Transfer film structure

A transfer film and hardening film technology, applied in special decorative structures, printing, decorative art, etc., can solve the problems of ink pattern damage, ink layer damage, easy downward penetration, etc., to enhance structural strength and improve yield , the effect of preventing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be specifically introduced below in conjunction with the accompanying drawings and specific embodiments.

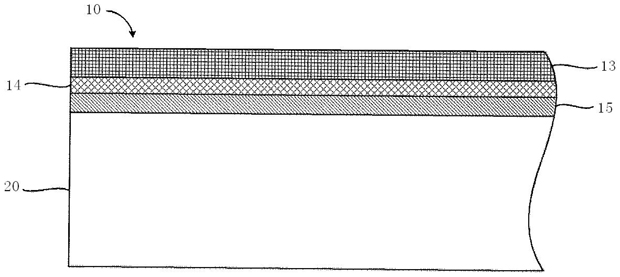

[0021] The present invention proposes a transfer film structure, which aims to prevent the glue on the adhesive film layer from penetrating into the decorative pattern layer, so as to maintain the integrity of the ink decorative pattern and strengthen the structural strength of the film layer.

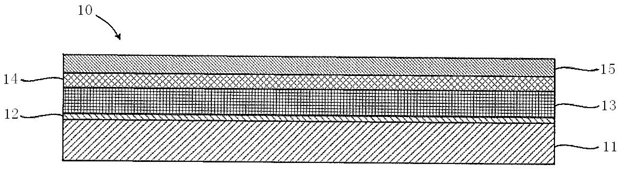

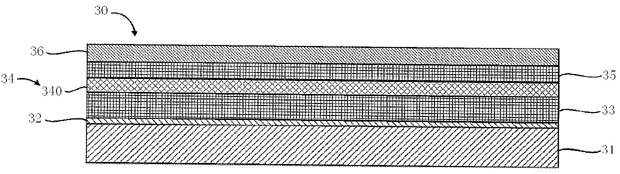

[0022] image 3 It is a schematic cross-sectional view of the first specific embodiment of the transfer film structure of the present invention. As shown in the figure, the transfer film structure 30 includes a base film layer 31, a release layer 32, a first cured film layer 33, a pattern layer 34, a second cured film layer 35 and an adhesive film layer 36 . Wherein, the release layer 32 is arranged on the upper surface of the base film layer 31, the first cured film layer 33 is arranged on the upper surface of the release layer 32, the pattern ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com