Method for rapidly measuring particle size of titanium nitride in high-speed wire steel

A high-speed wire rod, rapid measurement technology, used in particle size analysis, measuring device, particle and sedimentation analysis, etc., can solve the problem of undetectable and unsuitable titanium nitride particle size, and achieve smooth product logistics, improved identification ability, and improved preparation. easy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0035] The rapid determination method of the particle size of titanium nitride in the high-speed wire steel of the present invention comprises the following steps:

[0036] 1) The sample is analyzed by spark spectrometry, the time resolution window is opened at 60-350 μs, the sample is sparked 2000 times, and the light intensity measured by the titanium element channel is recorded for each discharge; figure 1 shown;

[0037] 2) Establish a calculation model:

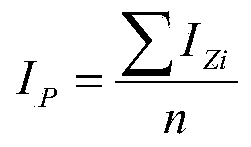

[0038] In order to obtain an accurate average value of normal pulse light intensity, abnormal pulses need to be eliminated successively. Titanium normal pulse (i.e. solid solution titanium part) light intensity I Zi The calculation formulas of the average value Ip and the standard deviation S are as follows formulas 1 and 2:

[0039] I P = Σ I Zi n Formula 1; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com