Modifying and washing automatic assembly line system for china sanitary ware green bodies

A sanitary ware and assembly line technology, applied in conveyors, mechanical conveyors, transportation and packaging, etc., can solve the problems of large space occupation, harsh environment, low efficiency, etc., and achieve the effect of efficiency improvement and standardized management

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be described in further detail below in conjunction with the accompanying drawings.

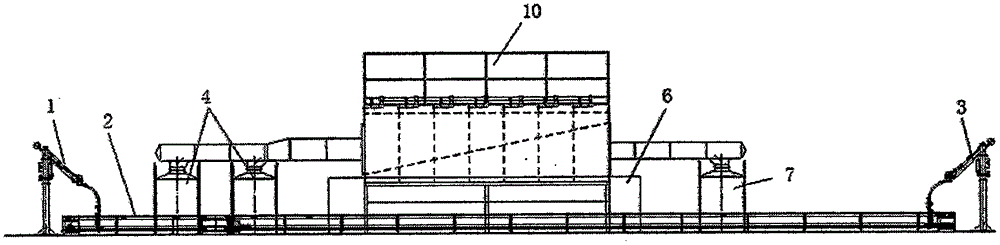

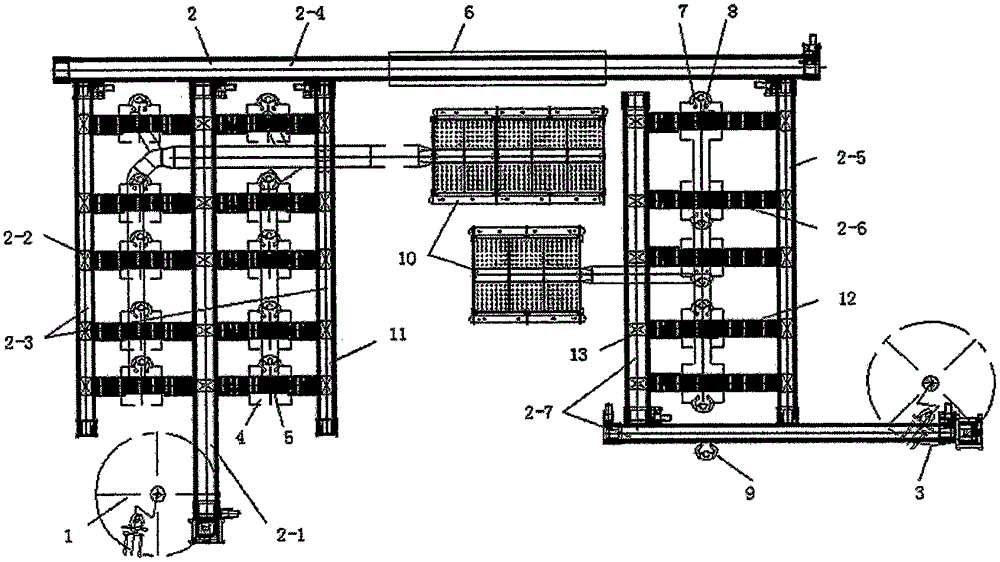

[0025] Such as figure 1 , figure 2 As shown in the figure, an automatic assembly line system for changing and washing ceramic sanitary ware bodies, including a green body on-line booster arm 1, a conveying line system 2, and a green body off-line booster arm 3. Working room 4, drying line 6, fine reforming and washing billet dedusting workshop 7 and code scanning inspection station 9, rough reforming and washing billet dedusting workshop 4 is equipped with billet rough scraping and watering station 5, fine reforming and washing billet dedusting work Room 7 is equipped with a body fine scraping and oil inspection station 8, the rough body rough scraping and watering station 5 of the rough reforming and washing billet dedusting workshop 4 and the billet fine scraping and oil inspection station 7 of the fine reforming and washing billet dedusting workshop 7 S...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com