Method and device for preparing household garbage derived fuel

A domestic waste and derived fuel technology, applied in the field of manufacturing high-quality waste-derived fuel, can solve the problems of ineffective mechanical sorting, reducing the calorific value of waste, and complicated processes, etc., to achieve easy operation and mechanized control, reduce moisture content, The process is compact and reasonable

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

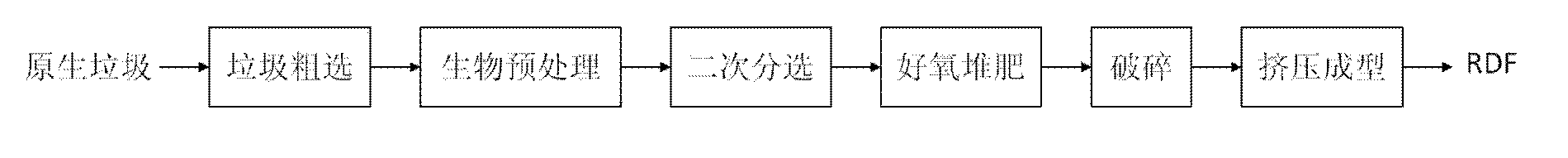

[0060] A municipal solid waste treatment plant with a daily processing capacity of 1,000 tons. After the primary waste enters the plant, it undergoes processes such as waste bag breaking and rough separation, biological pretreatment, waste fine separation and recycling of resource-based products, bio-composting treatment, and preparation of waste-derived fuels. , Realize the reduction, harmlessness and recycling of domestic waste.

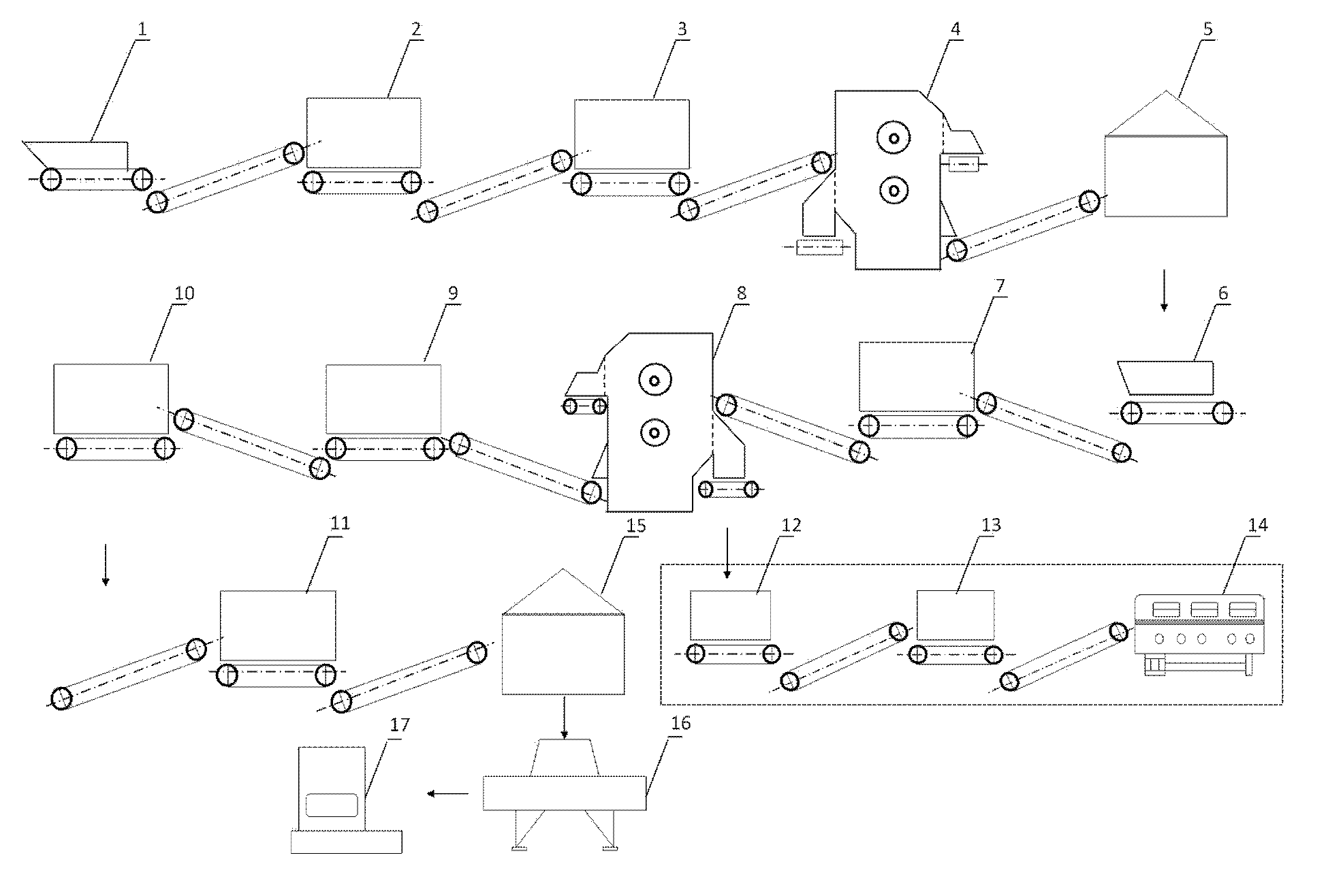

[0061] 1. Coarse sorting of domestic garbage: After the raw garbage enters the receiving port 1, it will be screened by two-stage bag-breaking screening device. The drum screen is 8m long and the drum diameter is 2m. ; The secondary bag-breaking drum sieve 3 is a strip-shaped sieve hole with an aperture of 10cm. Bulk garbage, unbroken bag garbage, shoes, etc. are separated and collected, and the undersize enters the first-level magnetic separation device 4 and is divided into three parts: ferromagnetic materials, inert materials and organic materia...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com