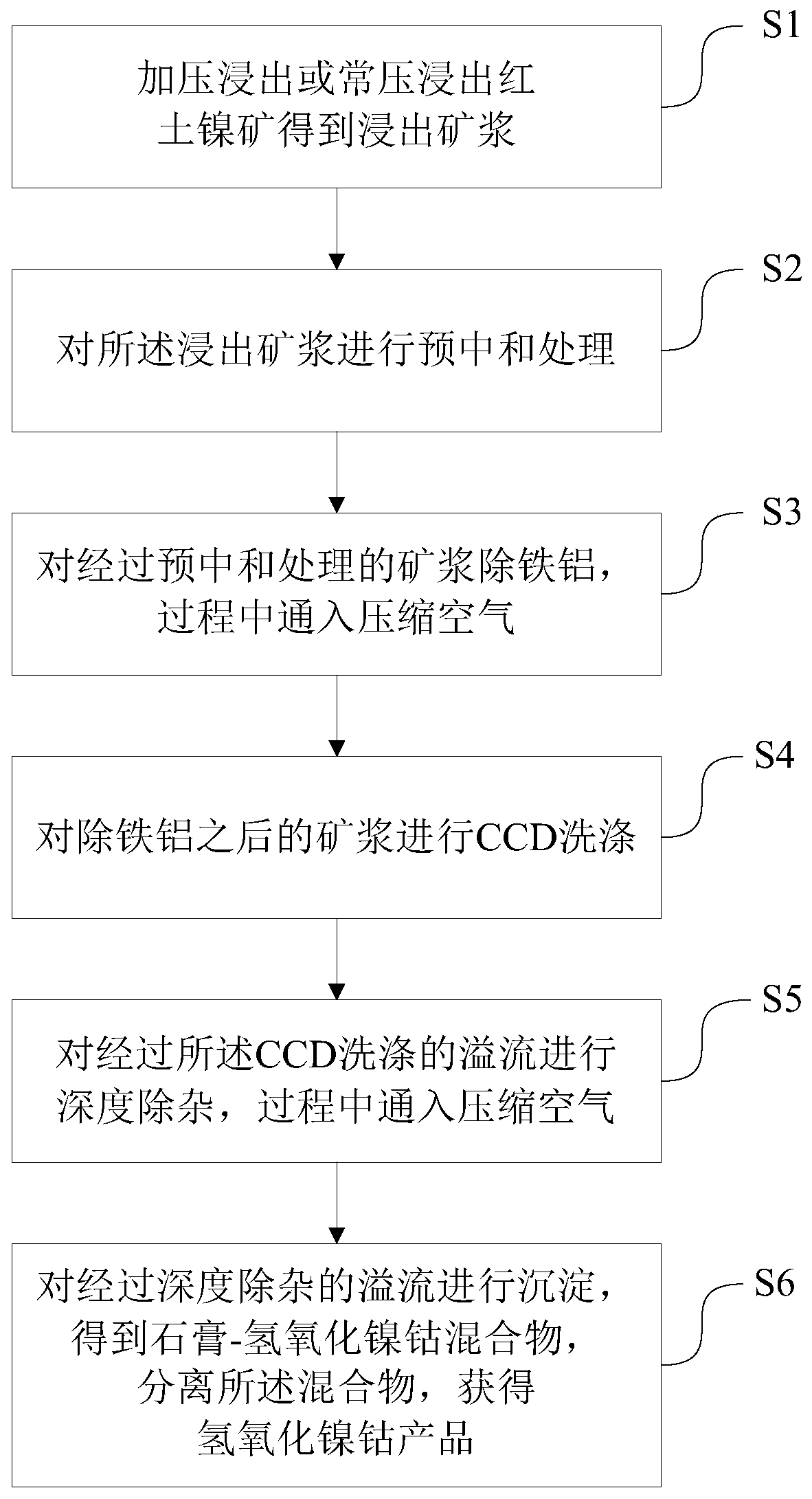

Method for producing nickel-cobalt hydroxide by hydrometallurgy of laterite nickel ore

A technology of nickel-cobalt hydroxide and laterite nickel ore is applied in the direction of improving process efficiency, which can solve the problems of high operating cost, poor settling energy, unfavorable post-separation, etc., and achieves lower production cost, easy separation and compact overall process. reasonable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

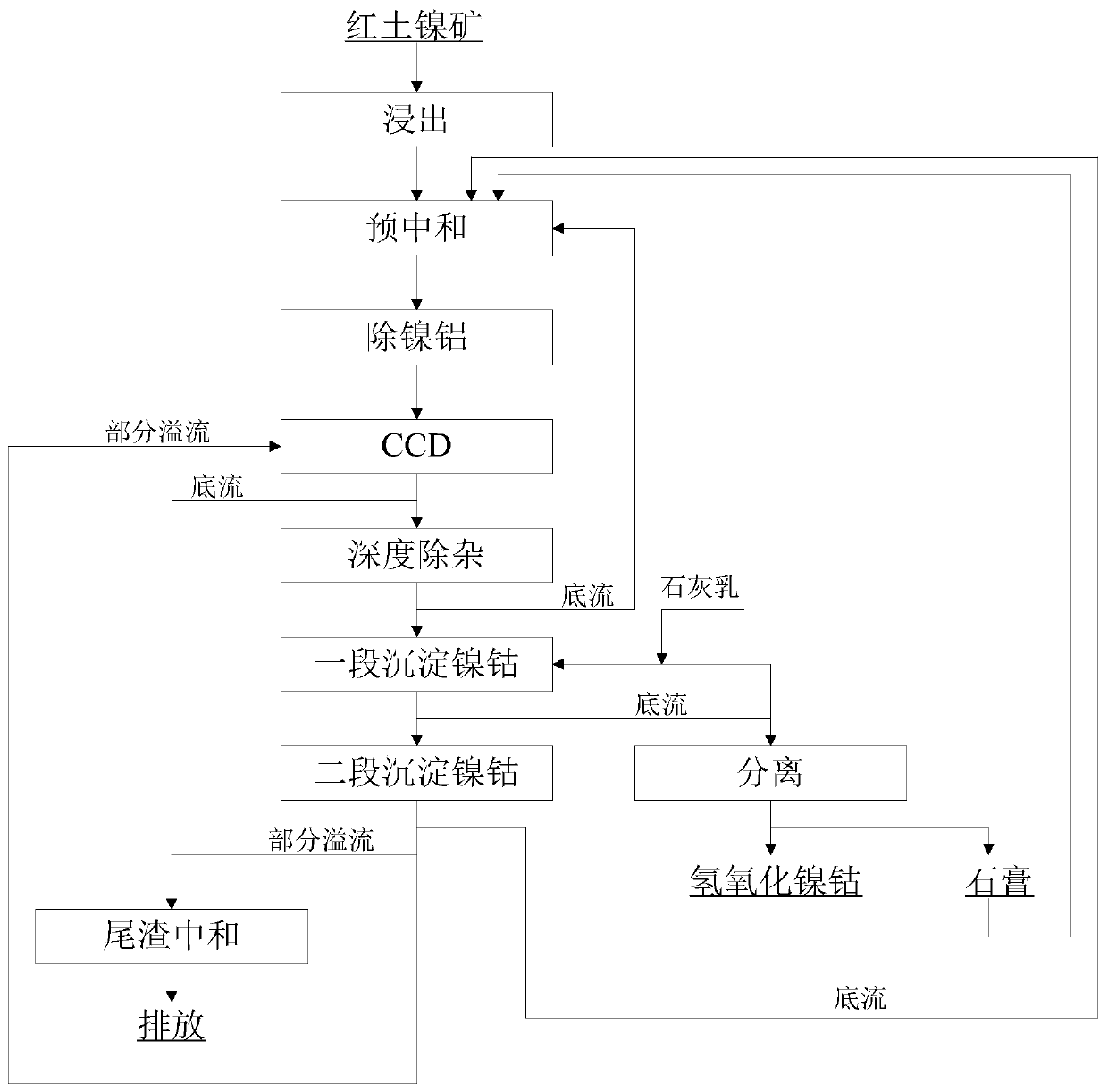

Method used

Image

Examples

Embodiment 1

[0030] Limonite-type lateritic nickel ore, with a nickel content of 1.4wt.%, an acid ore ratio of 350kg / t ore, and a leaching temperature of 240°C. After the leaching slurry is dissolved and returned to the mixture of the second-stage nickel-cobalt precipitation dense underflow slurry, the deep impurity-removing precipitation dense slurry, and the mixture of the gypsum slurry after the first-stage precipitation nickel-cobalt separation, add 20% concentration of magnesium oxide slurry and add 5kg / m 3 Sodium sulphate for pulp, to pH = 1.8. Continue to add magnesia pulp, feed compressed air, and adjust the pH value to 3.8, then enter the 6-stage CCD washing, the washing water is 2 times, the underflow is neutralized with lime milk, the overflow is added to the magnesia pulp, and the compressed air is fed to adjust the pH Dense after the value reaches 5.0. The underflow returns to leaching, and the overflow is used to precipitate nickel and cobalt. The precipitation uses 20% lime...

Embodiment 2

[0034] The limonite-type lateritic nickel ore and the residual ore-type lateritic nickel ore with a mass ratio of 4:1 have a nickel content of 1.6wt.%, an acid ore ratio of 480kg / t ore, and a leaching temperature of 240°C. After the leaching slurry is dissolved and returned to the mixture of the second-stage nickel-cobalt precipitation dense underflow slurry, the deep impurity-removing precipitation dense slurry, and the mixture of the gypsum slurry after the first-stage precipitation nickel-cobalt separation, add 20% concentration of magnesium oxide slurry and add 5kg / m 3 Sodium sulphate for pulp, to pH = 1.8. Continue to add magnesia pulp, feed compressed air, and adjust the pH value to 3.8, then enter the 6-stage CCD washing, the washing water is 2 times, the underflow is neutralized with lime milk, the overflow is added to the magnesia pulp, and the compressed air is fed to adjust the pH Dense after the value reaches 5.0. The underflow returns to leaching, and the overflo...

Embodiment 3

[0038] Limonite-type lateritic nickel ore, with a nickel content of 1.4wt.%, an acid ore ratio of 350kg / t ore, and a leaching temperature of 240°C. After the leaching slurry is dissolved and returned to the mixture of the second-stage nickel-cobalt precipitation dense underflow slurry, the deep impurity-removing precipitation dense slurry, and the mixture of the gypsum slurry after the first-stage precipitation nickel-cobalt separation, add 20% concentration of magnesium oxide slurry and add 5kg / m 3 Sodium sulphate for pulp, to pH = 1.8. Continue to add magnesia pulp, pass in compressed air, adjust the pH value to 3.8, then enter the 6-stage CCD washing, the washing water is 2 times, neutralize the underflow with lime milk, add magnesia pulp to the overflow, and pass in compressed air to adjust the pH Dense after the value reaches 5.0. The underflow returns to leaching, and the overflow is used to precipitate nickel and cobalt. The precipitation uses 20% lime milk, CaO / Ni=1.9...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com