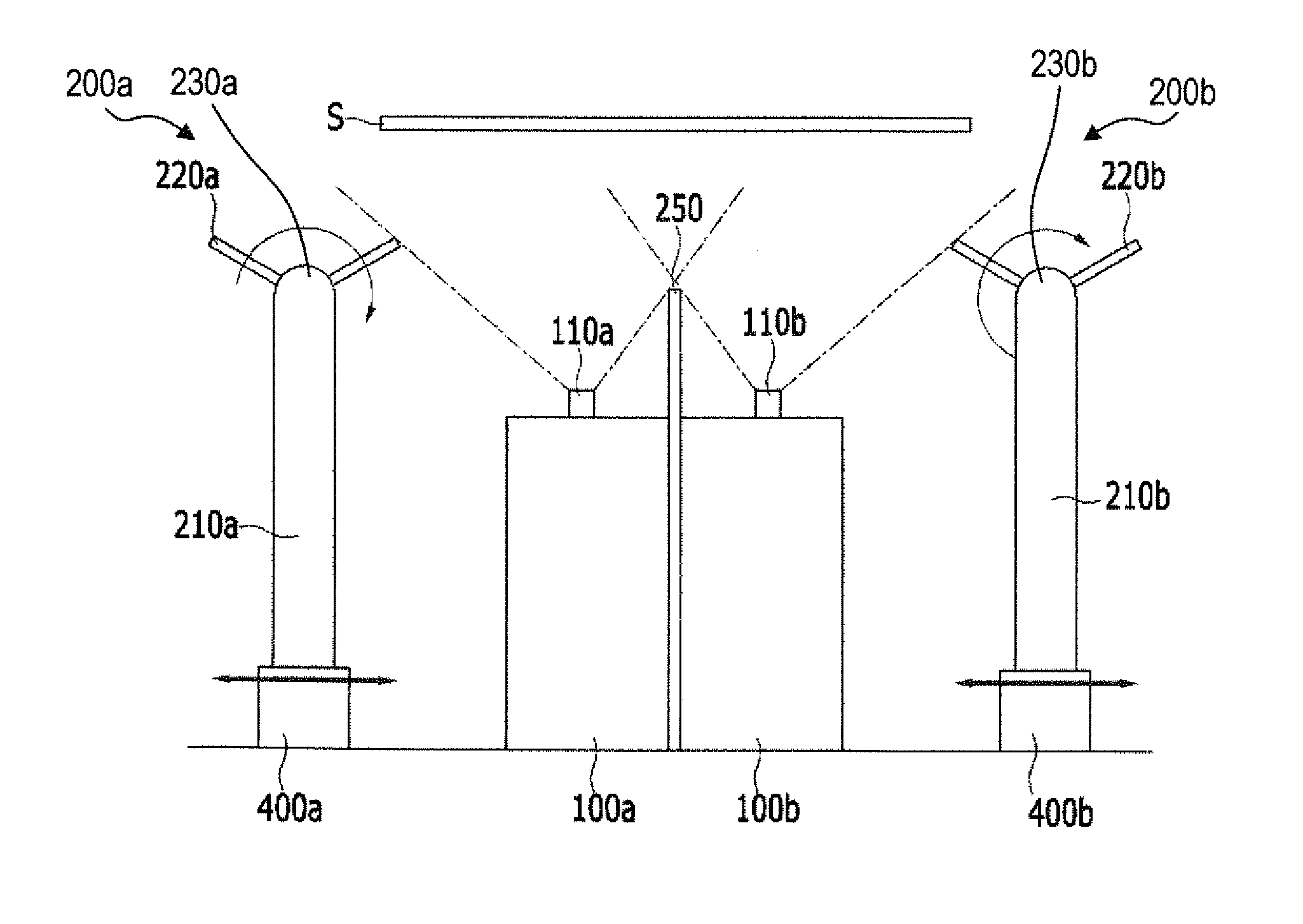

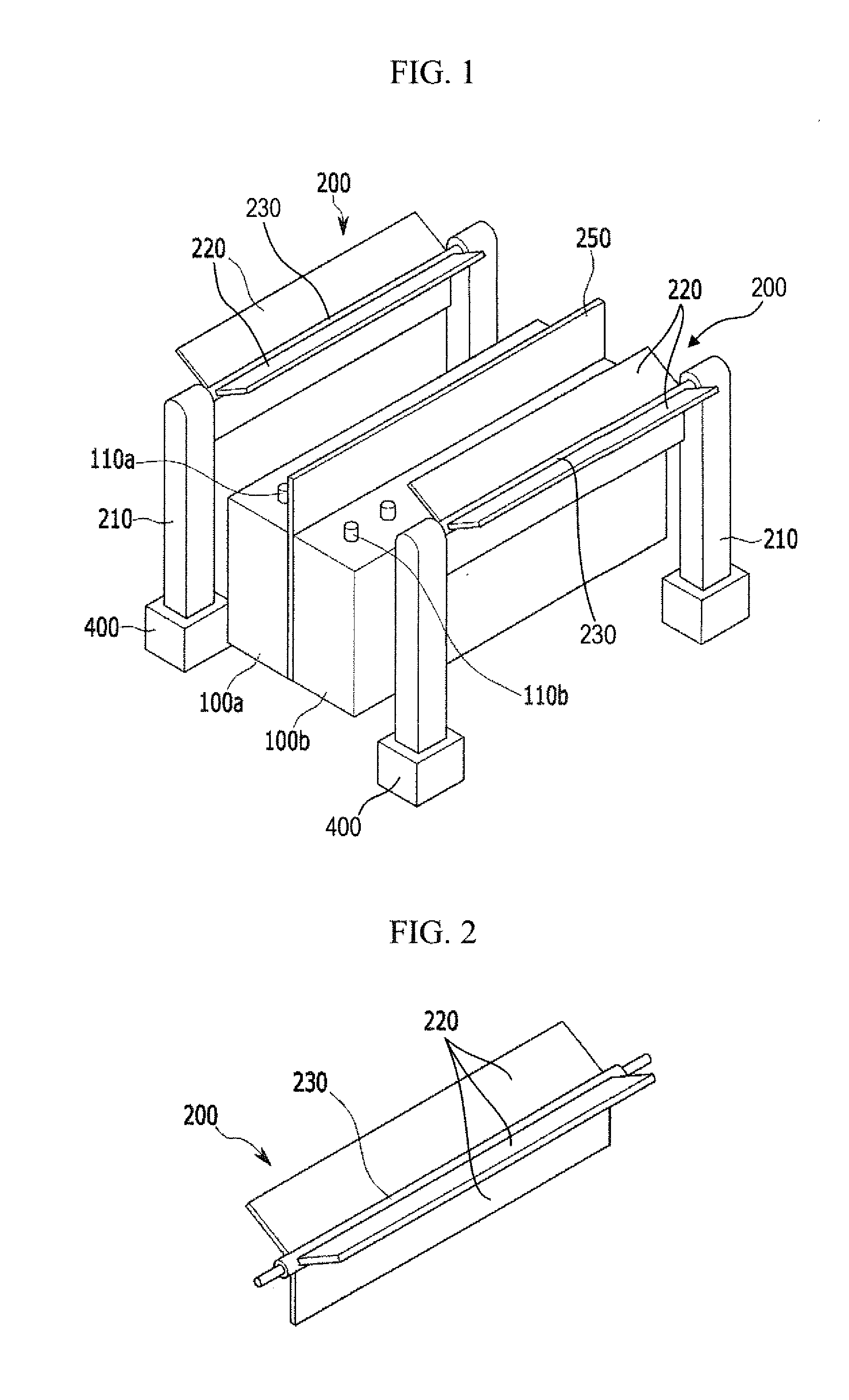

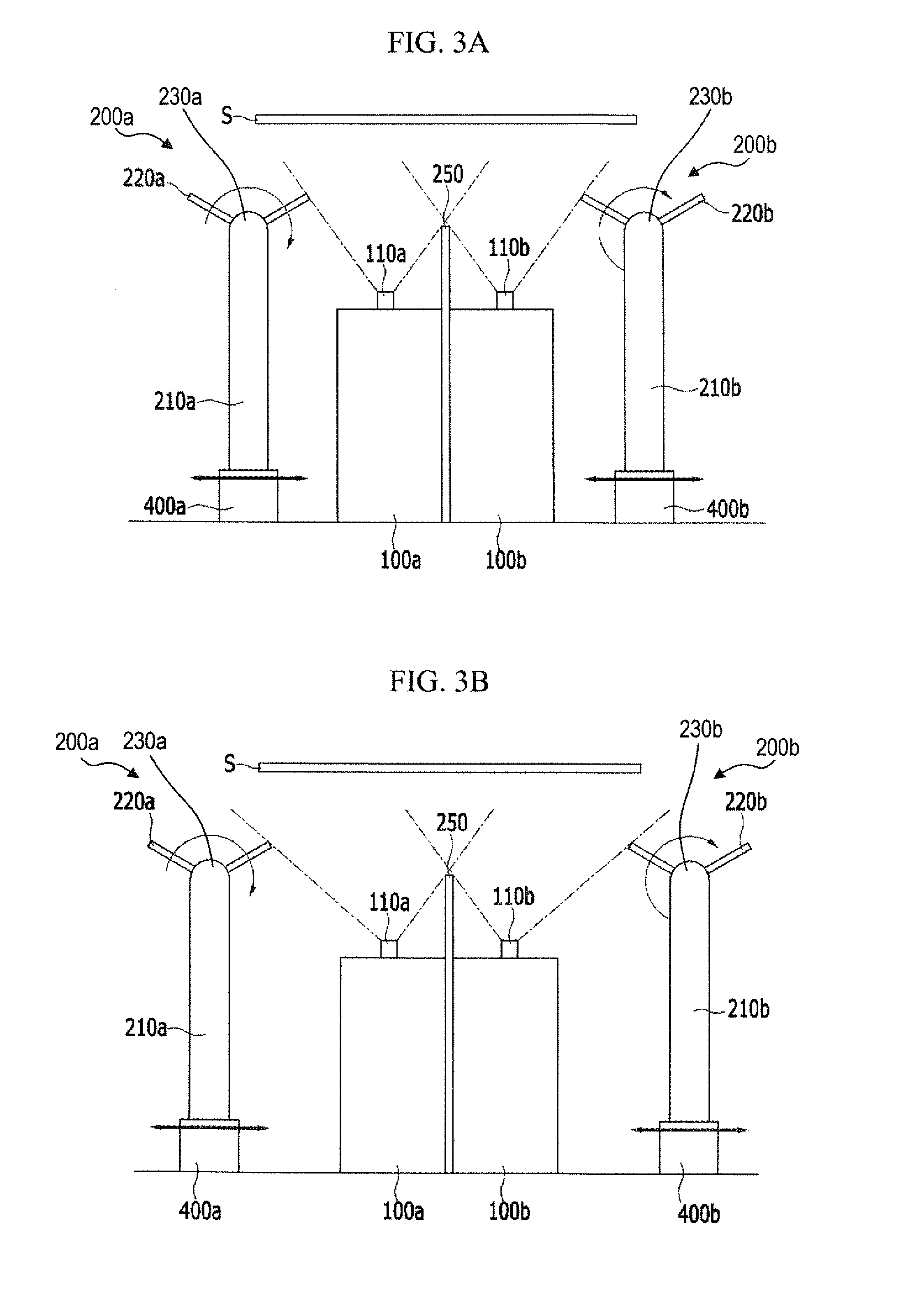

Deposition Apparatus and Method for Manufacturing Organic Light Emitting Diode Display Using the Same

ActiveUS20130323868A1Improve brightness uniformityEfficient use ofLiquid surface applicatorsSolid-state devicesDisplay deviceSpray nozzle

A deposition apparatus includes: a deposition source including a spray nozzle linearly arranged in a first direction and discharging a deposition material; and a pair of angle control members disposed at both sides of the deposition source and controlling a discharging direction angle of the deposition material. Each angle control member includes a rotation axis parallel to the first direction, and a plurality of shielding plates inst7lled about the rotation axis and separated from each other by a predetermined interval around the rotation axis. Although the deposition angle is changed according to the increasing of the process time, the deposition angle is compensated to form a uniform thin film. Also, the organic thin film may be uniformly deposited through each pixel of an organic light emitting diode (OLED) display, thereby increasing luminance uniformity for each pixel.

Owner:SAMSUNG DISPLAY CO LTD

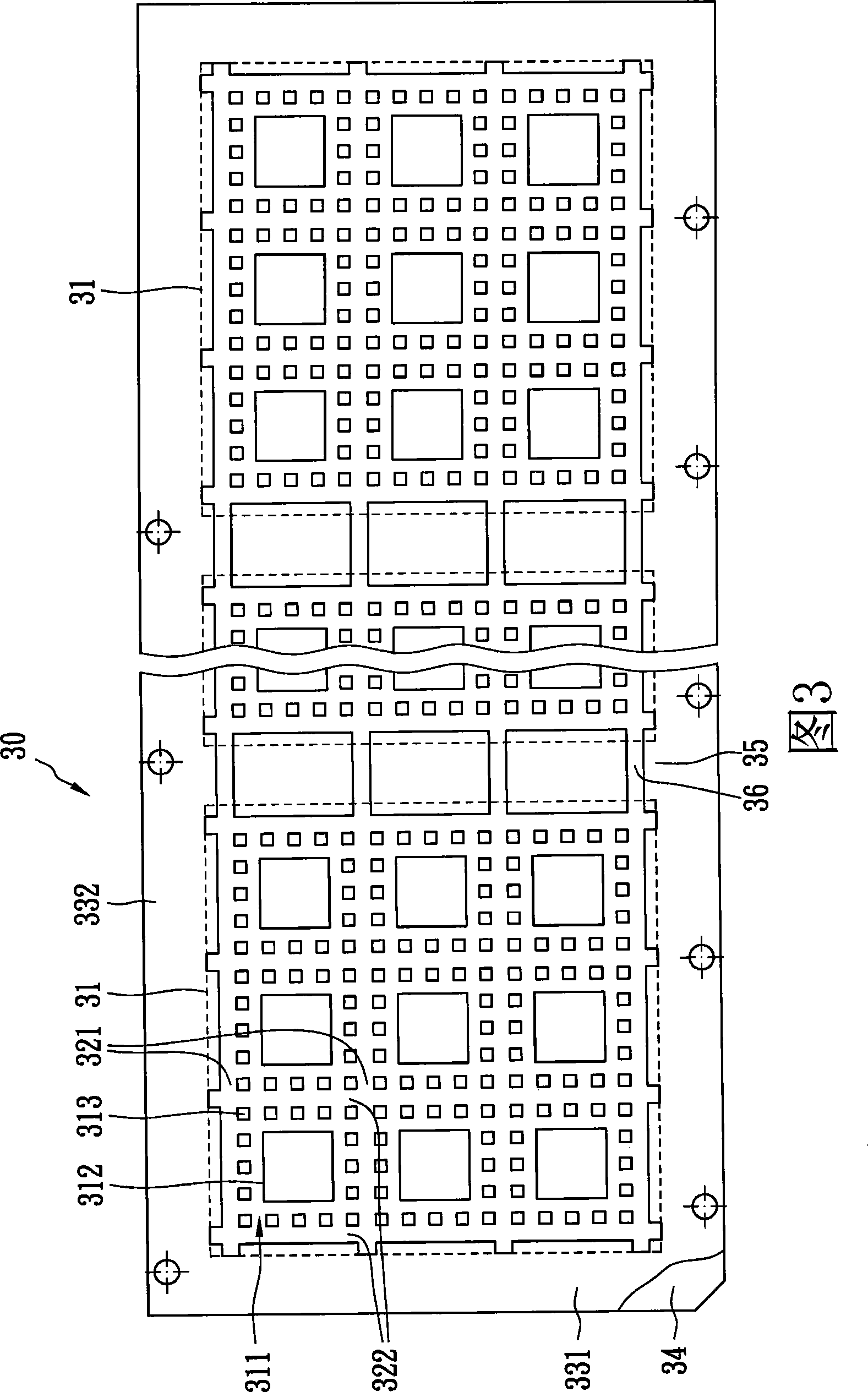

Lead frame of pinless encapsulation

InactiveCN101436576AShorten the pathReduce wearSemiconductor/solid-state device detailsSolid-state devicesEngineeringLead frame

The invention discloses a lead frame for lead-free package, which comprises a plurality of packaging areas, a plurality of clearances, a plurality of connecting parts, a plurality of openings and an adhesive tape. Each packaging area comprises a plurality of packaging units, and each packaging unit comprises a chip holder and a plurality of pins around the chip holder; and the plurality of the clearances are arranged around each packaging unit. The plurality of the connecting parts is connected with each packaging area. The plurality of the openings are arranged at the plurality of the connecting parts, and aligned to part of the plurality of the gaps respectively. The adhesive tape fixes the plurality of the packaging areas, the plurality of the connecting parts, the chip holder and the plurality of the pins.

Owner:CHIPMOS TECH INC

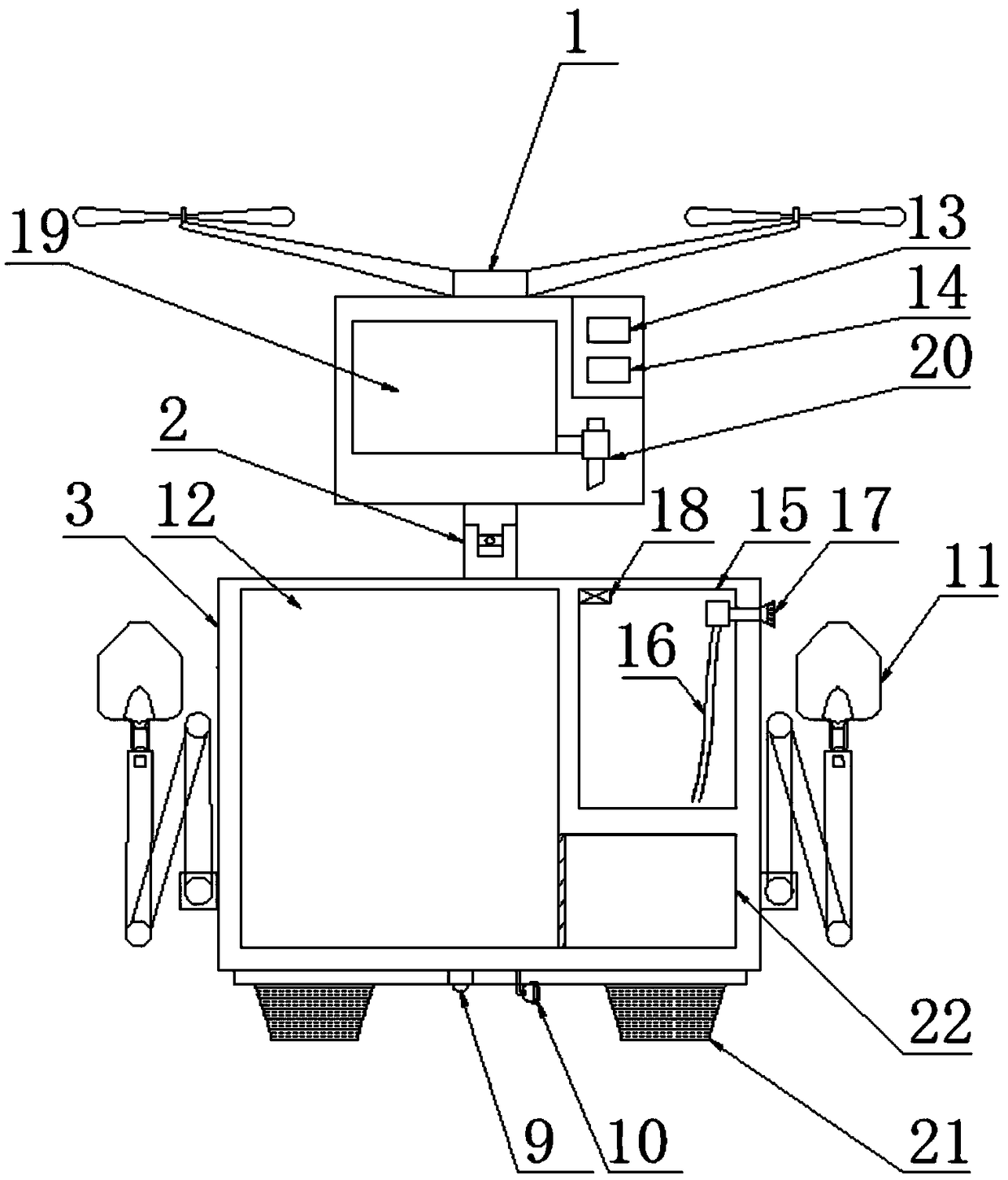

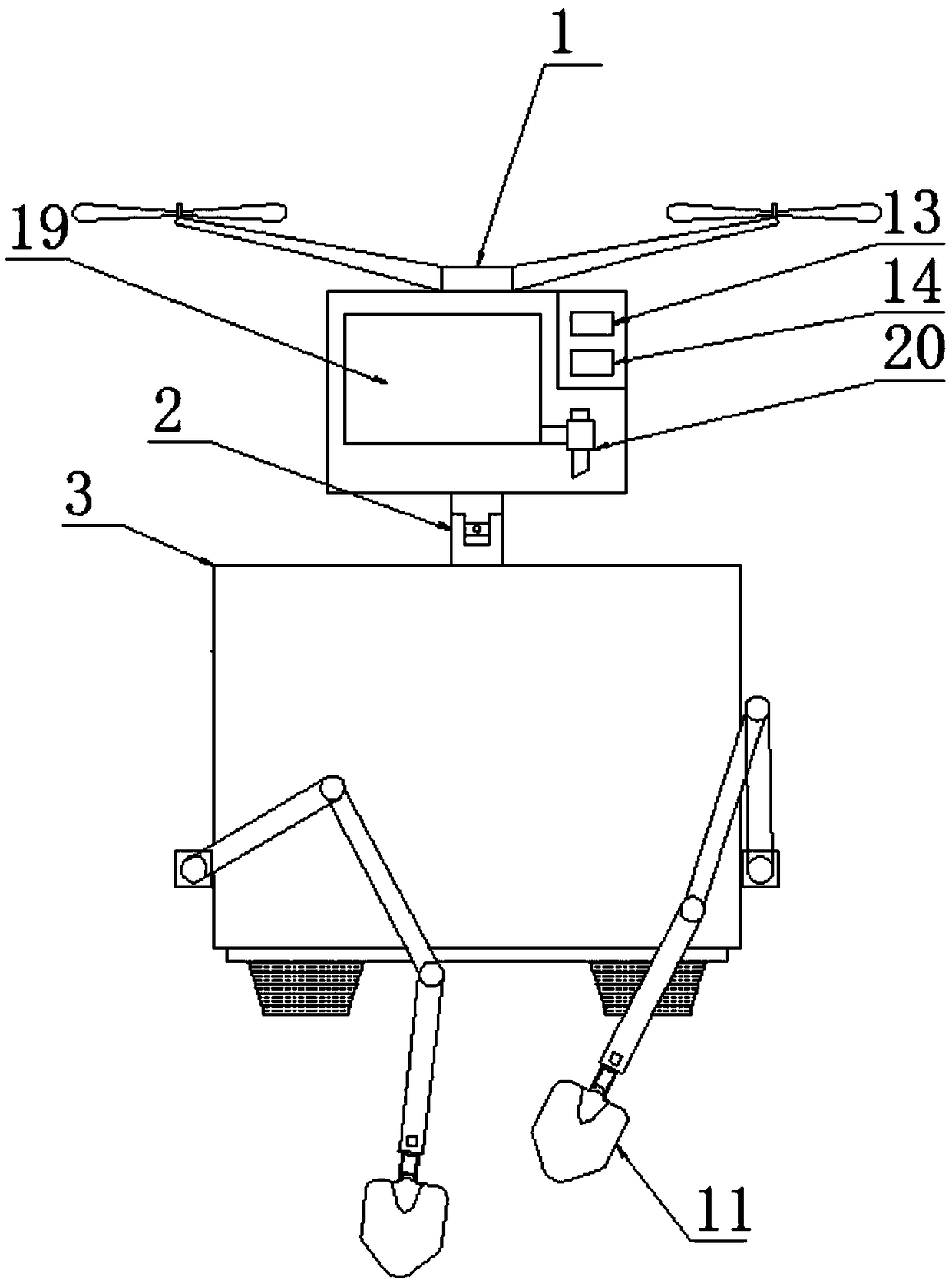

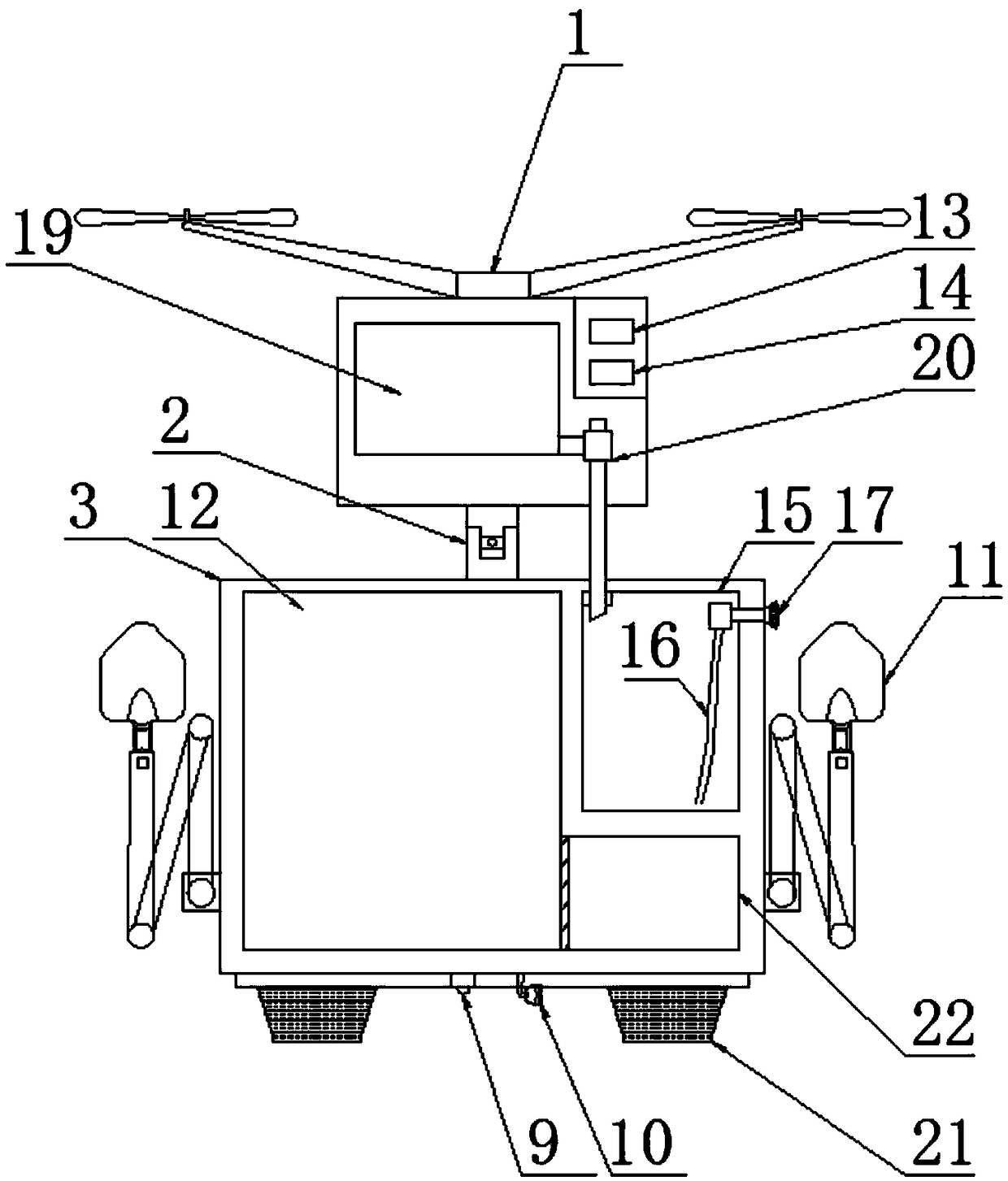

Underground crop excavating device for agricultural receiving and working method thereof

ActiveCN109104972AHigh yield efficiencyReduce damage rateWatering devicesDiggersMechanical shovelAgricultural engineering

The invention discloses an underground crop excavating device for agricultural receiving and a working method thereof. The underground crop excavating device comprises a drone, a connecting mechanism,an excavation mechanism and a control mechanism, wherein the control mechanism comprises a processor, a drive unit, a first positioning device and a first navigation device, the first positioning device is used for acquiring first position information of the excavation mechanism, the first navigation device is configured to generate a movement route of the excavation mechanism, the excavation mechanism includes a laser rangefinder, a camera device and a mechanical shovel, the laser rangefinder is used to detect altitudes from the surface of the earth and to compute the altitudes, the camera device is used for acquiring surroundings of excavation mechanism, the mechanical shovel is used to dig for underground crops, the drone is connected with the excavation mechanism through a connectionmechanism for controlling the connection relationship between the drone and the excavation mechanism, the drone comprises a second positioning device and a second navigation device, the second positioning device is used for acquiring the second position information of the drone, and the second navigation device is used for generating the flight path of the drone.

Owner:倪为勇

Preparation process of capacitive touch screen, and capacitive touch screen

InactiveCN104866152AHigh yield efficiencyReduced Alignment DifficultyInput/output processes for data processingAdhesiveTouchscreen

The present invention discloses a preparation process of a capacitive touch screen, which comprises the following steps: (1) laying a transparent conductive layer on a substrate, and coating an acid-proof film on the transparent conductive layer according to the set conductive patterns; (2) setting a target on the acid-proof film, and coating a transparent acid and alkali-resistant material on the target; (3) implementing etching to retreat the film to form the conductive patterns on the substrate, and reserving the target for protection of the acid and alkali-resistant material; (4) combining optically clear adhesive (OCA), and laying the OCA on the substrate to coat the conductive patterns; (5) cutting into particles, and dividing a large piece of substrate into several small functional pieces; (6) binding FPC, positioning through the target, and binding the target corresponding to the FPC to the functional pieces; and (7) combining transparent plates, and laying the transparent plates onto the functional pieces. The present invention further discloses a capacitive touch screen. The present invention solves the problem that the target on the transparent conductive layer is transparent and hard to perform contraposition, reduces contraposition difficulty, and improves yield rate efficiency of the process requiring contraposition.

Owner:陈彦林

Intelligent vehicle-letting system i under the road congestion condition

ActiveCN109272433AAchieve interactionIncrease application success rateDiscounts/incentivesGeographical information databasesCommunication unitGeolocation

The invention discloses an intelligent vehicle-letting system under the road congestion condition, comprising a lane positioning module, comprising a plurality of magnetic pins embedded in the lane; auser module comprises a user node, the user node comprises user information, the user information comprises at least lane information, and the user node can establish a block requested by the vehicle; a data module, the data module comprising electronic map data based on geographical position; The magnetic pin and the user node are provided with a communication unit, a geographic position positioning unit connected with the communication unit data, a user node and an information verification unit. Using this system, the vehicle can fulfill the request by exchanging information with the vehicle with the same lane information in case of emergency.

Owner:NANJING UNIV OF SCI & TECH

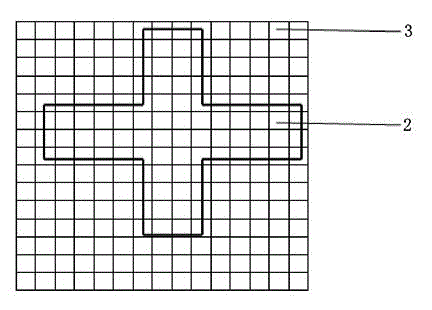

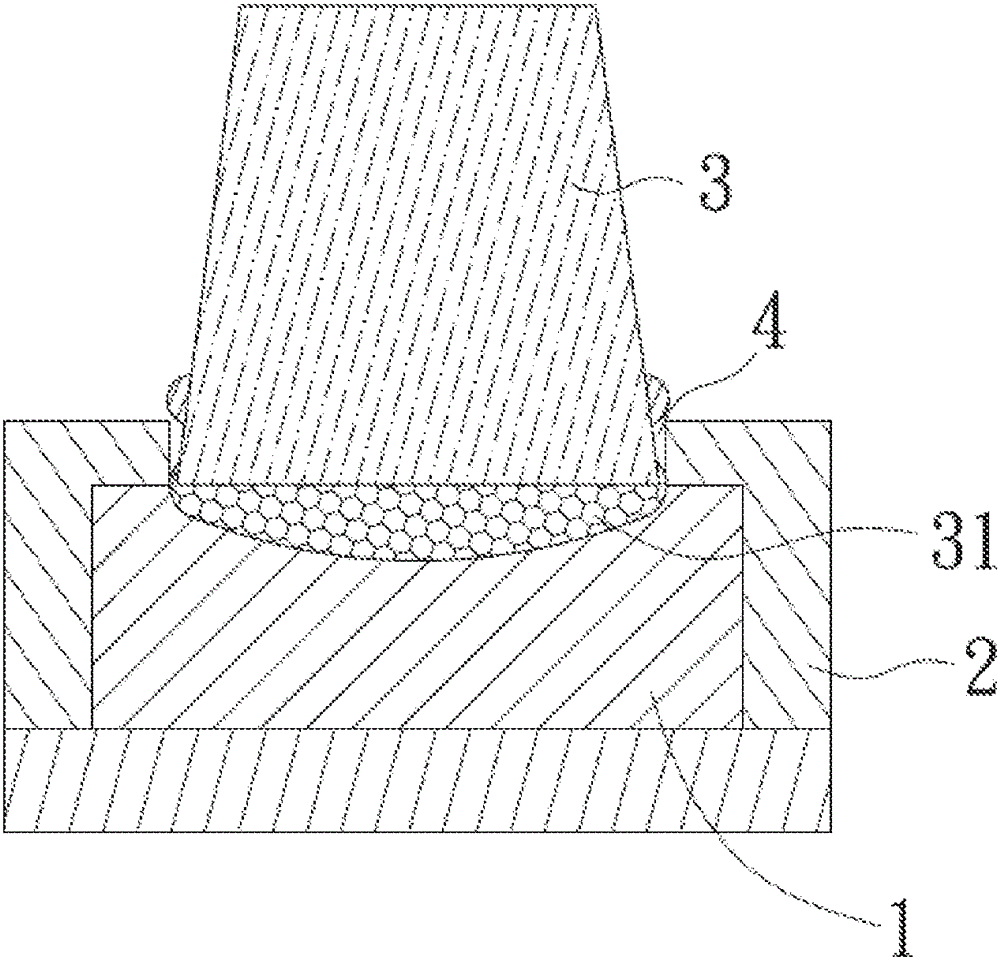

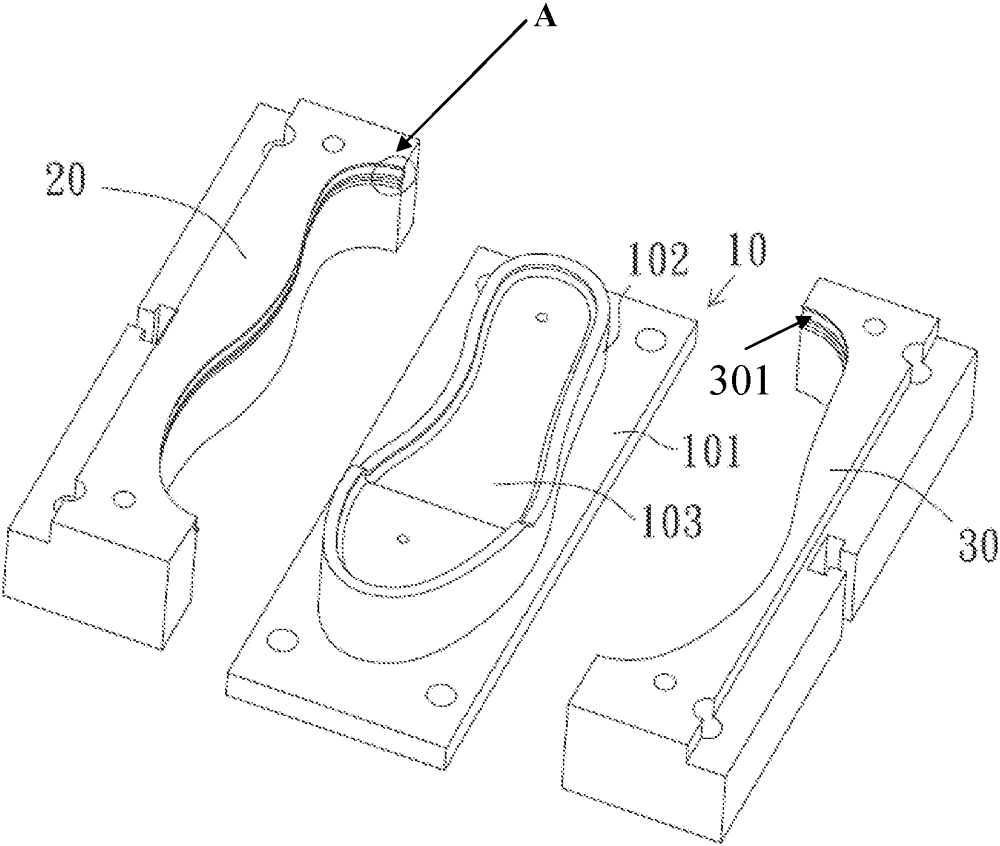

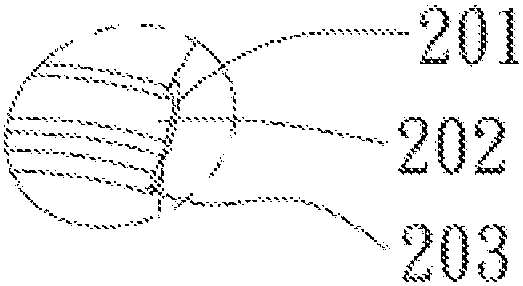

Sole Manufacturing Mold

Owner:陈铭德

Instant porridge potato chips and production method thereof and used granule slicing machine

InactiveCN105918973AFast and fast leachingImprove consistencyMilk preparationMetal working apparatusChipped potatoesEngineering

The present invention discloses instant porridge potato chips which are cooked. The thicknesses of the potato chips are more than 0.01 mm and less than 1 mm, the lengths of the potato chips are less than 10 mm, the widths of the potato chips are less than 8 mm, and the water contents of the potato chips are more than 1% and less than 10%. The potato chips are instant foods. A production method is as follows: the potatoes are washed clean, the washed potatoes are cut into thick potato slices, the thick potato slices are cured, the cured thick potato slices are dried, the dried thick potato slices are cut into potato granules using a granule slicing machine, the potato granules are rolled into dried potato slices, the dried potato slices are dried, the dried potato slices are sterilized, and the sterilized dried potato slices are packaged. The granule slicing machine consists of an upper body and a lower body, rotary cutters, a rotary cutter beam, a core table, a pile base, a motor and a motor house. The lower mouth of the upper body and the upper mouth of the lower body have the same diameter and are connected and located using a flange, the upper part of the core table is in a round pie shape, the lower part of the core table is a straight cylinder and inserted into and fixed to the pile base, the pile base is supported in the lower body to enable the core table, upper and lower bodies, and motor in a same shaft axis, the diameter of the lower mouth of the upper body is larger than the diameter of the large diameter of the upper part of the core table, and the height of the lower mouth of the upper body is the same as that of the upper part of the core table, the center of the rotary cutter beam is vertically connected to the lower end of a motor shaft in a T-shaped manner and higher than the core table, the rotary cutters are connected to the two end heads of the rotary cutter beam in a T-shaped manner, the lower tips of the rotary cutters are inserted into gaps between the lower mouth of the upper body and large diameter of the upper part of the core table, and raw materials enter from the upper body and discharge from the lower body.

Owner:SICHUAN COCICO JUICE

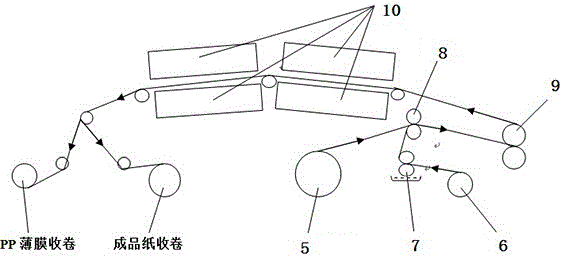

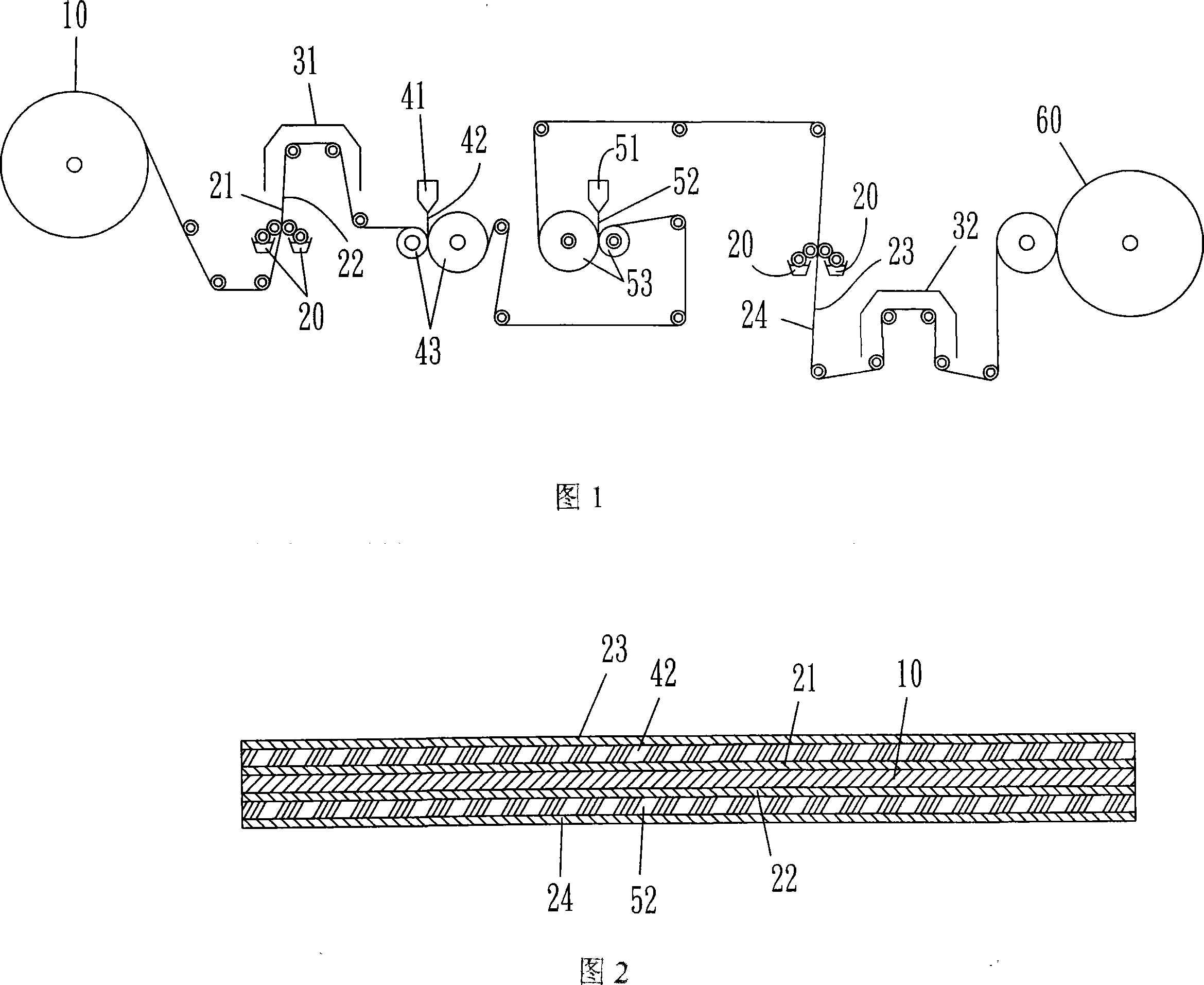

Environmental protection paper structure for foods container and manufacture method thereof

InactiveCN101200865AAvoid stickingShorten production timeSpecial paperPaper/cardboardCoated surfacePulp and paper industry

The invention relates to an environmental protection paper structure for a food container and a method for producing the environmental protection paper structure, belonging to the living goods. The method comprises the steps as follow: the two sides of the primary reel layer are firstly roll-printed through a roller group to cover the first upper and lower bridging agent coat; the first upper andlower bridging agent coating is then molded through a first drying device; a first biological resoluble film layer coat is firstly covered on the surface of the first upper bridging agent coat through a film lamination machine, and then is integrated through a cooling roller group; a second biological resoluble film layer coat is then covered on the surface of the first lower bridging agent coat through an other group of film lamination machine, and then is integrated through another cooling roller group; finally, a second bridging agent coat and an anti-adhesive coat are covered on the outersurface of the first biological resoluble film layer coat and the second biological resoluble film layer coat through another roller group, and then are dried and molded through a second drying device; and a collecting rack is used for collecting the finished products. The invention has the advantages of continuous operation, short production time, increased yield, reduced cost and anti-adhesive property.

Owner:张锡卿

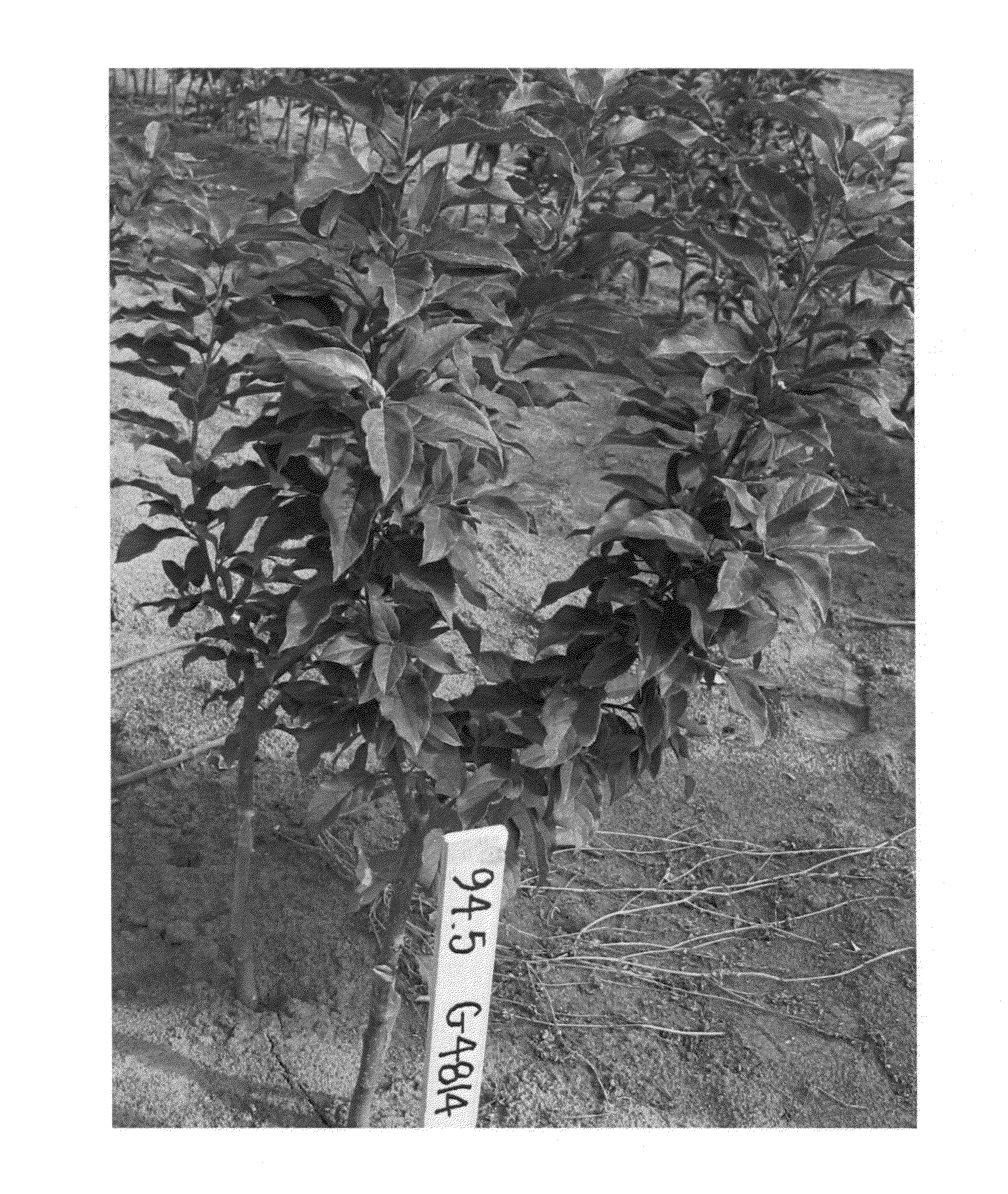

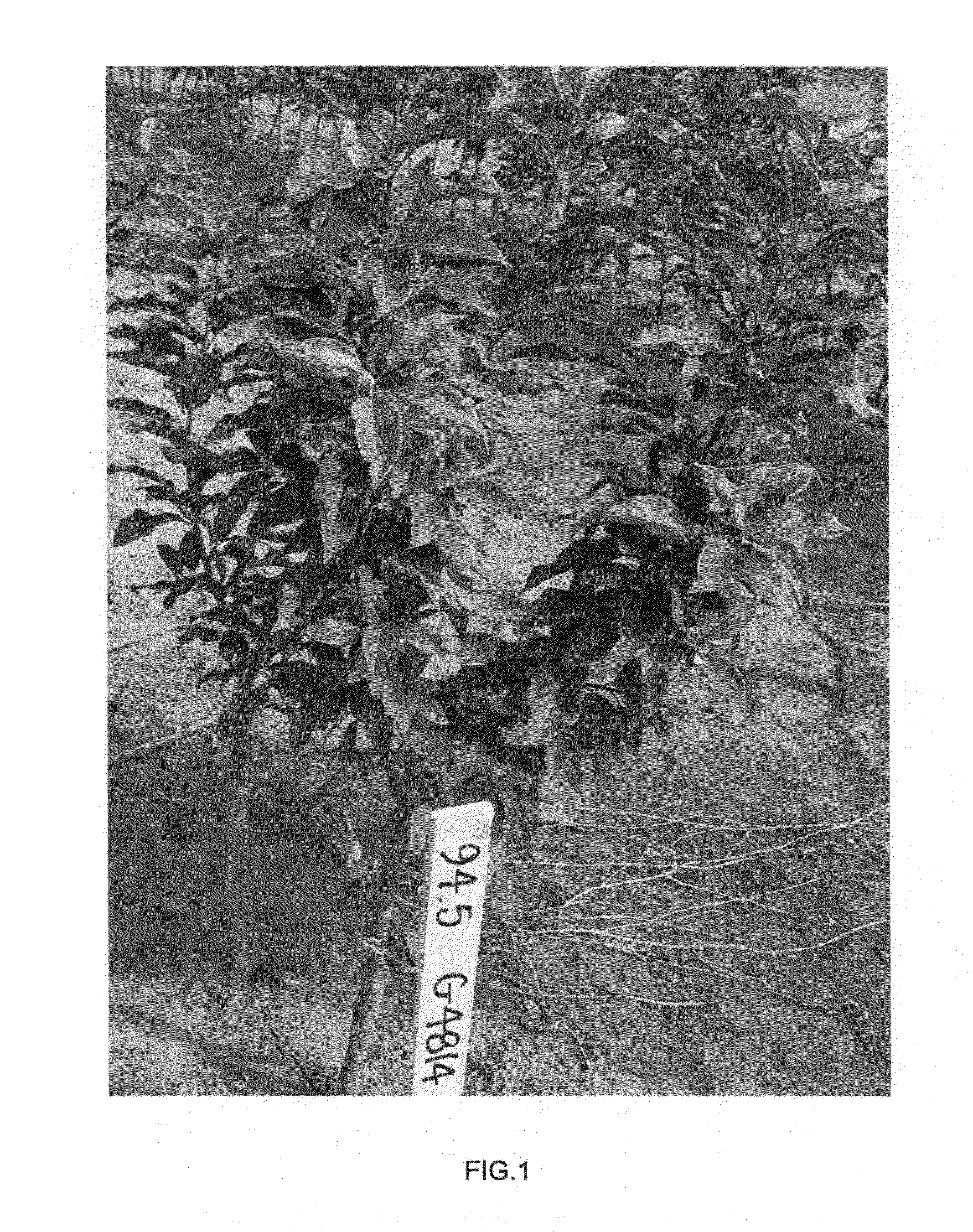

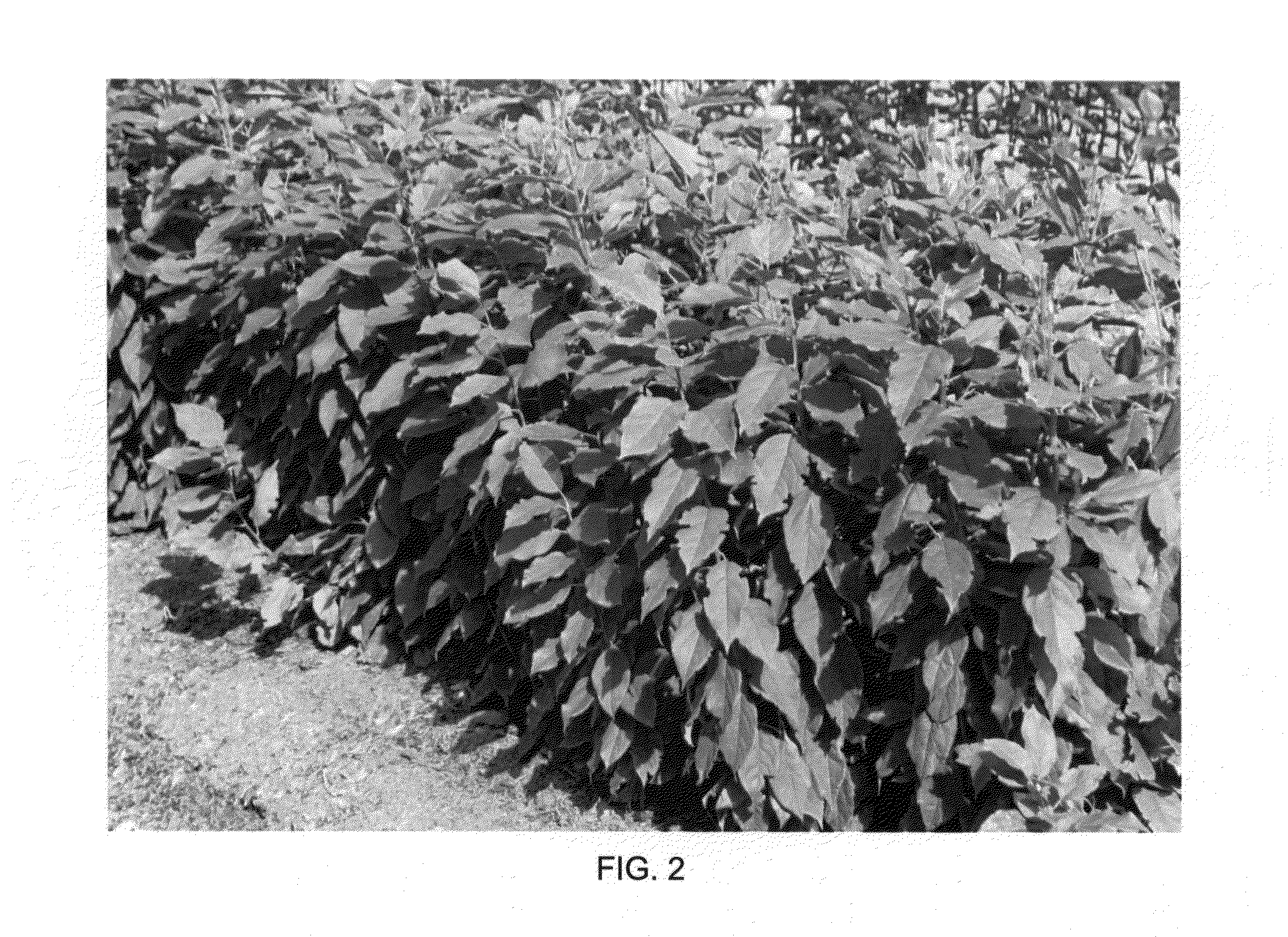

Apple tree named 'G.814'

ActiveUS20150342101P1Induces scion precocityHigh yield efficiencyAngiosperms/flowering plantsDiseaseFire blight

The present invention relates to a new and distinct variety of apple tree named ‘G.814.’‘G.814’ is useful in that it can be propagated clonally and used as a rootstock or root system for apple trees as well as for interstems of apple trees. When used as a rootstock, ‘G.814’, is: dwarfing, induces scion precocity, is cold hardy, induces scion precocity, has a high yield efficiency, is tolerant to replant disease, and is resistant to: crown and root rot (Phytophthora cactorum), fire-blight (Erwinia amylovora), and powdery mildew. ‘G.814’ is susceptible to Apple Stem Grooving Virus (ASGV) and wooly apple aphid.

Owner:US SEC AGRI +1

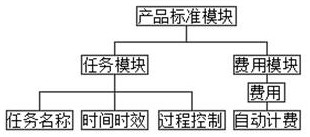

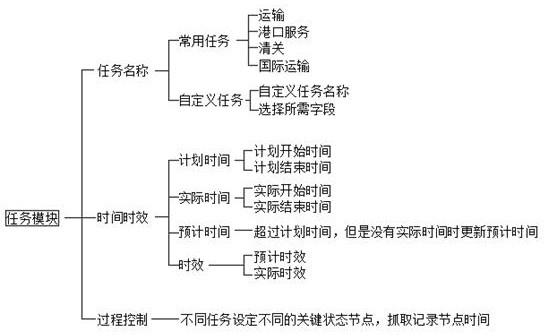

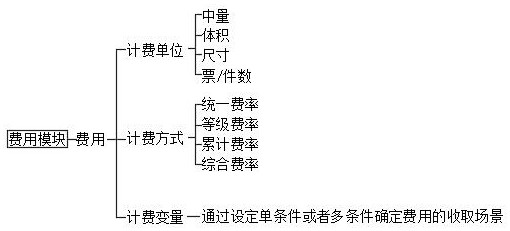

Freight product standardization scheme

PendingCN113095764AReduce productionShorten the timeOffice automationLogisticsCost calculationIndustrial engineering

The invention discloses a freight product standardization scheme, which belongs to the technical field of freight, and comprises a product standard module, and the product standard module comprises a task module and a cost module. According to the freight product standardization scheme, cost calculation is standardized from three dimensions of billing units, billing modes and billing variables, automatic cost calculation is achieved, various non-standardized cooperative tasks are subjected to standardized packaging through a task module and a cost module, and a unified standardized product is formed. The task standardization can solve the collaboration problem, reduce the low-efficiency communication efficiency and improve the per unit yield efficiency; the cost standardization can realize automatic charging and automatic account checking, reduce the bill making and confirmation time, and avoid the conditions of missing and less receiving; the invention can improve the management level, adopt more abundant management means, provide a digital basis for flat management, improve the production efficiency to a certain extent, and can reduce the labor intensity.

Owner:SHANGHAI RUZHI INFORMATION TECH CO LTD

Nanometer printing and dyeing ink and using method thereof

InactiveCN105585900ANo pollution in the processGood penetration and coloringInksDyeing processOrganic dyeFatty acid

The invention belongs to the field of preparation of printing and dyeing ink, and particularly relates to nanometer printing and dyeing ink and a using method thereof. The ink is prepared from, by mass, 15% of organic dye, 62.7% of deionized water, 18% of polar monomer, 0.8% of a polymer synthesis additive, 2% of a fatty acid hydrogenation catalyst and 2% of a formaldehyde-free fixing agent. The nanometer printing and dyeing ink can replace traditional dye ink, the traditional printing and dyeing cost and technological procedures are greatly reduced, energy consumption is reduced, no sewage is drained, ecological environmental protection is achieved, and sustainable development is facilitated.

Owner:张国志

Preparation method for extracting and refining crystals by dimethylolbutyric acid

PendingCN110483277AEasy to purifyEasy to controlCarboxylic compound separation/purificationDistillationEvaporation

The invention relates to the technical field of chemical purification of dimethylolbutyric acid, in particular to a method for preparing refined crystals by extracting dimethylolbutyric acid, which comprises the following steps: 1) adding reacted mixed concentrated solution containing dimethylolbutyric acid into rotary evaporation equipment, and carrying out reduced pressure distillation on the mixed concentrated solution; 2) adding methanol into rotary evaporation equipment, and carrying out reduced pressure distillation to obtain a faint yellow viscous kettle liquid; 3) adding the faint yellow viscous kettle liquid into a centrifugal reactor, and adding an ester solvent, so that the mixed solution is in a transparent state; 4) cooling the mixed solution to obtain a mixed solution containing dimethylolbutyric acid crystals; 5) performing centrifugal treatment on the mixed solution by controlling a centrifugal reactor to obtain a wet dimethylolbutyric acid finished product, and 6) adding the wet dimethylolbutyric acid finished product into a double-cone dryer for drying treatment to obtain the dimethylolbutyric acid finished product.

Owner:河南精众生物科技有限公司

Ultrasonic ball mill pulverizer

InactiveCN102284326BGet the most out of collision grindingMake full use of ultrasonic cavitation to promote collision grindingGrain treatmentsMotor driveHigh density

The invention provides an ultrasonic ball mill pulverizer which comprises a frame, a mixing tank, a transmission motor driving a stirring shaft to rotate, the stirring shaft pushing mill balls to crush and grind a material, a material circulation system, as well as a cooling water jacket layer, a water inlet, a water outlet, a material inlet, a material outlet and a ball discharge port which are arranged on the mixing tank. The ultrasonic ball mill pulverizer is characterized in that: holes for inserting ultrasonic generators and an assembly bosses are formed on the upper cover or / and wall of the mixing tank; 1 to 12 sets of ultrasonic generators are vertically or / and obliquely inserted into the assembly bosses which are connected or welded on the cover or the wall of the mixing tank through threads or flanges; and probes of the ultrasonic generators are inserted deep into the mixing tank and contacted with the material, so that the material completely absorb strong ultrasonic energy. While performing stirring and ball milling to the material, the ultrasonic ball mill pulverizer applies strong ultrasonic field action to generate a high-density energy filed, so that micron-grade or sub-micron-grade (0.7-30mu m) powder can be crushed into nano-grade (20-600nm) powder. The ultrasonic ball mill pulverizer has the advantages of high yield and efficiency, simple process, is easy to operate and control and can eliminate local concentration unevenness, effectively prevent particle agglomeration, and is suitable for industrial production.

Owner:CHANGSHA SDLUBE SCI & TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com