Infiltration technique and device

A technology of impregnation and process, applied in the field of impregnation process and its devices, to achieve the effects of reducing production costs, good surface finish, and ensuring civilization and cleanliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

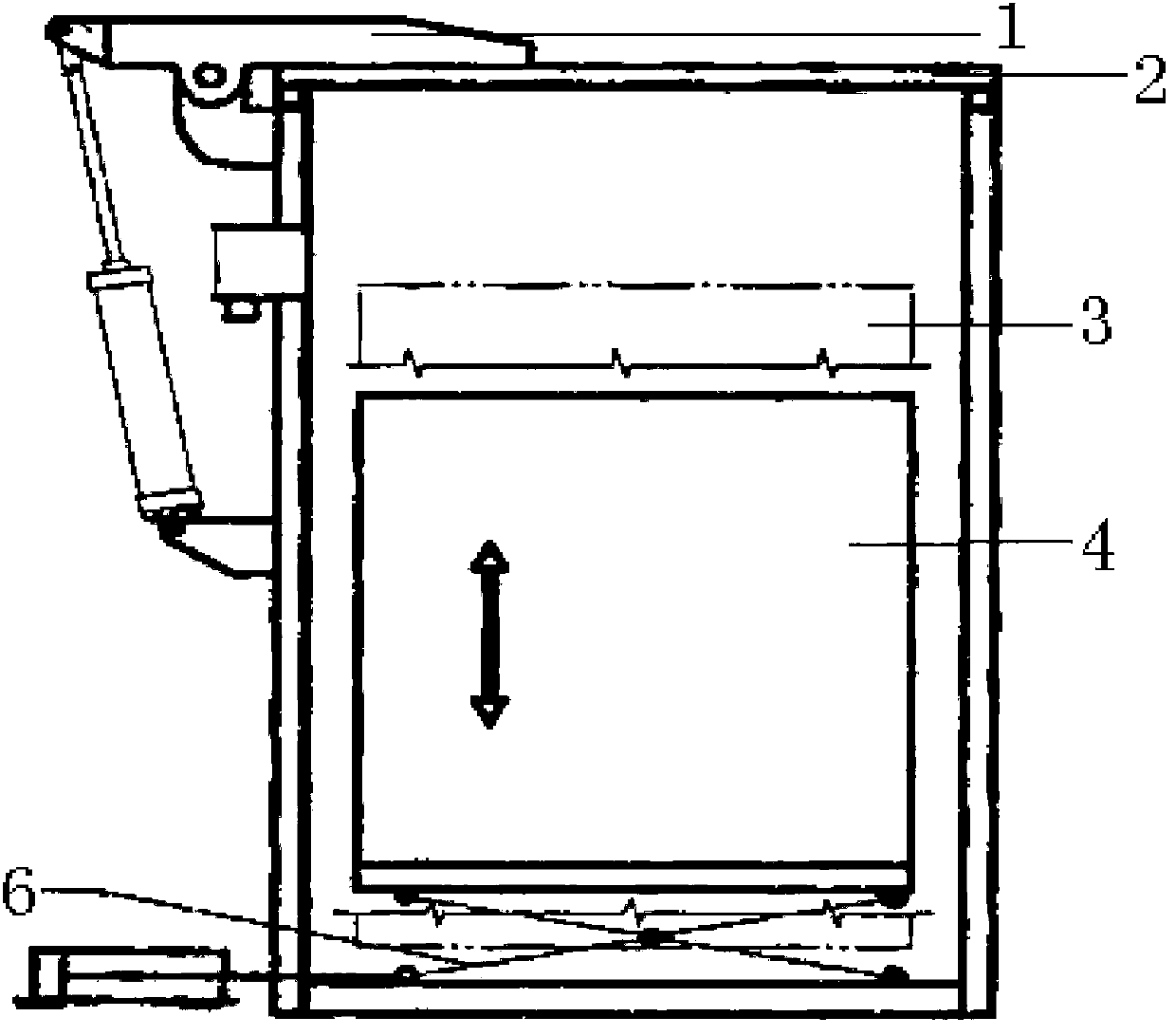

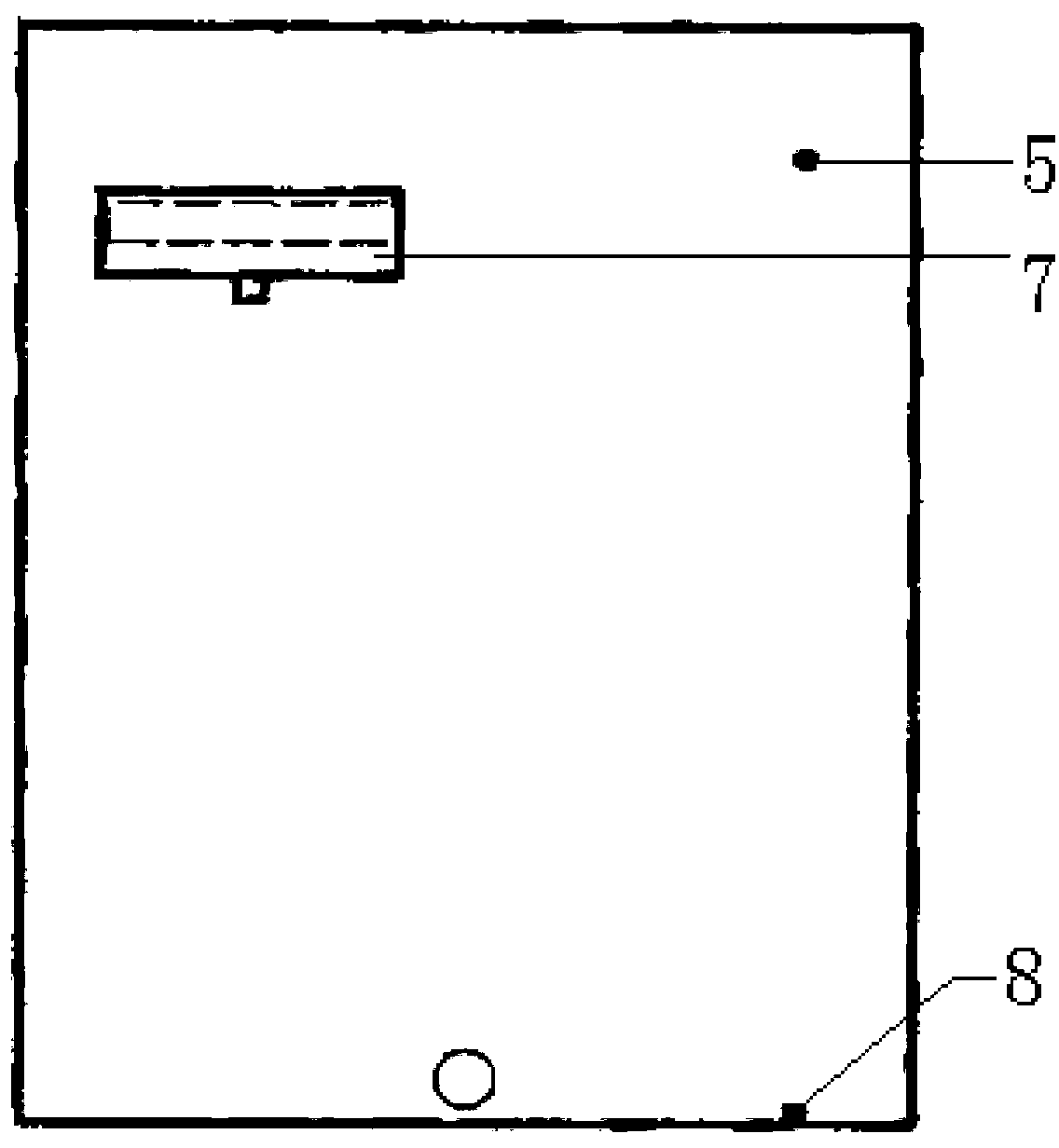

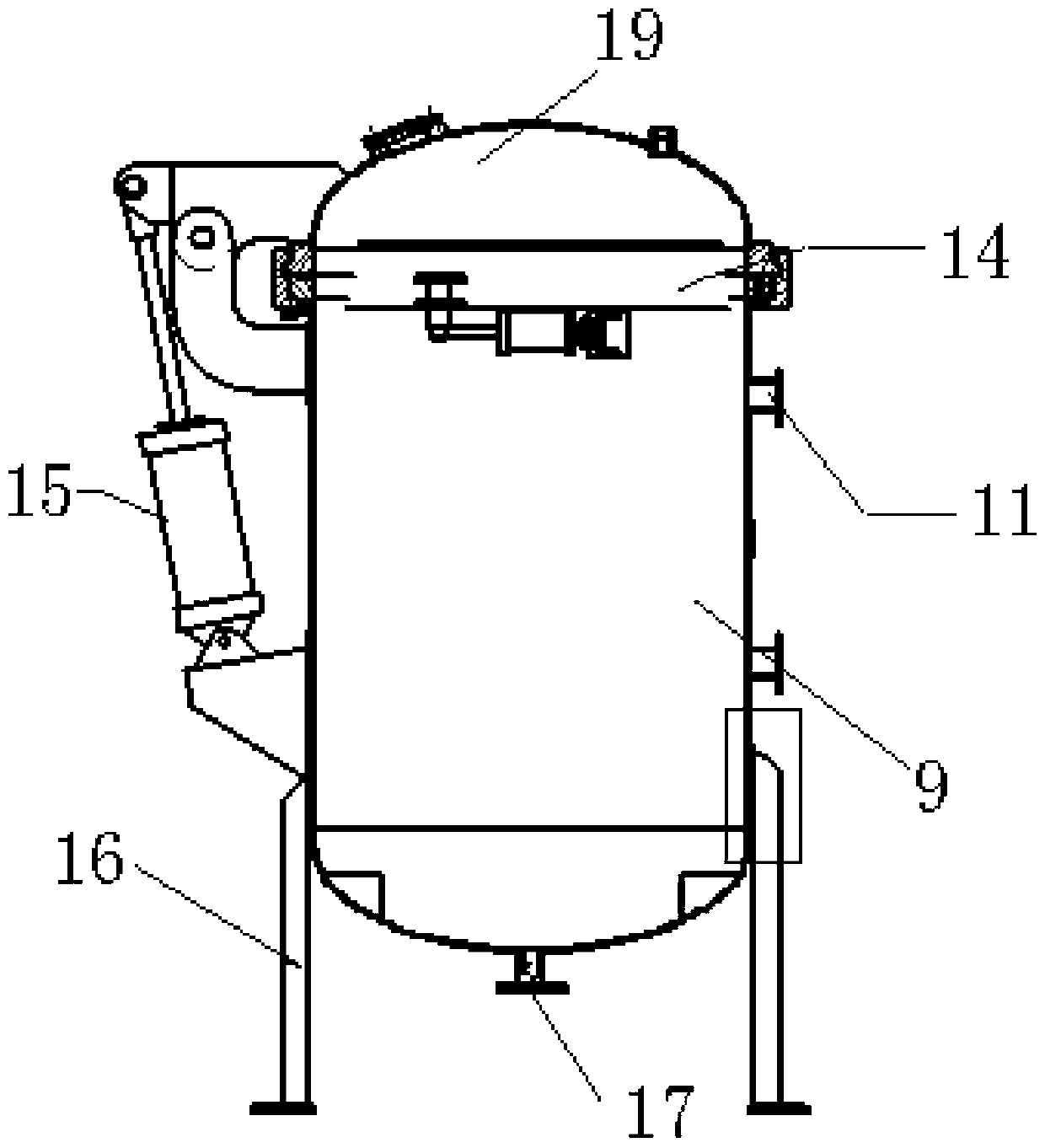

[0021] An impregnation process, which includes three stages of impregnation pretreatment, impregnation treatment, and impregnation post-treatment.

[0022] The impregnation pretreatment is as follows: manually put the workpiece into the impregnation basket, hang the impregnation basket into the degreasing tank with a gourd crane, close and lock the cover of the degreasing tank, bubbling for 15 minutes, open the cover, take out the impregnation basket and remove it. Put it into the cleaning tank, wash it with cold water for 2 minutes, up and down 5 times, take out the impregnation basket and move it to the centrifuge tank, close the tank, dry it centrifugally (forward rotation, reverse rotation, stop), open the cover, take out the impregnation basket and move it to the Dry in an oven at 110°C for 10 minutes, then move to a drying rack to dry.

[0023] The impregnation treatment is as follows: put the impregnation basket containing the workpiece into the impregnation tank withou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com