Technique for selecting tobacco leaf

A tobacco leaf and process technology, which is applied in the field of tobacco leaf selection process, can solve problems such as high labor intensity, chaotic logistics organization, and difficult selection quality assurance, and achieve the effects of guaranteed processing quality, smooth logistics, and uniform flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] On the existing threshing and redrying production line of Anhui Huahuan International Tobacco Co., Ltd., some equipment was selected and two batches of experiments were carried out. Each batch was 50 packs, and the grade was Shaanxi Ankang C2F. Set the selection ratio of Class C cigarettes to 20%.

[0049] The first batch is completely selected online and statically, and the selected tobacco leaves are transported by belts at each station;

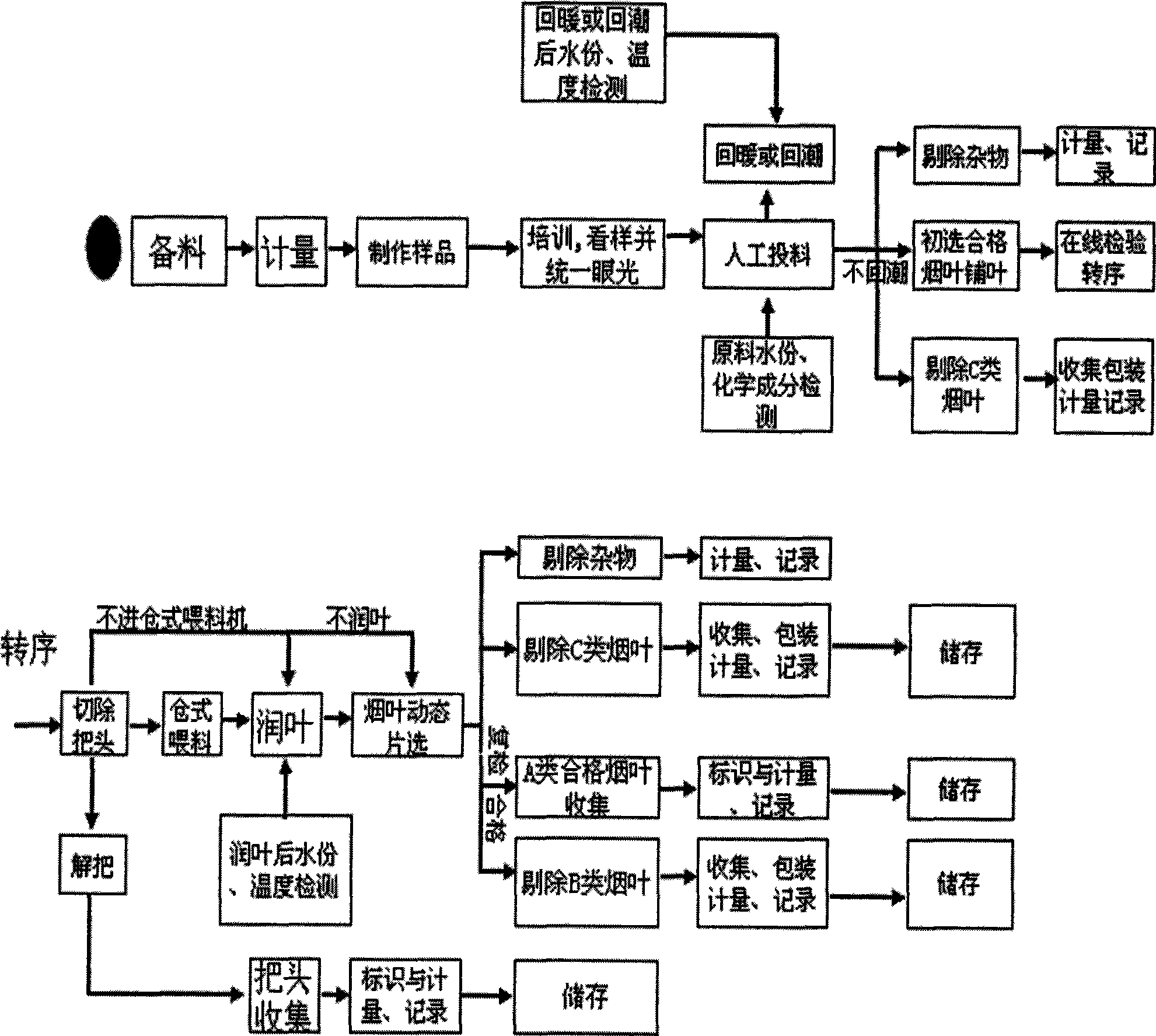

[0050] The second batch adopts a combination of dynamic and static selection process. The tobacco leaves are prepared and rehydrated. The leaf laying table adopts static sorting. After selection, the tobacco leaves are laid and moistened. Its process is as image 3 As shown, it includes the following process steps: material preparation and moisture recovery, leaf laying and selection, base cutting and removal, flow control, leaf moistening and loosening, tobacco leaf distribution, online leaf selection, automatic collection, meteri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com