High-yield efficient tunnel kiln

A tunnel kiln and high-efficiency technology, which is applied in the field of industrial kilns and sintered brick tunnel kilns, can solve the problems of low output of large-section tunnel kilns, and achieve the effects of increasing natural dehydration time, high sintering temperature, and high kiln output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

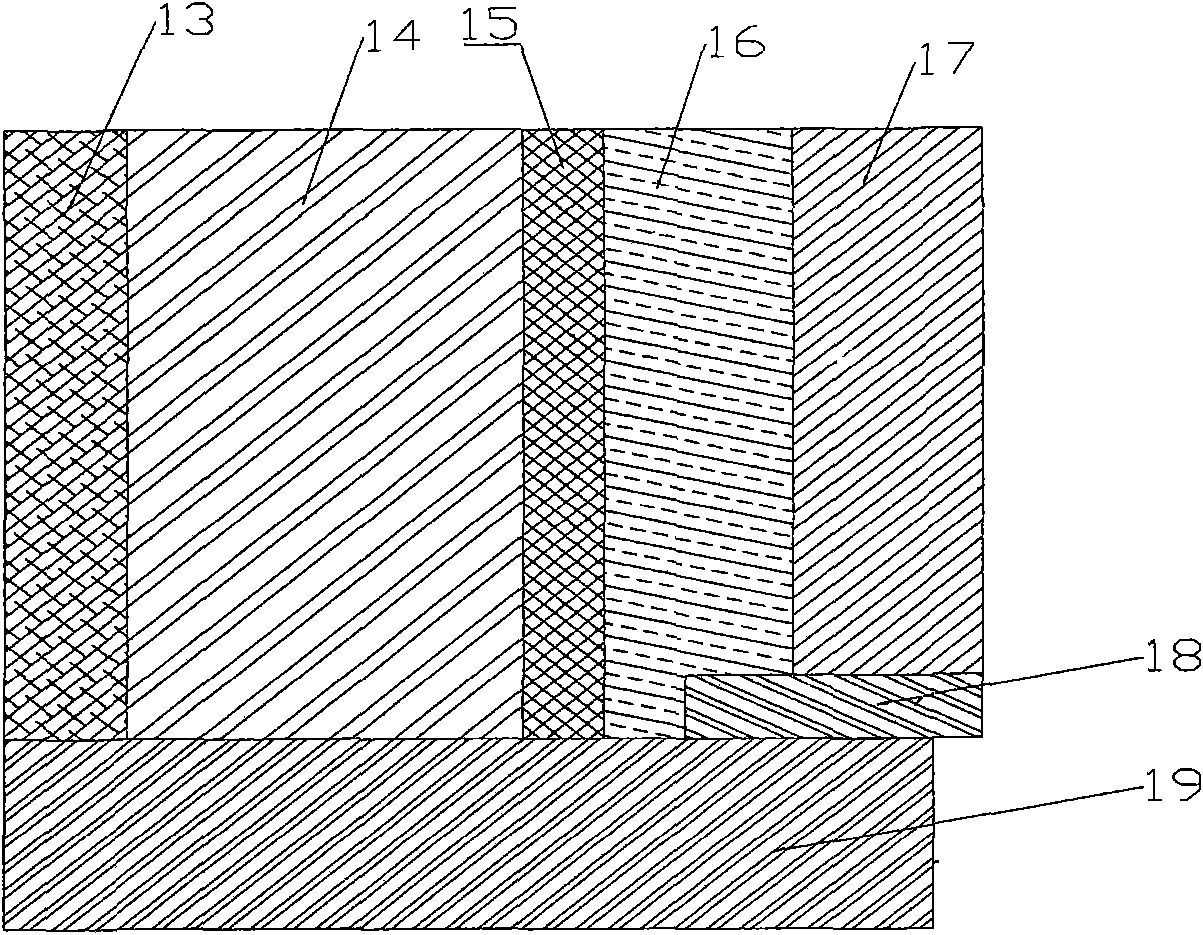

[0045] High-yield and high-efficiency large-section tunnel kilns, including drying kilns and roasting kilns,

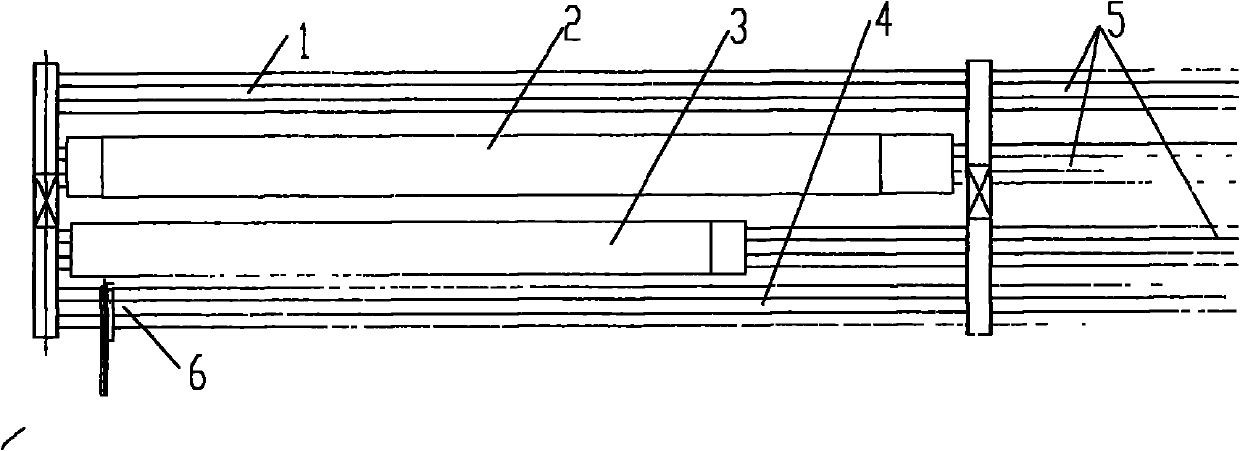

[0046] a) The tunnel kiln adopts the circular kiln car running line layout process, that is, a longer blank storage line is set between the stacking line and the drying kiln, and a longer empty return line is set between the unloading line and the stacking line , so that the entire operation line forms a closed loop, which can not only store a large number of billets, but also ensure that the kiln car after unloading has enough natural cooling time (attached Figure 1 );

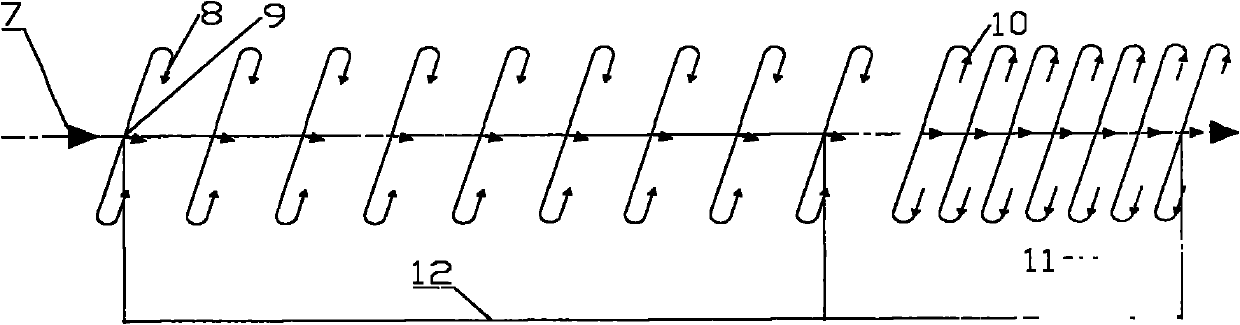

[0047] b) The drying kiln has the following characteristics:

[0048] A. The total length of the kiln is 75-95m (determine the specific length according to the properties of the brick raw materials)

[0049] B. The width of the kiln is 4.6m, 6.9m, 9.2m, 10.4m (the specific width is determined according to the required output)

[0050] C. The height of the kiln is 2.0--2.55m (the specific height i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com