Unloading and framing method and equipment for crude tobacco bales

A technology for cigarette packs and framing, which is used in transportation and packaging, loading/unloading, stacking of objects, etc., and can solve the problem of requiring many workers (generally at least 10 to 12 workers, large secondary crushing of tobacco leaf raw materials, etc.). The problem of low efficiency of unloading and framing, to achieve the effect of shortening the working time of workers, good framing effect, and reducing labor intensity of workers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

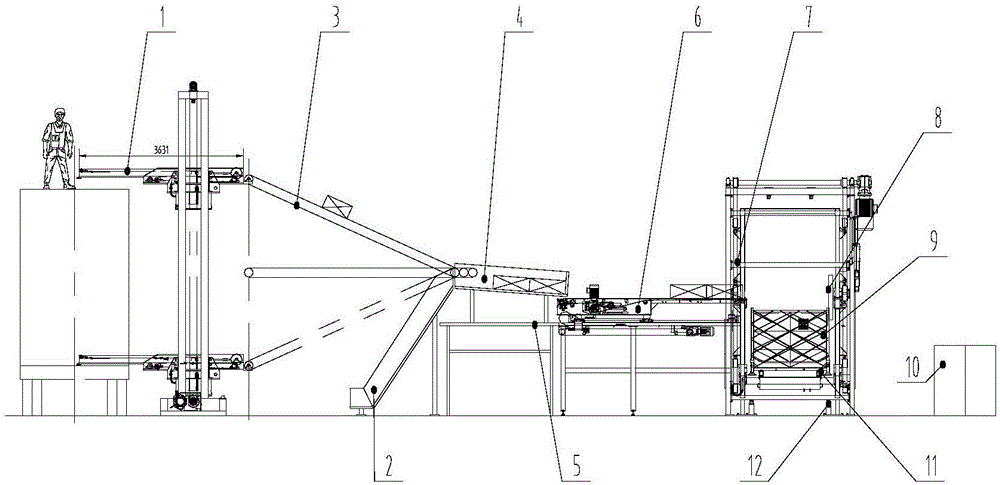

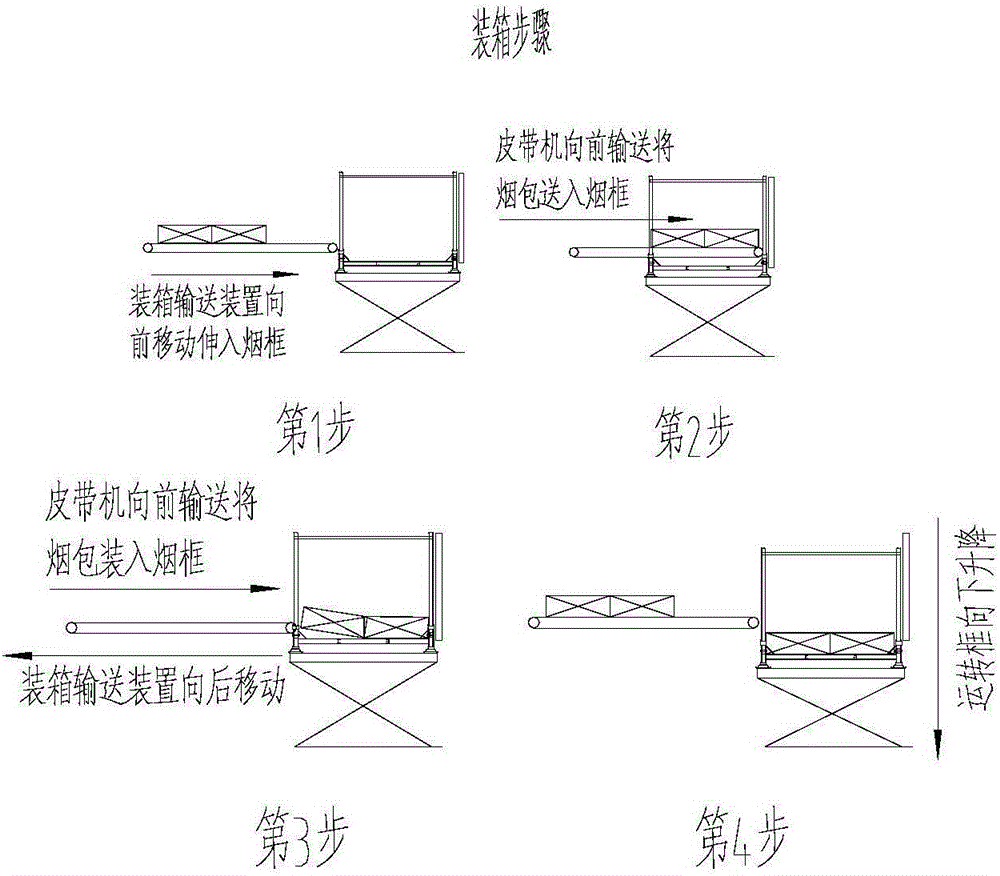

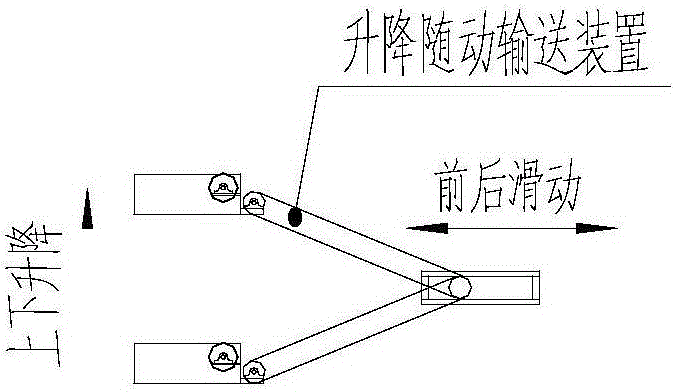

[0018] Such as figure 1 As shown, a device for unloading and framing raw cigarette packs, the present invention is characterized in that it includes a lift-type telescopic or fixed conveying mechanism (1) located at the front end, and a lift-and-follow-up mechanism behind the lift-type telescopic or fixed conveying mechanism (1) Conveyor device (3), connect and be arranged at the random inspection chute (2) below the tail end of lifting follow-up conveying device (3), be connected and be arranged at the universal direction and package sorting device ( 4), the mobile or telescopic conveyor (6) docked with the universal packing device (4), the support and platform ( 5), the transfer frame lifting device (7) located at the tail of the mobile or telescopic conveyor (6), the material retaining device (8) located on the rear side of the transfer frame lifting device (7), and the transfer frame lifting device (7) ) the cigarette bale transfer frame (9) at the lower part of the fram...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com