Factory production working system and its operating method

A processing system and factory-produced technology, applied in the direction of exposure devices, optics, instruments, etc. in the photoengraving process, which can solve the problems of multiple production lines, production line stoppages, and unsmooth logistics transmission lines, and achieve smooth logistics and reduce manufacturing costs. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

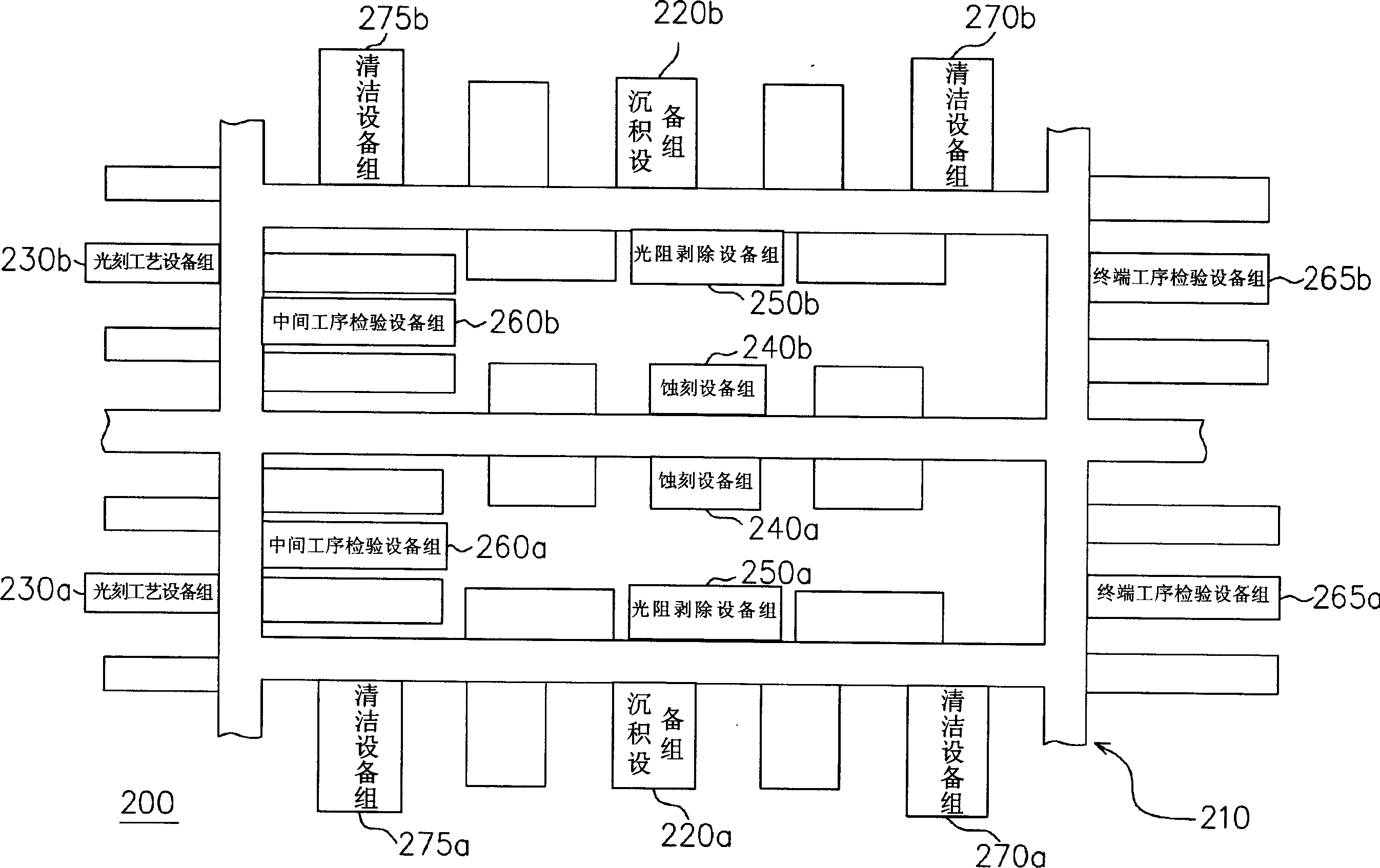

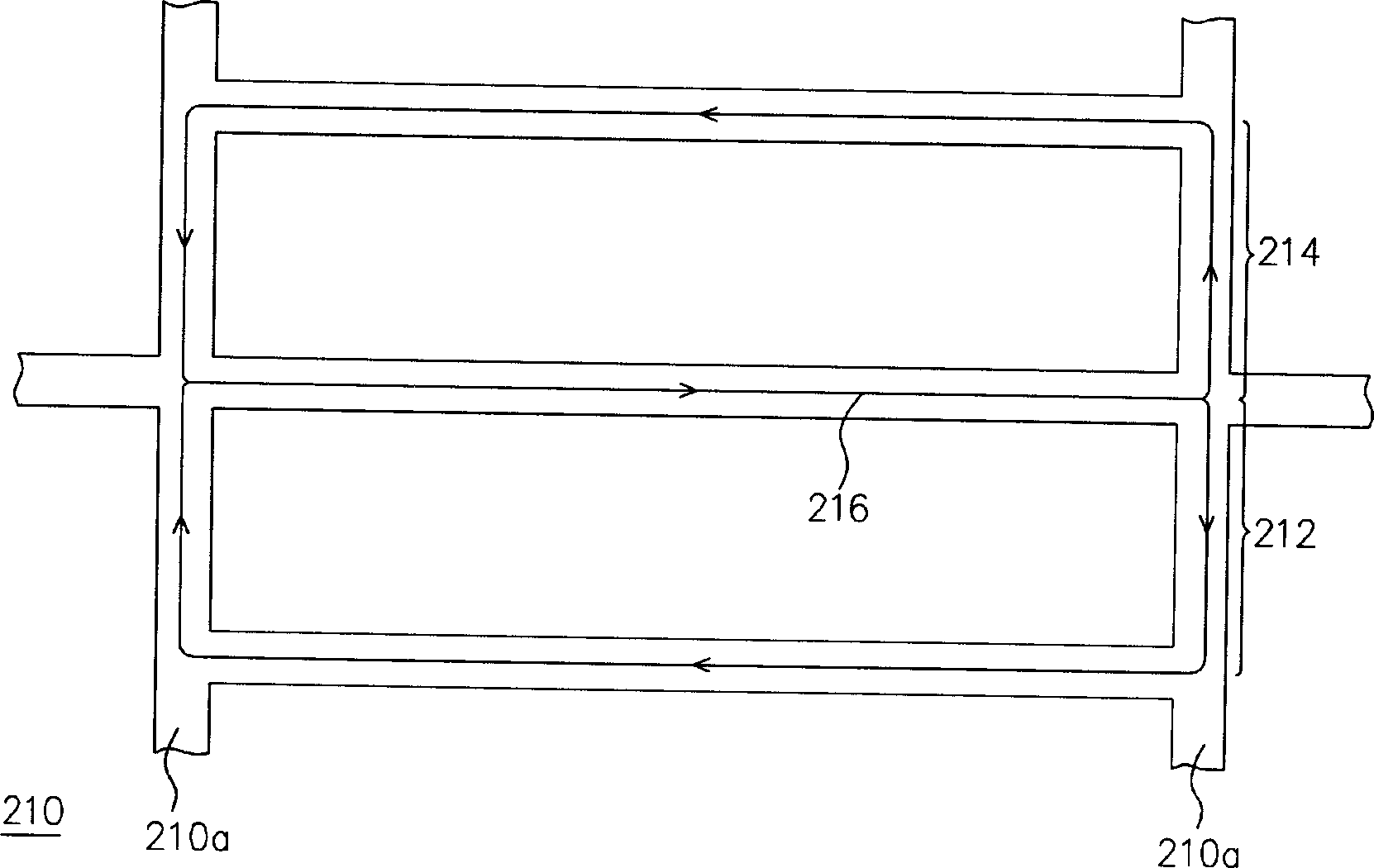

[0011] Figure 2A It is a schematic diagram of a factory production and processing system in a preferred embodiment of the present invention. Figure 2B for Figure 2A Schematic diagram of the route of the transmission system of the production and processing system in the factory. Please also refer to Figure 2A and 2B , the factory production and processing system 200 of the present invention is suitable for manufacturing liquid crystal displays (Liquid Crystal Display, LCD) or other semiconductor components. Engraving process equipment groups 230a, 230b, two etching equipment groups 240a, 240b, two photoresist stripping equipment groups 250a, 250b, etc. The transport system 210 includes, for example, an automated material handling system (Automatic Material Handling System, AMHS), etc., and the automated material handling system, for example, at least includes an automatic guided vehicle (Automatic Guided Vehicle, AGV), an in-line storage warehouse (In-Line Stocker) or ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com