High-efficiency energy-saving rail type lithium battery oven

A high-efficiency, energy-saving, track-type technology, applied to battery electrodes, circuits, drying, etc., can solve problems such as uneven drying in the oven, and achieve the effects of increased production efficiency, large volume, and fast heating

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

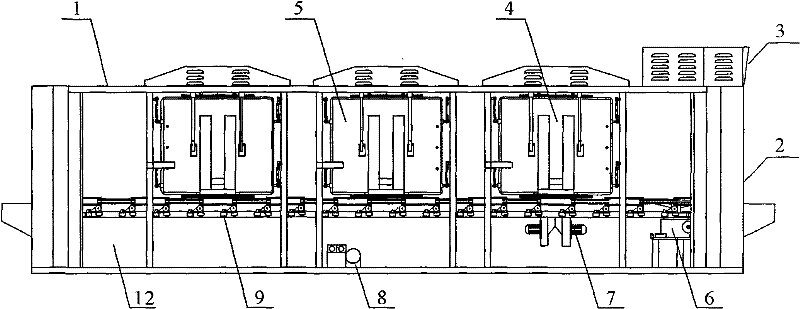

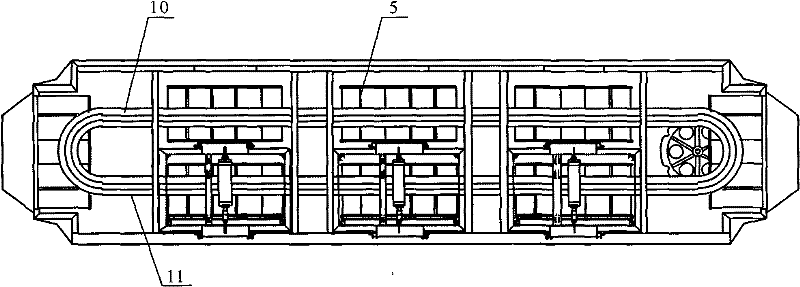

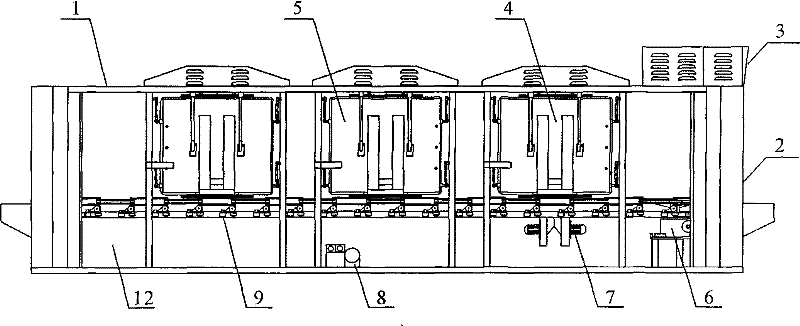

[0010] figure 1 , 2 As shown, a high-efficiency and energy-saving track-type lithium battery oven consists of a box body 1, a door seal 2, a temperature control device 3, a vacuum box 4, a heating device 5, a transmission variable frequency motor 6, a motor 7, a vacuum pump 8, a guide wheel 9, and a track 10. Composed of chain drive belt 11 and bracket 12, carbon fiber heating device 5 is installed on the inner walls of the left and right sides of box body 1, stepless temperature control device 3 is installed on the front side of the upper end panel of sealing door 2, and several temperature circulation fans are installed in the middle of the lower end of box body 1 7. Install a number of temperature exhaust devices in the middle of the upper end of the box body 1, which is characterized in that: the inside of the box body 1 is a track 10 type, using a chain drive belt 11, and the guide wheel 9 is installed and fixed on the upper end of the bracket 12, and then the track 10 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com