Compact medium-width strip steel production process

A production process and wide-band steel technology, which is applied in the field of wide-band steel in the production of compact process layout, can solve the problems that the continuous casting slab cannot be directly heated into the heating furnace, the mold slag has strict performance requirements, and is not very compact, and achieves economical Benefits and technical level are improved, the process is compact and reasonable, and the effect of shortening the length

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0058] The technical solutions of the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

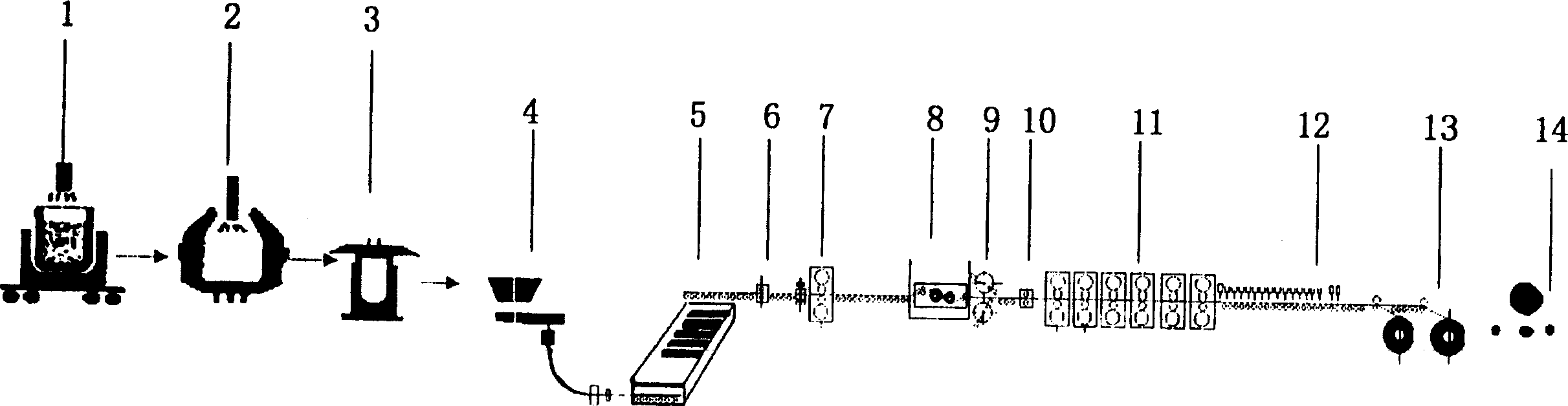

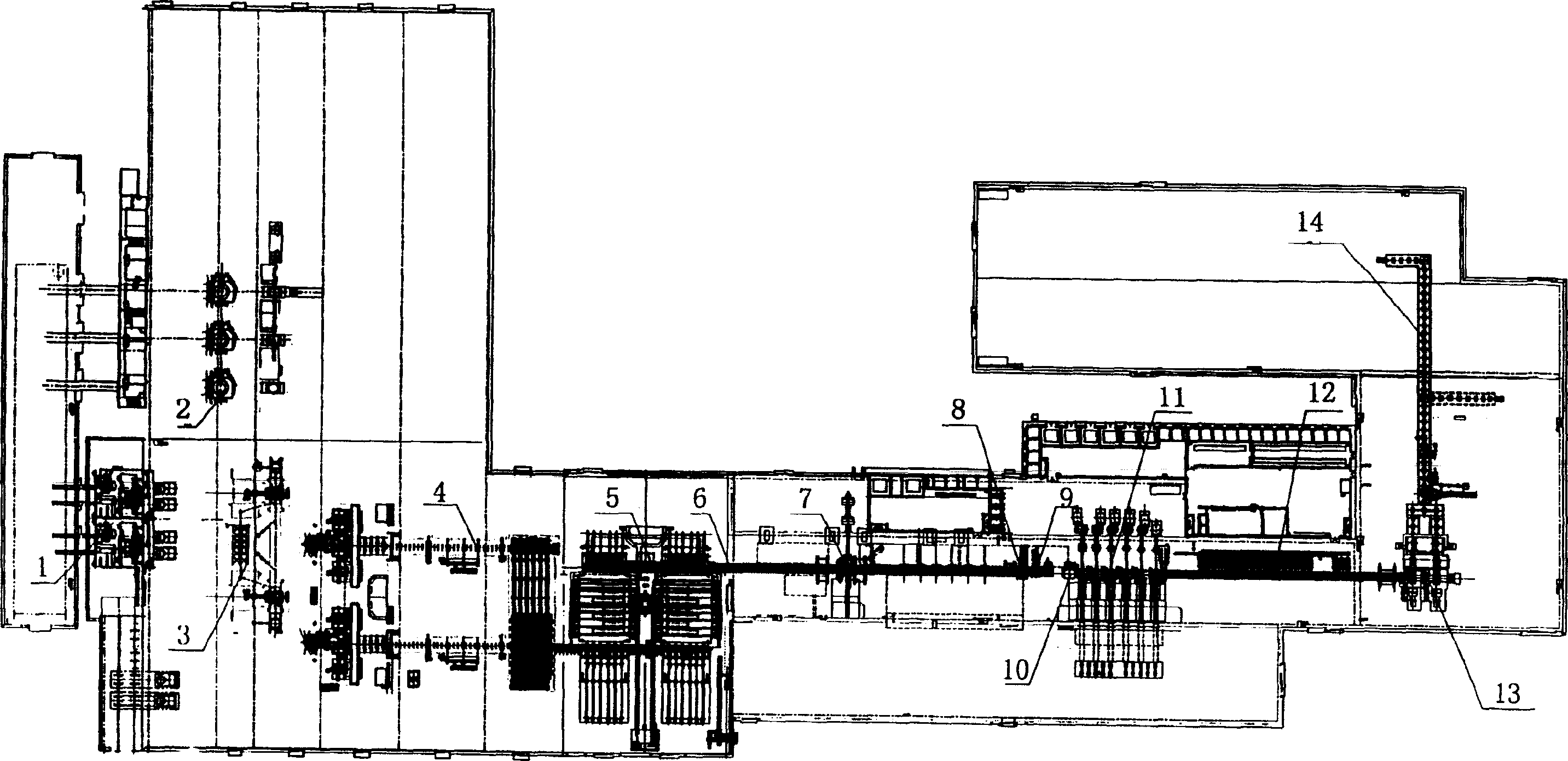

[0059] Such as figure 1 and figure 2 As shown, the present invention provides an embodiment of a high-compact medium and wide-band steel production process, which has made outstanding improvements to the prior art. The process steps are: hot metal desulfurization pretreatment 1, converter steelmaking 2, molten steel refining 3 , continuous casting 4, heating and soaking in walking beam heating furnace 5, billet descaling 6, rough rolling mill rolling 7, hot coil box coiling 8, intermediate billet cutting head and tail 9, intermediate billet descaling 10, finish rolling Process 11, strip steel laminar flow cooling system 12, coiling process 13, strip steel coil conveying 14. The present invention arranges all the production processes described above in the same factory building and in the factory buildings connected...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com