Instant porridge potato chips and production method thereof and used granule slicing machine

A potato chip, slicing and granulator technology, applied in application, metal processing, dairy products, etc., can solve the problems of difficult control, easy to break, poor popularity, etc., to prevent gastrointestinal lesions, promote gastrointestinal motility, and facilitate defecation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

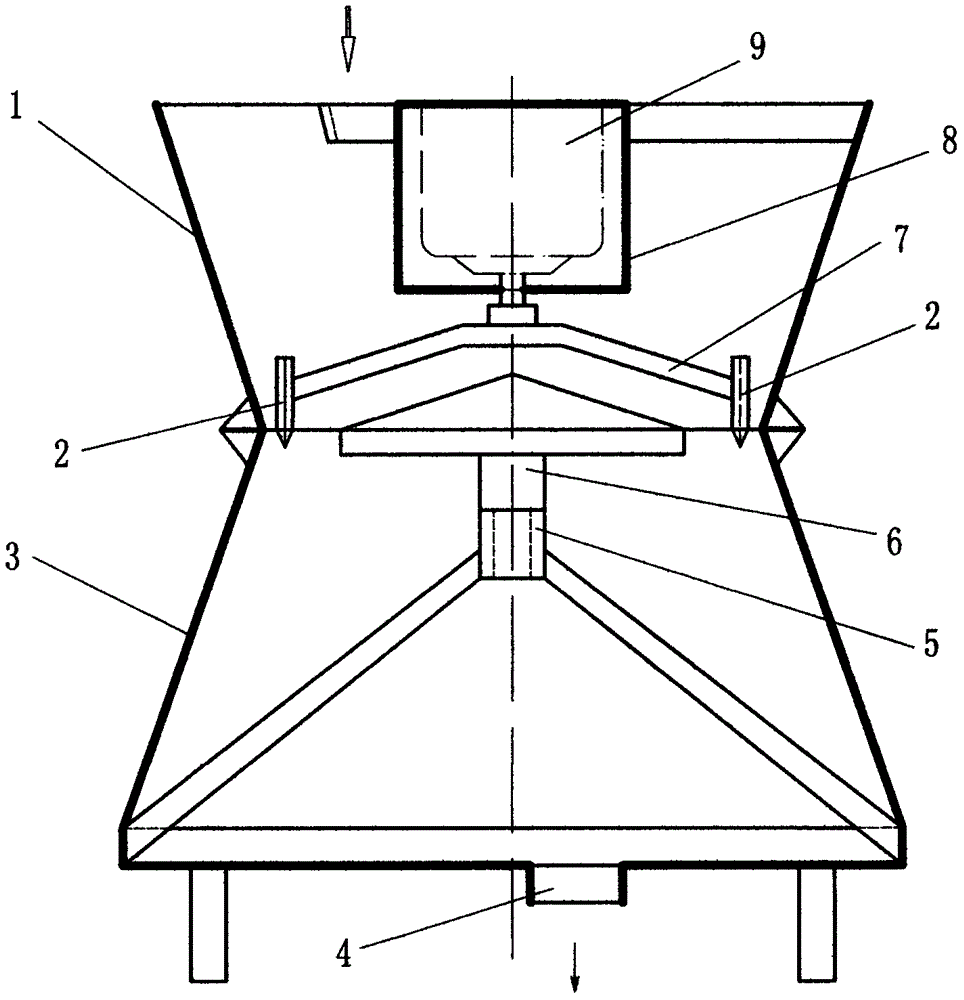

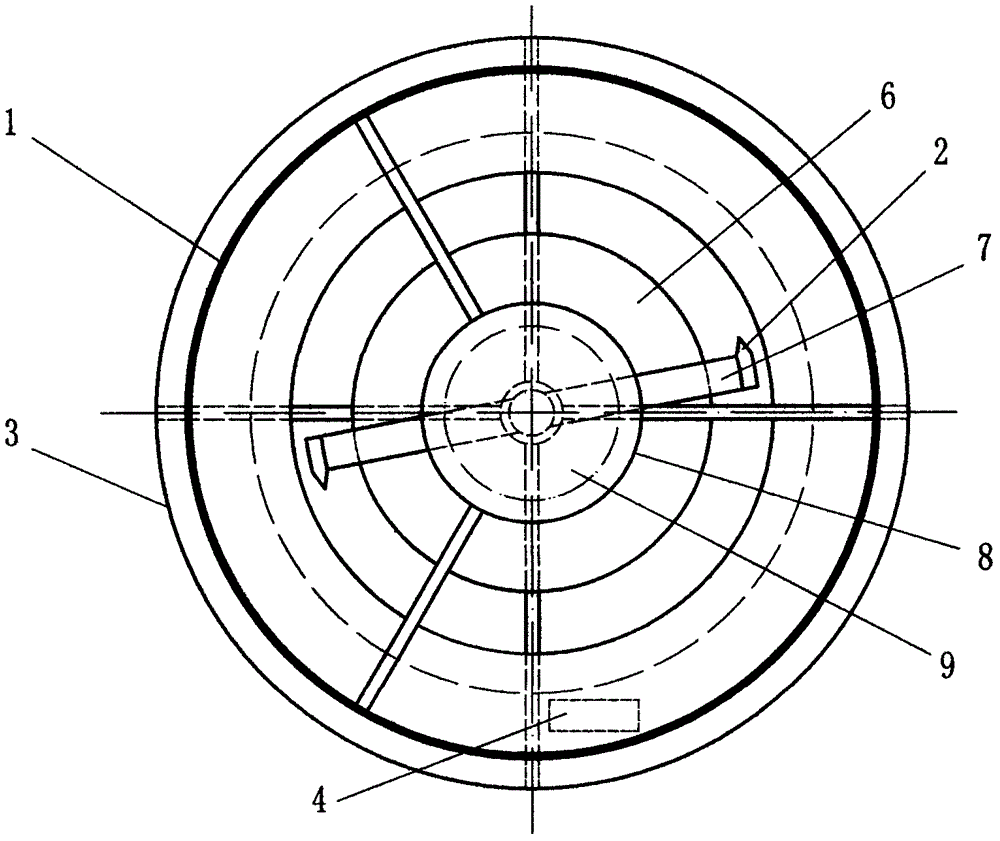

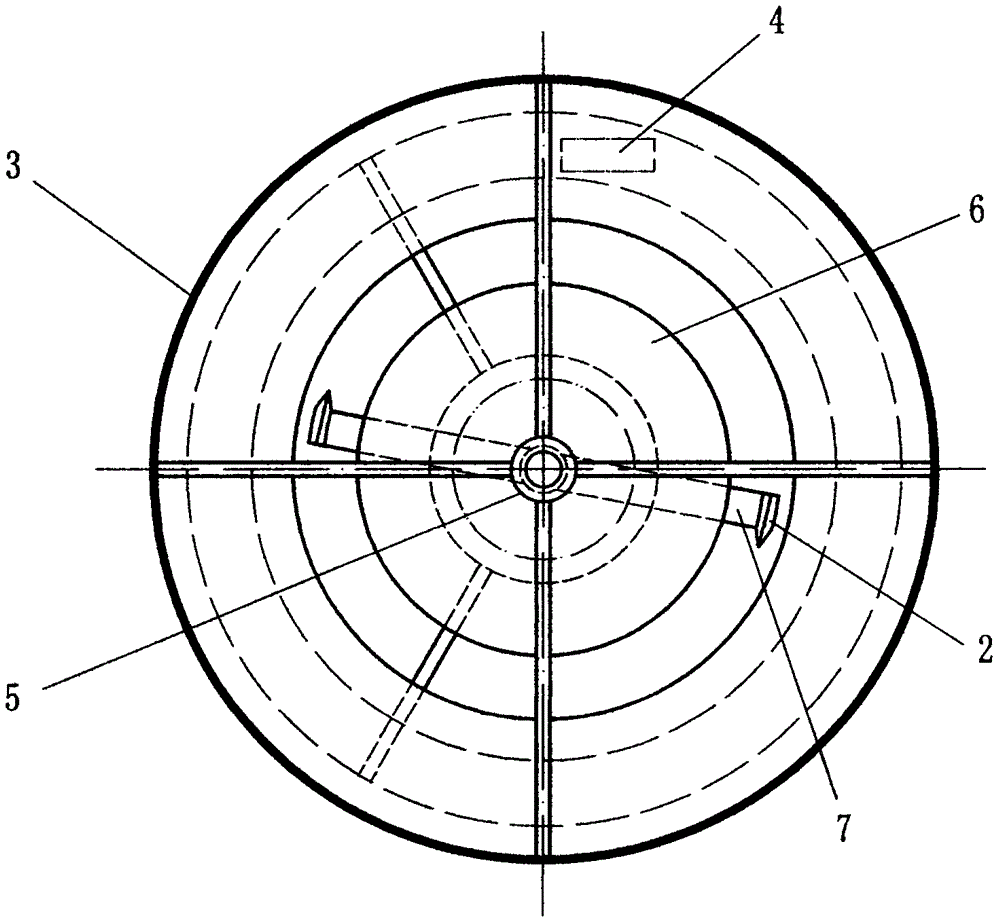

Image

Examples

Embodiment Construction

[0049] Potatoes are cleaned, cut into thick slices (thick ≈ 8mm), slaking (steaming or roasting), cooling and drying (moisture ≈ 12%), cutting into particles (particle diameter ≈ 1.6 mm) with the slicer of the present invention, and rolling. The plastic potato granules are cut into thin slices (thickness ≈ 0.5 mm), processed to a length ≈ 5 mm, width ≈ 4 mm, dried and sterilized (water content of potato chips ≈ 5%) to obtain dried potato slices.

[0050] Fresh wolfberry is dried (moisture ≈ 12%), cut into particles (particle diameter ≈ 1.6mm) with the slicer of the present invention, and this plastic wolfberry grain is rolled into thin slices (sheet thickness ≈ 0.5mm), processed to the length of the sheet ≈5 mm, slice width ≈4 mm, dry and sterilize (the content of water in the wolfberry slices is ≈5%) to obtain dried wolfberry slices.

[0051] Fresh milk is used as raw material, and the moisture is removed by spraying method, and then dried to obtain milk powder.

[0052] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com