Production line control system and its control method

A control system and production line technology, applied in the field of control, can solve problems such as failure to achieve effectively, and achieve the effects of avoiding data recording errors, reducing workload, and reducing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

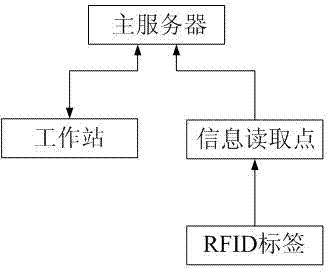

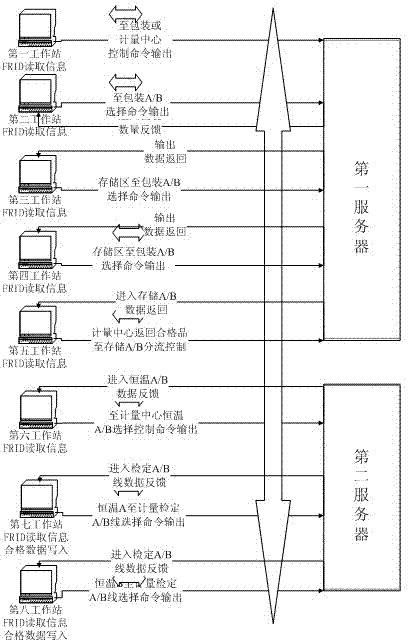

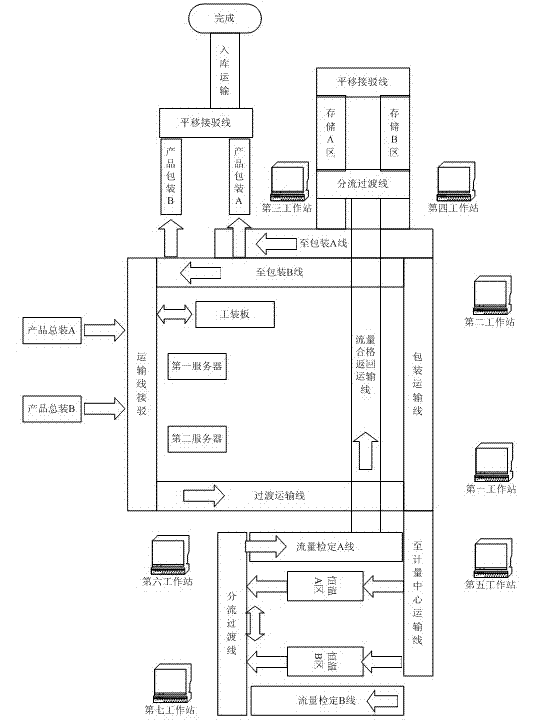

[0030] The information reading point reads the data information in the RFID tag on the tooling board, and transmits the data information to the main server. The data information in the RFID tag includes product information and production data information. There are multiple information reading points.

[0031] A stopper is also arranged on the production line, and the information reading point and the stopper are arranged in sequence along the running direction of the production line. The stopper is controlled by the PLC system. When the tooling board runs to the stopper, the stopper blocks the tooling board on the production line, and the information reading point reads and transmits the data information in the RFID tag on the tooling board to the main server. The server transmits the control information to the blocker so that the tooling board continues to run.

[0032] The workstations are located around the information reading point. The workstation receives the control...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com