A filter type biological fermentation drying tower

A technology of biological fermentation and drying tower, which is applied in biological sludge treatment, dewatering/drying/concentrating sludge treatment, etc. Large, promote the effect of material turning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

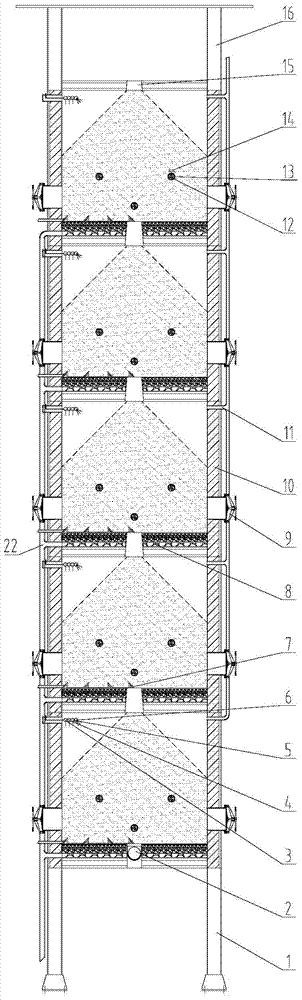

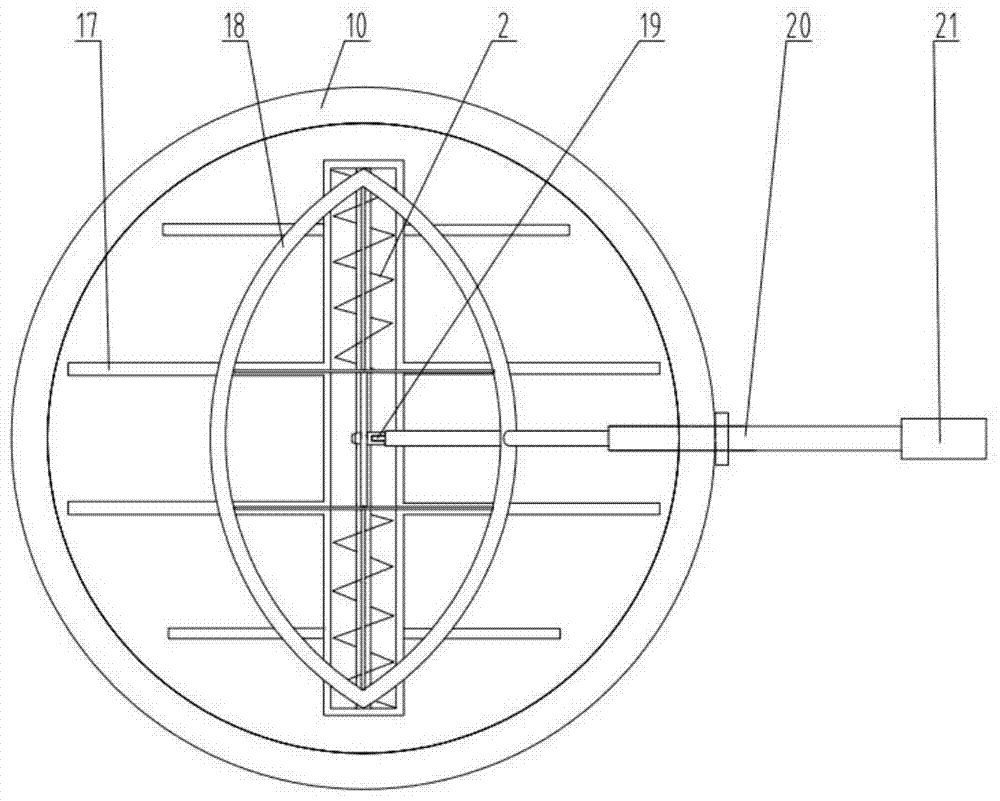

[0027] like figure 1 As shown, in this example, the water filtration type biological fermentation drying tower is equipped with five layers of fermentation chambers, including the bottom layer 1 of the drying tower, the tower body 10 of the drying tower, the tower top 16, the feed inlet 15, the carriage system 7, the material Floor height measuring instrument 3, air supply pipeline 12, air flow meter 13, valve 14, oxygen concentration measuring instrument in the tower 4, temperature measuring instrument in the tower 5, humidity measuring instrument in the tower 6, exhaust pipeline 11, percolation Type drainage system 8, screw conveyor 2, manhole 9 for maintenance and automatic control system.

[0028] The dewatered sludge is mixed with the material to be fermented on the tower top 16 from the feeding equipment through the feed port 15 into the fifth fermentation bin at the top of the drying tower body 10, the carriage system from the first fermentation bin to the fourth fermen...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com