Patents

Literature

62results about How to "Smooth logistics" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

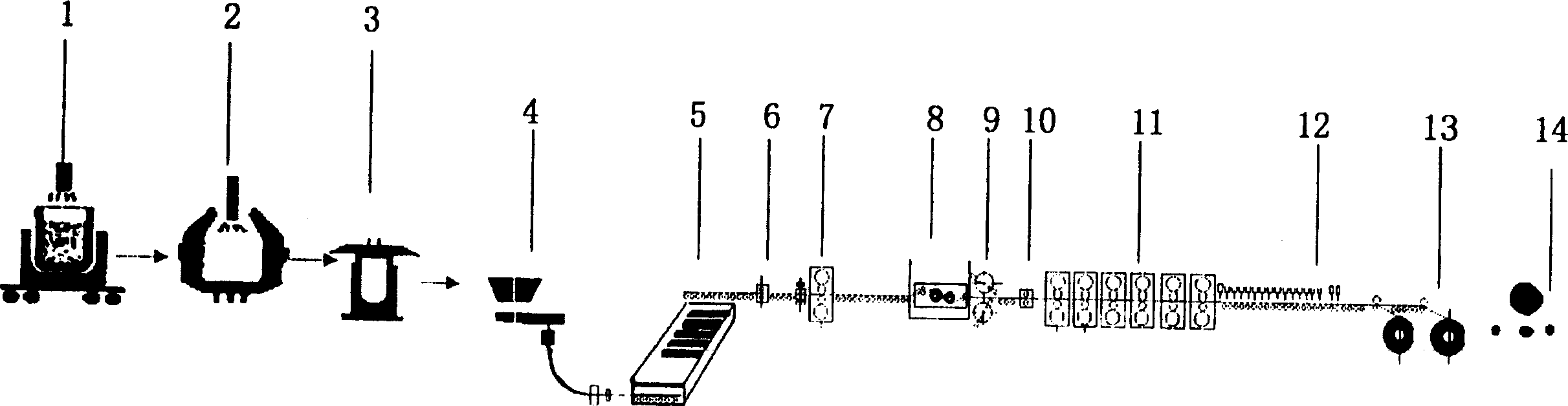

Compact medium-width strip steel production process

ActiveCN1864878AThe process is compact and reasonableSmooth logisticsMetal rolling arrangementsEconomic productionHigh pressure water

The invention relates to a compact method for producing middle-wide strip steel, which comprises: using melt iron to process pretreatment; smelting liquid steel; refining liquid steel; continuously casting the middle-thin plate blank; step beam heater heats uniformly; high-pressure water scale breaker breaks scale; one-frame four-roller reversible roughing mill mills; hot winding box winds; cutting the head and end of middle blank; the high-pressure water scale breaker breaks scale; the finishing roll machine continuously rolls; cooling the interlayer flow; the underground winder winds; and transporting steel coil. Wherein, all processes are inside one workshop or connected workshops. The invention can be used in middle steel factory with 1-2 million ton / year yields to match the metal flow, temperature flow and time flow effectively, to feed the high-temperature non-defect sheet blank at 920Deg. C into step beam heater, to save energy more than 60%, improve 1-2% of metal yield, reduce the producing cost and reduce the transport cost of middle process.

Owner:BERIS ENG & RES CORP +2

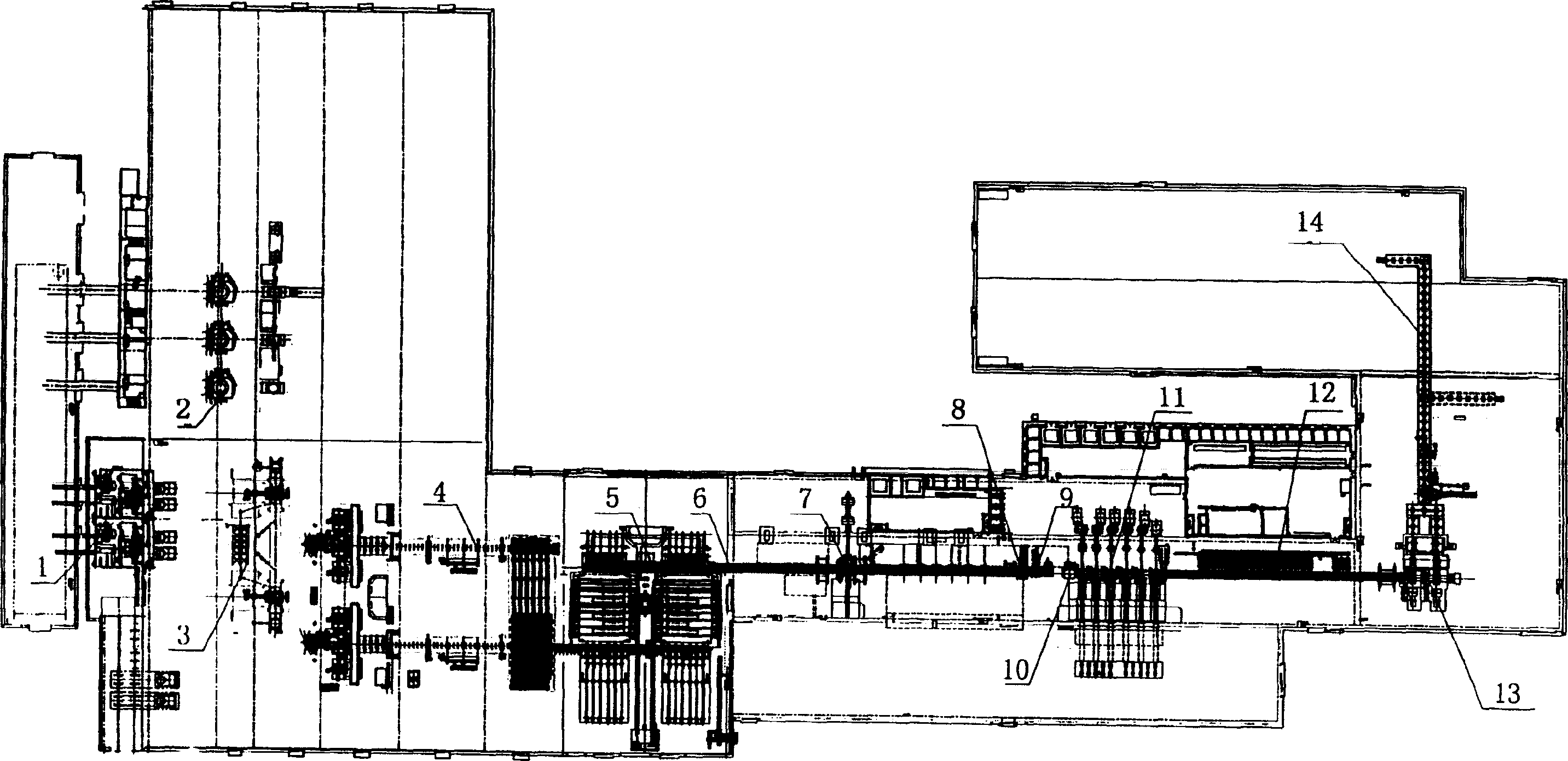

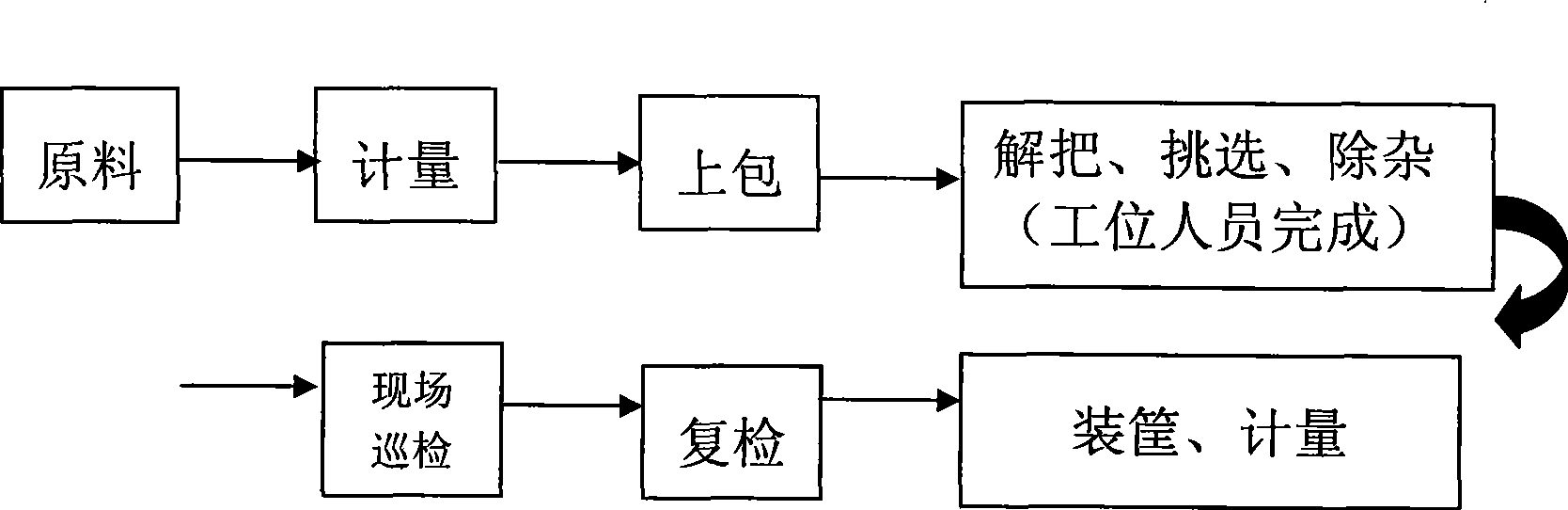

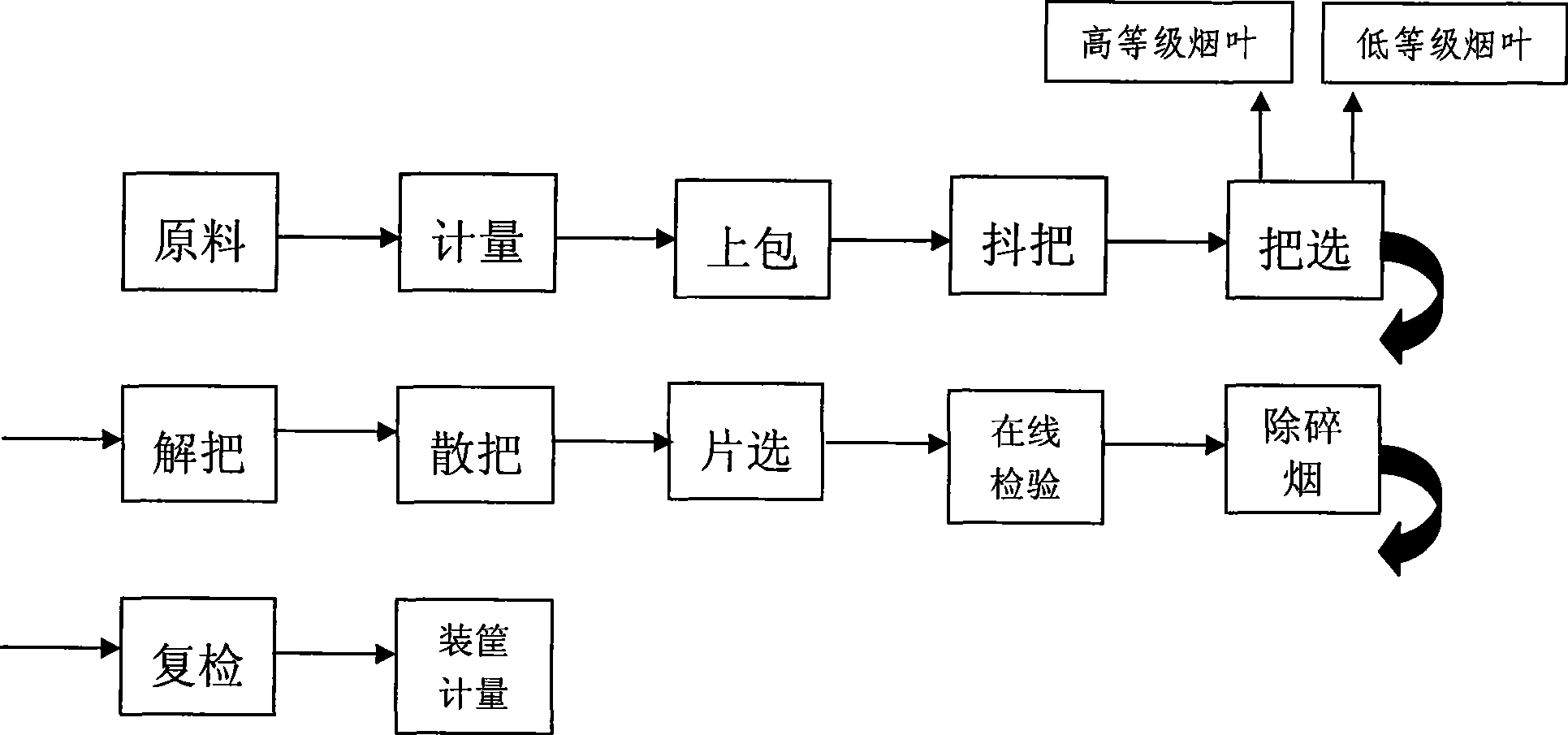

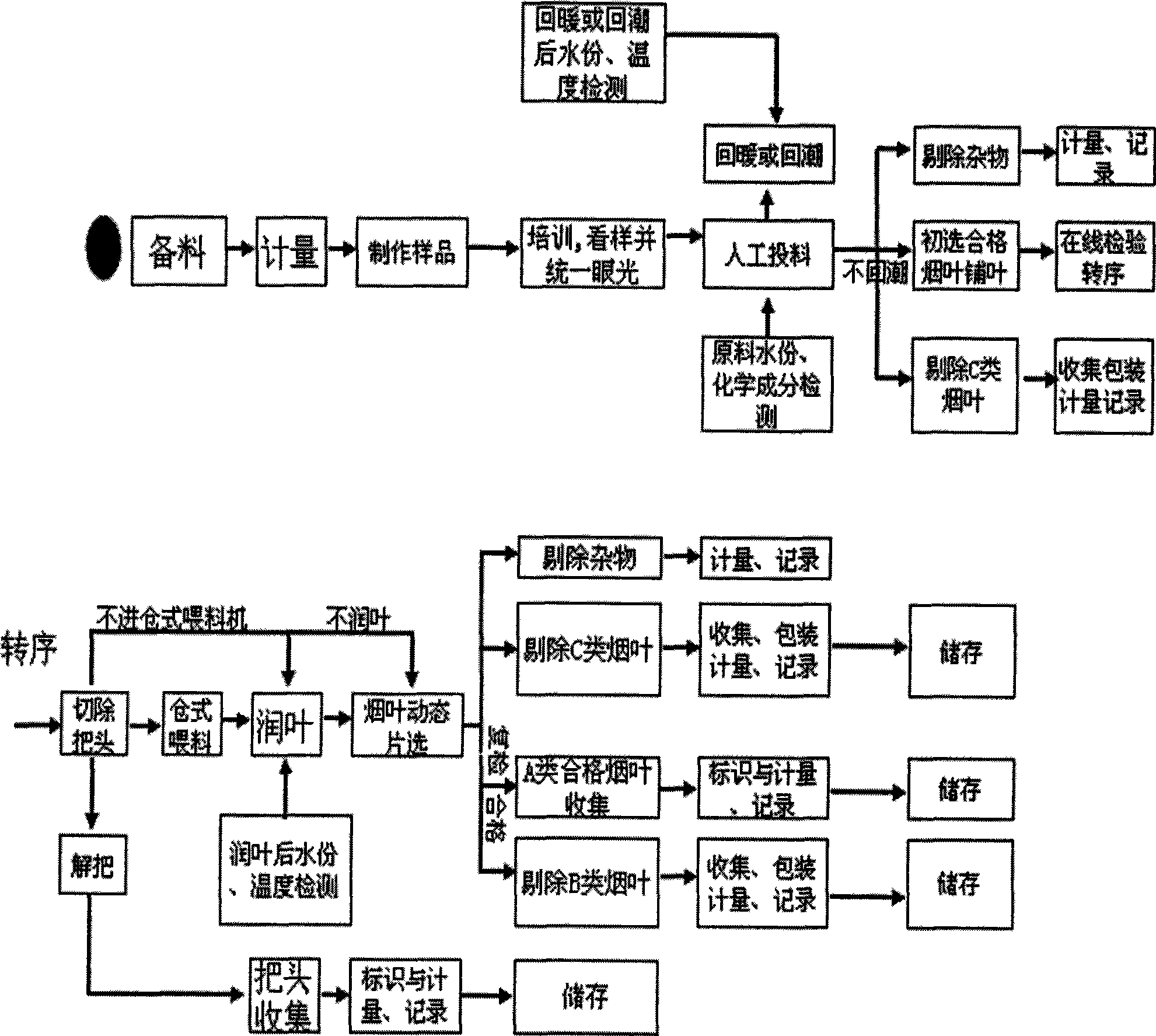

Technique for selecting tobacco leaf

ActiveCN101375736AReduce manual labor intensityImprove selection qualityTobacco preparationTobacco treatmentEngineeringRaw material

The invention discloses a tobacco leaf selection process which comprises the following steps: re-moisturizing of stock materials, spreading of tobacco leaf stalks, cutting of tobacco leaf stalks, flow rate control, wetting and loosening of tobacco leaves, tobacco leaf distribution, on-line selection of tobacco leaves, automatic collection and metering and packaging. The tobacco leaf selection process is applicable to the selection procedure of tobacco leaf raw materials for high-grade cigarettes, reduces the labor intensity, increases the purity of tobacco leaves, and ensures the inherent quality of the cigarette product.

Owner:SHANGHAI TOBACCO GRP CO LTD

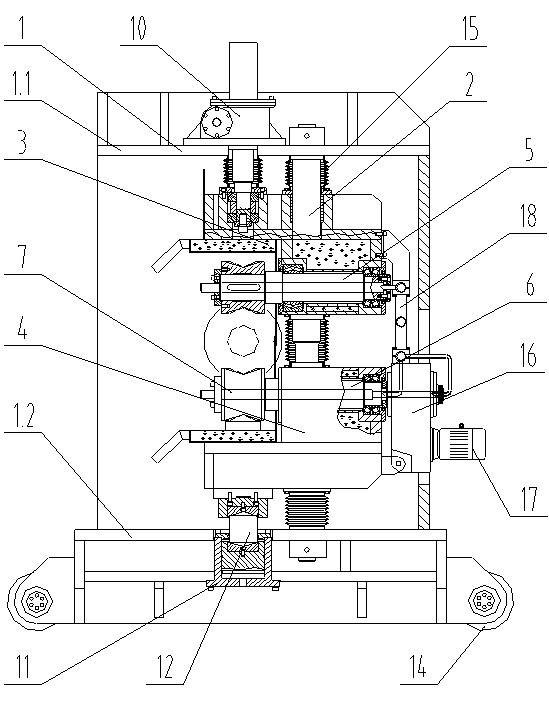

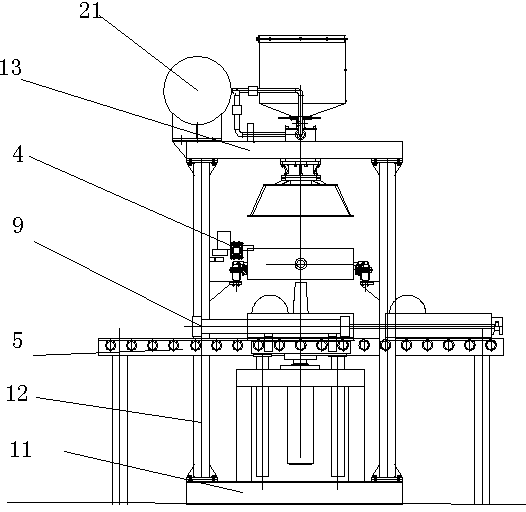

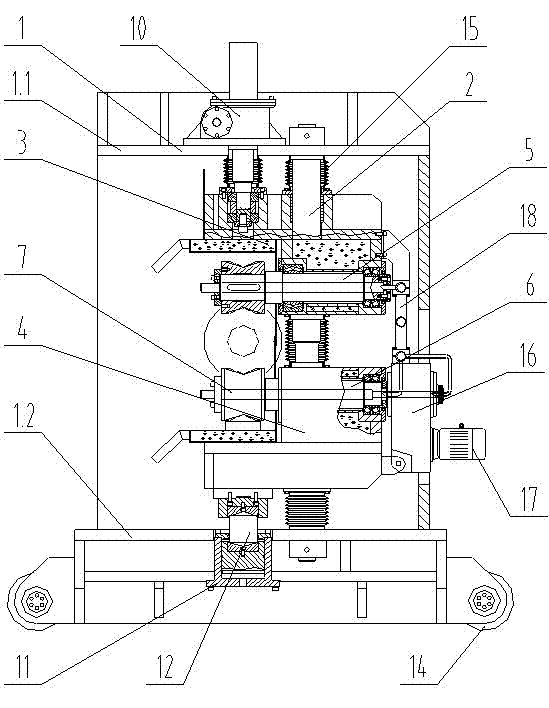

Equipment and method for improving sand lined casting efficiency

ActiveCN103203434AImprove efficiencyReasonable structural designMoulding machinesIndustrial engineeringCasting

The invention relates to equipment and a method for improving sand lined casting efficiency, and belongs to the technical field of iron sand lined casting. The equipment comprises a supporting frame composed of an upper beam, a base and a vertical pillar between the upper beam and the base, a sand adding and jetting device, and a rotating mechanism arranged on the base. The equipment is characterized by further comprising a four-station working platform, a lifting type sand jetting head and a lifting type roller bed opening and closing mechanism, wherein the four-station working platform is fixed on the rotating mechanism; the lifting type sand jetting head is connected at one side of the upper beam, and the lifting type roller bed opening and closing mechanism is connected at the other side; the lifting type sand jetting head and the lifting type roller bed opening and closing mechanism are respectively arranged on left and right sides; and the four-station working platform is arranged below the lifting type sand jetting head and the lifting type roller bed opening and closing mechanism. The equipment disclosed by the invention is reasonable in structure and design, convenient to clean mold, high in sand lined casting efficiency and convenient for users to operate.

Owner:浙江省机电设计研究院有限公司

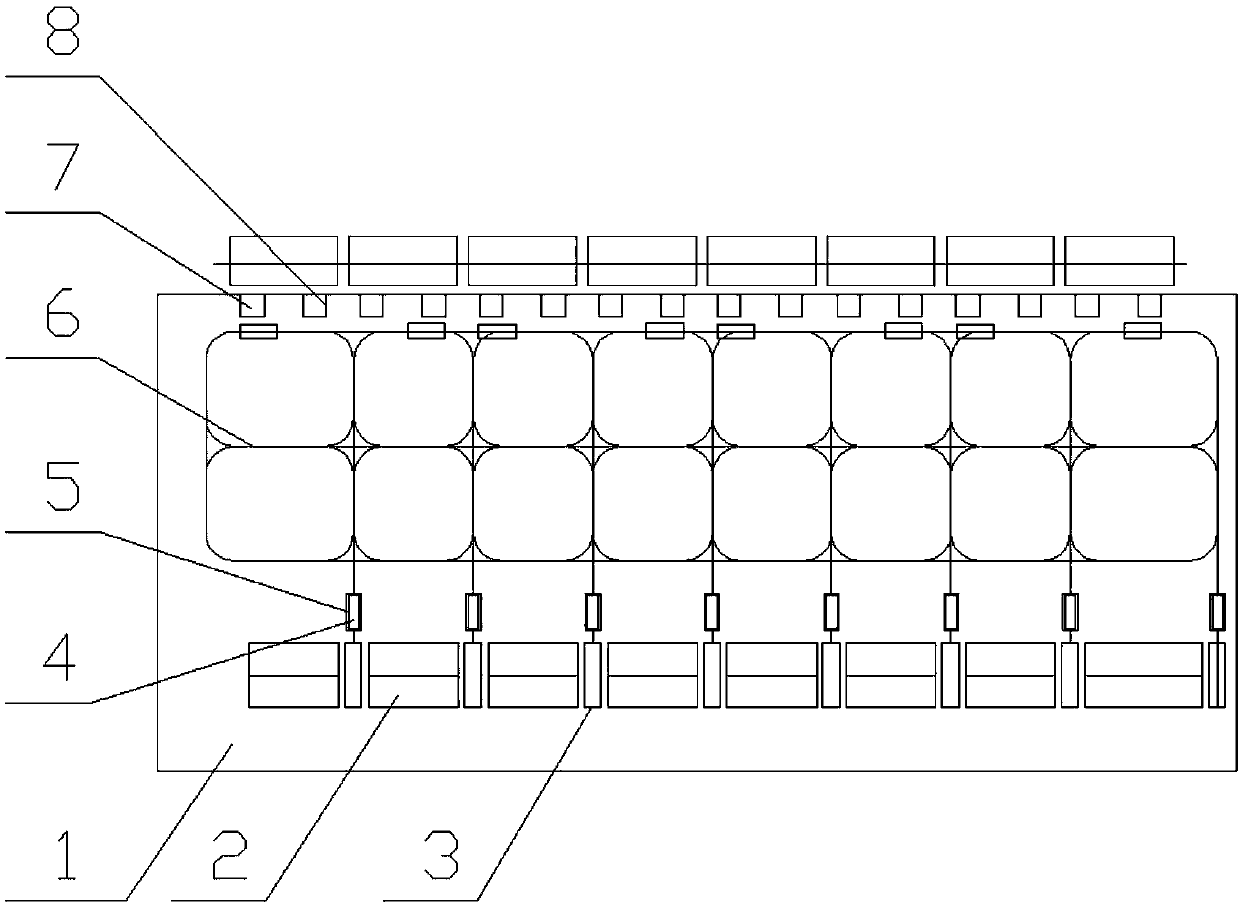

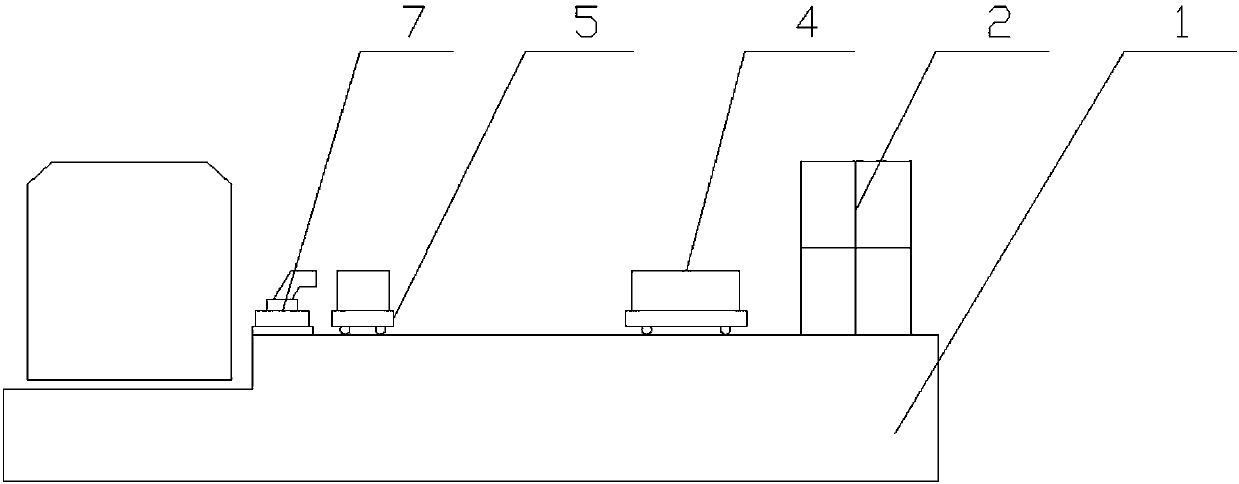

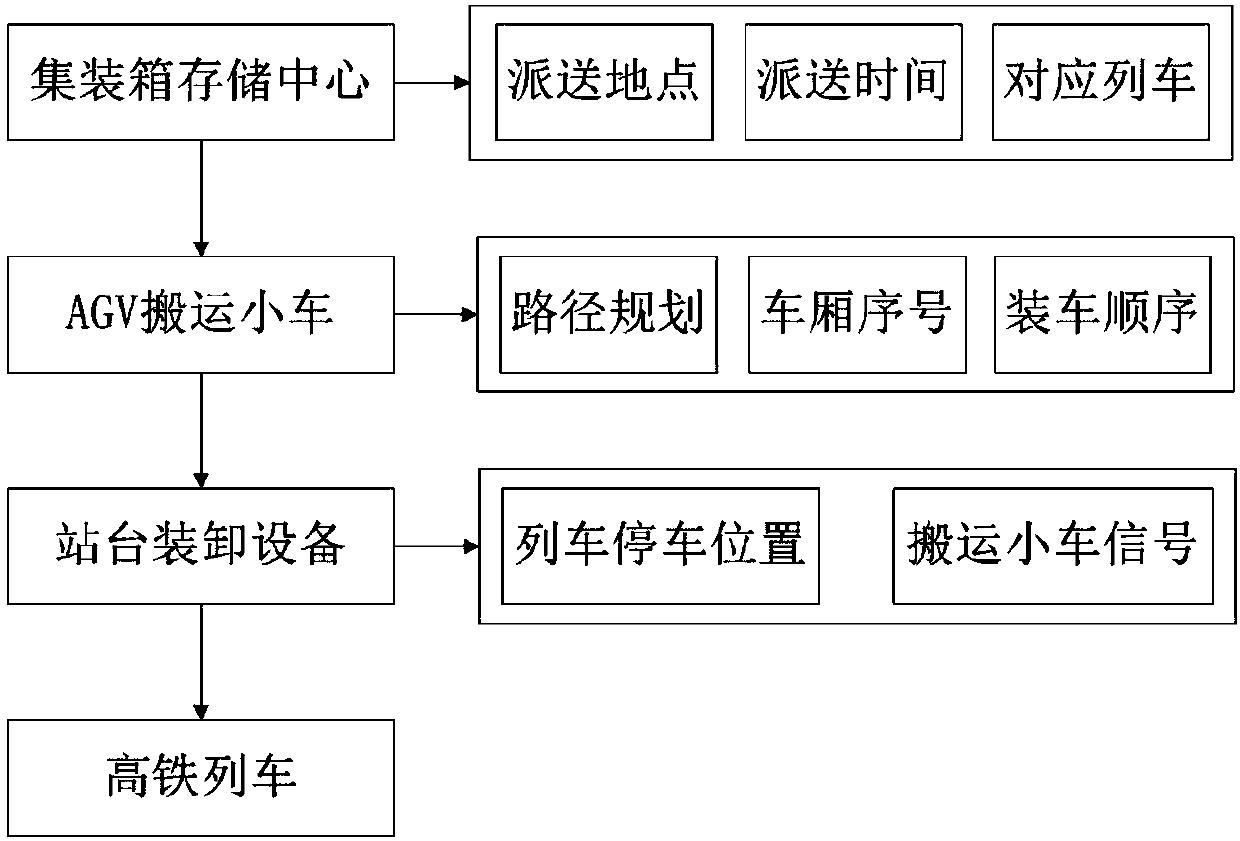

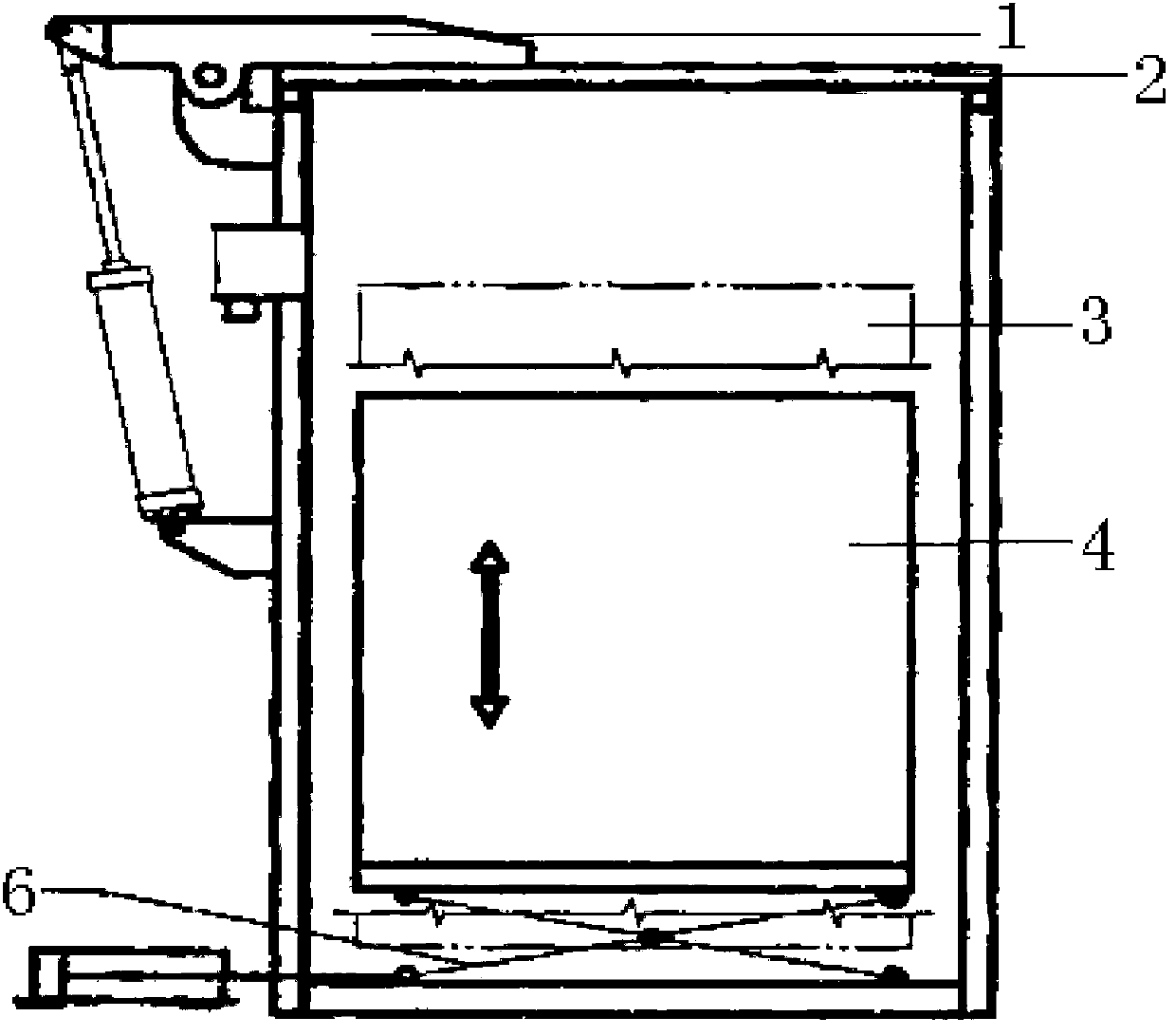

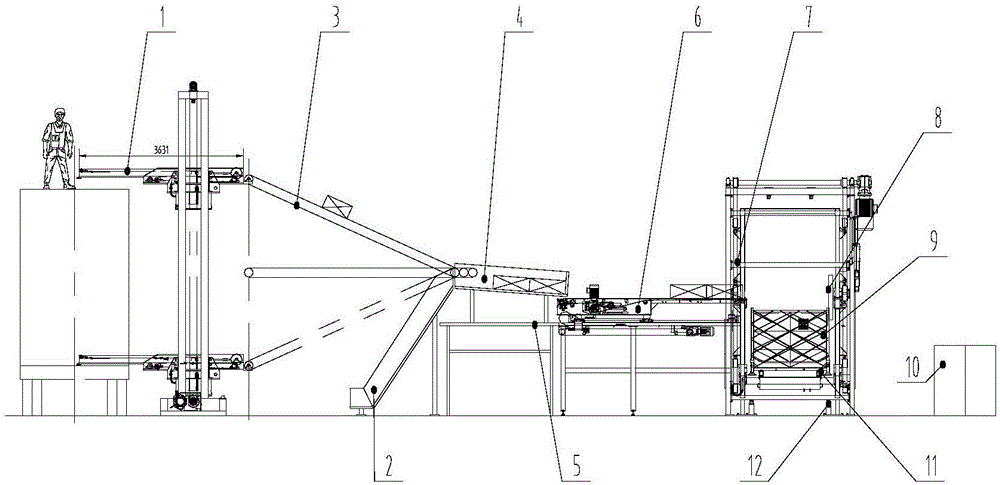

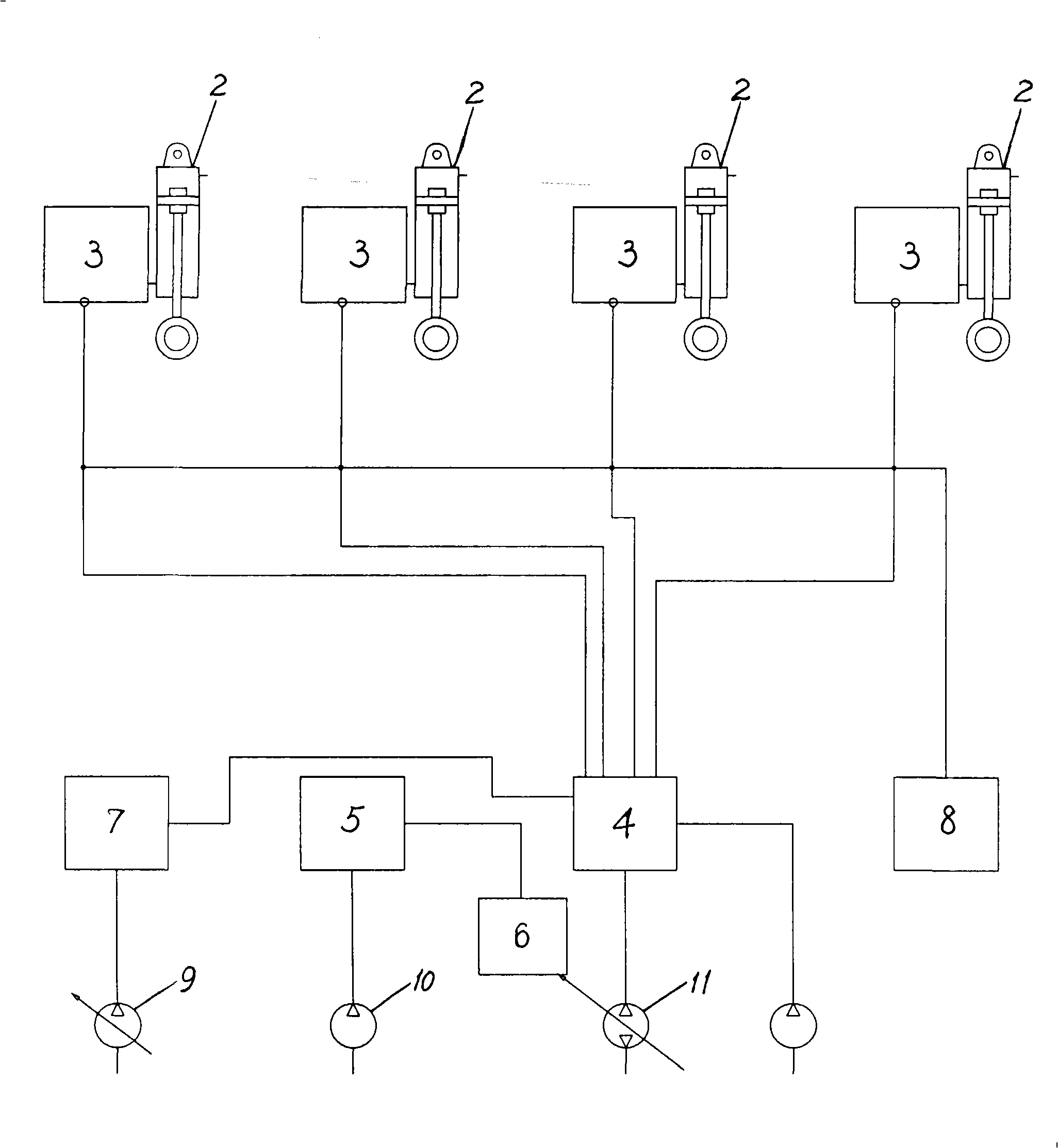

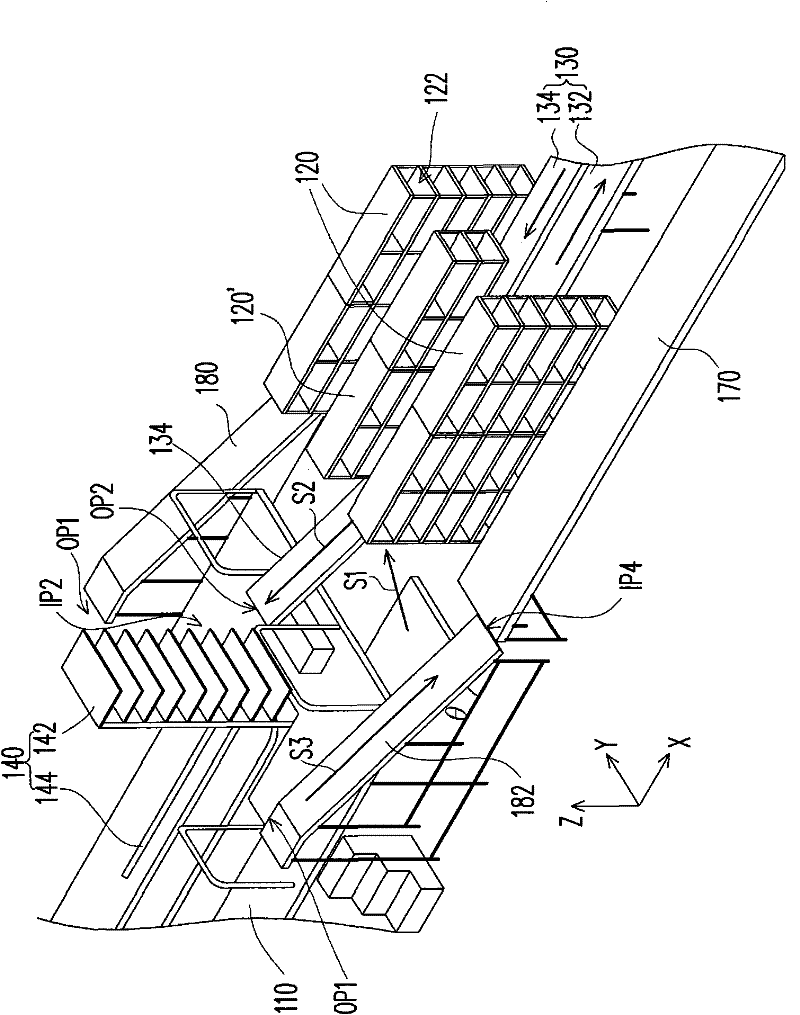

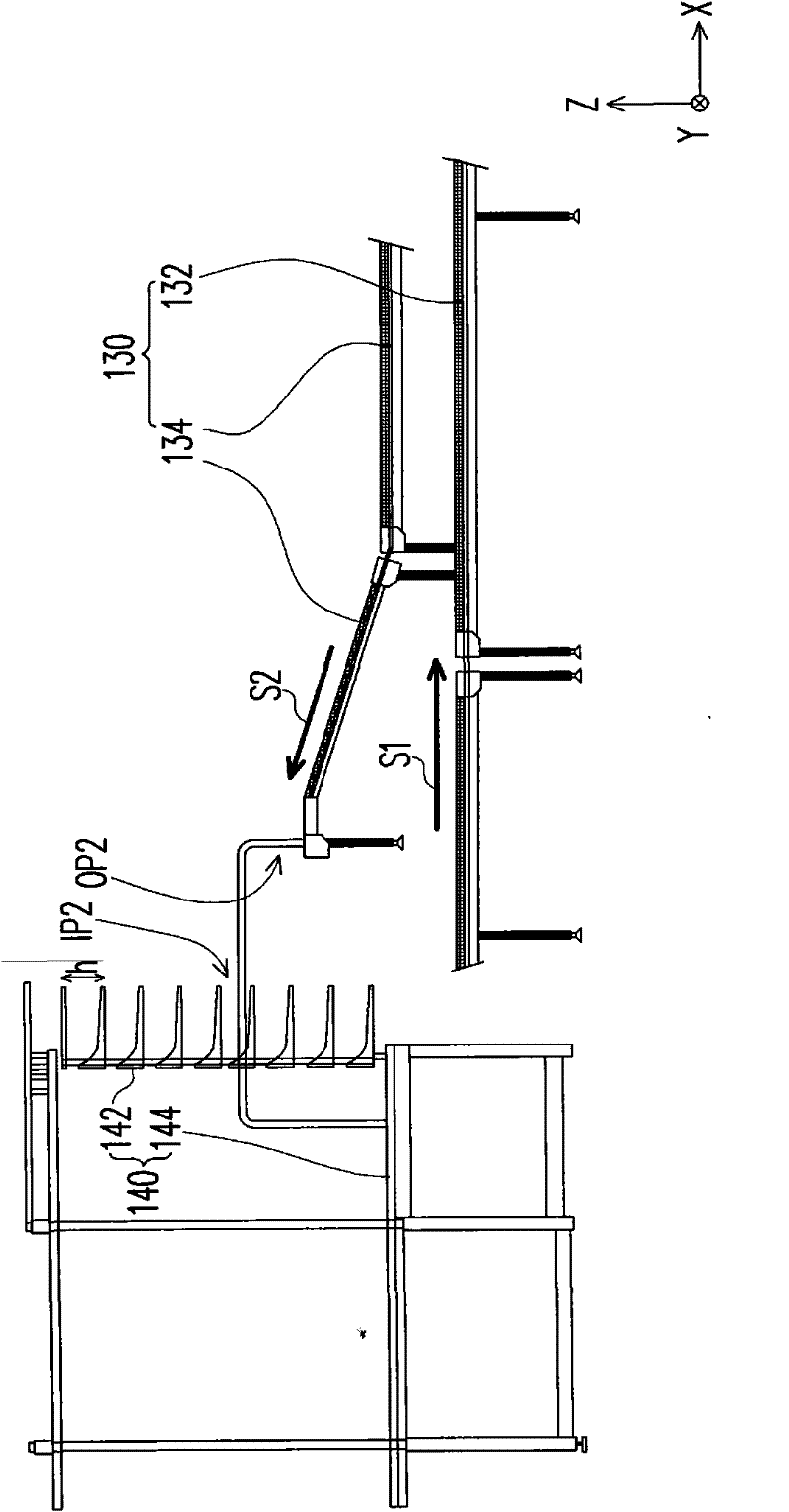

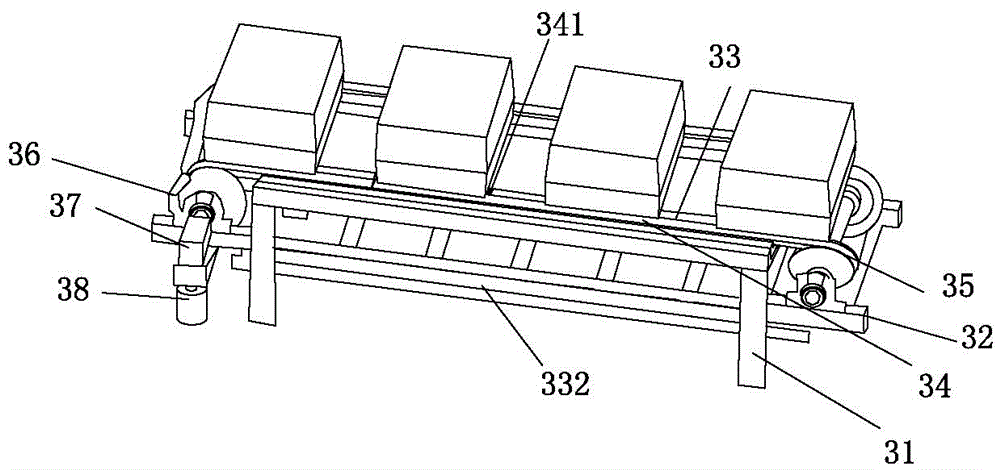

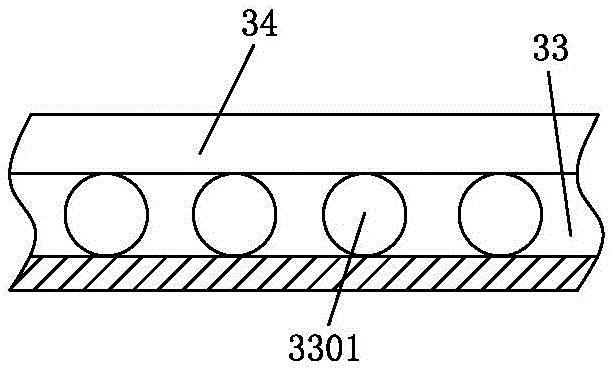

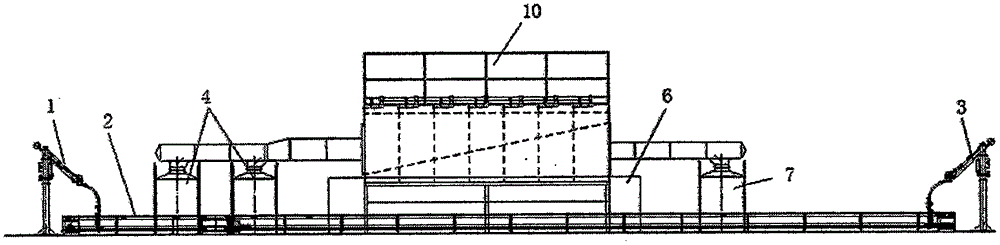

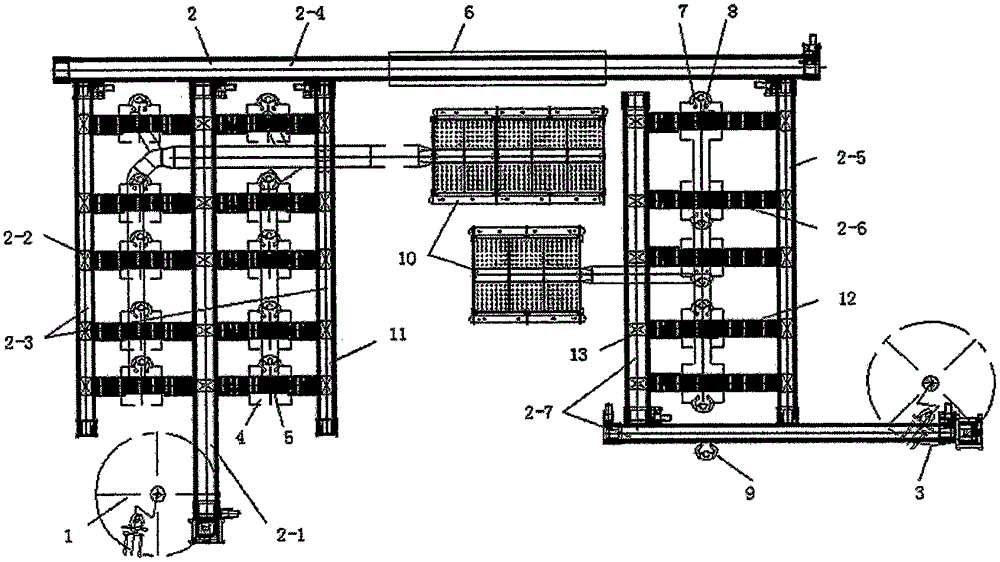

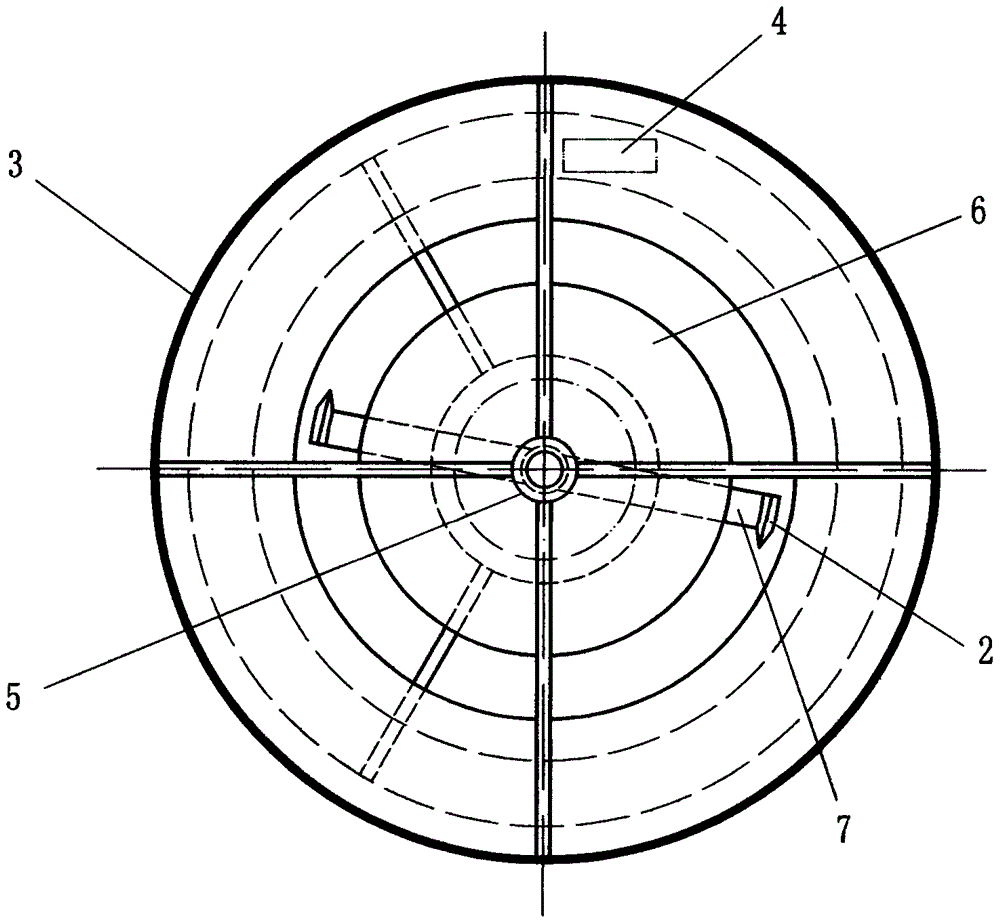

High-speed train logistics intelligent loading and unloading system and method based on AGV trolleys

ActiveCN107601062AImprove efficiencyHigh speedLoading/unloadingStorage devicesLogistics managementEngineering

The invention discloses a high-speed train logistics intelligent loading and unloading system based on AGV trolleys, and the high-speed train logistics intelligent loading and unloading system is arranged on a platform (1). A container storage warehouse (2) is arranged on one side of the platform (1), a train is arranged on the other side of the platform (1), a plurality of containers (4) are arranged in the container storage warehouse (2), a plurality of AGV trolleys (5) are arranged between the container storage warehouse (2) and the train, and a plurality of container loading facilities (7)and a plurality of container unloading facilities (8) are arranged on the side, close to the train, of the platform (1). The invention further discloses a high-speed train logistics intelligent loading and unloading method based on the AGV trolleys. According to the intelligent loading and unloading system, the intelligent loading and unloading facilities are used, the speed is higher, loading operation and unloading operation are carried out at the same time, efficiency is higher, multi-line multi-loading-and-unloading-facility parallel treatment is carried out, more safety and reliability are achieved, at least two sets of automatic carrying trolleys are arranged, and it can be guaranteed that at least one loading or unloading carrying trolley always stays in a loading and unloading waiting zone for waiting operation.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

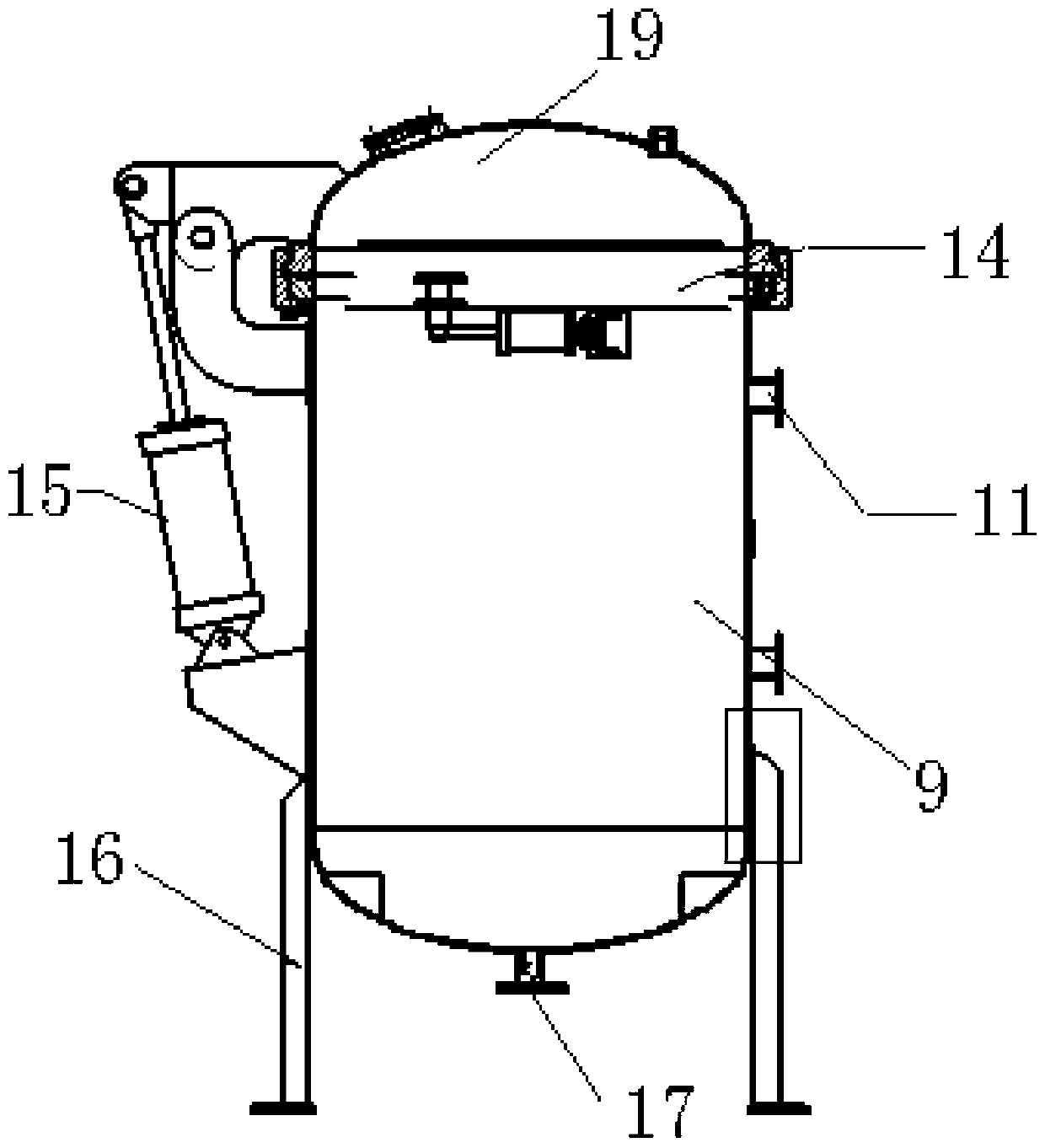

Infiltration technique and device

ActiveCN103341434AHigh surface finishHigh shape and size accuracyLiquid surface applicatorsCoatingsCooking & bakingRelative motion

The invention relates to an infiltration technique and device. The technique comprises three phases, namely infiltration preprocessing, infiltration processing and infiltration postprocessing. The infiltration device comprises an infiltration basket, a hoist hook, a degreasing pot, a cleaning pot, a centrifugal pot, a baking oven, an infiltration pot, a vacuum pump, a glue storing pot, an air compressor, a washing pot, a solidifying pot and a pressure test device, wherein all the components are arranged in a straight line. Due to the fact that the infiltration pot is cylindrical, influence of sewage on a production site can be effectively avoided. Due to the fact that the infiltration pot is locked with a method that a sealing lock ring is inflated by a lock ring cylinder and both a toothed ring of a pot cover and the lock ring are manufactured with whole materials, sealing performance is good, operation is safe and fast, the pot cover can be opened and closed automatically and fast, no relative motion exists between the pot cover and a sealing ring, friction does not exist, opening is flexible, and the service life is long. The infiltration technique and device have the advantages that the device is compact and reasonable in structure, the whole production site is beautiful, logistics is smooth, and fixed location management and civilization and cleanliness of the production site can be ensured.

Owner:NANTONG NINGYUAN AUTOMATION TECH

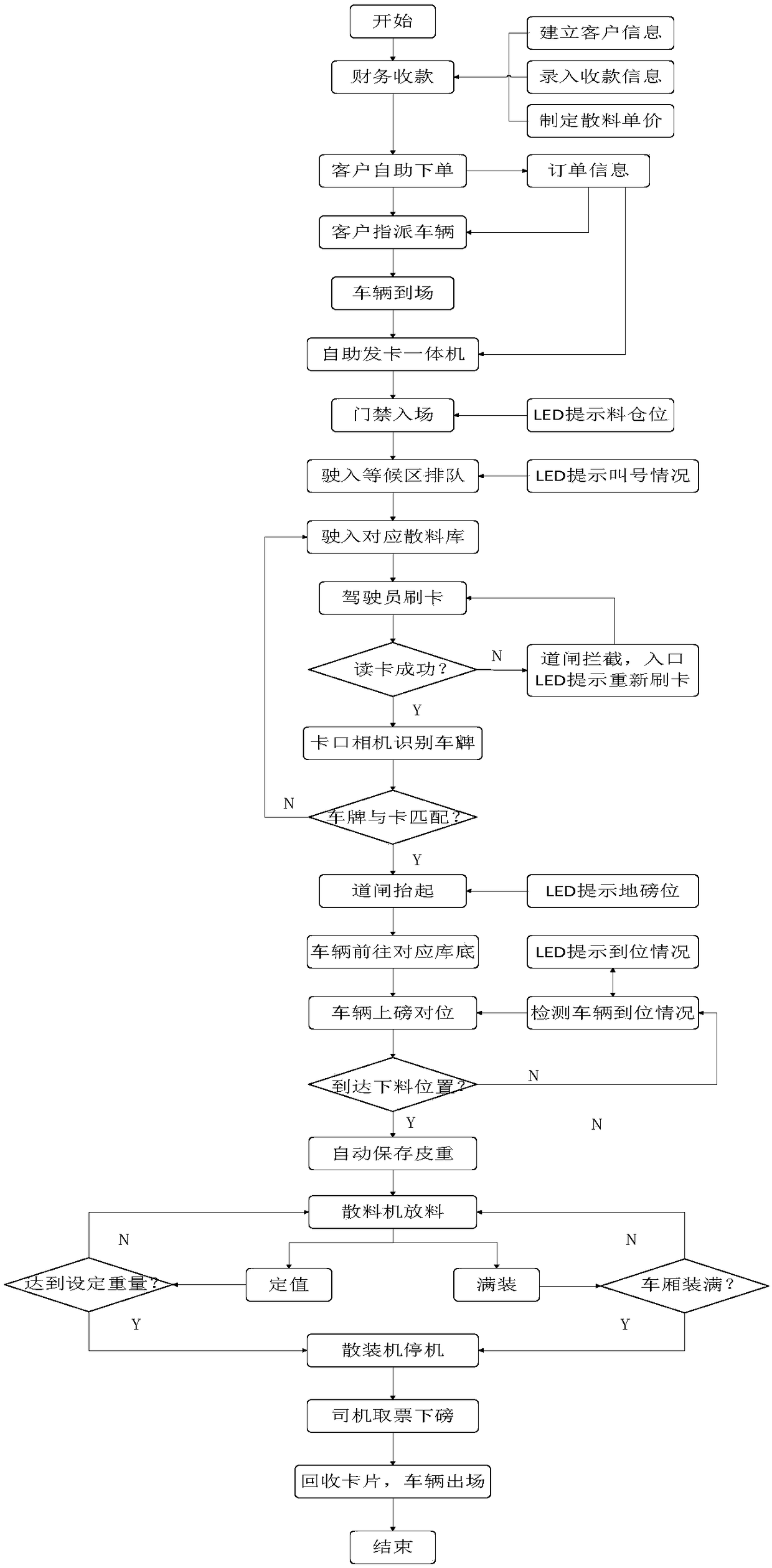

A delivery management system and method

PendingCN109284793AImprove accuracyEasy to operateCo-operative working arrangementsCommerceOperational systemLogistics management

The invention discloses a delivery management system and a method, wherein the system comprises an order operating system, a data processing center, a weighing and loading system, a license plate recognition system, a vehicle guidance and indication system, an RFID reader and writer, and an RFID card. The data processing center communicates with other systems, stores, processes, feeds back order information, and gives integrated control over card issuing and card retrieval, queuing into a factory, quantitative loading, factory delivery, card collection, bill printing and other links; stores and transmits data information through the RFID electronic tag card , and provides double verification with the license plate identification system, so as to improve the accuracy and operability of themanagement system; and seamlessly docking with the ERP financial system for data sharing, and ultimately achieves the goal of smooth logistics, downsizing, and traceability.

Owner:SHANGHAI YUNTONG INFORMATION SCI & TECH CO LTD

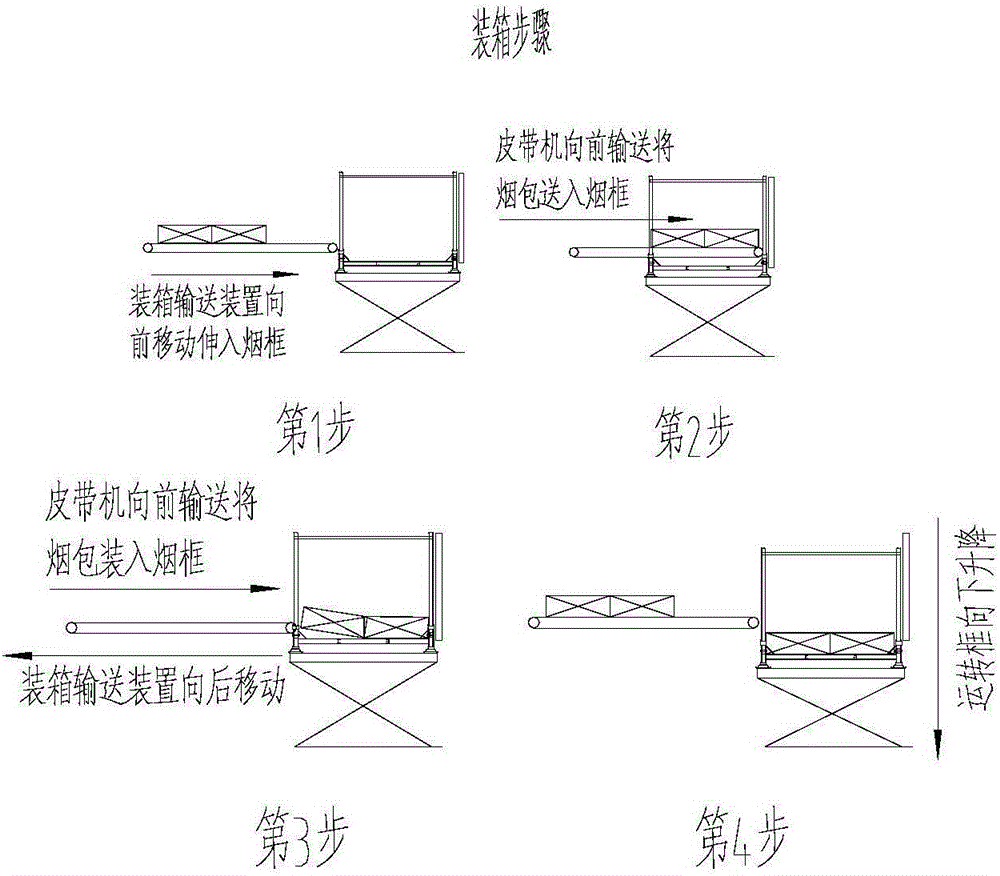

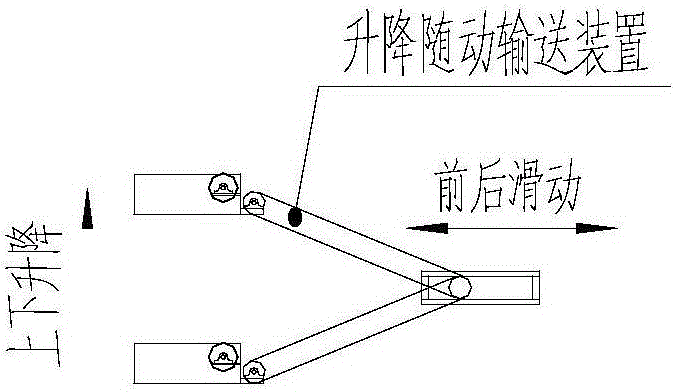

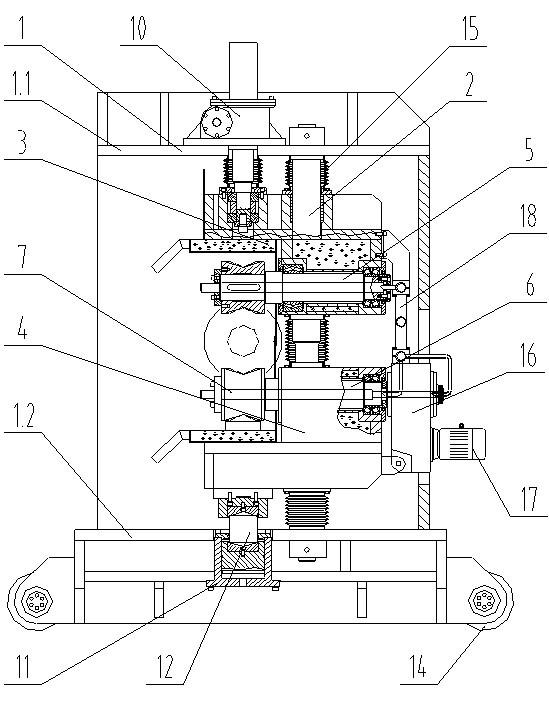

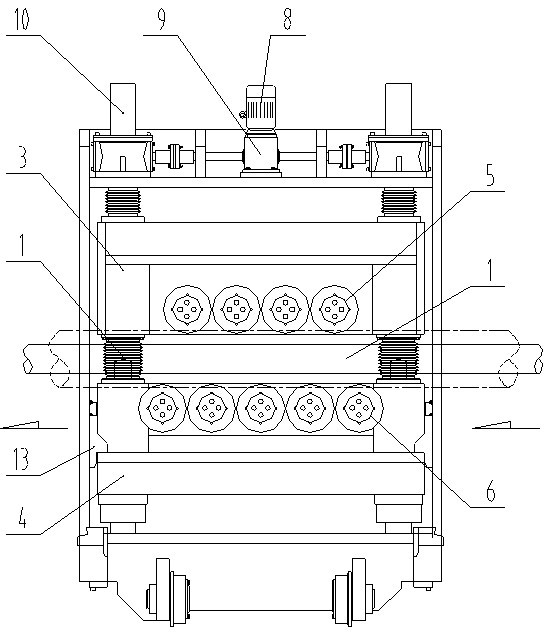

Unloading and framing method and equipment for crude tobacco bales

ActiveCN106219268AImprove utilization efficiencyReduce labor intensityStacking articlesLoading/unloadingButt jointEngineering

The invention relates to an unloading and framing method and equipment for crude tobacco bales. The equipment comprises a lifting type telescopic or fixed conveying mechanism located at the front end, a lifting follow-up conveying device located behind the lifting type telescopic or fixed conveying mechanism, a sampling inspection chute connected and arranged below the tail end of the lifting follow-up conveying device, a universal bale combination arrangement device connected to and arranged at the tail end of the lifting follow-up conveying device, a moving or telescopic conveyor in butt joint with the universal bale combination arrangement device, a support and platform located on the lower portion of the bale combination arrangement device and the lower portion of the moving or telescopic conveyor, a transfer frame lifting device located at the tail of the moving or telescopic conveyor, a material blocking device arranged on the rear side of the transfer frame lifting device, a tobacco bale transferring and conveying frame arranged on the lower portion of a frame of the transfer frame lifting device, a frame inlet and outlet conveying mechanism arranged at the bottom of the tobacco bale transferring and conveying frame, an empty solid empty weighing mechanism arranged at the bottom of the frame inlet and outlet conveying mechanism, and an electric control system arranged on the outer side of the whole equipment.

Owner:KUNMING KSEC LOGISTIC INFORMATION IND

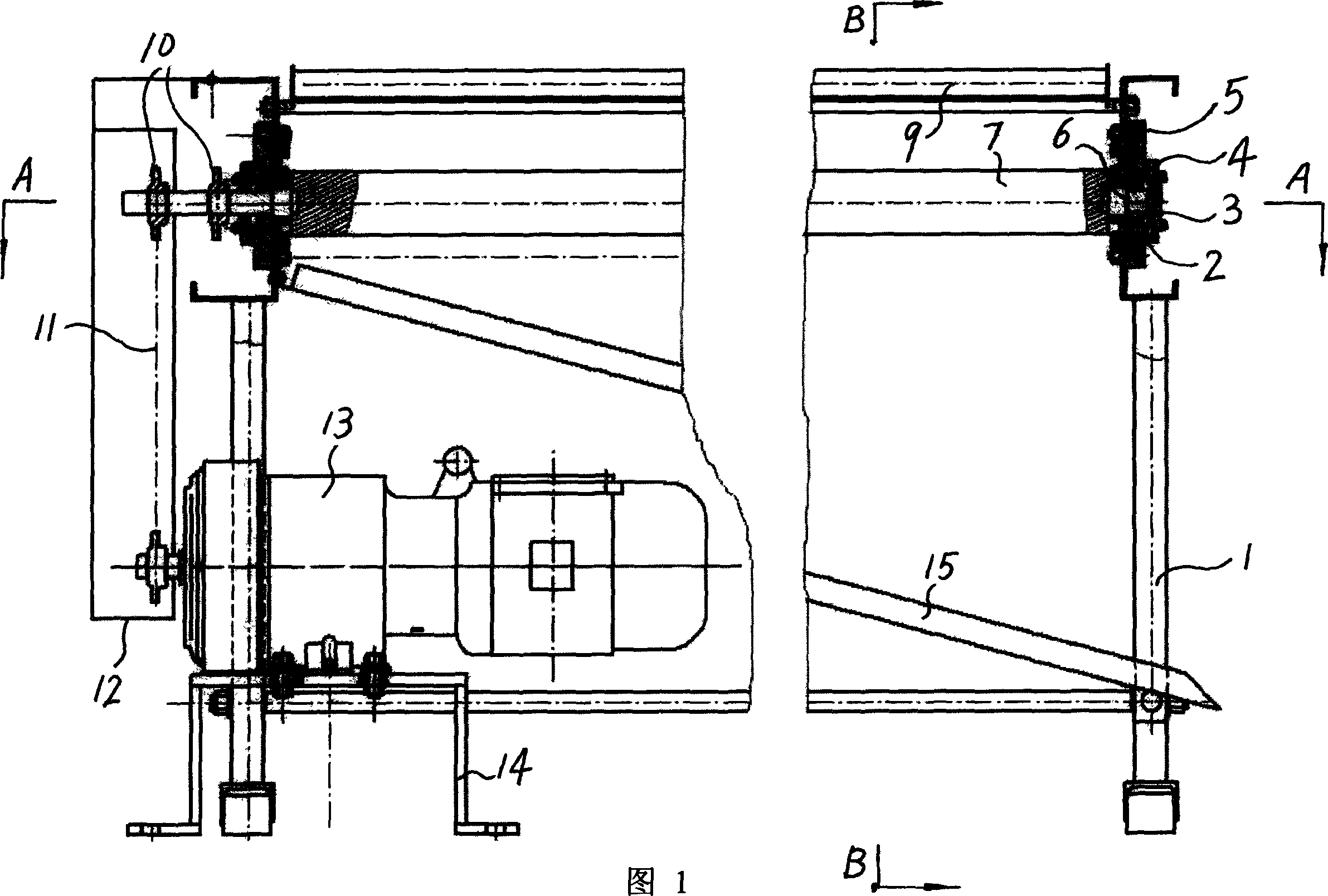

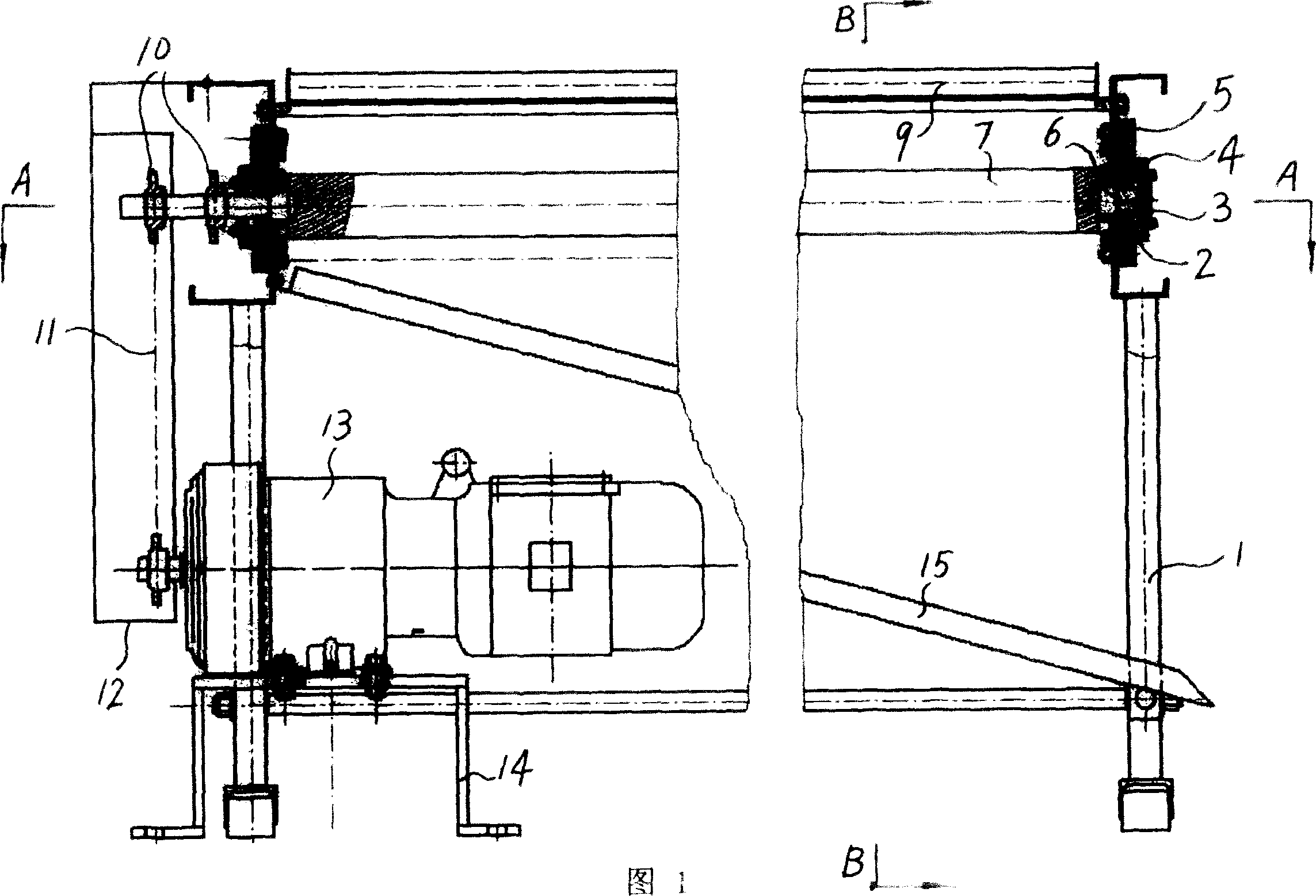

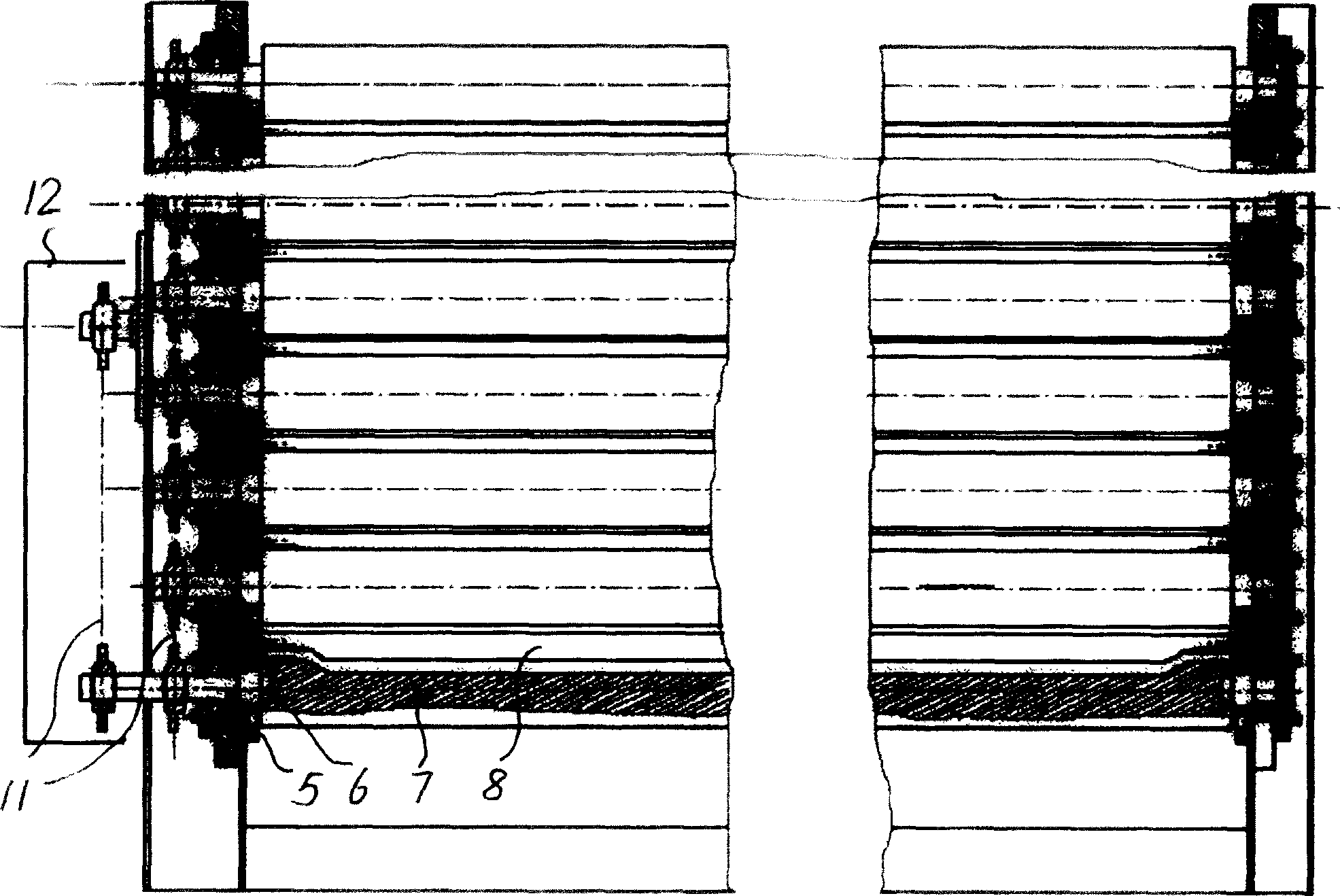

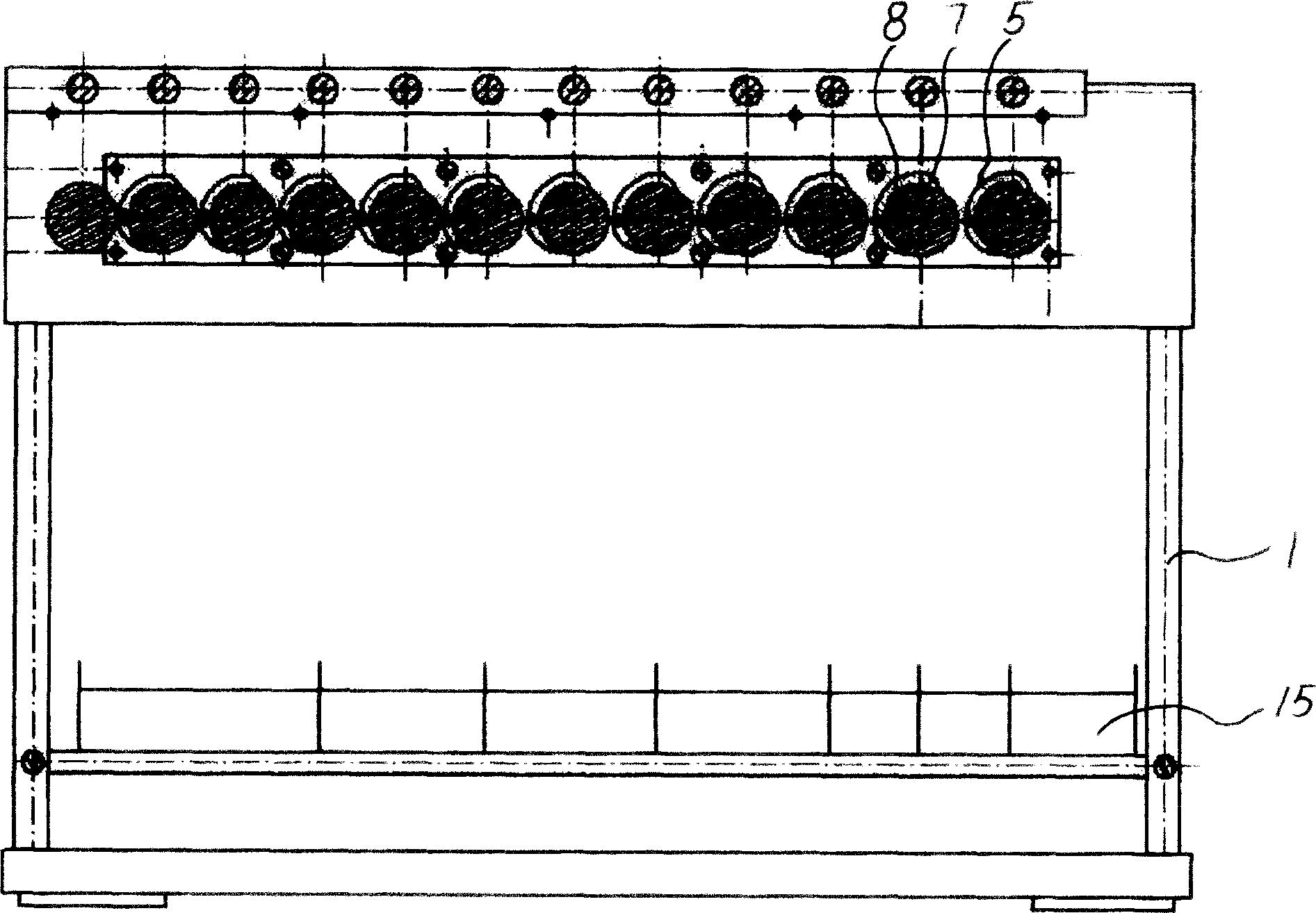

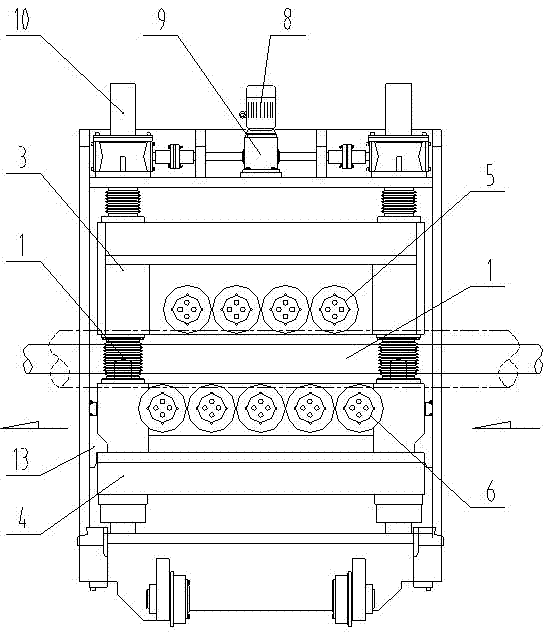

On-line red steel elbow straightener

The invention relates to an on-line red steel elbow straightener which comprises a stander (1) and an upper straightening roller group and a lower straightening roller group which are arranged on the stander (1), wherein each of the upper straightening roller group and the lower straightening roller group consists of a plurality of straightening rollers (7); the central lines of the straighteningrollers (7) of the upper straightening roller group are parallel to one another and positioned on the same horizontal line, and the central lines of the straightening rollers (7) of the lower straightening roller group are parallel to one another and positioned on the same horizontal line; and the straightening rollers (7) of the upper straightening roller group and the straightening rollers (7) of the lower straightening roller group are staggered from each other along the horizontal direction. According to the on-line red steel elbow straightener, the problem that the head of a bar materialwhich is discharged from a rolling machine is bent is solved, the yield is increased, a large amount of time and a large quantity of troubles are saved for the subsequent working procedure, and the logistics of the whole production loop is relatively smooth; and therefore, a phenomenon of repeated reversing is avoided, the production efficiency is improved, the manmade mixed steel risk is reduced, and the burden and the pressure of workers are reduced.

Owner:JIANGYIN DONGCHEN MACHINERY MFG

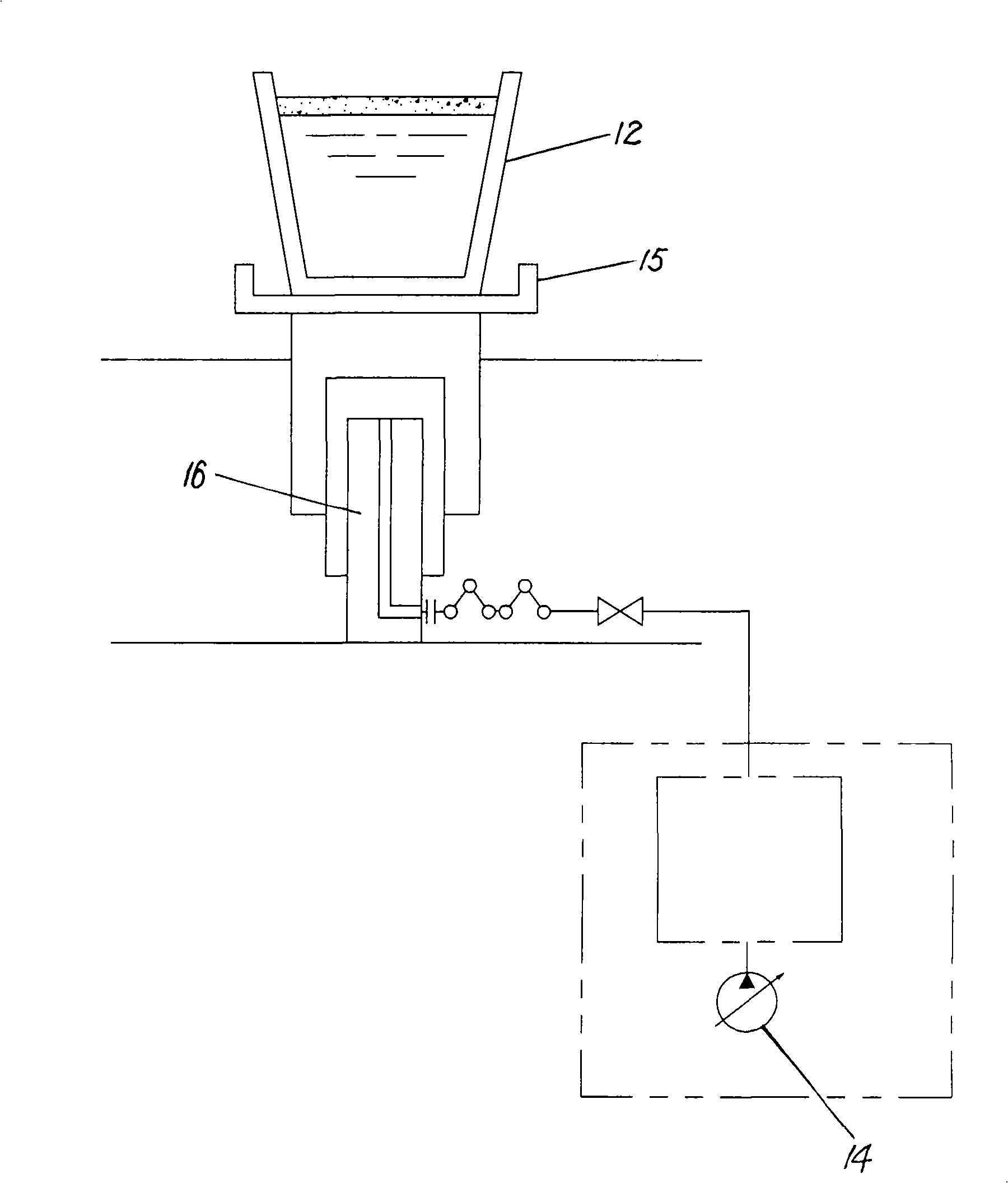

Ladle lifting hydraulic system using vacuum circulation degassing method

The invention relates to a ladle lifting hydraulic system using a vacuum circulation degassing method. The system comprises at least one ladle lifting frame, a plurality of ladle lifting hydraulic cylinders, a hydraulic cylinder synchronous control module, a main pump, a ladle lifting and speed control module, a control pump, a pressure servo variable control module and a hydraulic line connected therebetween. The ladle lifting frame is movably fixed and connected with ladles; the hydraulic cylinder synchronous control module evenly distributes hydraulic oil output from the main pump to each ladle lifting hydraulic cylinder; the control pump is connected with the pressure servo variable control module by the ladle lifting and speed control module, the ladle lifting and speed control module controls the control pump to drive pilot oil of the pressure servo variable control module; and the pressure servo variable control module controls hydraulic flow and output direction of the main pump. The ladle lifting hydraulic system releases a ladle trolley and molten steel transport operation, does not need to dig a deep pit in a workshop, simplifies steel making process and accelerates cycle of ladles.

Owner:BAOSTEEL ENG & TECH GRP

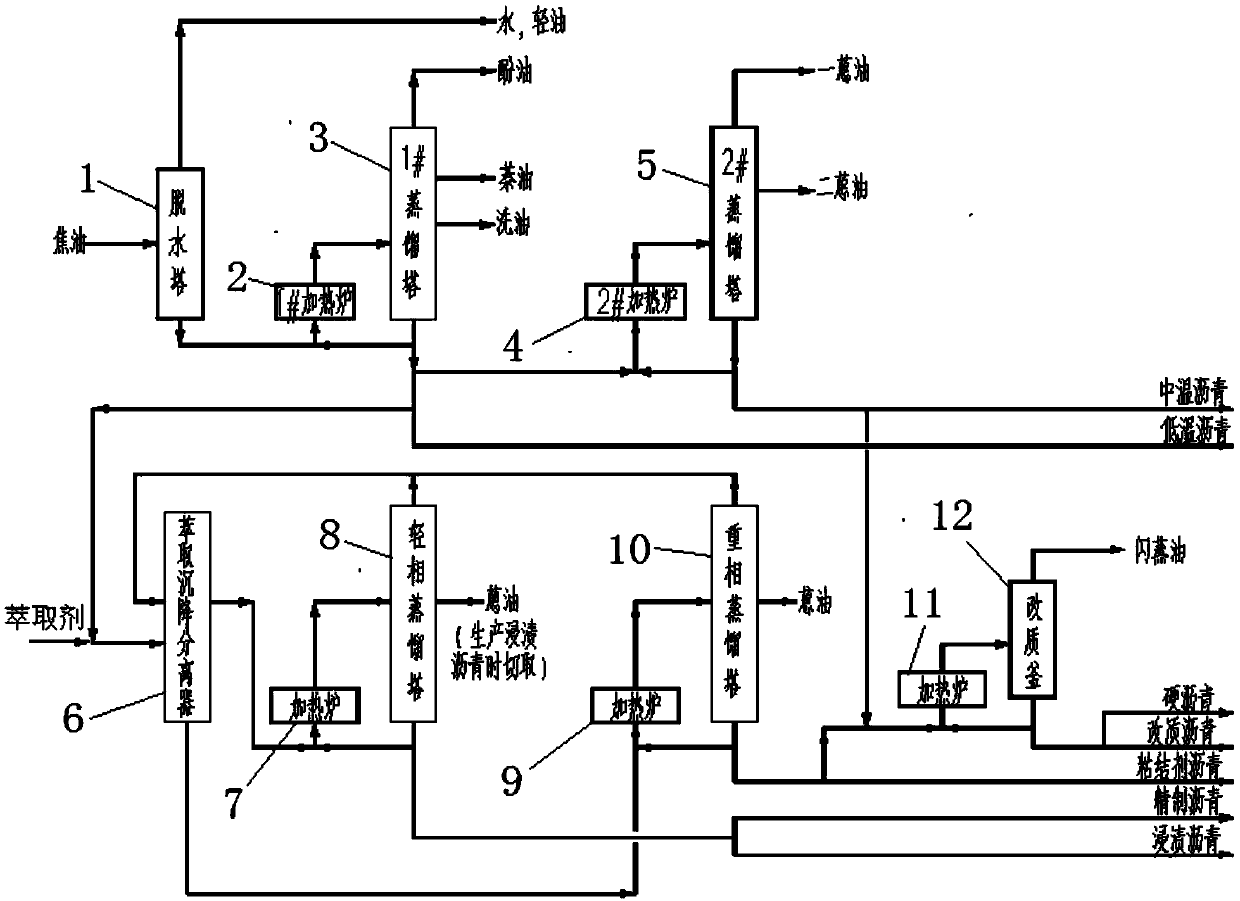

Process and device for producing various asphalt products by combining distillation and extraction

PendingCN109517614AMeet needsSolve the problem of low single added valueWorking-up pitch/asphalt/bitumen by distillationWorking-up pitch/asphalt/bitumen by selective extractionDistillationTar

The invention relates to a process and a device for producing various asphalt products by combining distillation and extraction. The device comprises a dehydration tower, a distillation system, an extraction system and an asphalt modification system. Coal tar is used as a raw material to produce low-temperature asphalt, medium-temperature asphalt, modified asphalt, low-quinoline insoluble refinedasphalt, impregnated asphalt, hard asphalt, binder asphalt and other products by using a combined production process of distillation, extraction and asphalt modification. A variety of high value-addedasphalt products can be produced simultaneously with a set of production device, the utilization of the device is maximized, and the process and the device are adaptive to the needs of large-scale tar processing.

Owner:ACRE COKING & REFRACTORY ENG CONSULTING CORP DALIAN MCC

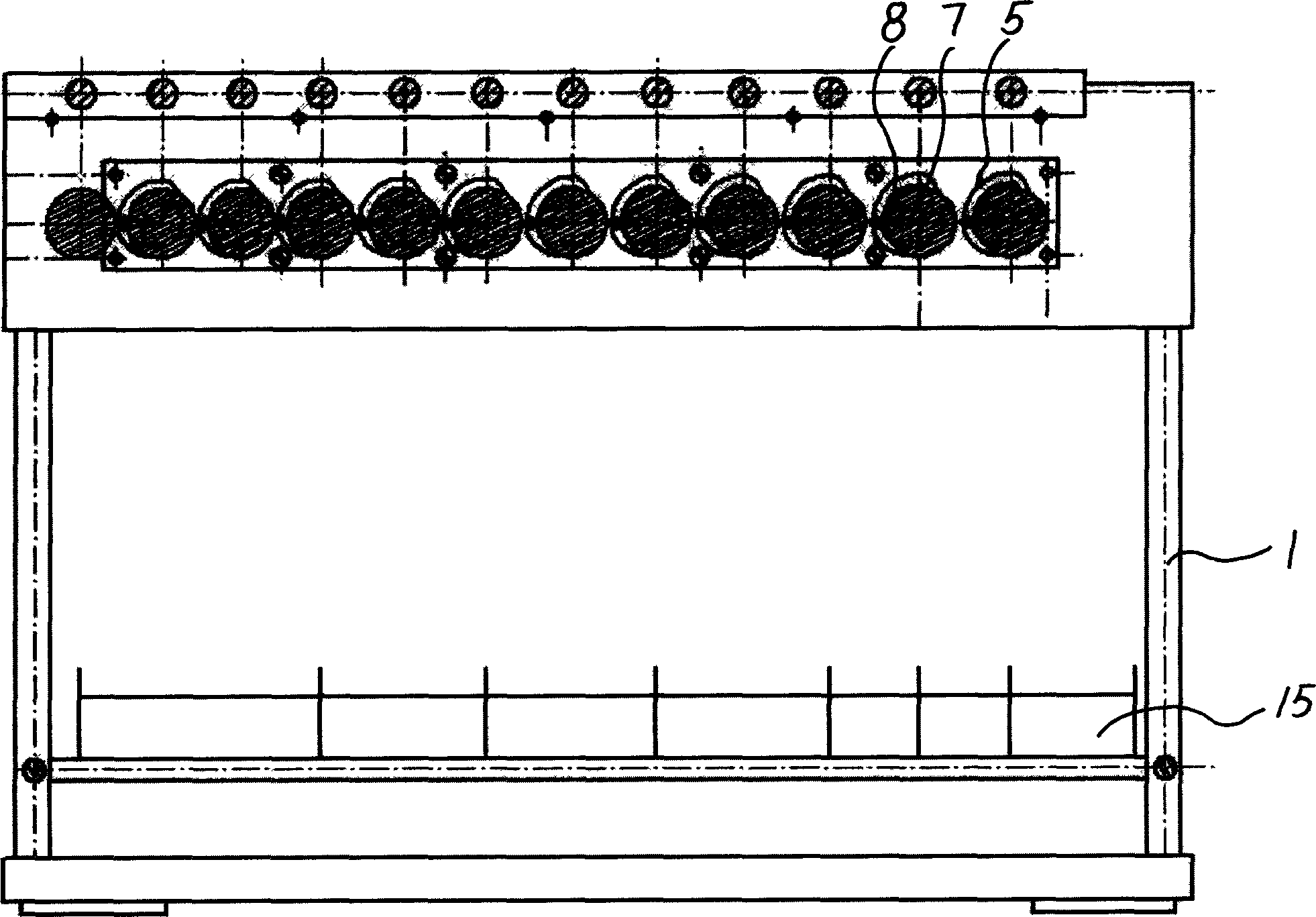

Scallop pole sorter

The present invention relates to aquatic product sorting machine, and is especially one kind of scallop pole sorter. The scallop pole sorter consists of frame, driver mechanism and transmission mechanism; and features that the scallop pole sorter is provided with one row of rollers on the frame in the interval required for grading material, bearings in bearing seats, roller shafts matching the bearings, cam plate in the inside of the frame, shifting plates inside the slots in the rollers, material accepting plates, etc. The present invention has high sorting precision, less noise, low power consumption and other advantages.

Owner:CHINA AGRI UNIV

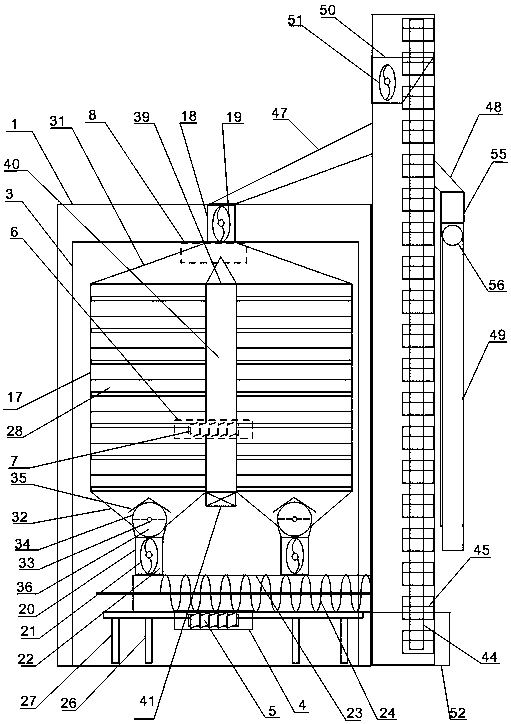

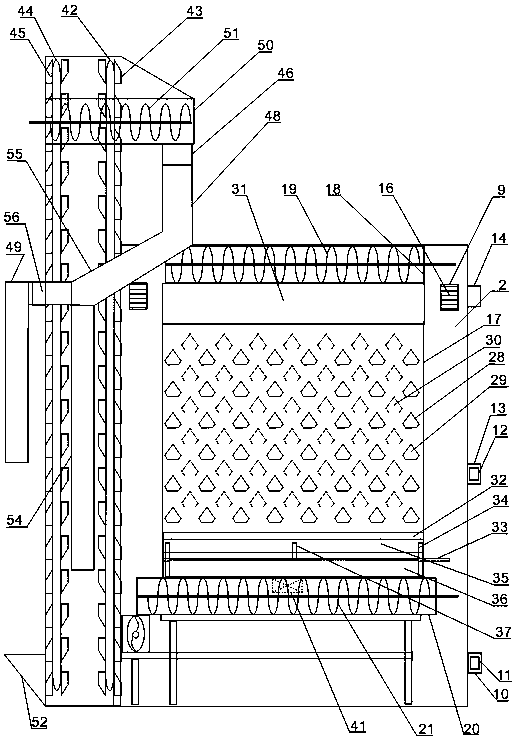

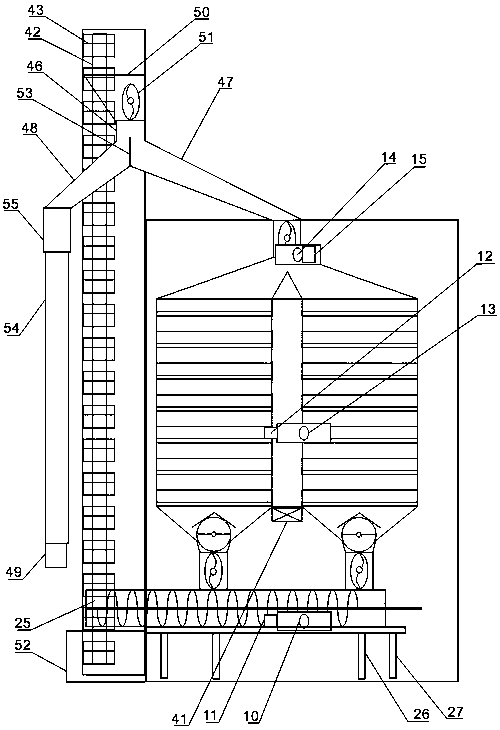

Hot air circulation drying equipment for grain

InactiveCN107771927ASimple structureEasy to installSeed preservation by dryingEngineeringTemperature difference

The invention relates to a drying device, in particular to hot air circulation drying equipment for grain. The invention provides the hot air circulation drying equipment, which is simple in structure, rapid in temperature rise, small in temperature difference and easy in moisture removal, can be used for drying materials in a circulating way and generates circulating hot air, for grain. The equipment comprises a hot air box body, a material box body and a lifting device, and is characterized in that the hot air box body is formed by assembling movable plates, the material box body comprises agrain cabinet, a feeding device, a material conveying device, a discharge device, a polygonal box, a blanking adjustment device and a support, and the lifting device comprises a material adding box,a material collecting box, a material adding device, a circulating material lifting device, a material conveying main pipeline and a material push packing auger; the material box body is arranged in the hot air box body. The hot air circulation drying equipment for the grain is low in manufacturing cost, simple to operate, convenient to use and easy to popularize.

Owner:马忠高

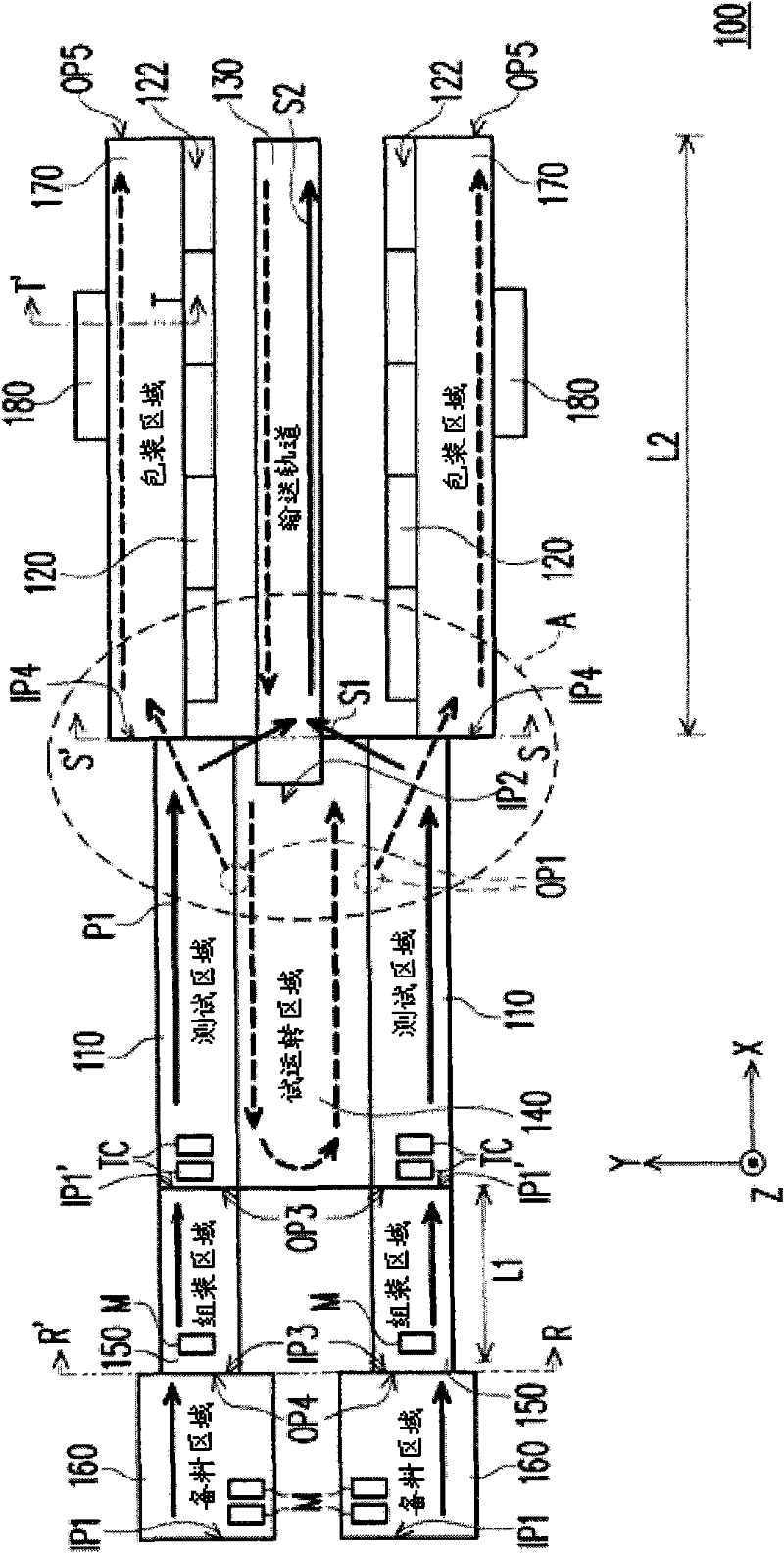

Production line machine of notebook computers

InactiveCN102530506AReduce distanceKeep the flowConveyor partsMechanical conveyorsParking spaceEngineering

The invention provides a production line machine of notebook computers. The production line machine comprises two stock regions, two assembling regions, two test regions, two first unloading regions, a delivery rail, a test run region and two packaging regions, wherein the two stock regions are arranged in parallel and used for receiving assembly materials required for the notebook computers and transmitting the assembly materials along a first direction; the test regions receive and transmit the notebook computers along the first direction; the first unloading regions provide parking spaces to the notebook computers; the delivery rail is suitable for receiving the notebook computers from the test regions or receiving the notebook computers from the first unloading regions, and transmits the notebook computers sequentially along the first direction and a second direction; and the test run region receives the notebook computers transmitted by the delivery rail along the second direction through the other inlet, rotates the notebook computers, which are transmitted along the second direction, to the first direction to transmit, so that the test run region transmits the notebook computers to two outlets. According to the invention, a machine frame contributes to improving the productive capacity.

Owner:张洪超 +6

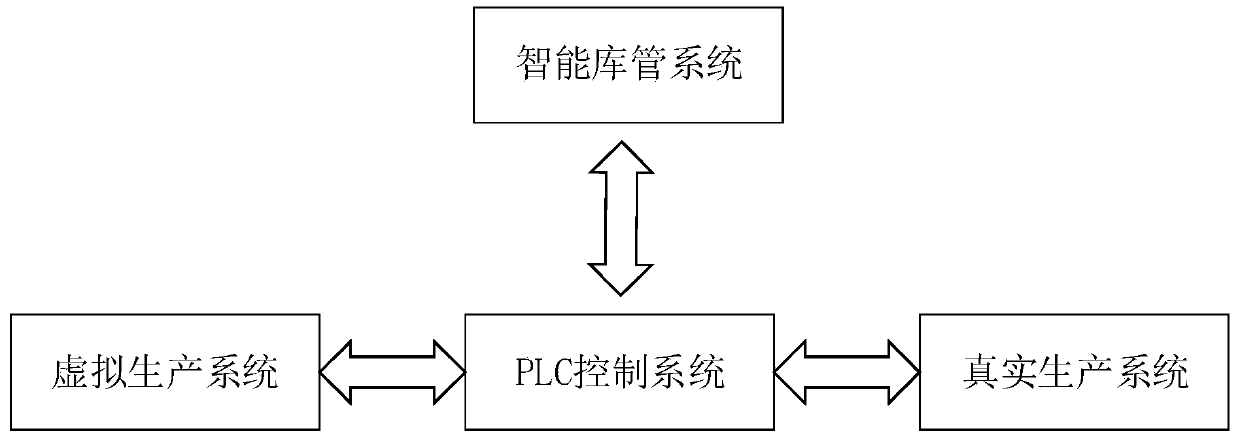

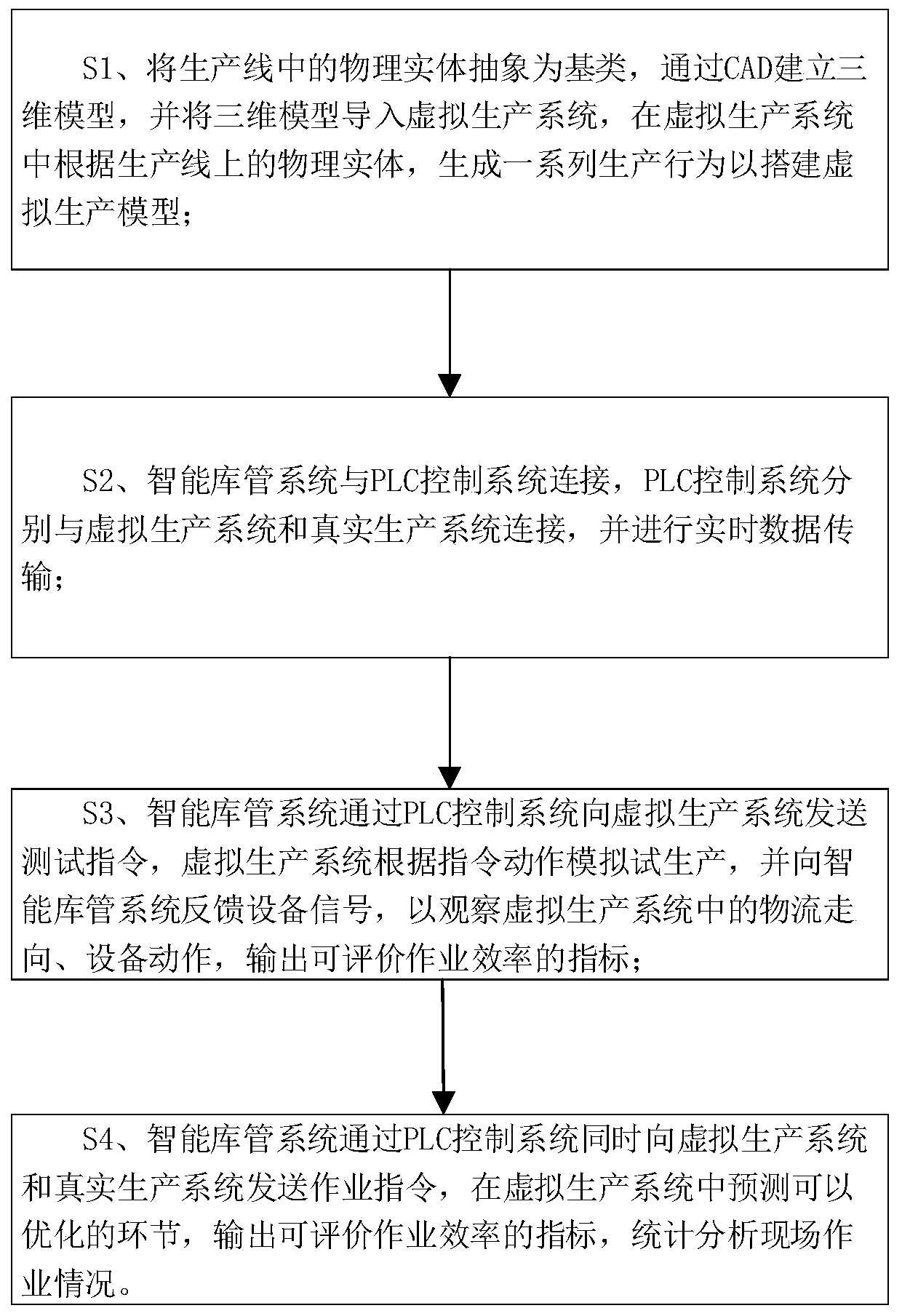

Unmanned warehouse logistics optimization system and method based on virtual production

ActiveCN110244676AWork efficiency can be evaluatedOptimize the logistics linkLogisticsTotal factory controlLogistics managementControl system

The invention provides an unmanned warehouse logistics optimization system based on virtual production. An intelligent warehouse keeper system, a PLC control system and a virtual production system are connected in sequence; the intelligent warehouse keeper system, the PLC control system and a real production system are connected in sequence; the intelligent warehouse keeper system is used for independently driving a virtual production model to act for production trial operation, so as to observe the logistics trend and the equipment action in the virtual production system and output an index capable of evaluating the operation efficiency; the intelligent warehouse keeper system is further used for driving the virtual production model and a real production site to act at the same time, predicting a link capable of being optimized in the virtual production system, outputting the index capable of evaluating the operation efficiency, and counting and analyzing the field operation condition. Through real-time interaction between the intelligent warehouse keeper system, the PLC system and the virtual production model, trial production can be carried out under a new condition, a high-load condition or other conditions, so as to evaluate the production process; virtual production and actual production can be controlled to be conducted synchronously; and the logistics link capable of being optimized can be mined, so that the logistics is more smooth.

Owner:CHONGQING UNIVERSITY OF SCIENCE AND TECHNOLOGY

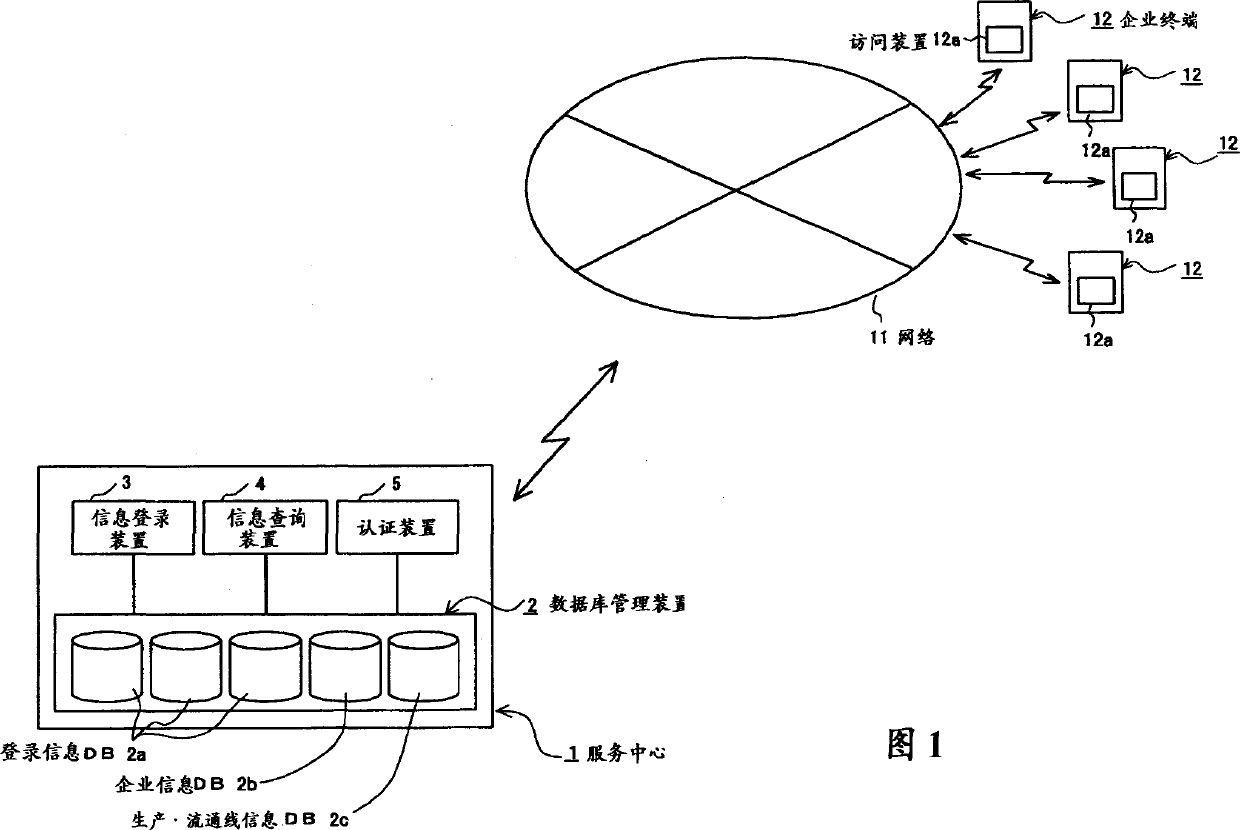

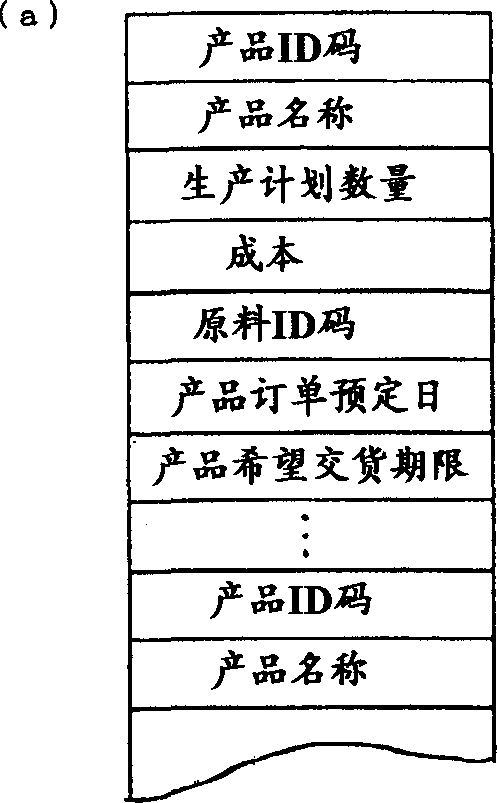

Information shared system

InactiveCN1334513AImprove visual effectsSmooth logisticsData processing applicationsSpecial data processing applicationsInformation seekingInformation sharing system

PROBLEM TO BE SOLVED: To provide an information sharing system which enables respective companies concerned in product production having multistage production and distribution structure to act more systematically and actualize sufficient QR. SOLUTION: This system is equipped with a database 2a stored with information regarding product production and distribution, an information registering means 3 which registers the information regarding product production and distribution inputted from a company terminal 12 in the database 2a through a network 11, and an information inquiring means 4 which inquires of the company terminal 12 information stored in the database 2a at a request to browse the database 2a from the company terminal 12 through network 11.

Owner:WWIN CO LTD

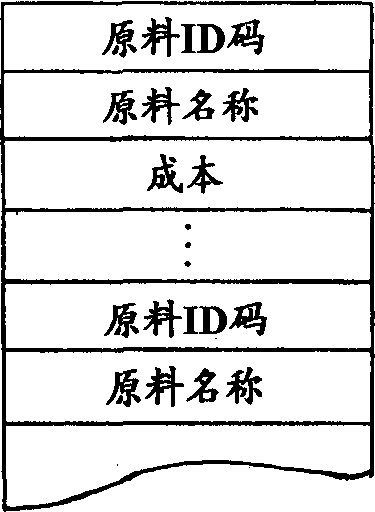

Automatic sand box forming production line

InactiveCN106694829AEasy to operateImprove scalabilityMoulding toolsProduction lineElectrical control

The invention discloses an automatic sand box forming production line which comprises a base, wherein a mechanical hand is arranged on the center of the base; by taking the base as center, a plurality of rotary clamping mechanisms are distributed around the base; a hoarding is arranged outside the rotary clamping mechanisms; an electrical control box is arranged outside the hoarding; a loading conveyor line is arranged between the two rotary clamping mechanisms at the left side of the mechanical hand; an unloading conveyor line is arranged between the two rotary clamping mechanisms at the right side of the mechanical hand; and the unloading conveyor line is connected with an oven. The automatic sand box forming production line is convenient to expand, is smooth in logistics, is safe and reliable, and is long in service life. The mechanical hand is adopted to pick and place parts, and an independently controlled motion control system is adopted, so that control precision is high and production speed is high. A touch screen is arranged, so that the model of a sand core is conveniently input manually, and grouting quantity and model configuration can be controlled to complete corresponding grouting work.

Owner:六和金属(湖北)有限公司

Modifying and washing automatic assembly line system for china sanitary ware green bodies

InactiveCN105600327AImprove efficiencyStandardized managementMechanical conveyorsAssembly lineEngineering

The invention discloses a modifying and washing automatic assembly line system for china sanitary ware green bodies. The modifying and washing automatic assembly line system comprises a green body feed assistance arm, a conveying line system and a green body discharge assistance arm. The conveying line system is provided with a rough modifying and washing green body dust removal workshop, a drying line, a fine modifying and washing green body dust removal workshop and a code scanning and checking station. The rough modifying and washing green body dust removal workshop is provided with green body rough scraping and water feeding stations. The fine modifying and washing green body dust removal workshop is provided with green body fine scraping and oil test stations. The green body rough scraping and water feeding stations of the rough modifying and washing green body dust removal workshop and the green body fine scraping and oil test stations of the fine modifying and washing green body dust removal workshop are connected with a dust removal device. The conveying line system comprises a green body inlet section, an automatic distributing rough scraping and water feeding section, a convergence section, a drying section, a diversion section, an automatic distributing, fine scraping and oil test section and a green body outlet section. Compared with the prior art, the modifying and washing automatic assembly line system has the advantages that labor is saved, the damage rate is decreased, the occupied place is small, the site environment is clean, and management is more standard.

Owner:江门市久谷科技有限公司

Method for rapidly measuring particle size of titanium nitride in high-speed wire steel

ActiveCN103926177AImproved granularity recognitionEasy to manufactureParticle size analysisTitanium nitrideSpectrometer

The invention discloses a method for rapidly measuring the particle size of titanium nitride in high-speed wire steel. The method comprises the following steps of analyzing a sample on a spark spectrometer, opening a time-resolved window at 60 to 350 microseconds, performing spark discharge on the sample 1,000 to 2,000 times, and recording the measured light intensity of a titanium channel during the discharge each time; calculating an average value Ip and the standard deviation S of regular pulses I(Zi), calculating a threshold value Y of the pulse light intensity, converting the titanium irregular pulse intensity I(Yi) and the titanium regular pulse intensity I(Zi) into corresponding titanium content by using a standard curve respectively, calculating the content of titanium in the titanium nitride by using a difference value of the converted titanium content, calculating the content of the titanium nitride, and converting the content of the titanium nitride into the mass of the titanium nitride so as to finally obtain the particle size of the titanium nitride. According to the method, requirements on the preparation of the sample are un-harsh, the high measurement speed is ensured, the omission is avoided, a lower limit value of detection on the particle size of the titanium nitride can be lowered to be less than 1 micrometer, and a new solution is provided for the rapid measurement on the particle size of the titanium nitride.

Owner:武汉钢铁有限公司

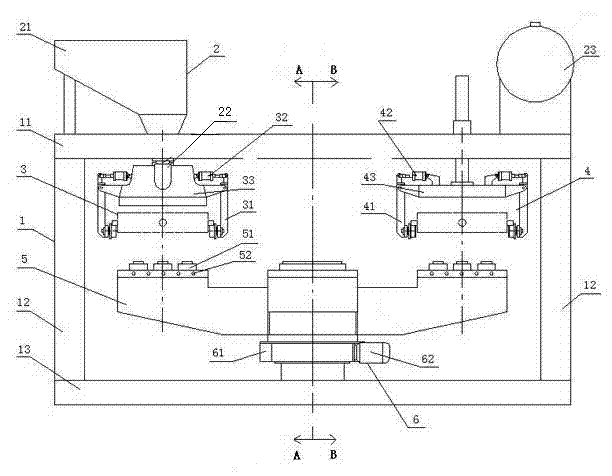

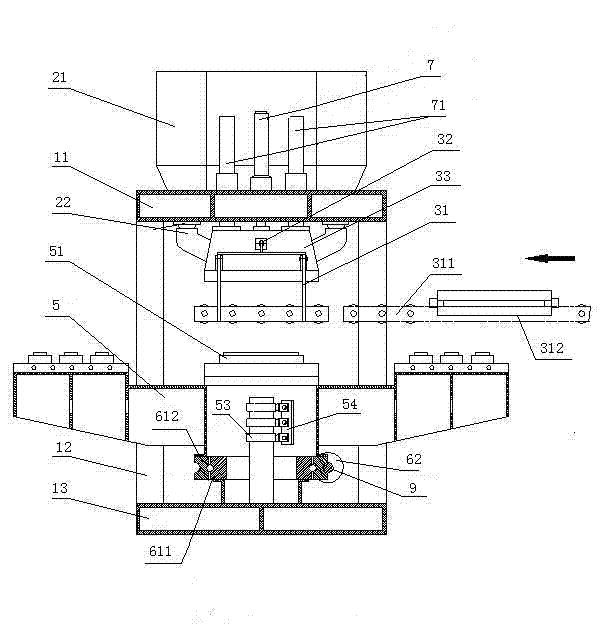

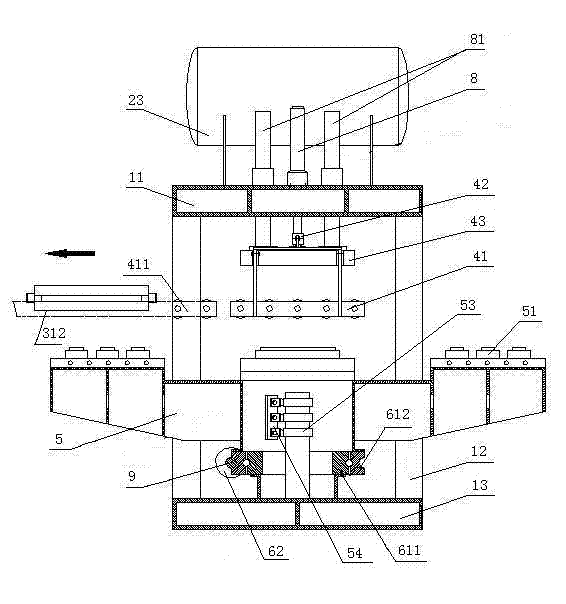

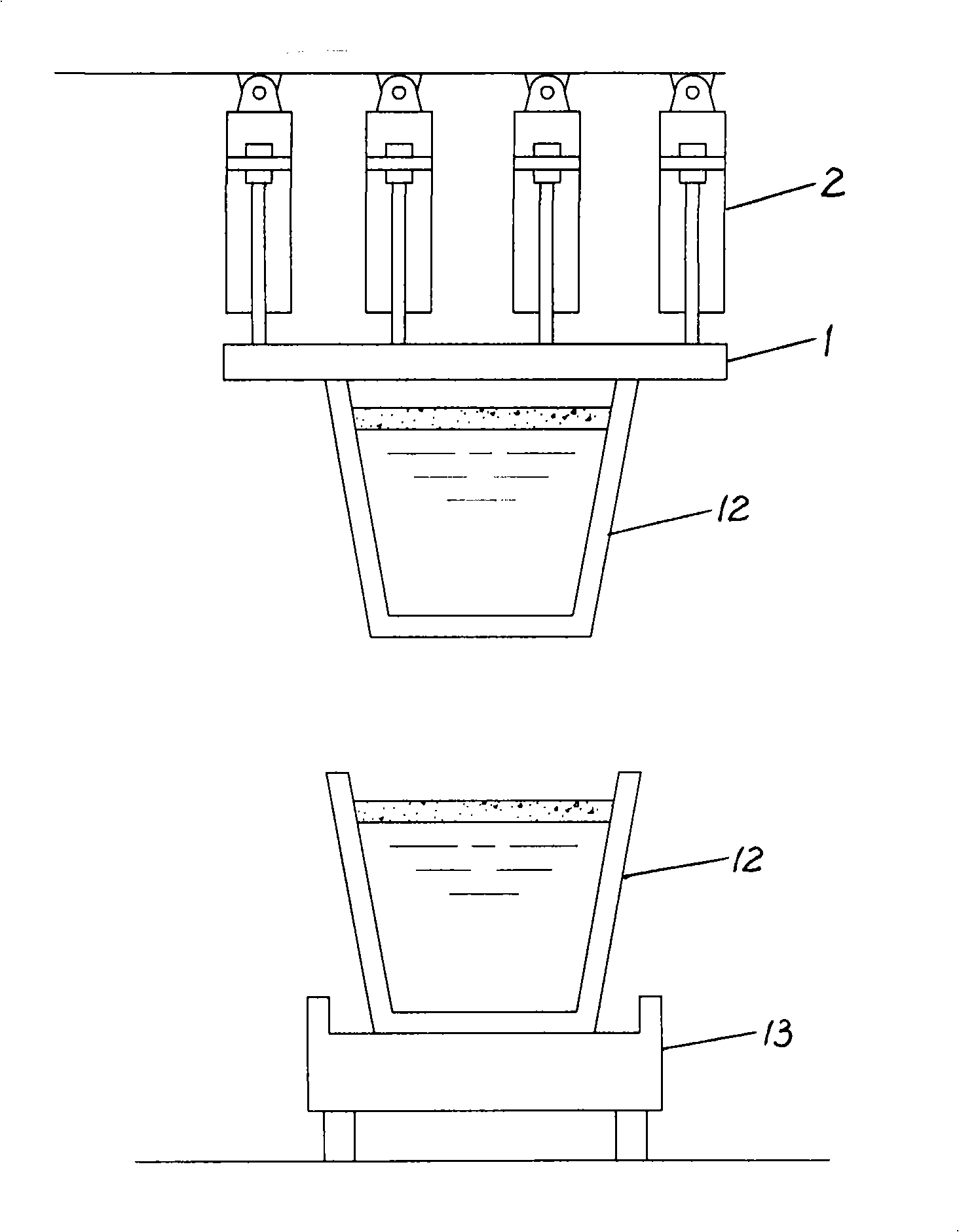

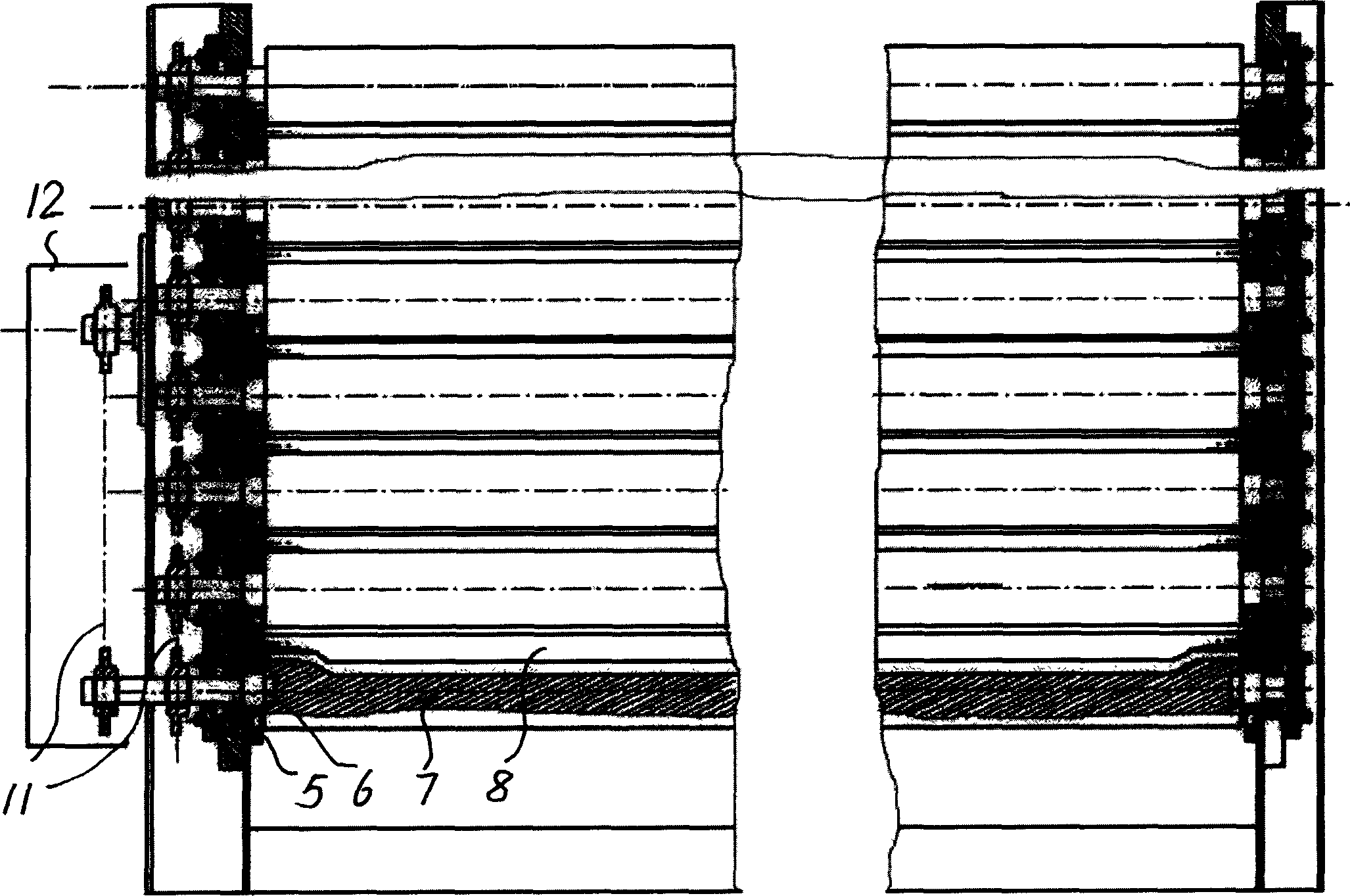

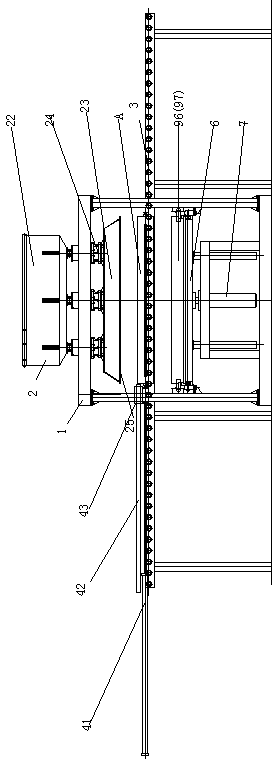

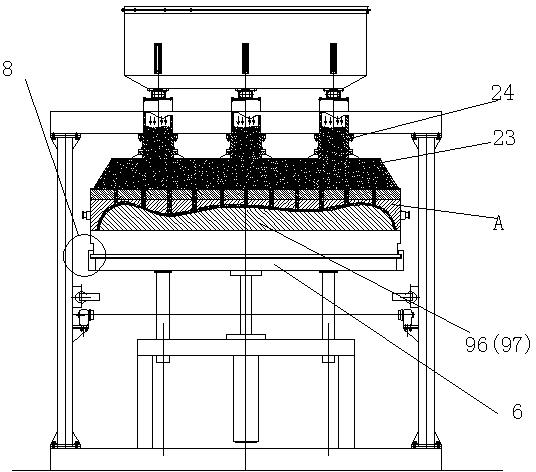

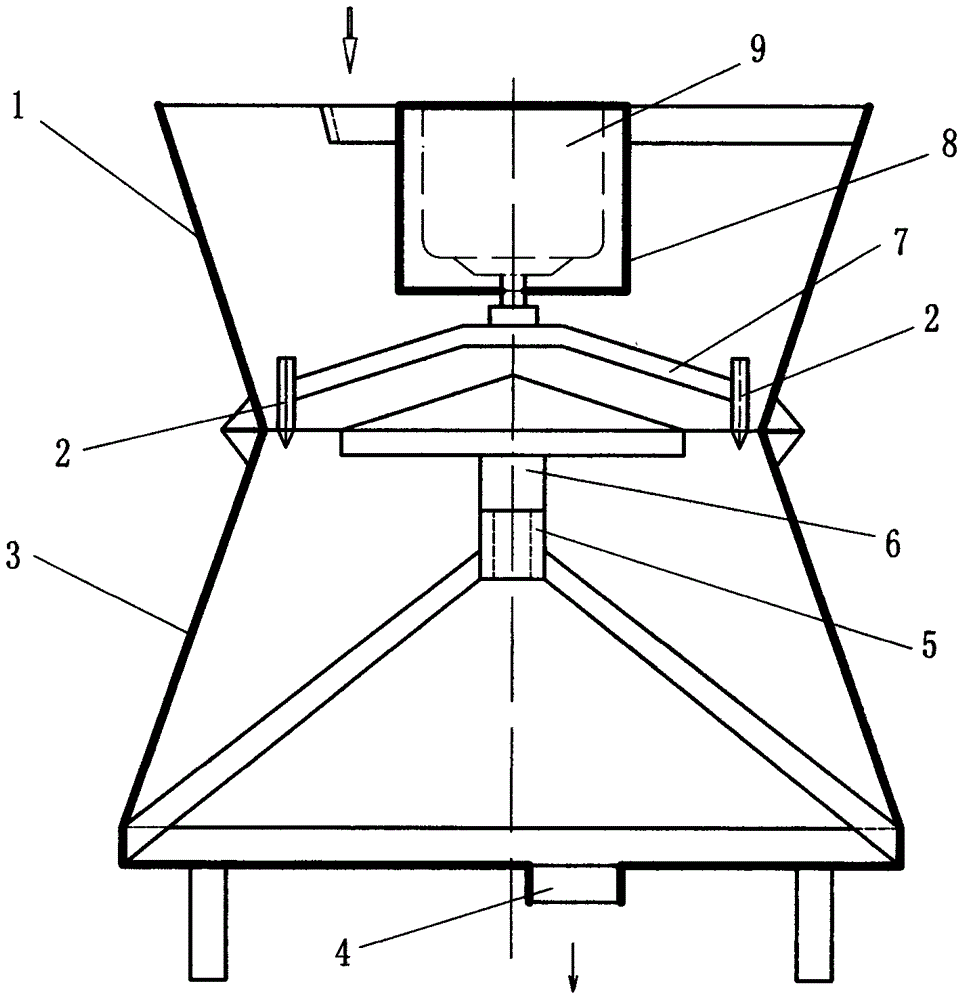

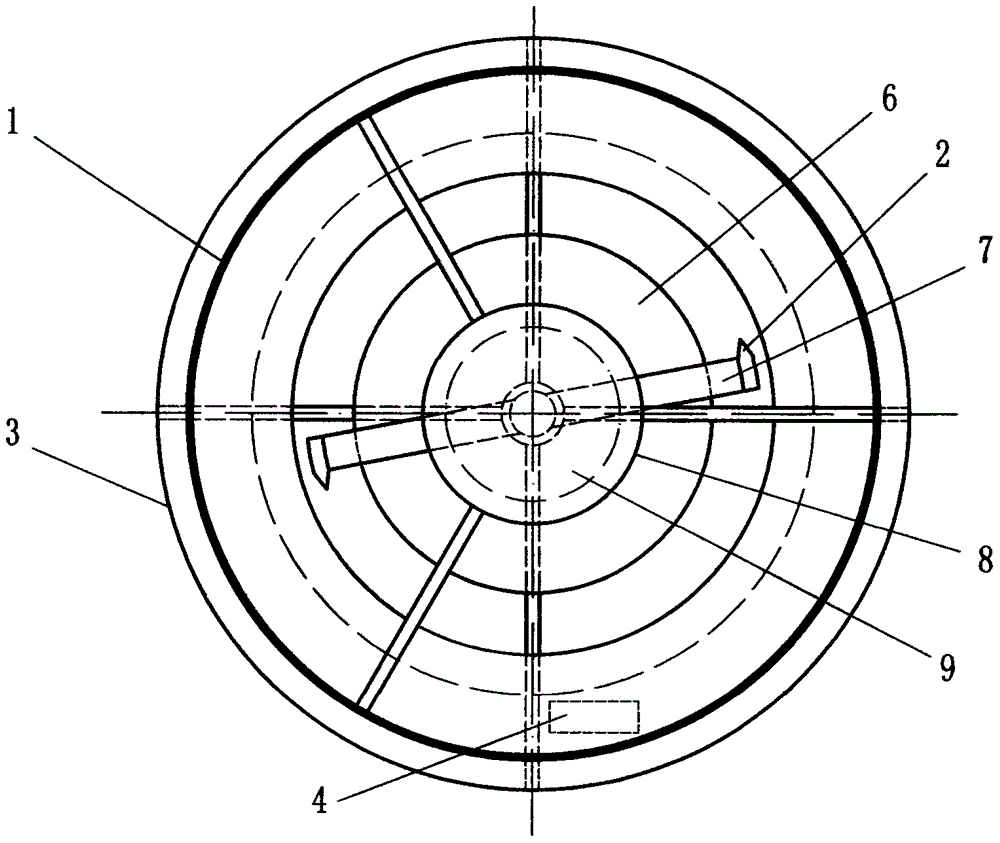

Sand-coating molding device and method for large metal mold

ActiveCN102861880BConsistent sand covering pressureOptimize layoutMoulding machinesHydraulic cylinderMarine engineering

The invention relates to a sand-coating molding device and a method for a large metal mold. The device comprises a supporting frame and a metal mold rollgang. The supporting frame is composed of a lower beam base, columns and an upper beam, wherein a sand coating and shooting device is arranged on the upper beam, a lifting hydraulic cylinder is arranged on the lower beam base, and a lifting working platform is fixed on the lifting hydraulic cylinder. The supporting frame, the sand coating and shooting device, the lifting hydraulic cylinder and the lifting working platform form a sand-coating molding station. The device is characterized in that a lifting mold assembling and drawing device, mold shuttle shifting devices, a metal mold box-delivery device and a mold rollgang are provided, wherein the mold rollgang and the metal mold rollgang are arranged up and down, the mold shuttle shifting devices are fixedly installed on the columns and arranged over two sides of the mold rollgang, the metal mold box-delivery device is fixedly installed on one side of one column and above the metal mold rollgang, and the lifting mold assembling and drawing device is installed on the side of the working platform. The device is compact in structure, small in occupied area and low in production cost.

Owner:浙江省机电设计研究院有限公司

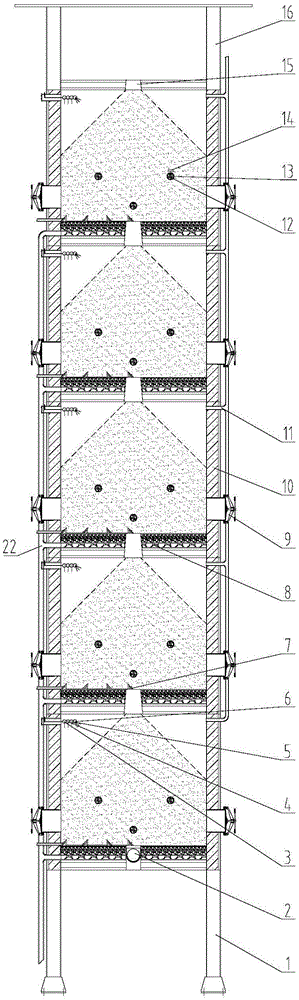

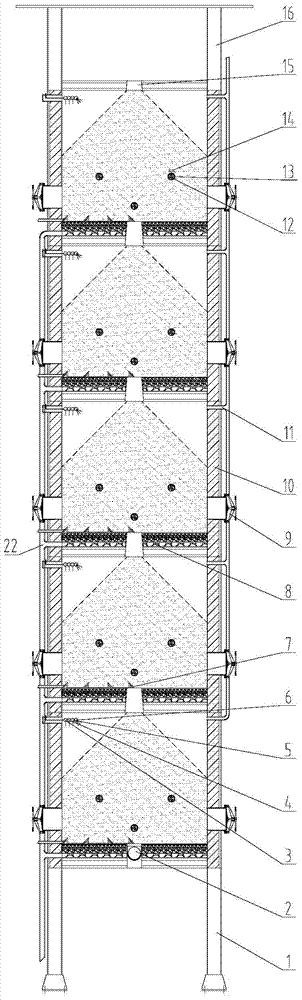

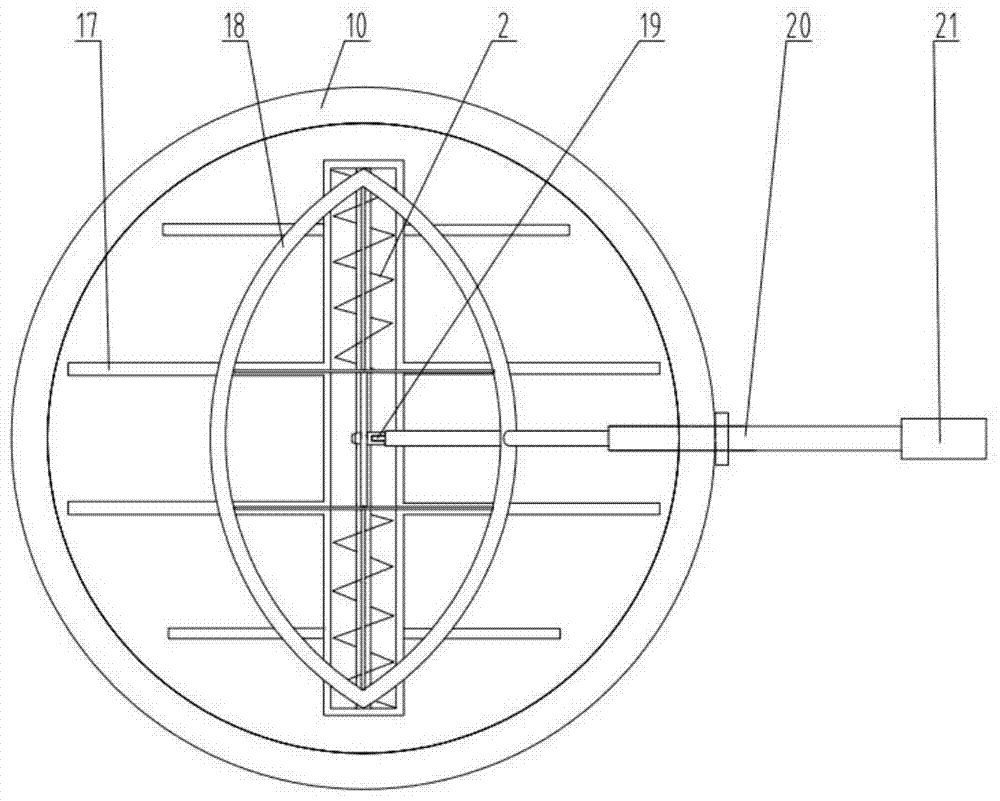

Water-filter-type biological fermentation drying tower

ActiveCN105130148ATurn easilyIncrease motivationSludge treatment by de-watering/drying/thickeningBiological sludge treatmentSludgeWater filter

The invention relates to a water-filter-type biological fermentation drying tower. The water-filter-type biological fermentation drying tower comprises at least one fermentation chamber, wherein the top portion of the fermentation chamber is provided with a feed inlet and the bottom portion of the fermentation chamber is provided with a discharge outlet; a percolation type drainage system is installed at the bottom portion of the fermentation chamber, and materials are placed on the upper surface of the percolation type drainage system, and a drain outlet of the percolation type drainage system is communicated with the outside; a discharge groove is formed in the middle of the percolation type drainage system; a screw conveyer is arranged in the discharge groove and the screw conveyer pushes the materials to the discharge outlet; a sliding rack system for moving the materials into the discharge groove is arranged on the upper surface of the percolation type drainage system; the middle portion of the side wall of the fermentation chamber is provided with at least one air supply hole and the air supply hole is communicated with the outside through an air supply system; the side wall of the fermentation chamber is further provided with an exhaust hole connected with an exhaust system. The device has the advantages that the working environment is good; the aerobic fermentation is controlled; the material flow process is smooth; the working environment is obviously improved and the like, and is applicable to sludge dehydration of rural and urban sludge plants, manure water treatment of livestock farms and the like.

Owner:CHANGSHA JINYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

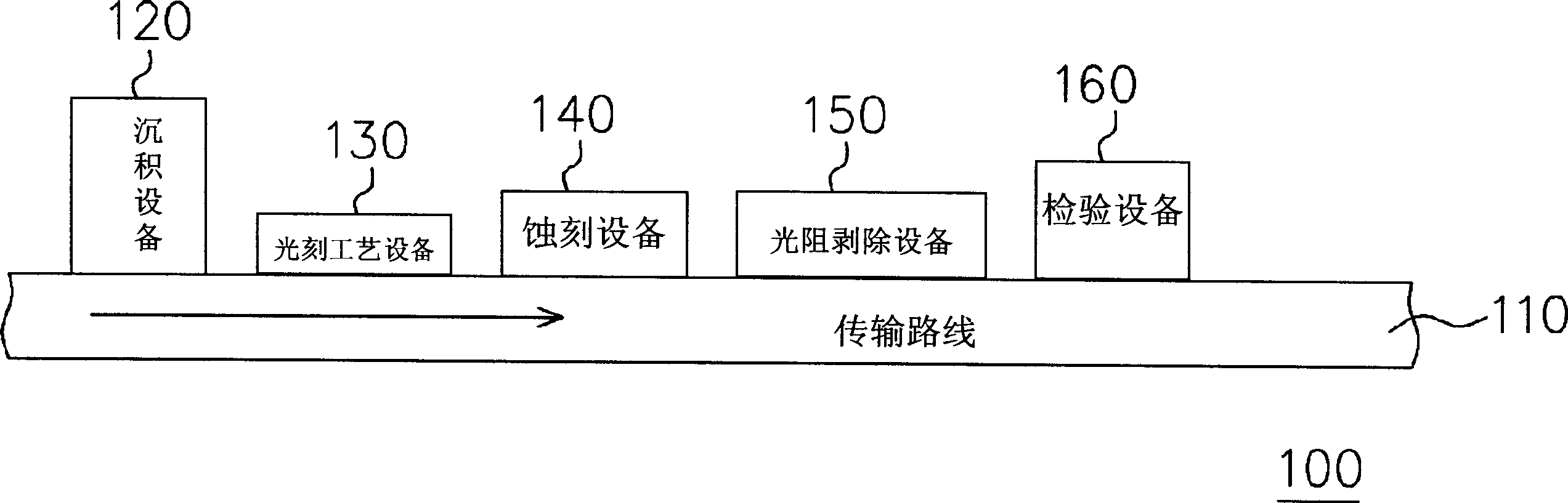

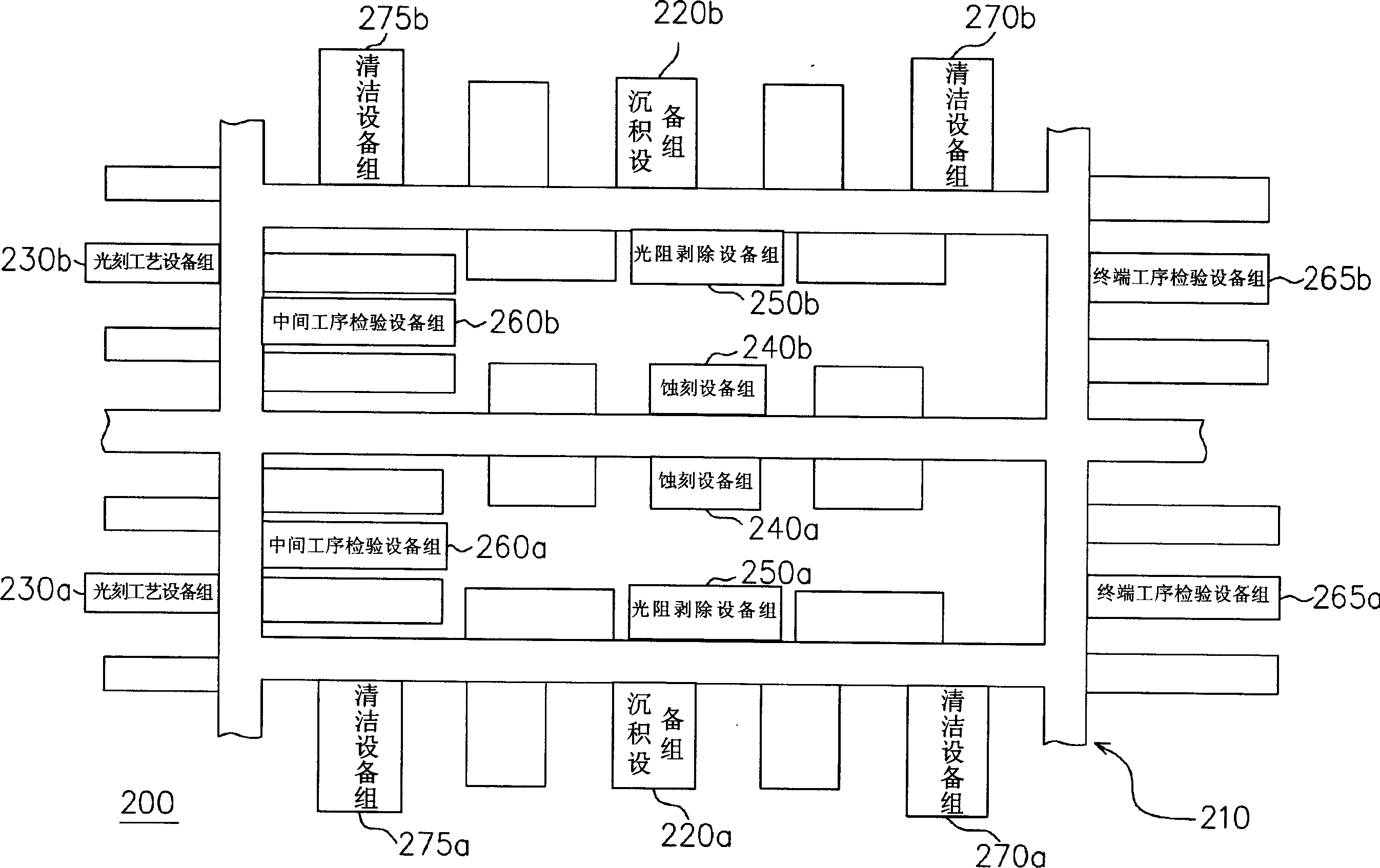

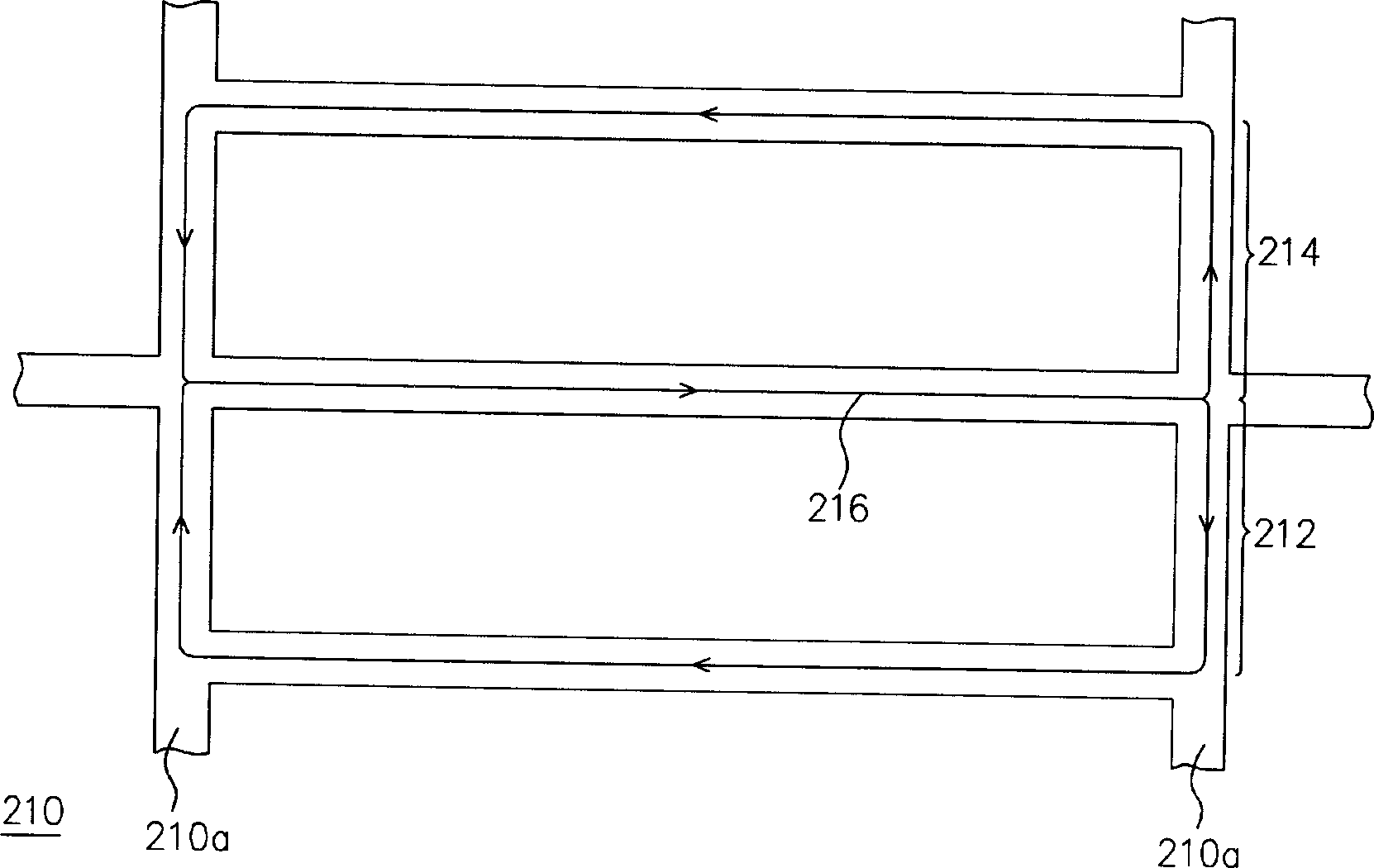

Factory production working system and its operating method

InactiveCN1815337AReduce manufacturing costSmooth logisticsStatic indicating devicesSemiconductor/solid-state device manufacturingMachining systemCluster type

The system of processing includes at least transmission system, two sets of deposition equipment, etching apparatus set, photoetching technical equipment set, and two sets of photoresistive divesting equipment. The transmission system includes multiple transmission paths. At least two connected circular paths are included in the transmission paths. Connected place between two circular paths is as public path. photoetching technical equipment set is setup on two circular paths between two sets of deposition equipment. The disclosed system of processing integrates both advantages of cluster type system of processing, and continuous type system of processing.

Owner:CHUNGHWA PICTURE TUBES LTD

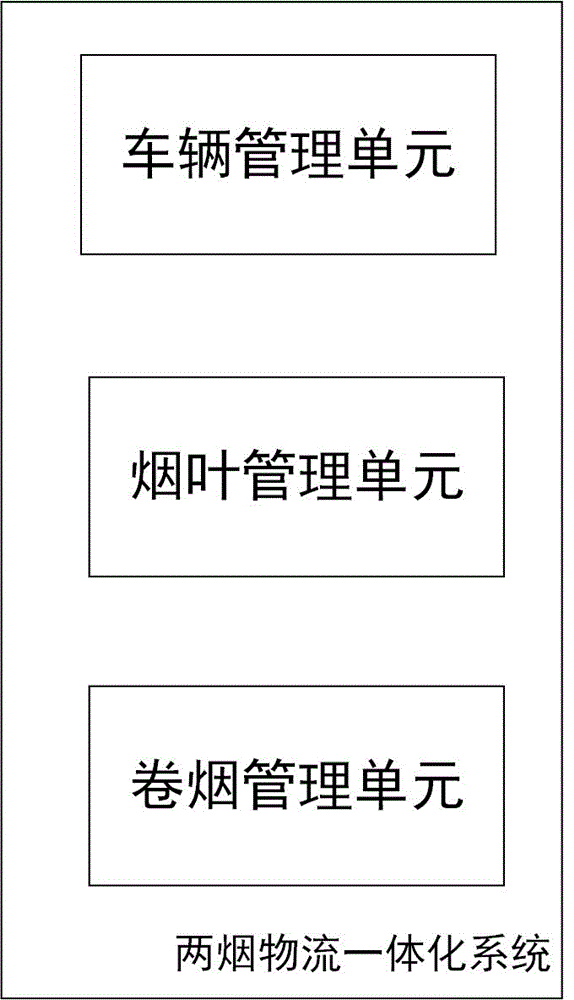

Integrated system of tobacco leaf and cigarette logistics

InactiveCN105719115AImprove loading and unloading efficiencyConvenient ArrangementLogisticsAgricultural scienceLogistics management

The invention relates to an integrated system of tobacco leaf and cigarette logistics. The integrated system comprises a vehicle management unit, a tobacco leaf management unit and a cigarette management unit. The vehicle management unit is used for cooperating with the tobacco leaf management unit and the cigarette management unit to achieve logistic transportation management of tobacco leaves and cigarettes, especially bidirectional transportation management of the tobacco leaves and the cigarettes. The tobacco leaf management unit and the cigarette management unit are respectively used for managing logistic management of the tobacco leaves and the cigarettes. In the bidirectional transportation management, after a cigarette transporter arrives at a logistic transfer station, if the cigarette transporter turns with empty load, when the cigarette transporter passes a tobacco station, it will transport parts of tobacco leaves according to the arrangement of current vehicle management unit, thereby increasing delivery rate. According to the invention, logistic resources are highly integrated and professional management quality is increased.

Owner:FUJIAN TOBACCO CORP NANPING CORP

Innovative environmental-friendly energy-saving alloy catalysis device

ActiveCN103290461AReflect the requirements of cleaner productionReflect the problem of energy saving and emission reductionCellsElectric power systemAlloy

An innovative environmental-friendly energy-saving alloy catalysis device is mainly used in equipment systems for carrying out surface pre-treatments and catalytic treatments to metals, and intelligently arranges and controls deoiling and rust removal work and alloy catalysis work in order to reach the effects of simple process and controllable quality. The technical problems of energy saving, emission reduction and automatic temperature control are mainly solved; in order to solve energy saving and emission reduction, a counter current rinsing mode is employed, and all waste water is discharged by pipelines; pipeline connection is in a flange connection mode as possible, and therefore running, emitting, dribbling and leaking phenomena are reduced; in order to realize industrial control monitoring automation, a two-stage control mode of an upper computer and a lower computer (PLC) is employed in an electric control system; for temperature control, an actual temperature in each coating bath is confirmed by input data, and actual values of temperatures are read by a temperature control module; by determination of a liquid level of each coating bath and an actual temperature difference through the PLC, starting and stopping of a heating (cooling) system is confirmed; and PID adjusting control is employed by temperature control to make the temperature control better.

Owner:北京中科创新科技发展中心

A filter type biological fermentation drying tower

ActiveCN105130148BRealize automated productionImprove processing efficiencySludge treatment by de-watering/drying/thickeningBiological sludge treatmentWorking environmentPulp and paper industry

A filter-type biological fermentation and drying tower, comprising at least one fermentation chamber, the top of the fermentation chamber is provided with a feed port, and the bottom is provided with a discharge port; the bottom of the fermentation chamber is equipped with a percolation drainage system, and the material Placed on the percolation drainage system, the outlet of the percolation drainage system communicates with the outside world; a discharge trough is arranged in the middle of the percolation drainage system; a screw conveyor is provided in the discharge trough, and the screw conveyor The conveyor pushes the material to the discharge port; the upper surface of the percolation drainage system is provided with a carriage system for dialing the material into the discharge trough; the middle part of the side wall of the fermentation bin is provided with at least one air supply hole , the air supply hole communicates with the outside world through the air supply system; the side wall of the fermentation bin is also provided with an exhaust hole connected to the exhaust system. This device has good working environment, controlled aerobic fermentation, and logistics process It is suitable for the treatment of dewatered sludge in urban sludge plants and manure from livestock farms.

Owner:CHANGSHA JINYUAN ENVIRONMENTAL PROTECTION TECH CO LTD

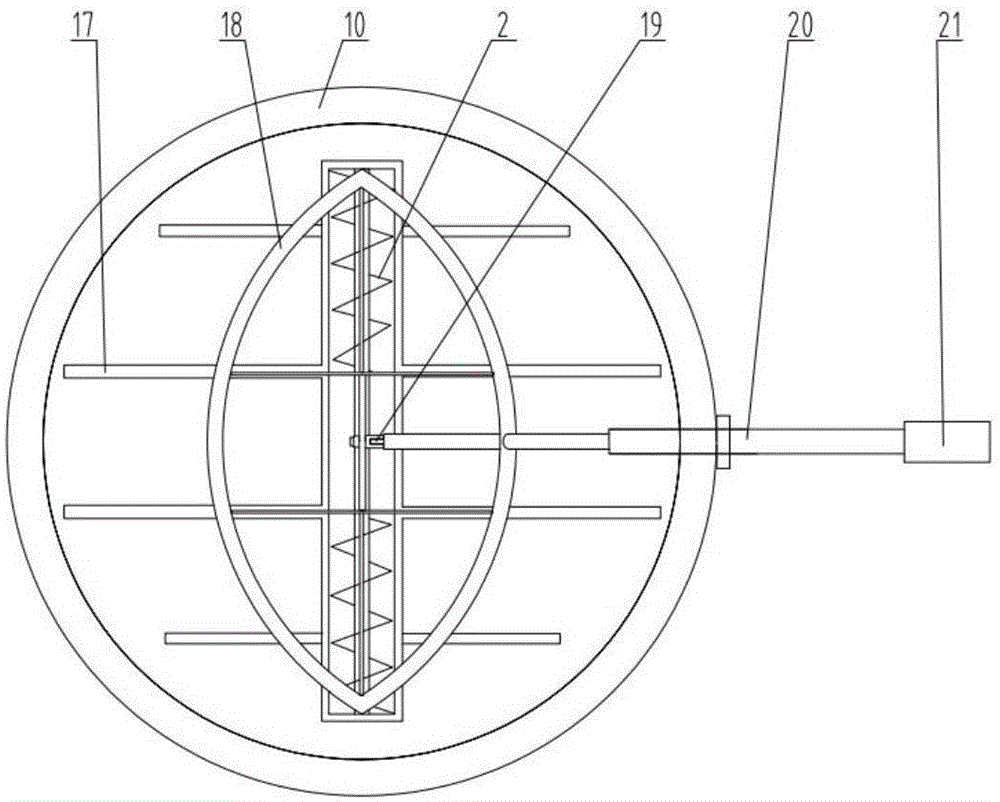

Dry raw potato granules as well as slicing and dicing machine for preparing dry raw potato granules

InactiveCN105942341AControl tablet finenessSmooth logisticsFood shapingCircular surfaceWater content

The invention discloses dry raw potato granules of which the granular sizes are larger than 0.1 millimeter and smaller than 30 millimeters and the water contents are higher than 1% and lower than 10%; and the prepared dry raw potato granules are convenient to store. The dry raw potato granules are cheap nutritious and health-care staple-food-like food products which can be cooked as whole potato granules or in a mixture with rice, or used for other purposes. The slicing and dicing machine for preparing the dry raw potato granules is composed of the following components: an upper body, a lower body, rotary cutters, a rotary cutter crossbeam, a core worktable, a pile base, an electric motor and an electric motor room; the upper body is shaped like a hopper; the lower body is a cone-shaped barrel; the lower opening of the upper body and the upper opening of the lower body are identical in diameters, but the lower opening of the upper body is the smallest; the upper body and the lower body are connected and positioned by a flange; the core worktable is formed by connection of the upper part and the lower part; the upper part of the core worktable is shaped like a round cake, and the lower part of the core worktable is a right circular cylinder which is inserted and fixed in the pile base; the pile base is supported in the lower body by using radial ribs, and makes the core worktable, the upper body, the lower body and the electric motor coaxial; the height of the upper circular surface of the major diameter of the core worktable is identical to the heights of the upper body and the lower body; the lower caliber of the upper body is larger than the major diameter of the core worktable; the center of the rotary cutter crossbeam is perpendicularly connected to the lower end of the electric motor shaft in T-shaped state; the rotary cutter crossbeam is higher than the top of the upper part of the core worktable; the rotary cutters are respectively connected to the two end heads of the rotary cutter crossbeam in T-shaped state; the lower tips of the rotary cutters are inserted in a gap between the lower opening of the upper body and the major diameter of the core worktable; and the raw materials are fed through the upper opening of the upper body, and prepared materials are discharged through the bottom opening of the lower body.

Owner:SICHUAN COCICO JUICE

Compact production process for mid-wide strip steel

InactiveCN108080416AImprove pickling efficiencyThe process is compact and reasonableWork treatment devicesMetal rolling arrangementsAlloyStrip steel

The invention discloses a compact production process for mid-wide strip steel. The compact production process for the mid-wide strip steel comprises the following steps that S1, a desulfurizing agentis added to a molten iron surface, air is blown in through a vent plug installed at the bottom of a molten iron ladle, molten iron is stirred for desulfurizing, and hten the molten iron is added intoa converter or an electric stove for smelting; S2, a molten steel ladle is hoisted to a molten steel refining furnace, molten steel and alloy fine-tuning components are added to make the temperature and components of the molten steel be uniform, accordingly inclusions are further reduced, and after the specified requirements are met, the molten steel ladle is hoisted to a ladle turret of a continuous casting machine according to the requirement of the technical time rhythm; and S3, a tundish is preheated at the temperature of 1200-1250 DEG C, afterwards the molten steel is poured into the tundish, the degree of superheat is controlled to be 20-60 DEG C, andwater gaps of the tundish are distributed to crystallizers. According to the compact production process for the mid-wide strip steel, the configured procedures are compact and reasonable, logistics is smooth, the temperature is matched and suitable, the subsequent product processing procedures and cost are reduced, the product quality is improved, energy is saved, and the production process meets the national policy of energy conservation and emission reduction.

Owner:滁州宝岛特种冷轧带钢有限公司

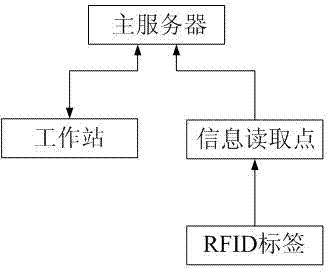

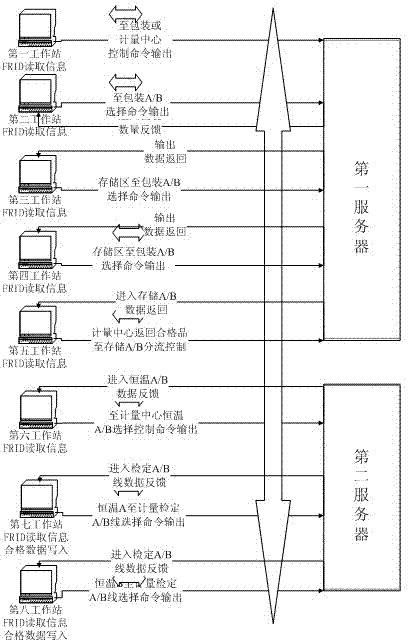

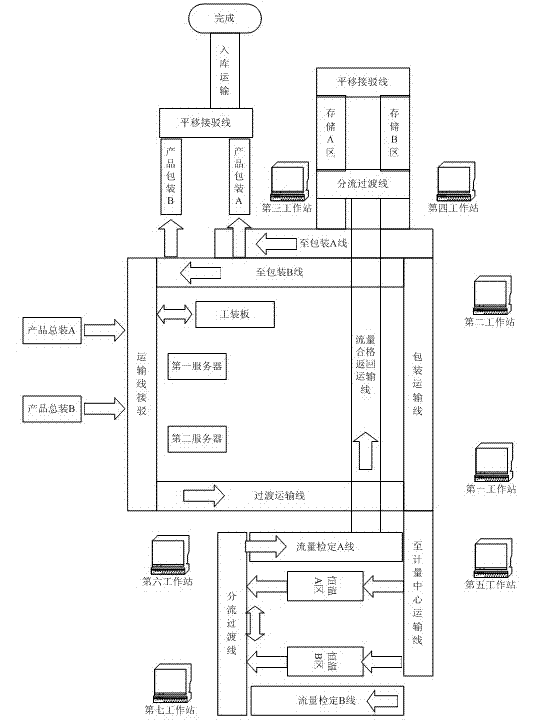

Production line control system and its control method

ActiveCN103116348BRealize information transferTo achieve the purpose of joint control of the production lineTotal factory controlProgramme total factory controlInformation transmissionProgrammable logic controller

The invention discloses a production line control system and a control method thereof and relates to the technical field of control. The production line control system comprises a programmable logic controller (PLC) system and a main server. The PLC system comprises multiple work stations connected to the main server. The production line control system further comprises a radio frequency identification device (RFID) radio frequency read-write system. The RFID radio frequency read-write system comprises information reading points and RFID labels, wherein the information reading points are arranged on production lines, and multiple tool plates are further arranged on the production lines, and the RFID labels are written on the multiple tool plates. The information reading points read data information in the RFID labels on the tool plates and transfers the data information to the main server. Due to the fact that the production line control system enables the PLC system and the RFID radio frequency read-write system to be compatible, control of a production device and acquisition of the product data information are synchronously performed, information transmission between two sub-systems is achieved, and the purpose of common control of the production line is achieved.

Owner:CHENGDU QIANJIA TECH CO LTD

Scallop pole sorter

The invention relates to a sorting machine for aquatic products, in particular to a sorting machine for scallop shells. It includes a frame, a power device, and a transmission device. It is characterized in that a row of rollers is installed on the frame, and the distance between each roller is set according to the requirements of material classification. Bearing seats and bearings are installed on the frame positions at both ends of the rollers. And the end cover, the roller shaft and the bearing are assembled together. A cam plate is installed inside the frame. There is an axial groove on the roller, and a dial is inserted in the groove. The dial shaft is inserted into the cam track of the cam plate. A receiving plate is provided. The invention has the advantages of high sorting precision, compact product structure, low noise, low energy consumption, smooth logistics, etc., and can also be connected with the yellow edge removing machine in the previous process to form a complete set of equipment, eliminating the heavy labor of manual handling , greatly improving work efficiency.

Owner:CHINA AGRI UNIV

On-line red steel elbow straightener

The invention relates to an on-line red steel elbow straightener which comprises a stander (1) and an upper straightening roller group and a lower straightening roller group which are arranged on the stander (1), wherein each of the upper straightening roller group and the lower straightening roller group consists of a plurality of straightening rollers (7); the central lines of the straightening rollers (7) of the upper straightening roller group are parallel to one another and positioned on the same horizontal line, and the central lines of the straightening rollers (7) of the lower straightening roller group are parallel to one another and positioned on the same horizontal line; and the straightening rollers (7) of the upper straightening roller group and the straightening rollers (7) of the lower straightening roller group are staggered from each other along the horizontal direction. According to the on-line red steel elbow straightener, the problem that the head of a bar material which is discharged from a rolling machine is bent is solved, the yield is increased, a large amount of time and a large quantity of troubles are saved for the subsequent working procedure, and the logistics of the whole production loop is relatively smooth; and therefore, a phenomenon of repeated reversing is avoided, the production efficiency is improved, the manmade mixed steel risk is reduced, and the burden and the pressure of workers are reduced.

Owner:JIANGYIN DONGCHEN MACHINERY MFG

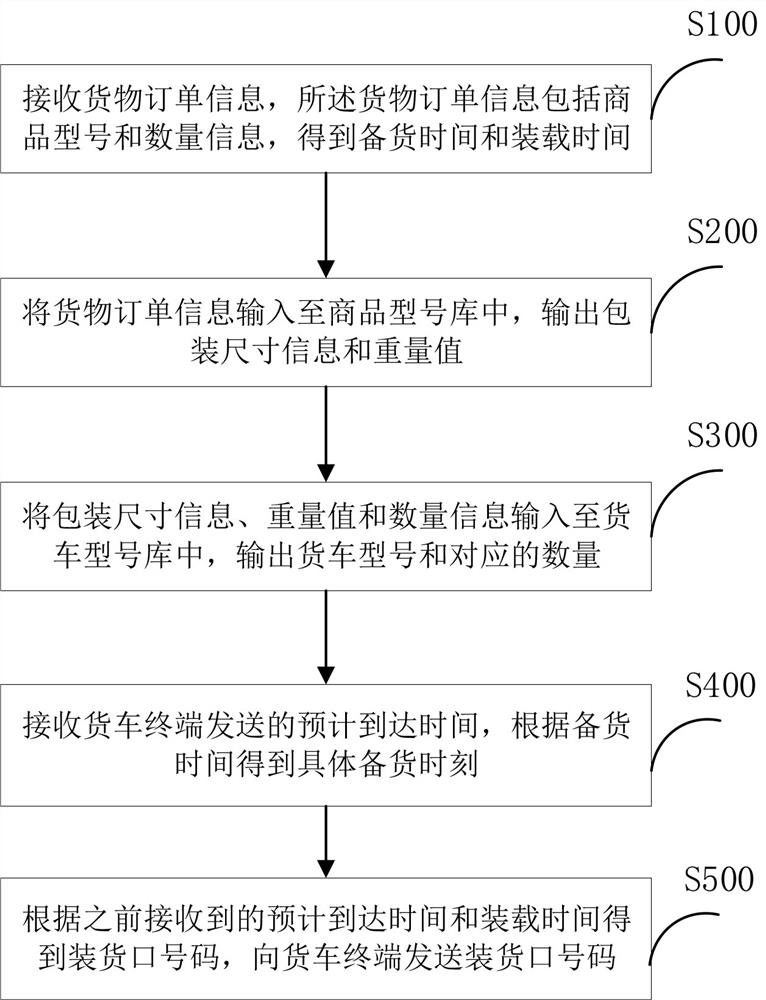

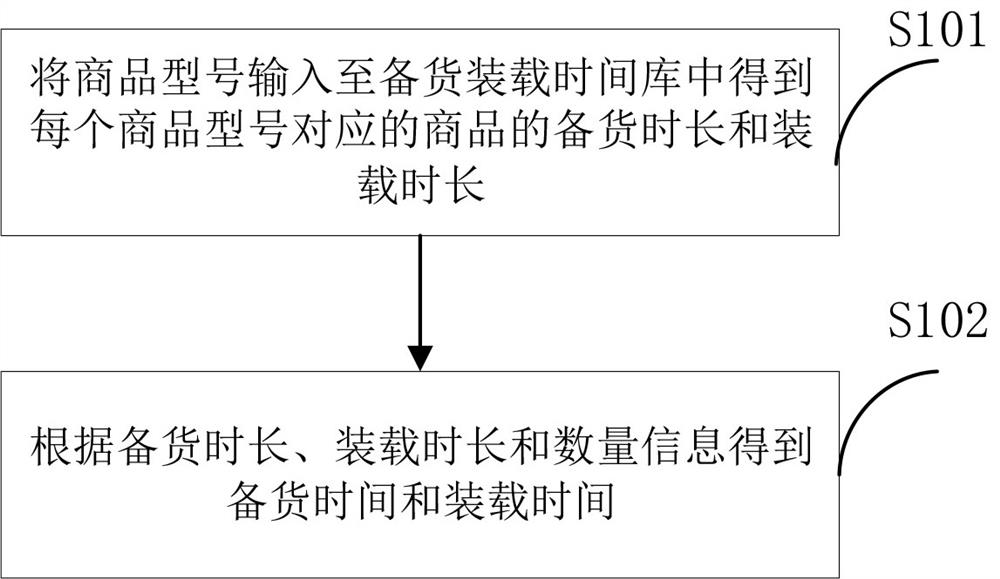

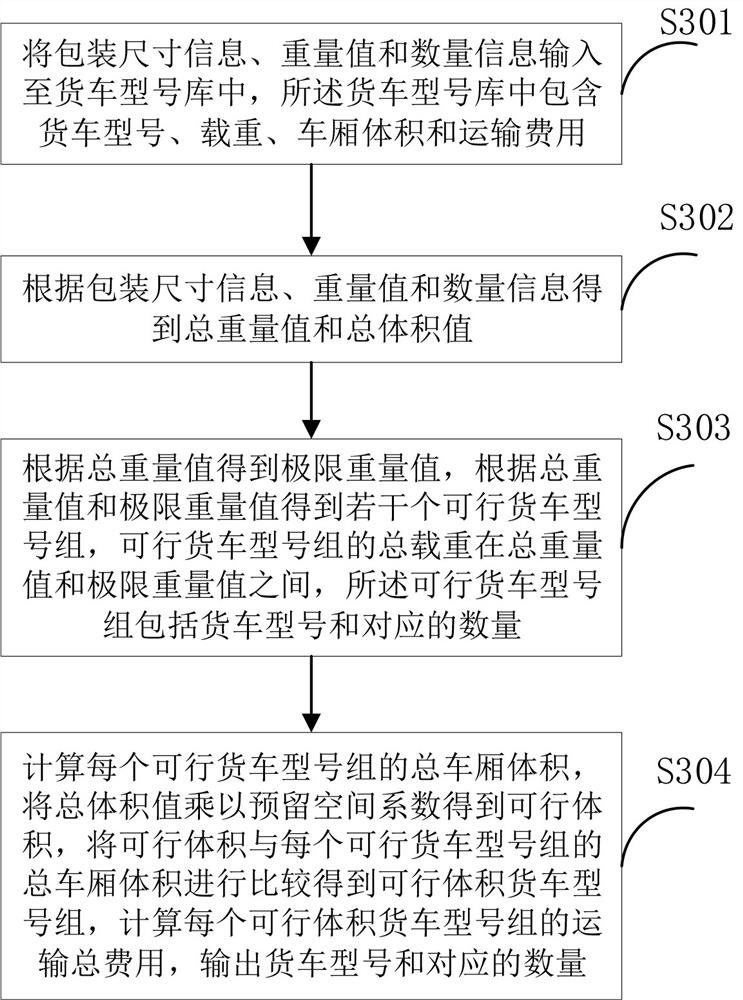

An intelligent logistics management method and system

ActiveCN114581020BNo overloadingSmooth logisticsForecastingResourcesLogistics managementArrival time

Owner:深圳市运无忧网络科技有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com