Scallop pole sorter

A kind of sorting machine and scallop technology, which is applied in classification, solid separation, filtering and screening, etc., can solve the problems of bulky and bulky machine body, poor sorting precision, high vibration noise, etc., and achieve high sorting precision, low energy consumption and low noise small effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

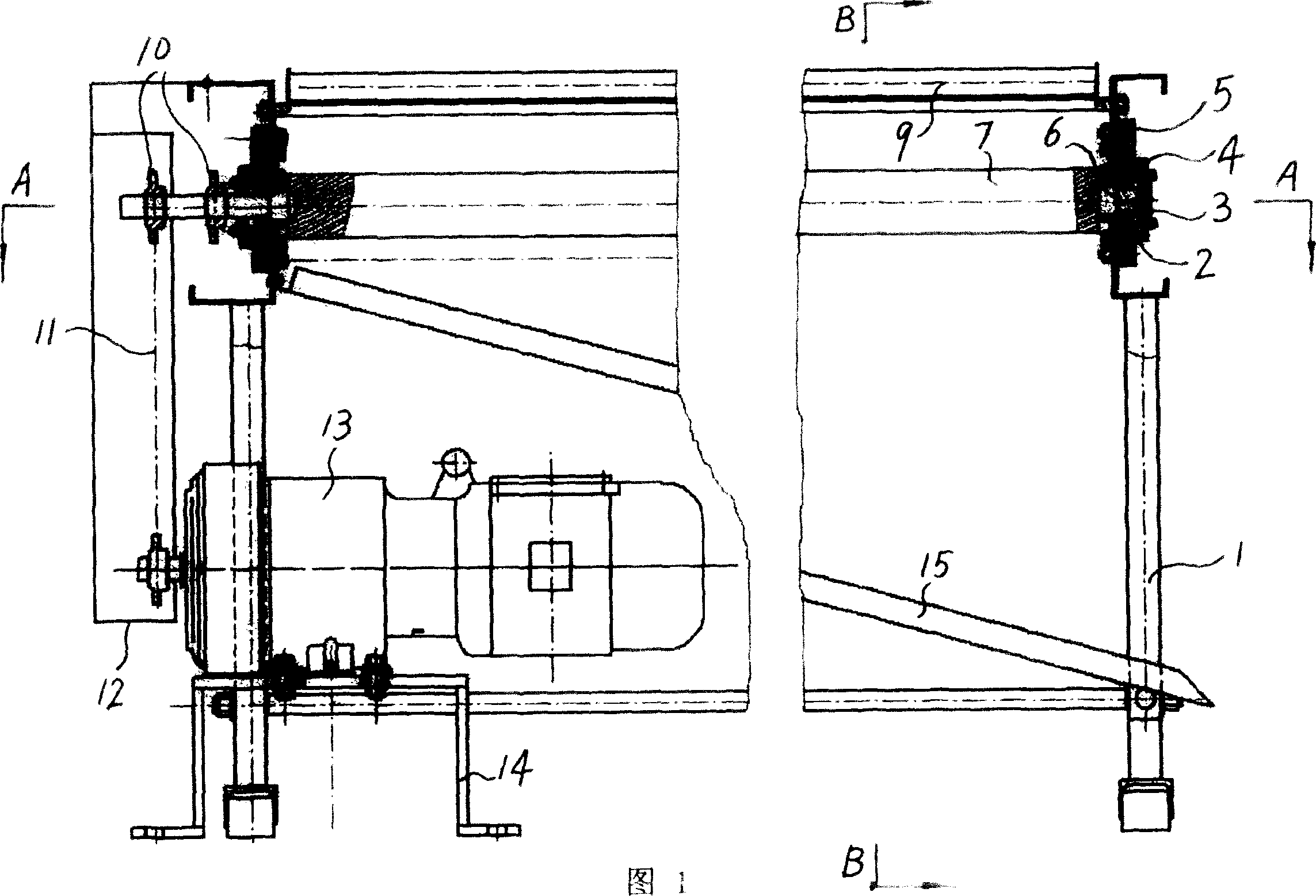

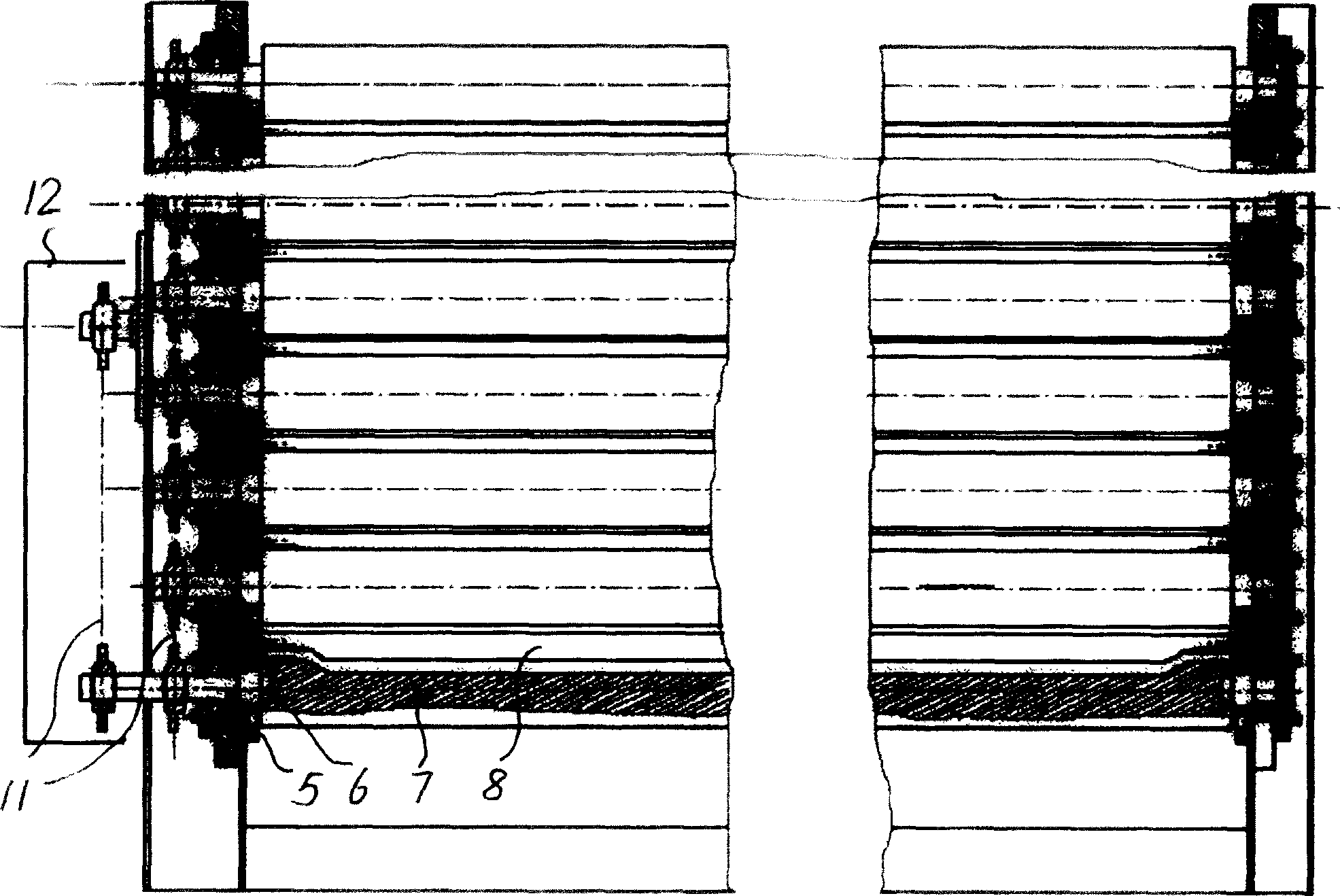

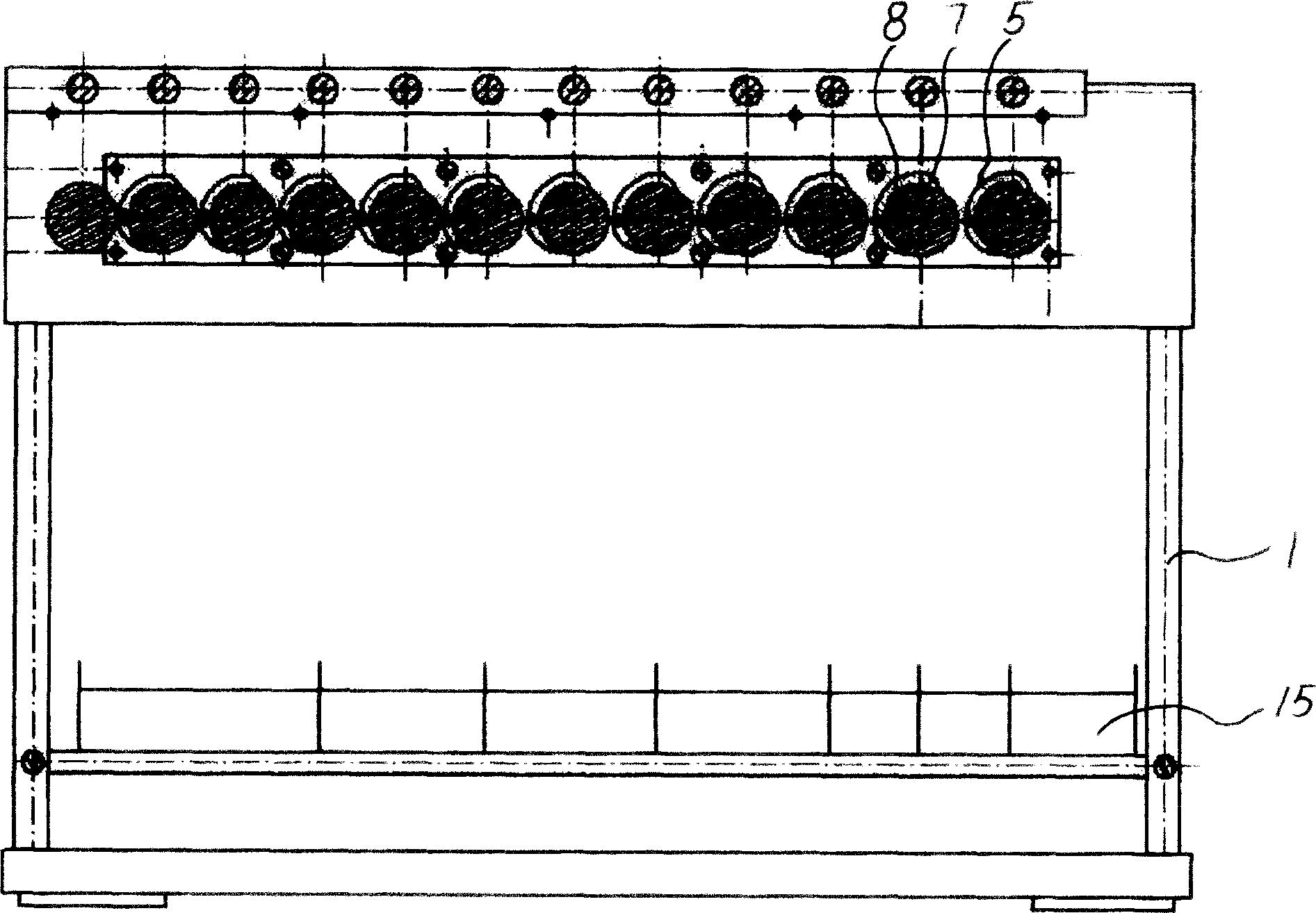

[0020] The invention is a novel sorting machine designed mainly for the disadvantages of poor sorting accuracy and high noise of the current vibrating screen type scallop column sorting machine. The technical scheme of the present invention is to sort scallop shells according to different diameters. The principle is that according to the difference in the distance between the two rollers, the material can fall between different rollers, so as to achieve the purpose of classification. The working process is as follows: firstly, the material is sent to the sorting machine from the last roller on the yellow edge removing machine and arranged on the first-stage roller, the smallest diameter falls down, in order to make the material of this level fall completely, three consecutive The same spacing is divided into the first level, the second, third, and fourth levels use two identical spacings, the fifth and sixth levels use one spacing for sorting, and the seventh level is the last...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com