Preparation process of capacitive touch screen, and capacitive touch screen

A technology of capacitive touch screen and preparation process, applied in the direction of electric digital data processing, input/output process of data processing, instruments, etc., can solve problems such as high difficulty, low product yield and production efficiency, poor contact, etc., and achieve improvement The effect of improving efficiency, improving product yield, and improving alignment accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

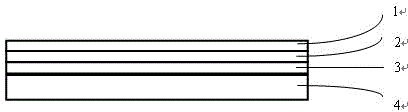

[0031] Example: such as figure 1 , figure 2 Shown, the preparation technology of a kind of capacitive touch screen of the present invention, it comprises the following steps:

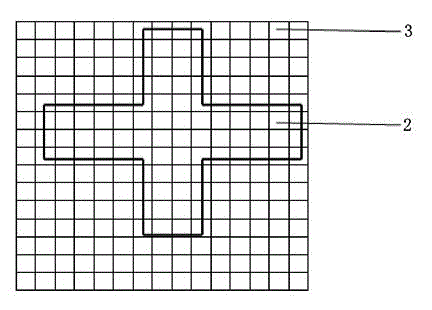

[0032] (1) Lay the transparent conductive layer 3 on the substrate 4, and coat the acid-resistant film 2 on the transparent conductive layer 3 according to the set conductive pattern. The acid-resistant film 2 is used to protect the part of the transparent conductive layer 3 that does not need to be etched ;

[0033] (2) if figure 2 As shown, the target is set on the acid-resistant film 2, and the transparent acid and alkali resistant material 1 is coated on the target; figure 1 Among them, the diagram is a structural diagram after etching, and the acid-resistant film 2 is the target;

[0034] (3) Etching and removing the film, the part of the transparent conductive layer 3 that is not coated with the acid-resistant film 2 is acid-etched, thereby forming a conductive pattern on the substrate 4, an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com