Ladle lifting hydraulic system using vacuum circulation degassing method

A technology of vacuum cycle degassing and hydraulic system, applied in the field of hydraulic system, can solve problems such as the need to excavate ladle jacking pits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

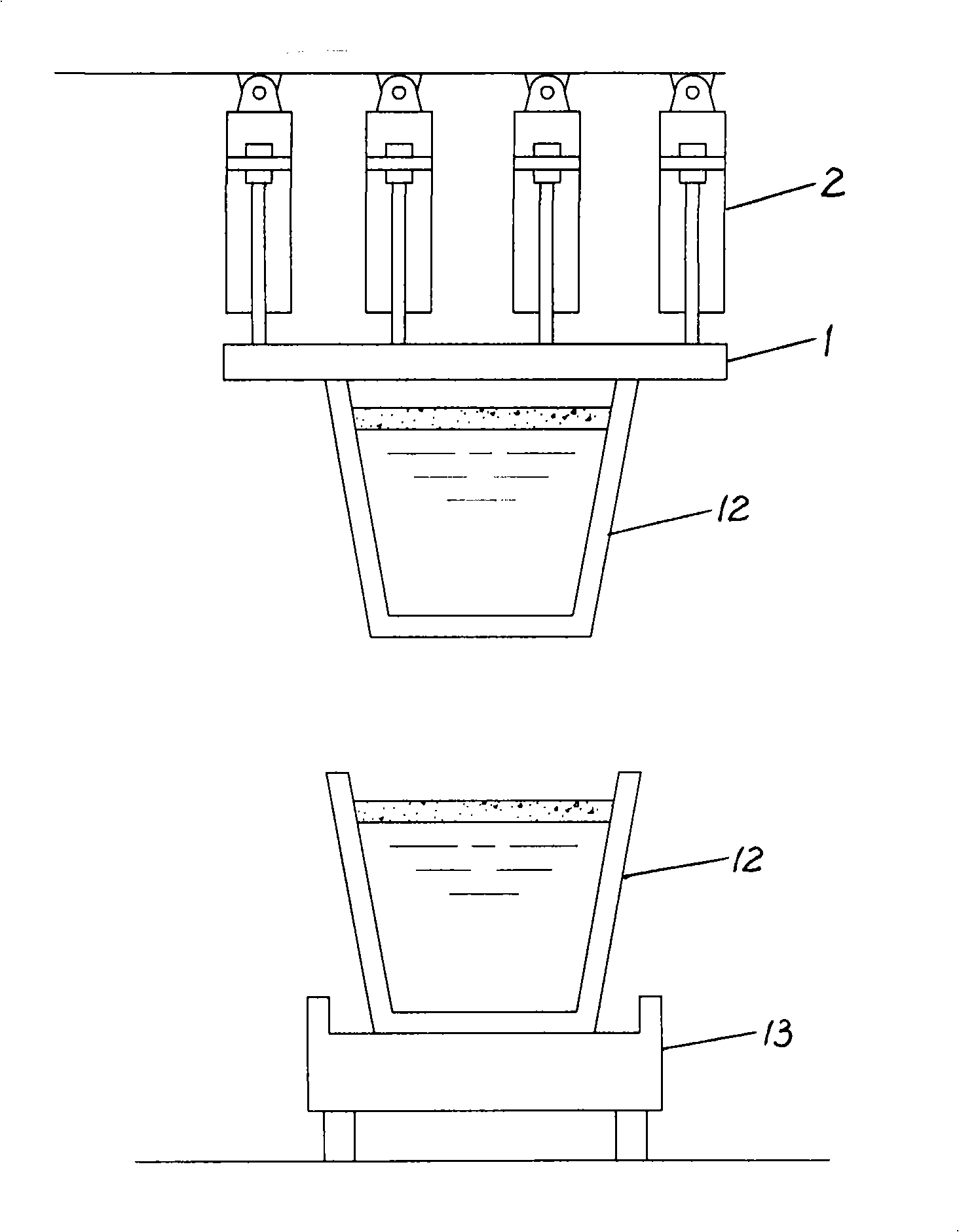

[0031] Attached below figure 2 , 3 A preferred embodiment of the present invention will be described in detail.

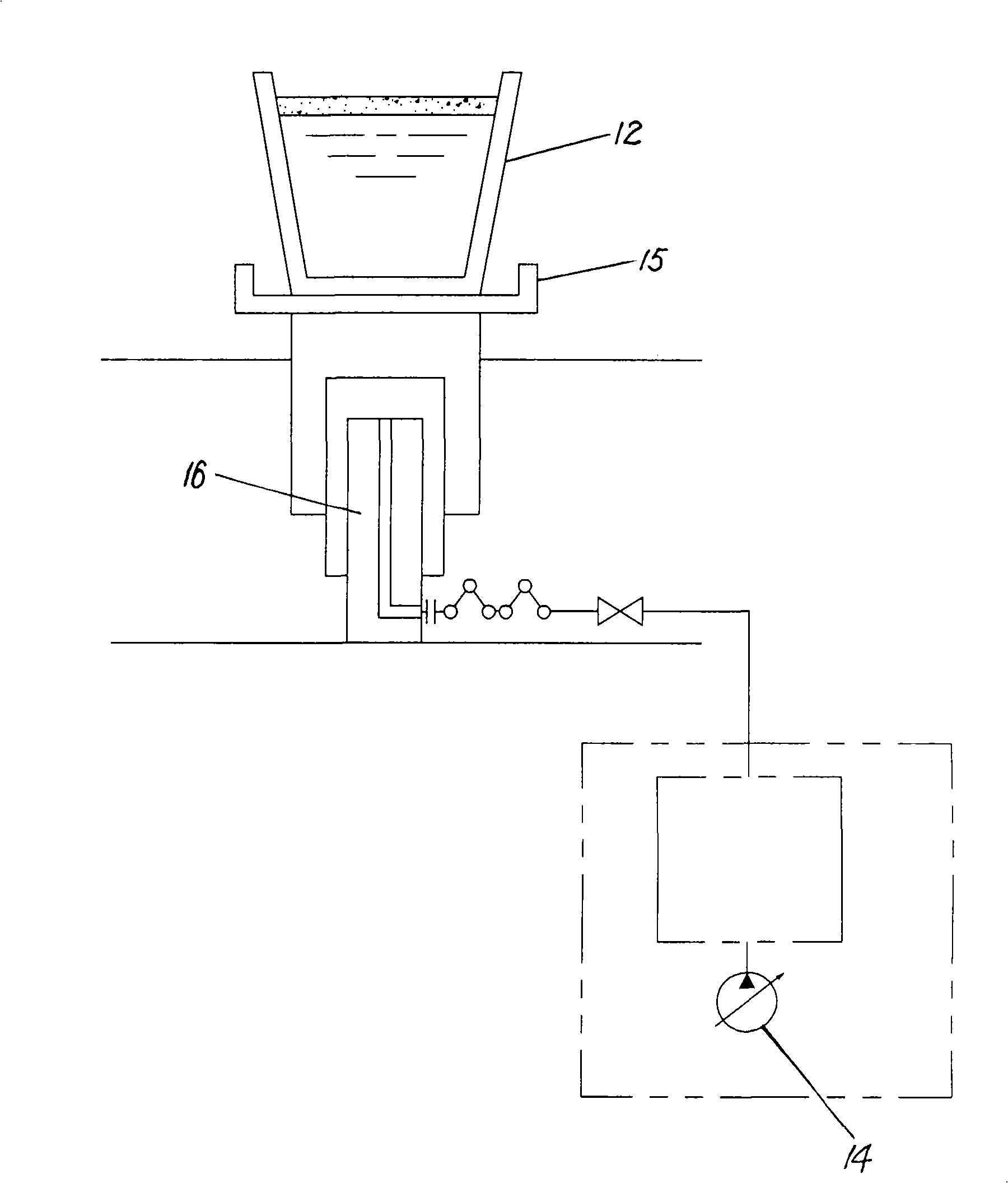

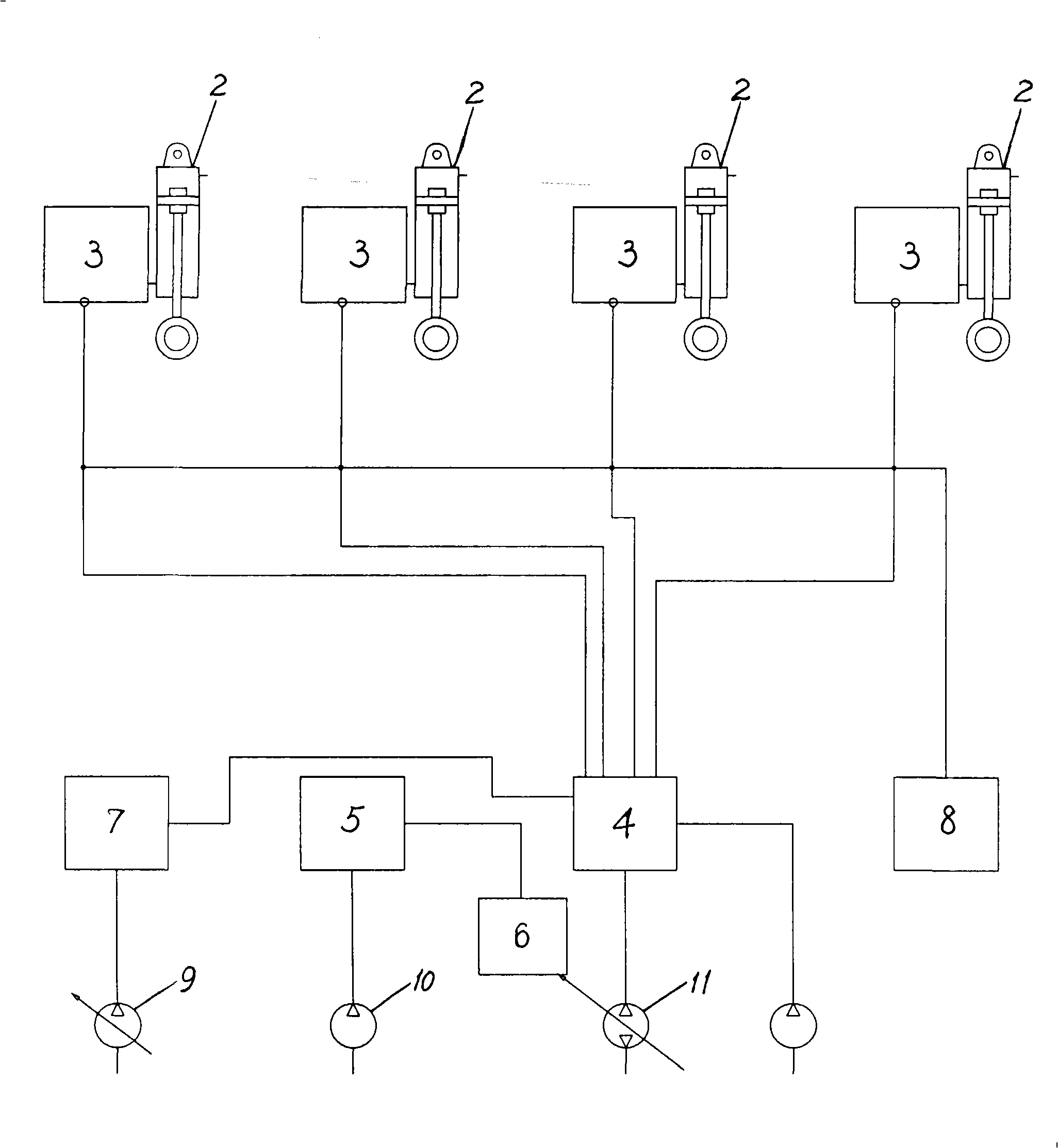

[0032] see figure 2 and image 3 , the vacuum circulation degassing method steel ladle lifting hydraulic system of the present invention is installed on the steel factory production line, is used for lifting steel ladle 12. The ladle lifting hydraulic system mainly consists of a ladle lifting frame 1, four ladle lifting hydraulic cylinders 2, a ladle trolley 13, a hydraulic cylinder synchronous control module 4, a main pump 11, a ladle lifting and speed control module 5, a Control pump 10, a pressure servo variable control module 6 and hydraulic pipelines connected between them.

[0033] A ladle hook device is installed on the ladle lifting frame 1, and the steel ladle 12 is movably fixed by the ladle hook at the center of the ladle lifting frame 1. The ladle hook and the auxiliary control module 7 are respectively connected to the hydraulic cylinder synchro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com