Lead frame of pinless encapsulation

A lead frame, leadless technology, applied in the field of lead frames, can solve the problems of short life, decreased output per hour, wear of the blade and so on

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

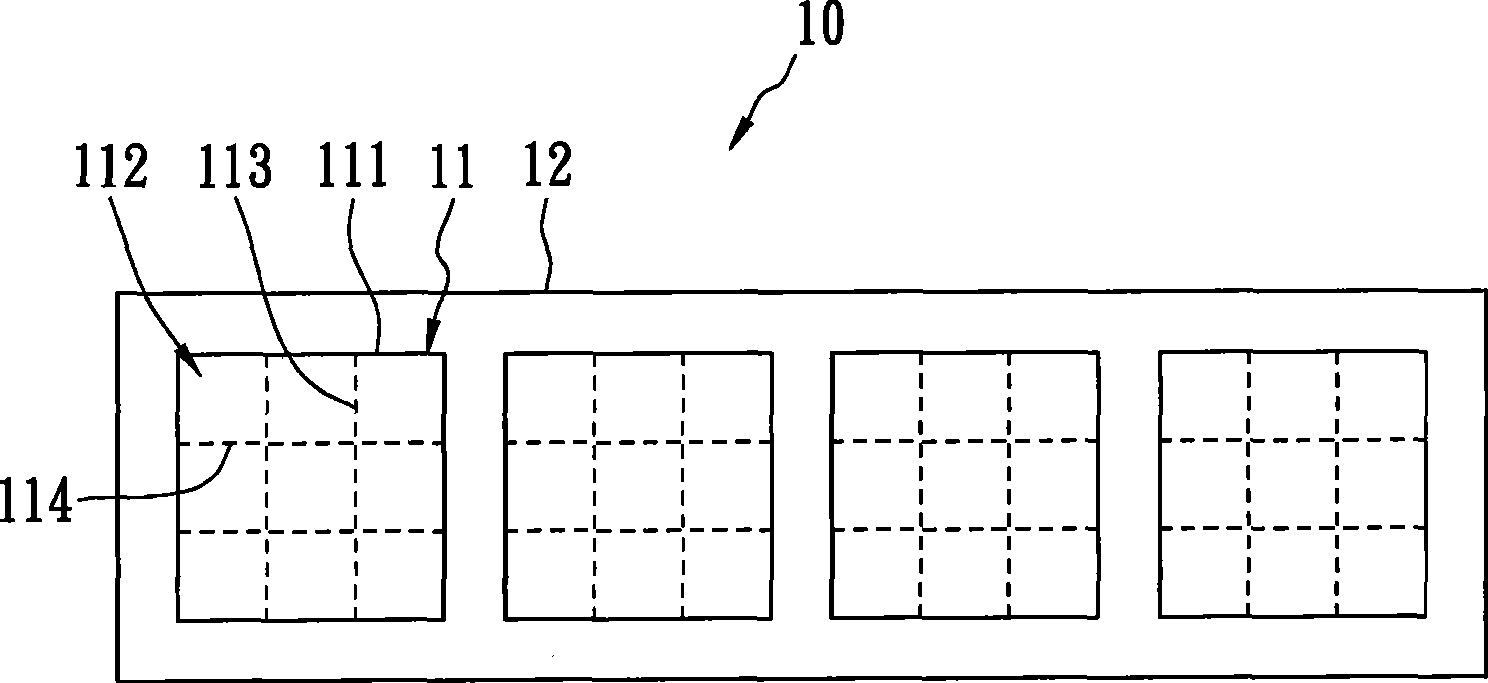

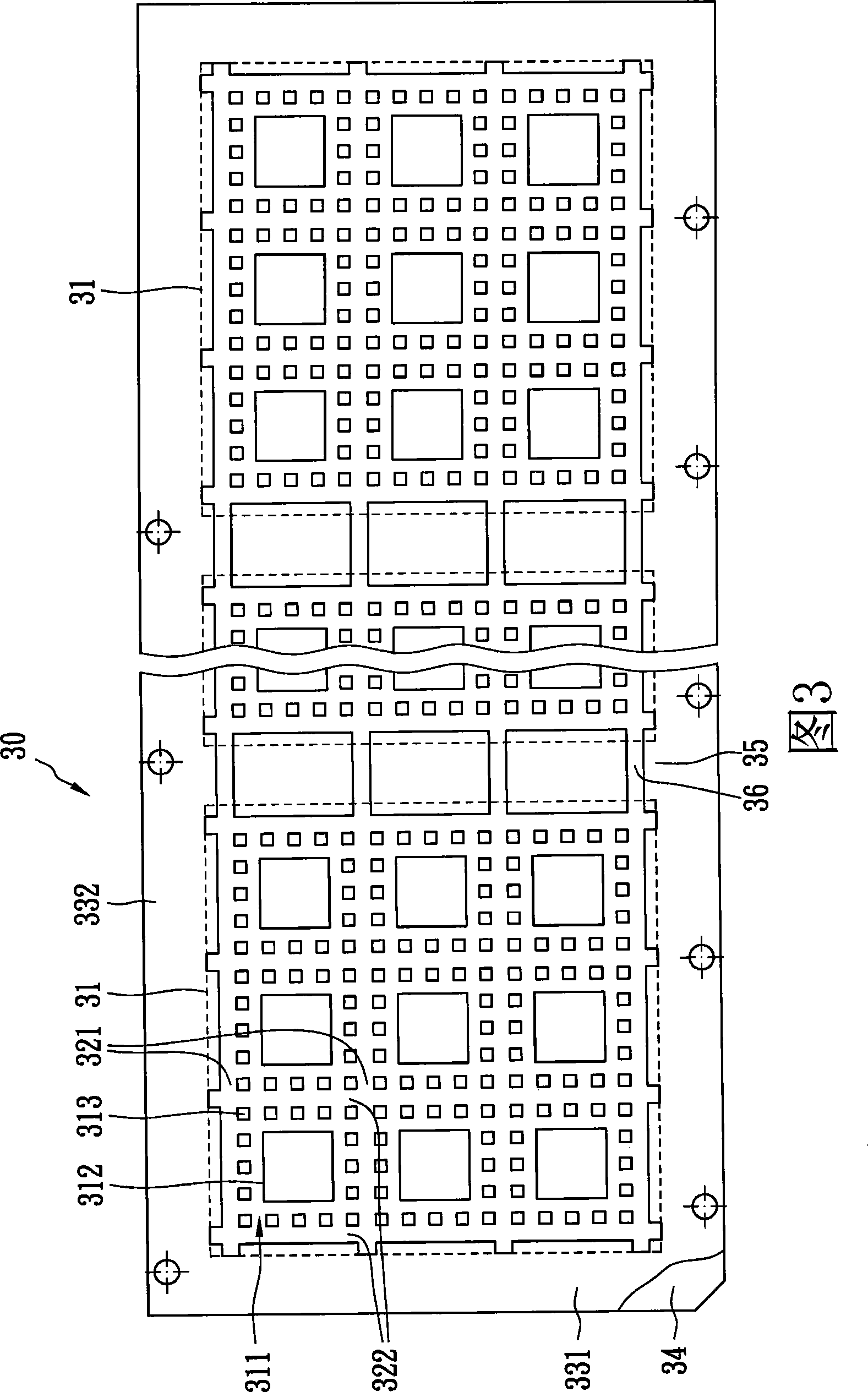

[0021] FIG. 3 is a top view of a lead frame of the present invention for a leadless package. The lead frame 30 includes a plurality of packaging areas 31 , a plurality of gaps 321 , 322 , a plurality of connecting portions 35 , a plurality of openings 36 and a tape or film 34 . Each packaging area 31 includes a plurality of packaging units 311 arranged in an array, and a connecting portion 35 is provided between two adjacent packaging areas 31 . The plurality of gaps 321, 322 are located around each package unit 311, wherein each gap 321 extends longitudinally along the lead frame 30, and is connected or communicated with the opening 36; connect. The plurality of openings 36 are provided at each connecting portion 35 and are aligned with the partial gaps 321 respectively. Each packaging unit 311 includes at least one die holder 312 , and pins 313 are distributed around the periphery of the die holder 312 . The adhesive tape 34 is used to fix the plurality of packaging regio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com