On-line red steel elbow straightener

A straightening machine and elbow technology, which is applied in the field of metallurgical auxiliary equipment, can solve problems such as bar bending at the exit of the rolling mill, and achieve the effects of improving the yield, saving time and trouble, and reducing burden and pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

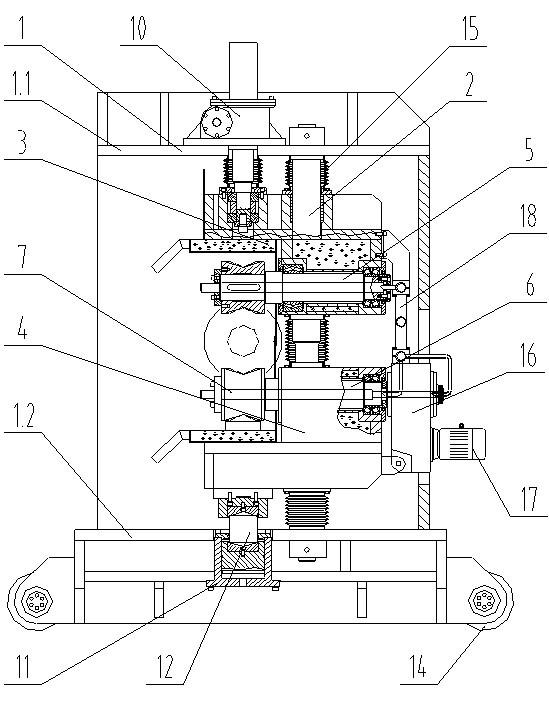

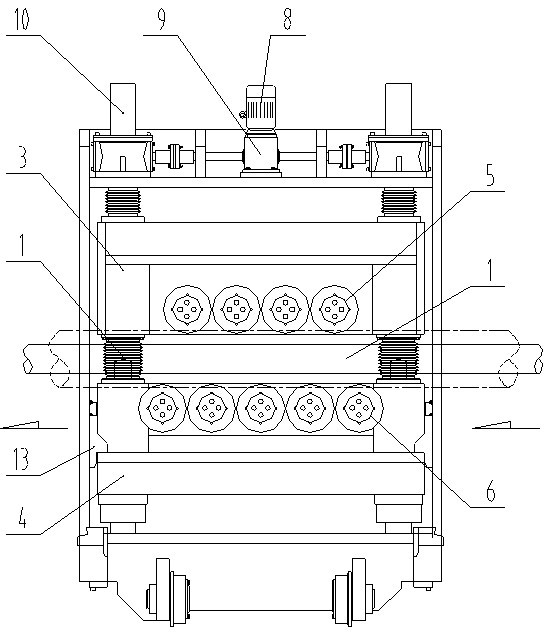

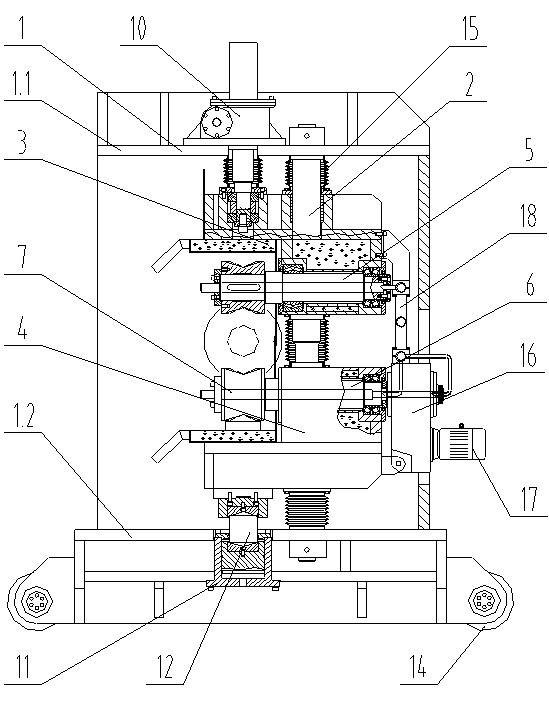

[0037] see figure 1 , figure 2 , the present invention relates to an online red steel elbow straightening machine, which includes a frame 1, the frame 1 includes a top plate 1.1 and a bottom plate 1.2, two guide columns 2 are arranged between the top plate 1.1 and the bottom plate 1.2, The two guide columns 2 are symmetrically arranged left and right, and the upper movable beam 3 and the lower movable beam 4 are set on the two guide columns 2, and a plurality of driven shafts 5 are arranged on the upper movable beam 3 through bearings. The centerlines of the driven shafts 5 are located on the same horizontal plane, and the lower movable beam 4 is provided with a plurality of active shafts 6 through bearings, the centerlines of the plurality of driven shafts 6 are located on the same horizontal plane, and the plurality of driven shafts are arranged on the same horizontal plane. 5 and a plurality of driving shafts 6 are arranged staggered along the horizontal direction, each o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com