Low-torque spinning process

A low-torque, crafted technology, used in spinning machines, continuous-winding spinning machines, textiles and papermaking, etc., can solve the problems of easy breakage, low strength, and high yarn twist, and achieve good prospects for social benefits and efficiency. Improved, less hairy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

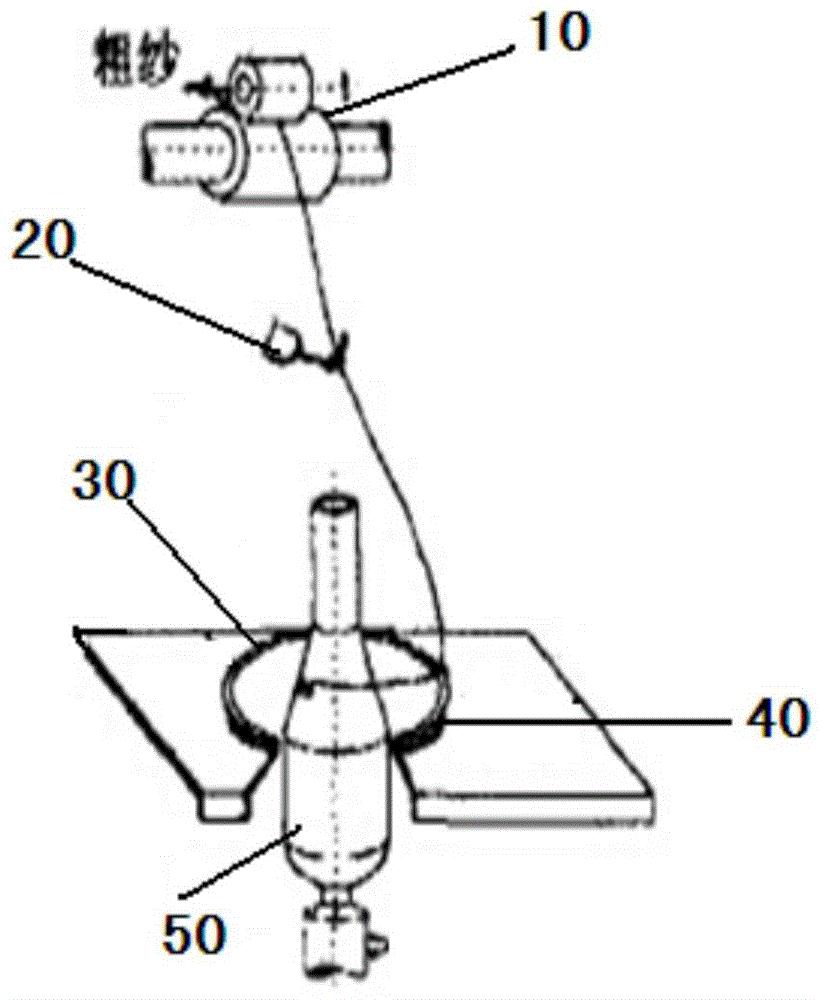

[0027] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific illustrations.

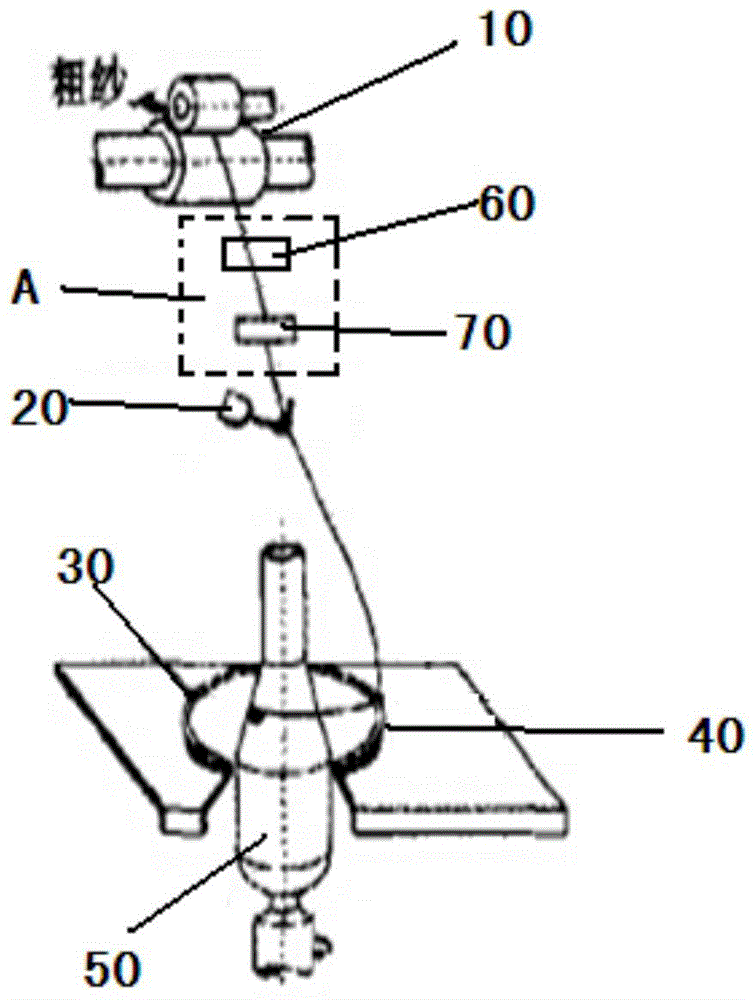

[0028] see figure 2 with image 3 Shown, the present invention discloses a kind of low torque spinning technique; This technique comprises the steps:

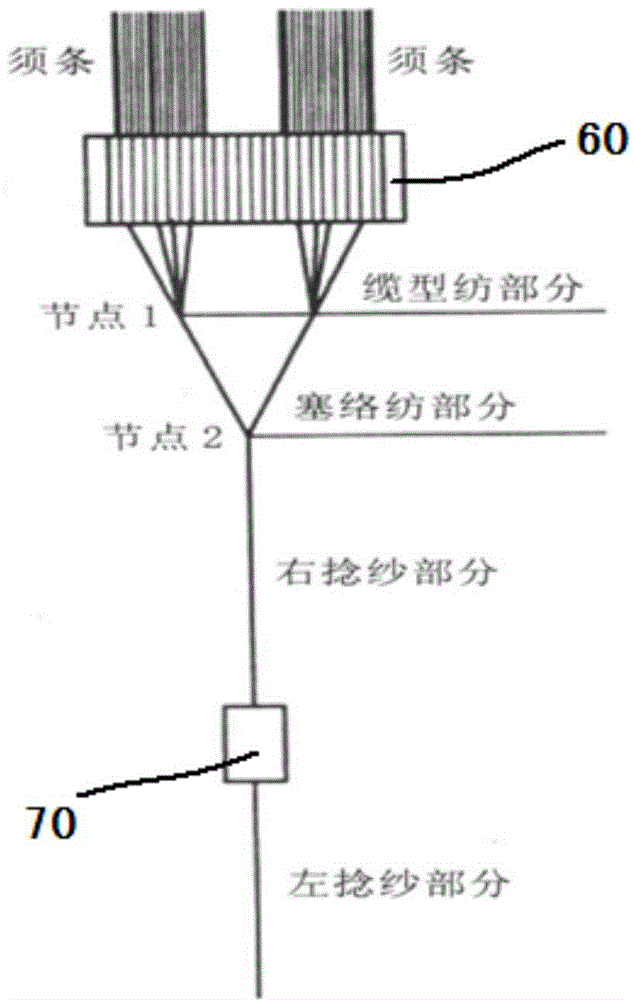

[0029] (1) First, the spinning frame is fed with double rovings, and the two rovings always keep a certain distance in the drafting area of the drafting device of the spinning frame and move downward equally. The bar is sent to the fiber arrangement adjustment device installed between the front roller 10 and the yarn guide hook 20 after going out of the front jaw of the spinning frame, that is, on the dividing wheel 60 .

[0030] (2) Each strand is immediately divided into more than two fiber bundles by the separator wheel 60, and the fiber bundles first rotate around the center of rotation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com