Sand-coating molding device and method for large metal mold

A technology of sand-covered molding and iron molding, which is applied to molding machines, manufacturing tools, casting molding equipment, etc., can solve problems such as difficulty in maintaining consistent sand shooting pressure, difficulty in guaranteeing sand-coated quality, and huge sand-coated molding mechanism. The effect of smooth conveying logistics, compact and compact sand covering, and simplified equipment procedures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

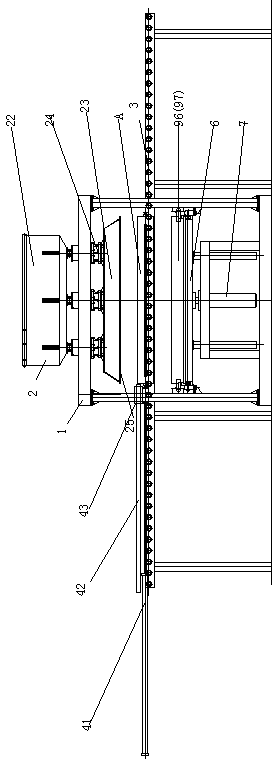

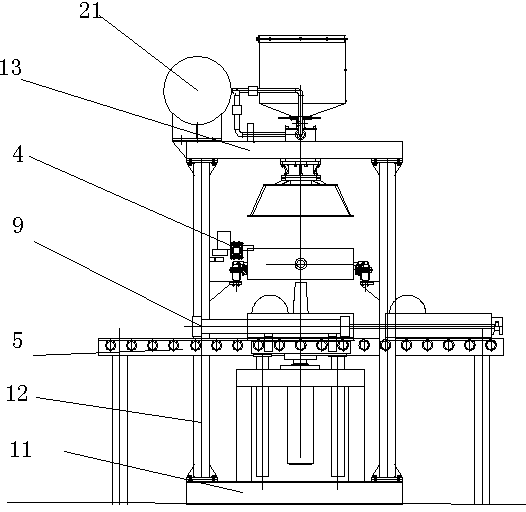

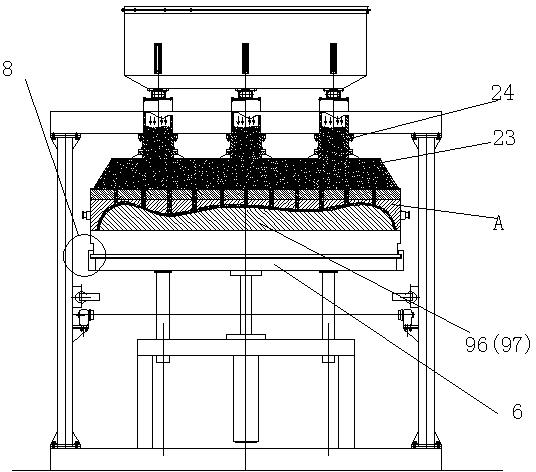

[0024] see figure 1 , 2 , 4, 5, 8, the present invention includes a support frame 1, a sand-covered sand shooting device 2, an iron-shaped conveying roller table 3, an iron-formed box delivery device 4, a model conveying roller table 5, a lifting table 6, and a lifting hydraulic cylinder 7 , Elevating mold closing device 8 and model shuttle moving device 9.

[0025] The support frame 1 includes a lower beam base 11, a column 12 and an upper beam 13, and the three are fixed and installed with each other to form an integral structure. Lifting table 6 is fixedly installed on the lifting hydraulic cylinder 7, and rises and falls along with the lifting of lifting hydraulic cylinder 7. The support frame 1, the price-raising workbench 6, and the lifting hydraulic cylinder 7 form a sand-covered molding station. The lifting hydraulic cylinder 7 is installed and fixed on the lower beam base 11 . The iron-shaped conveying roller table 3 part is fixedly installed on the column 12, and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com