Sole Manufacturing Mold

A technology for manufacturing molds and bottom molds is applied in the field of improved structure of shoe-making molds, and can solve the problems of lowering yield rate, damage to processing cost of shoe uppers, and low yield rate.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

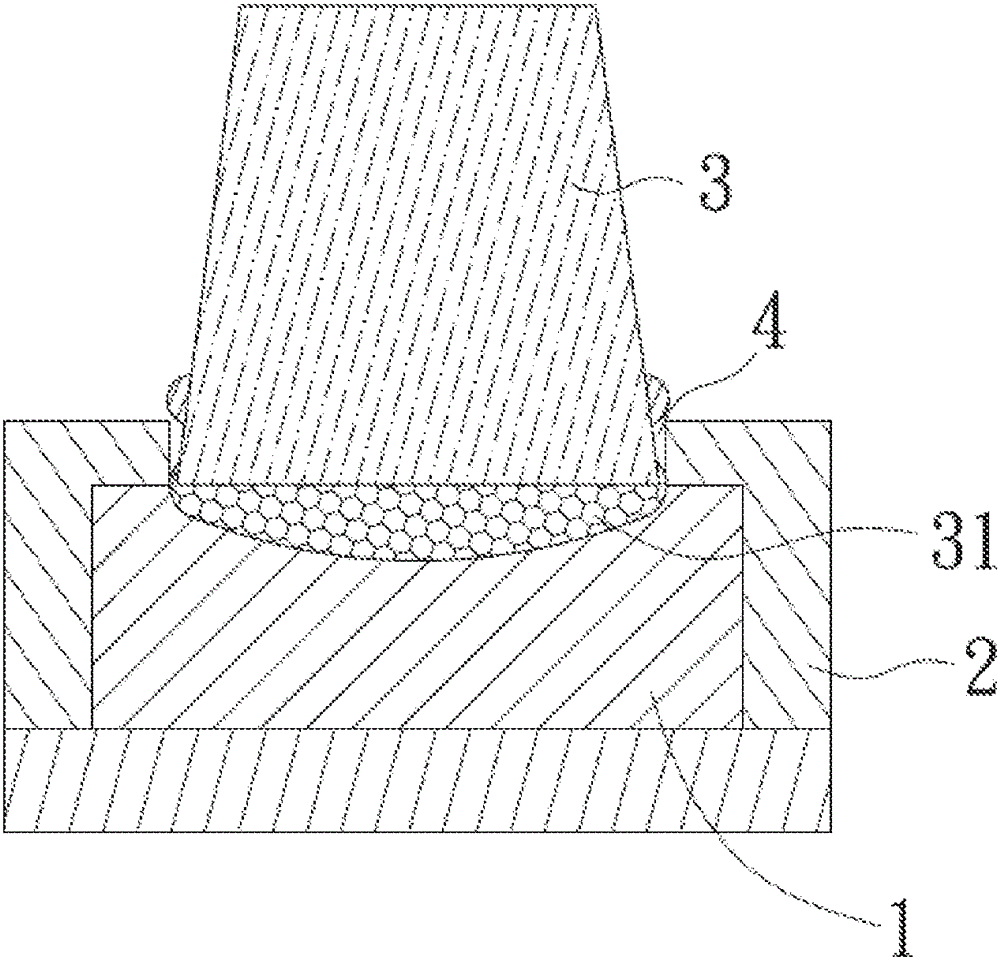

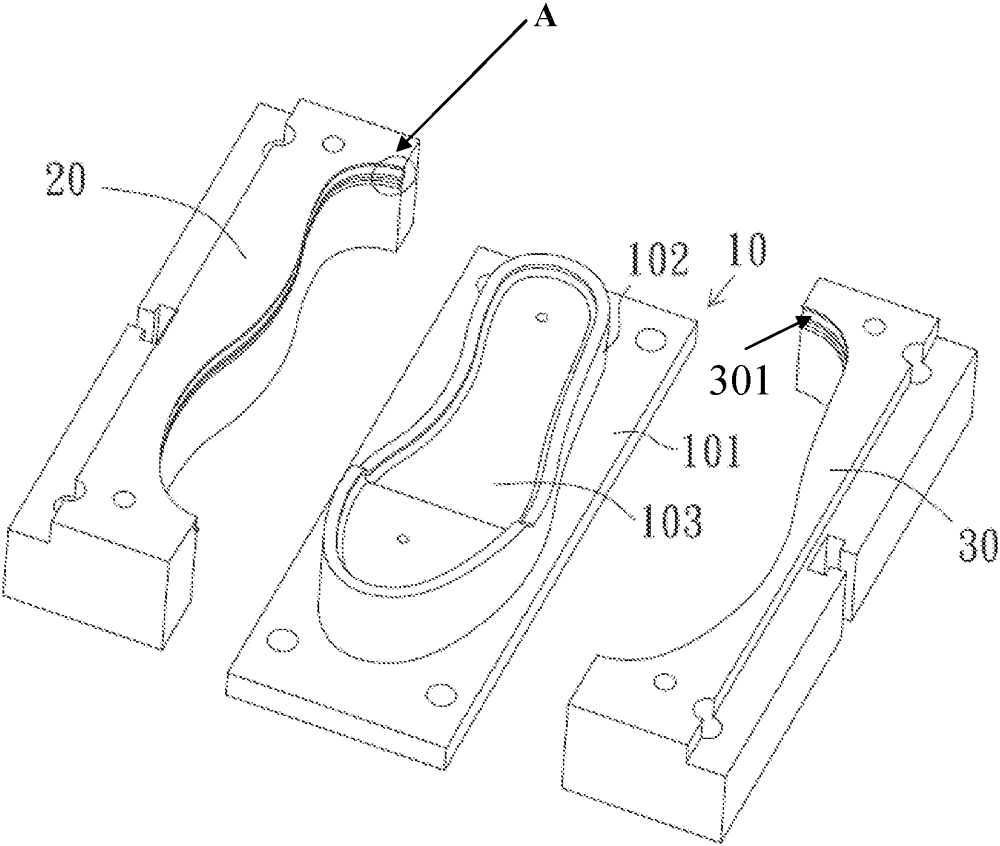

[0040] The present invention relates to an improved structure of a shoe sole manufacturing mold, please refer to Figure 2a , Figure 2b and Figure 3a , Figure 3b As shown, it mainly includes a bottom mold 10, its top 101 is provided with a shoe shape body 102, and the top surface of the shoe shape body 102 is concaved to form an inner concave portion 103 that can be used to form the sole shape of the shoe body;

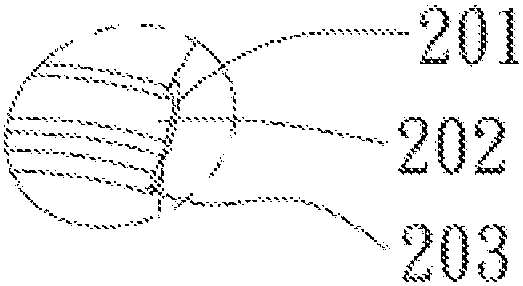

[0041] There is a left mold 20 and a right mold 30, which are relatively abutted against the left and right sides of the bottom mold 10, and are located inwardly along the inner sides of the left and right molds 20, 30 above the left mold 20 and the right mold 30. A positioning part 201, 301 is concavely provided (the positioning part 201 is located at the left side mold 20, and the positioning part 301 is located at the right side mold 30, and these two positioning parts correspond to each other), and the outer layer of the positioning parts 201, 301 is covered ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com