U-shaped short wheelbase high-speed and high-efficiency multi-wire cutting method

A multi-wire cutting, high-speed technology, applied in the direction of working accessories, fine working devices, stone processing equipment, etc., can solve the problems of affecting cutting stability, low cutting efficiency, easy to cause broken wires, etc., to reduce single-chip wire consumption The effect of reducing cost, improving sheet output efficiency, and shortening the wheelbase of the main roller

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

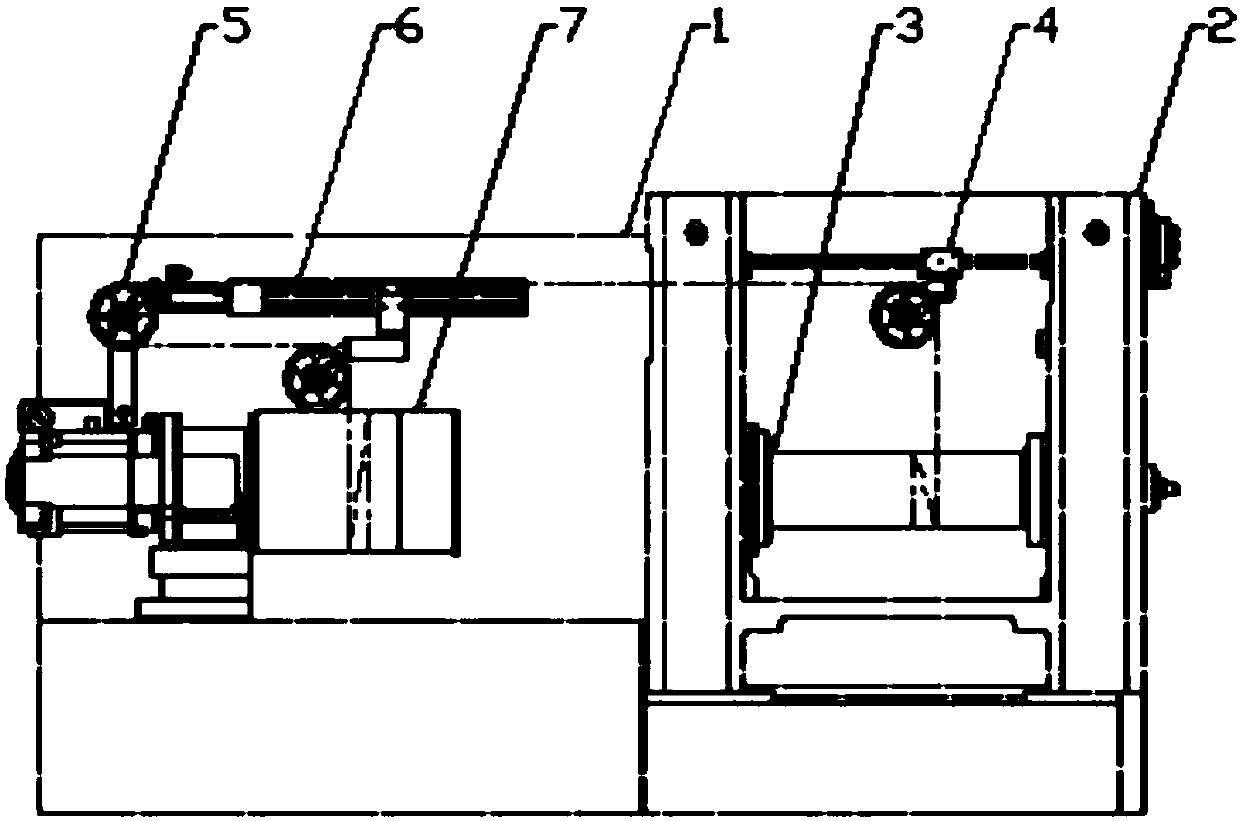

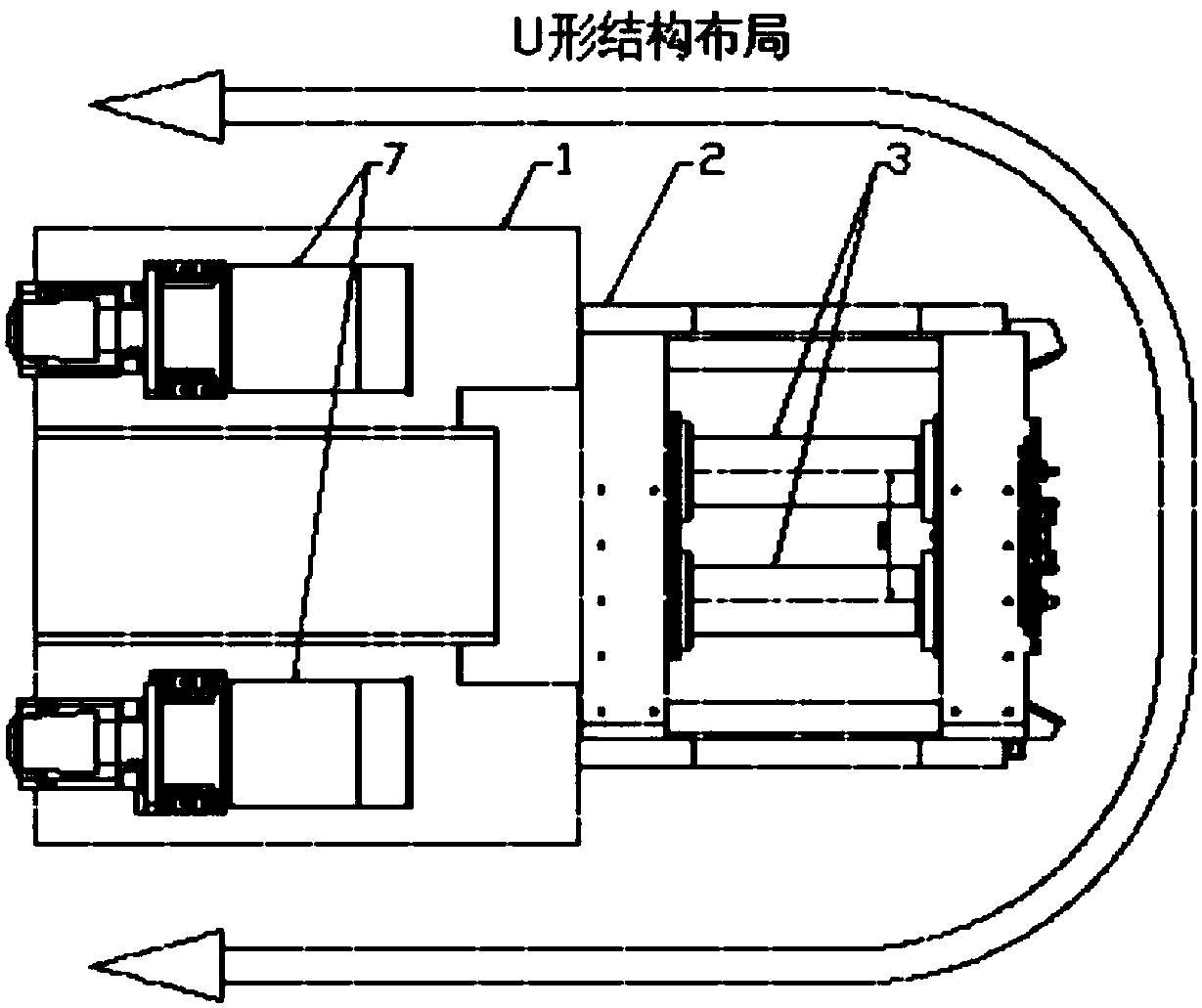

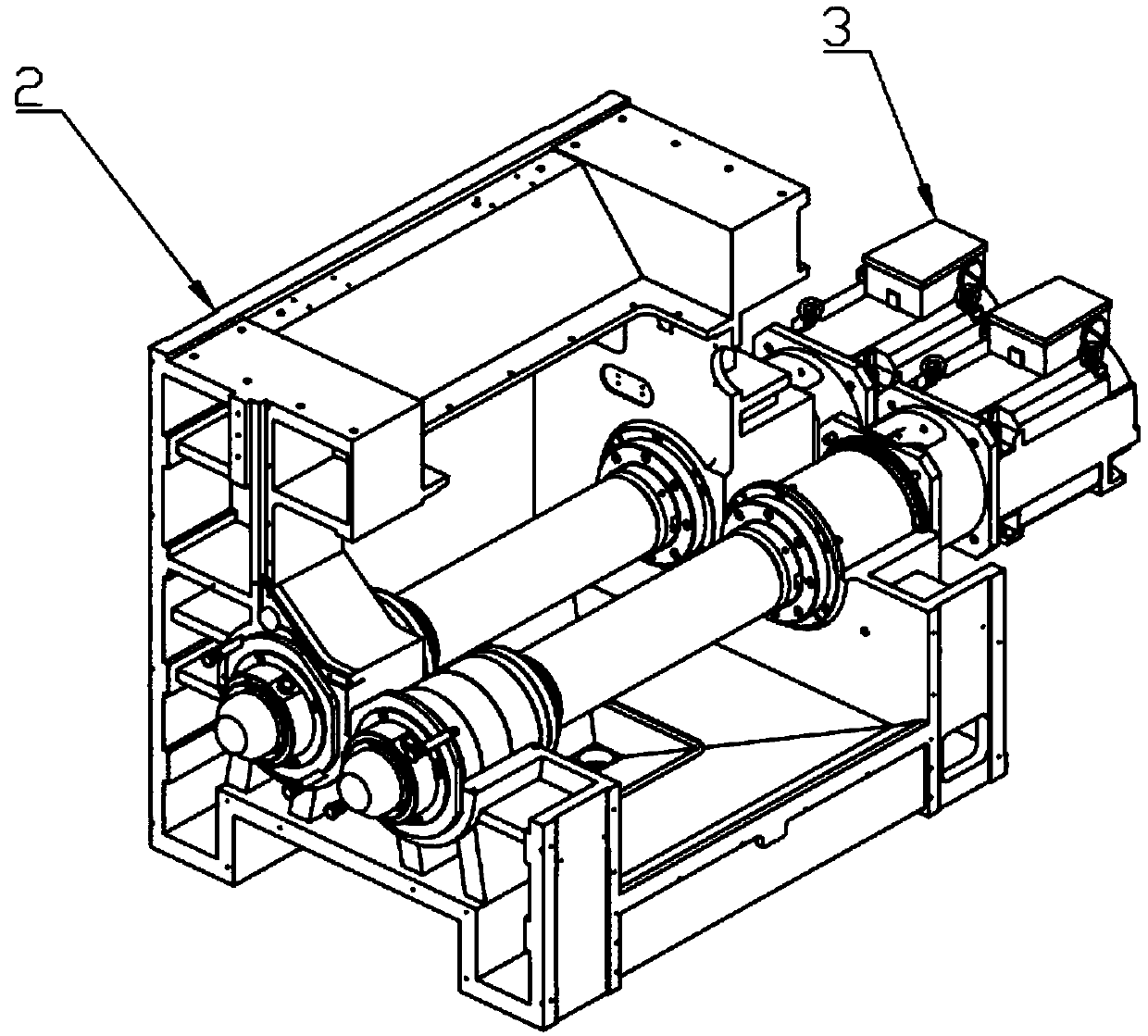

[0021] refer to figure 1 with figure 2 , a U-shaped short wheelbase high-speed and high-efficiency multi-wire cutting method adopts the overall structure of a U-shaped layout, including a frame 1, a cutting room system 2, a spindle system 3, a wire system 4, a tension system 5, and a cable system 6. Take-up / pay-off system 7; the take-up / pay-off system 7, the tension system 5, and the cable arrangement system 6 are symmetrically installed on both sides of the frame 1, and the cutting room system 2 is installed on the front side of the frame 1, The take-up / pay-off system 7, the tension system 5, the wire arrangement system 6, the wire system 4, and the spindle system 3 are sequentially connected through the cutting line, so that the three operation areas of take-up, take-off and cutting are independent of each other, and the overall structure U-shaped layout.

[0022] In this embodiment, the cutting speed is increased to 1800m / min, the structure of the frame 1 and the cutting...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com