Method for preparing water purifying agent poly-ferric sulfate chloride by utilizing iron-containing wastewater in potassium fluotitanate production

A technology of ferric sulfate chloride and potassium fluorotitanate, applied in chemical instruments and methods, multi-stage water/sewage treatment, neutralized water/sewage treatment, etc., can solve problems such as iron-containing wastewater pollution, and achieve simplified treatment process , overcoming poor, easy-to-control effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

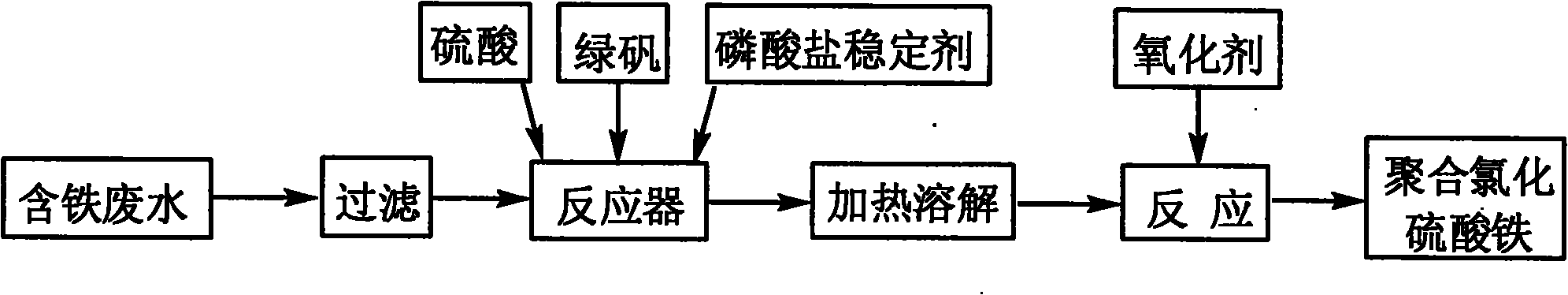

Method used

Image

Examples

Embodiment 1

[0032] (1) Add 75L of iron-containing waste water produced by filtered potassium fluotitanate into a 150L corrosion-resistant reactor, add 62kg of vitriol and 3.84L of industrial sulfuric acid with a concentration of 98% by mass, and then add dihydrogen phosphate Sodium-sodium tartrate composite stabilizer (the mol ratio of sodium tartrate and phosphorus is 0.1: 1) 4.60kg, be warming up to 50 ℃ of dissolvings and make solution;

[0033] (2) Slowly add a saturated solution containing 4.72kg of sodium chlorate dropwise to the above solution, and react at 60-70°C for 1 hour to obtain a dark red transparent viscous liquid, and measure its T Fe=10.52%, B=7.11%, density ρ=1.41g / cm 3 (20°C), sample A, that is, water purifying agent.

Embodiment 2

[0035] (1) Add 75L of iron-containing waste water produced by filtered potassium fluotitanate into a 150L corrosion-resistant reactor, add 62kg of vitriol and 3.38L of industrial sulfuric acid with a concentration of 98% by mass, and then add dihydrogen phosphate Sodium-sodium tartrate composite stabilizer (the mol ratio of sodium tartrate and phosphorus is 0.126: 1) 5.02kg, be warming up to 60 ℃ of dissolvings and make solution;

[0036] (2) Slowly add a saturated solution containing 4.82kg of sodium chlorate dropwise to the above solution, and react at 70-80°C for 1 hour to obtain a dark red transparent viscous liquid, and measure its T Fe =10.67%, B=8.41%, density ρ=1.42g / cm 3 (20°C), sample B, that is, water purifying agent.

Embodiment 3

[0038] (1) Add 75L of iron-containing waste water produced by filtered potassium fluotitanate into a 150L corrosion-resistant reactor, add 62kg of vitriol and 3.14L of industrial sulfuric acid with a concentration of 98% by mass, and then add dihydrogen phosphate Sodium-sodium tartrate composite stabilizer (the mol ratio of sodium tartrate and phosphorus is 0.15: 1) 5.34kg, be warming up to 70 ℃ of dissolvings and make solution;

[0039] (2) Slowly add a saturated solution containing 4.96kg of sodium chlorate dropwise to the above solution, and react at 70-80°C for 1 hour to obtain a dark red transparent viscous liquid, and measure its T Fe =11.34%, B=9.03%, density ρ=1.43g / cm 3 (20°C), sample C, that is, water purifying agent.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com